DOI: 10.11817/j.ysxb.1004.0609.2020-35717

时效温度对Ti-50.8Ni-0.1Nb合金相变和形状记忆行为的影响

刘康凯,贺志荣,冯 辉,杜雨青,冀荣耀

(陕西理工大学 材料科学与工程学院,汉中 723001)

摘 要:采用X射线衍射仪、示差扫描量热仪、激光扫描共聚焦显微镜、TEM和拉伸实验研究了时效温度(tag)对(300,400,500,600 ℃;1 h)时效态Ti-50.8Ni-0.1Nb形状记忆合金相变、组织和形状记忆行为的影响。结果表明:300~600 ℃时效态Ti-50.8Ni-0.1Nb合金的相组成为B2和B19′。随tag升高,合金冷却/加热相变类型发生由A→R→M/M→R→A型向A→M/M→A型转变(A—母相B2,CsCl结构;R—R相,菱方结构;M—马氏体相B19′,单斜结构),R相变温度先升高后降低,M相变温度先降低后升高再降低;R和M相变热滞分别在3.8~12.0 ℃和8.7~131.7 ℃之间变化。随tag升高,合金中Ti3Ni4析出相的形态发生由点状→针状→透镜状→片状转变。400、 500 ℃时效态合金的抗拉强度高于300、600 ℃时效态合金的,其伸长率则低于后者。300、400、600 ℃时效态合金呈超弹性,500 ℃时效态合金呈形状记忆效应。随应力-应变循环次数增加,合金的应力-应变曲线平台应力下降并趋稳,300、400 ℃时效态合金的超弹性稳定性良好。

关键词:Ti-50.8Ni-0.1Nb合金;形状记忆合金;时效温度;相变;形状记忆行为

文章编号:1004-0609(2020)-08-1802-09 中图分类号:TG113.25 文献标志码:A

形状记忆合金(Shape memory alloys,简称SMA)是集感知和驱动功能于一体的新型智能材料,Ti-Ni基SMA是SMA中性能最优者[1-3]。Ti-Ni基SMA不仅具有独特的形状记忆效应(Shape memory effect,简称SME)、超弹性(Superelasticity,简称SE),还表现出优异的高阻尼性、生物相容性、耐腐蚀性以及耐磨性[4-6],已广泛的应用于生物医学、微机电系统、耐磨涂层、机械制造、航空航天以及建筑工程等领域[7-11]。SME指将处于马氏体相(M)状态的合金进行适度变形,然后加热到母相(A)状态后,变形合金可恢复到变形前形状的现象;SE指将处于A状态的合金加载适度变形,卸载后变形合金可恢复到变形前形状的现象[12-14]。与Ti-Ni二元SMA相比, Ti-Ni-Nb三元SMA具有较好的加工塑性和较宽的相变温度滞后,能在低温环境下变形处理,马氏体相的稳定性良好[15-16]。Ti-47Ni-9Nb、Ti-36Ni-10Nb等合金已用于制造管接头、紧固件、管道的连接件等,为室温下运输、储存及其他工程的应用带来了便利[17-19]。目前,对Ti-Ni-Nb系SMA的研究主要集中在Nb添加量较多(5%~10%,

摩尔分数)的合金上,对Nb添加量较少的Ti-Ni-Nb合金研究较少。事实上,Nb含量较低的Ti-Ni-Nb合金能克服Nb含量较高合金恢复力不足的缺点,同时也能保持Nb含量高的相变滞后宽的优点[20-21]。为了进一步改善Ti-Ni-Nb系SMA的性能,拓展用途,增加品种,本研究通过在形状记忆性能良好的Ti-50.8Ni二元SMA中添加0.1%Nb,得到了Ti-50.8Ni-0.1Nb(摩尔分数)三元合金。贺志荣等[22]系统研究了退火温度对Ti-50.8Ni-0.1Nb合金组织、相变和形状记忆行为的影响,给出了该合金获得良好SME和SE的退火热处理工艺。Ti-50.8Ni-0.1Nb合金属于富镍Ti-Ni基合金,富镍Ti-Ni合金具有显著的时效处理效应[23],通过固溶时效处理,获得含有Ti3Ni4型析出物的显微组织,进而改善合金的形状记忆性能[24-27]。本论文旨在研究时效温度对Ti-50.8Ni-0.1Nb合金相变行为、显微组织、形状记忆效应和超弹性影响规律,为开发性能优异的Ti-Ni-Nb 系SMA及其热处理工艺提供理论依据和实验支撑。

1 实验

实验材料是直径1 mm的冷拉Ti-50.8Ni-0.1Nb(摩尔分数)合金丝材。合金原料是纯度分别为99.7%、99.9%和99.9%的海绵Ti,电解Ni和Nb粉。经熔炼、旋锻、拉丝等工序制成合金丝,每道次变形量为20%。用SK-GO6J23K型真空管式电阻炉对合金进行(800 ℃,30 min)固溶处理+(300,400,500,600 ℃;1 h)时效处理。用Rigaku Ultima IV型X射线衍射仪(XRD)分析合金的相组成。用TA-Q2000型示差扫描热分析仪(DSC)分析合金的相变行为,冷却/加热温度范围为-150~100 ℃,冷却/加热速率为10 ℃/min。用LSM800型激光扫描共聚焦显微镜(CLSM)分析合金的显微组织形貌,腐蚀剂为V(HF):V(HNO3):V(H2O)= 1:4:5的溶液。用JEM-200CX型透射电子显微镜(TEM)分析合金的显微组织,操作电压160 kV,相机长度60 cm,双喷减薄液成分(体积分数)为6%高氯酸+94%甲醇。用CMT5105型微机控制电子万能试验机测定合金在室温下的形变行为、形状记忆效应、超弹性和应力-应变循环特性,标距为50 mm,加载/卸载速率为2 mm/min,应力-应变循环试验应变量取6%。

2 结果及讨论

2.1 相组成

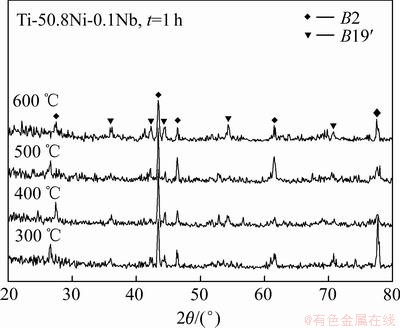

图1所示为(300,400,500,600 ℃;1 h)时效态Ti-50.8Ni-0.1Nb合金的XRD谱。由图1可以看出,室温下,时效态Ti-50.8Ni-0.1Nb合金由母相B2和马氏体B19′组成。衍射强度表明,合金组织中B2相较多,B19′相较少。由于B2相与SE对应,B19′相与SME对应[28],故该合金室温下呈SE+SME特性,以SE为主。

图1 时效温度对Ti-50.8Ni-0.1Nb合金相组成的影响

Fig. 1 Effect of aging temperature on phase composition of Ti-50.8Ni-0.1Nb alloy

2.2 显微组织

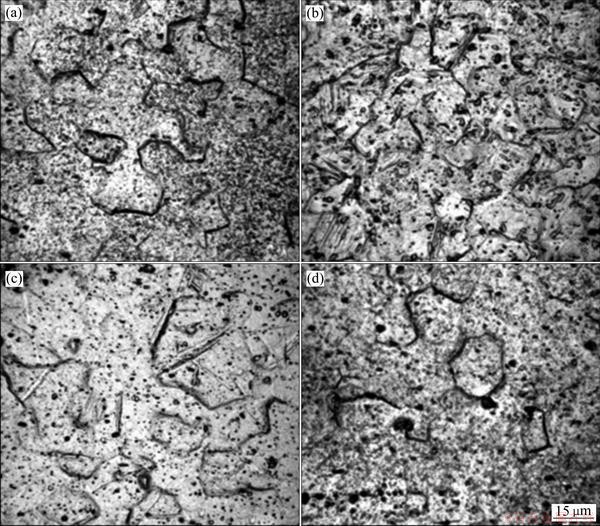

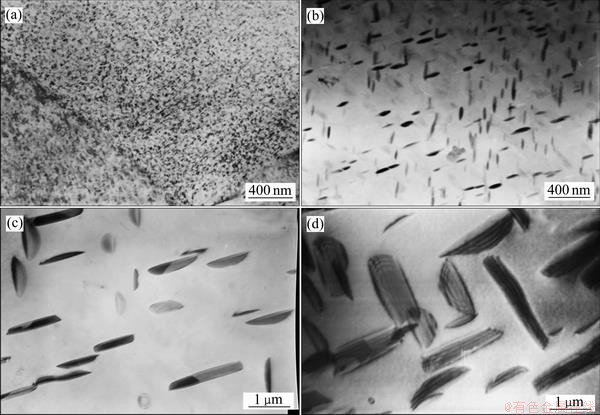

图2所示为(300,400,500,600 ℃;1 h)时效态Ti-50.8Ni-0.1Nb合金的激光扫描共聚焦显微组织。从图2中可以看出,随时效温度(tag)升高,合金的显微组织呈等轴状,晶粒尺寸在20~30 μm之间,表明tag对合金晶粒尺寸影响不大。图3所示为同状态合金的TEM显微组织。从图3中可以看出,时效态Ti-50.8Ni- 0.1Nb合金存在Ti3Ni4相析出,(300,400,500,600 ℃;1 h)时效态Ti-50.8Ni-0.1Nb合金Ti3Ni4析出相分别呈弥散分布点状、弥散分布针状、透镜状和粗片状,亦即随tag升高,该合金中Ti3Ni4析出相的形态发生由点状→针状→透镜状→片状转变,且尺寸增加。

2.3 相变行为

图4(a)所示为(300,400,500,600 ℃;1 h)时效态Ti-50.8Ni-0.1Nb合金的DSC曲线,给出了tag对该合金相变行为的影响规律。图中M、Mr分别代表正、逆马氏体相变峰,R和Rr分别代表正、逆R相变峰。从图4(a)中可看出,当300 ℃≤tag≤500 ℃时,合金在冷却/加热的过程中发生A→R→M/M→R→A(A—母相,CsCl型结构;M—马氏体,单斜结构;R—R相,菱方结构)型可逆相变,即合金冷却发生A→R和R→M两阶段正相变,加热时发生M→R和R→A两阶段逆相变;当tag=600 ℃时,R相变峰消失,合金冷却/加热时发生A→M/M→A型一阶段可逆相变。此外,与退火态Ti-50.8Ni-0.1Nb合金相变峰相比[22],时效态Ti-50.8Ni-0.1Nb合金相变峰强度比较微弱,原因是时效态合金中存在弥散分布的Ti3Ni4析出相,该析出相对基体的相变具有阻抑作用,使相变峰弱化甚至多阶段化[29]。

图2 时效温度对Ti-50.8Ni-0.1Nb合金激光扫描共聚焦显微组织的影响

Fig. 2 Effects of aging temperature on LSCM (Laser scanning confocal microscope) microstructure of Ti-50.8Ni-0.1Nb alloy aged at 300 ℃ (a), 400 ℃ (b), 500 ℃ (c) and 600 ℃ (d), respectively

图3 时效温度对Ti-50.8Ni-0.1Nb合金TEM显微组织的影响

Fig. 3 Effects of aging temperature on TEM microstructures of Ti-50.8Ni-0.1Nb alloy aged at 300 ℃ (a), 400 ℃ (b), 500 ℃ (c) and 600 ℃ (d), respectively

图4 时效温度对Ti-50.8Ni-0.1Nb合金相变类型、相变温度和相变热滞的影响

Fig. 4 Effect of aging temperature on transformation type (a), transformation temperature (b) and temperature hysteresis (c) of Ti-50.8Ni-0.1Nb alloy

图4(b)和(c)所示分别为时效温度对Ti-50.8Ni- 0.1Nb合金相变温度和热滞的影响。由图4(b)可以看出,随tag升高,R相变温度tR(R峰温度)先升高后降低,最低温度10 ℃在300 ℃时效后取得,最高温度35.2 ℃在400 ℃时效后取得;R逆相变温度tRr(Rr峰温度)升高,最低温度17.5 ℃在300 ℃时效后取得,最高温度38.3 ℃在500 ℃时效后取得;M相变温度tM(M峰温度)先降低后升高再降低,最低温度-127.5 ℃在400 ℃时效后取得,最高温度-8 ℃在500 ℃时效后取得;M逆相变温度tMr(Mr峰温度)先升高后降低,最低温度-26.5 ℃在300 ℃时效后取得,最高温度4.2 ℃在400 ℃时效后取得。

由图4(c)可知,随tag 升高,R相变热滞△tR(即tRr-tR之值)较小,当tag从300 ℃升至500 ℃时,△tR先降低后升高,当tag=400 ℃时,△tR达到最小值3.8 ℃,当tag=500 ℃时△tR达到最大值12 ℃。随tag 的升高,M相变热滞△tM(即tMr-tM之值)先升高后降低再升高,当tag=400 ℃时△tM达到最大值131.7 ℃,当tag=500 ℃时△tM达到最小值8.7 ℃。因此,若想得到较小的△tM,tag应取500 ℃。相变温度决定了形状记忆合金元件的开关温度,高、低相变温度合金可分别用于制作在高、低温场合使用的控温形状记忆元件或超弹性减震、阻尼元件。相变热滞反映了SMA元件动作温度范围的宽窄,Δt越小,动作温度范围越窄,亦即元件对温度的反应越灵敏[20]。小热滞SMA可用于制作传感器,大热滞SMA可用于制作连接元件。

2.4 形变行为

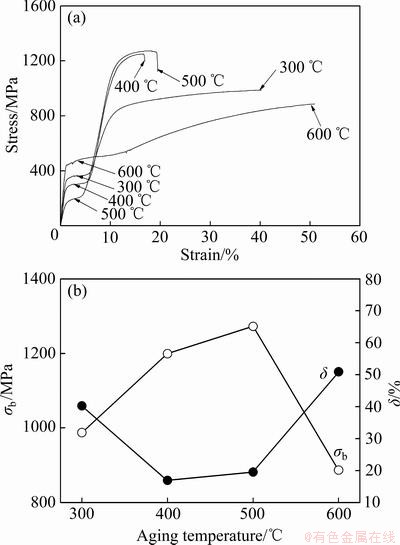

图5所示为tag对Ti-50.8Ni-0.1Nb合金室温拉伸曲线、抗拉强度σb和伸长率δ的影响。由图5可以看出,合金在拉伸过程中经历了母相弹性变形,应力诱发M相变和应力诱发M弹性变形、塑性变形、断裂等阶段[21]。随tag升高,合金的强度σb先升高后降低,400 ℃和500 ℃时效态合金σb最大,达1272 MPa,300 ℃时效态合金的σb较小,600 ℃时效态合金的σb最小,为886 MPa。要想获得高强度Ti-50.8Ni-0.1Nb合金,合金的时效温度应选取400~500 ℃。随tag升高,合金的塑性δ先降低后升高,300 ℃时效态合金的塑性较好,400 ℃和500 ℃时效态合金δ最差(16.8%~19.4%),600 ℃时效态合金的塑性最好,δ高达50.9%。要想对Ti-50.8Ni-0.1Nb合金进行大应变塑性加工,合金可在300 ℃或600 ℃时效处理。原因是400~500 ℃时效态合金中针状和透镜状Ti3Ni4析出相与基体呈共格关系,使基体强度提高,塑性受损;600 ℃时效态合金的Ti3Ni4析出相粗化,对基体强化效果减弱,使基体塑性得以发挥。

图5 时效温度对Ti-50.8Ni-0.1Nb合金拉伸曲线、抗拉强度σb和伸长率δ的影响

Fig. 5 Effect of aging temperature on tensile curves (a), tensile strength σb and elongation δ (b) of Ti-50.8Ni-0.1Nb alloy

2.5 形状记忆行为

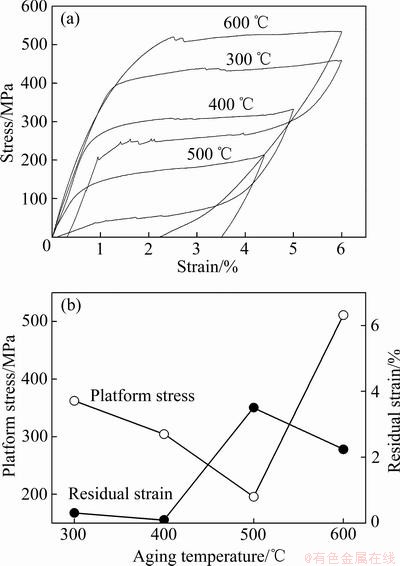

图6所示为tag对Ti-50.8Ni-0.1Nb合金形状记忆行为、加载/卸载应力-应变曲线平台应力和残余应变的影响。由图6(a)可知,300 ℃和400 ℃时效态Ti-50.8Ni-0.1Nb合金呈SE,500 ℃时效态合金呈SME,600 ℃时效态合金呈SE。与SE对应的应力平台的物理意义是应力诱发马氏体相变,与SME对应的应力平台的物理意义为马氏体再取向。500 ℃时效态合金呈SME的原因是该合金相变温度较高,室温下处于马氏体状态,加载时处于马氏体状态的合金发生马氏体再取向,加热时单取向马氏体逆转变为母相,因而合金呈现SME。600 ℃时效态合金呈SE的原因是该合金相变温度较低,室温下处于母相状态,加载时发生应力诱发马氏体相变,卸载时马氏体逆转变为母相,故合金呈现SE。此外,图6(a)中锯齿状应力-应变曲线与SMA合金孪生变形方式有关。因为孪生变形产生孪晶是形核、长大过程,孪晶形核所需应力远高于长大所需应力,故当孪晶出现时伴随载荷突然下降现象,在变形过程中孪晶不断形成,从而形成了锯齿状应力应变曲线[30]。 由图6(b)可以看出,随tag升高,合金加载/卸载应力-应变曲线平台应力先下降后上升,分别在500 ℃和600 ℃时效态取得最小值(195.6 MPa)和最大值(510.9 MPa);残余应变先降低后升高再降低,300 ℃和400 ℃时效态合金的残余应变最小,仅为0.09%~ 0.3%,SE优异。500 ℃时效态合金的残余应变最大,为3.5%,加热后该残余应变降为0,合金形状恢复,呈现SME。可见,要使Ti-50.8Ni-0.1Nb合金具有优异的SME,tag应取500 ℃;要使合金具有优异的SE,tag应取300~400 ℃。

图6 时效温度对Ti-50.8Ni-0.1Nb合金形状记忆行为和应力-应变曲线平台应力、残余应变的影响

Fig. 6 Effect of aging temperature on shape memory behavior (a) and platform stress, residual strain (b) in stress-strain curves of Ti-50.8Ni-0.1Nb alloy

2.6 循环变形行为

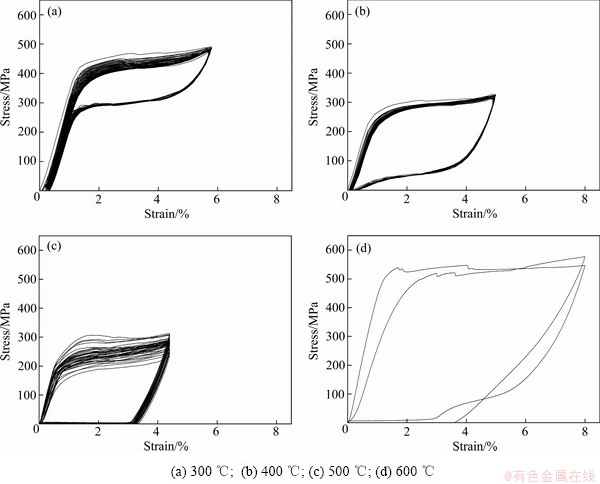

图7所示为应力-应变循环对300、400、500、600 ℃时效态Ti-50.8Ni-0.1Nb合金形状记忆行为的影响,其中300、400、500 ℃时效态合金循环了50次,600 ℃时效态合金循环了2次。由图7可以看出,随应力-应变循环次数增加,合金的应力-应变曲线平台应力下降并趋稳,300 ℃和400 ℃时效态合金保持超弹性行为,且由部分超弹性(残余应变不为0)转变为完全超弹性(残余应变为0)[31-32];500 ℃时效态合金在1~6次循环后呈现形状记忆行为,第7次循环往后呈现超弹性行为,600 ℃时效态合金在循环次数超过2次后试样断裂。可见,300 ℃和400 ℃时效态Ti-50.8Ni-0.1Nb合金超弹性的稳定性良好。

图7 应力-应变循环对不同温度时效态Ti-50.8Ni-0.1Nb合金形状记忆行为的影响

Fig. 7 Effect of stress-strain cycle on shape memory behavior of Ti-50.8 Ni-0.1Nb alloy aged at different temperatures

3 结论

1) 300~600 ℃时效态Ti-50.8Ni-0.1Nb合金的组成相为B2和B19′。随tag升高,该合金冷却/加热时的相变类型由A→R→M/M→R→A型向A→M/M→A型转变;R相变温度先升高后降低,M相变温度先降低后升高再降低;R相变热滞在3.8~12 ℃之间变化,M相变热滞在8.7~131.7 ℃之间变化。

2) 300~600 ℃时效态Ti-50.8Ni-0.1Nb合金的组织形态呈等轴状,存在Ti3Ni4析出相,随tag升高,Ti3Ni4析出相的形态发生由点状→针状→透镜状→片状转变,尺寸增加。 3) 400、500 ℃时效态Ti-50.8Ni-0.1Nb合金的抗拉强度高于300、600 ℃时效态合金,伸长率则低于后者;300、400、600 ℃时效态合金呈SE,500 ℃时效态合金呈SME。随应力-应变循环次数增加,时效态Ti-50.8Ni-0.1Nb合金的应力-应变曲线平台应力下降并趋稳,300、400 ℃时效态合金的SE稳定性良好。

REFERENCES

[1] HAYRETTIN C, KARAKOC O, KARAMAN I, MABE J H, SANTAMARTA R, PONS J. Two way shape memory effect in NiTiHf high temperature shape memory alloy tubes[J]. Acta Materialia, 2019, 163: 1-13.

[2] YI Xiao-yang, WANG Hai-zhen, SUN Bin, SUN Kui-shan, GAO Wei-hong, LIU Jing-jing, MENG Xiang-long, CAI Wei, ZHAO Lian-cheng. The crystallization process, microstructure, martensitic transformation and mechanical properties of Ti-Ni-Zr alloy ribbons[J]. Journal of Alloys and Compounds, 2019, 778: 542-553.

[3] SAGHAIAN S M, KARACA H E, TOBE H, TURABI A S, SAEDI S, SAGHAIAN S E, CHUMLYAKOV Y I, NOEBE R D. High strength NiTiHf shape memory alloys with tailorable properties[J]. Acta Materialia, 2017, 134: 211-220.

[4] BABACAN N, BILAL M, HAYRETTIN C, LIU J, BENAFAN O, KARAMAN I. Effects of cold and warm rolling on the shape memory response of Ni50Ti30Hf20 high-temperature shape memory alloy[J]. Acta Materialia, 2018, 157: 228-244.

[5] 贺志荣, 吴佩泽, 刘康凯, 冯 辉, 杜雨青, 冀荣耀. 激冷Ti-47Ni合金薄带的组织、相变和形状记忆行为[J]. 金属学报, 2018, 54(8): 1157-1164.

HE Zhi-rong, WU Pei-ze, LIU Kang-kai, FENG Hui, DU Yu-qing, JI Rong-yao. Microstructure, phase transformation and shape memory behavior of chilled Ti-47Ni alloy ribbons[J]. Acta Metallurgica Sinica, 2018, 54(8): 1157-1164.

[6] 金威威, 许仁波, 王云学. TiNi形状记忆合金表面改性技术研究进展[J]. 热加工工艺, 2018, 47(18): 30-33, 37.

JIN Wei-wei, XU Ren-bo, WANG Yun-xue. Research progress of surface modification technology for TiNi shape memory alloy[J]. Hot Working Technology, 2018, 47(18): 30-33, 37.

[7] JANI J M, LEARY M, SUBIC A, GIBSON M A. Review of shape memory alloy research, applications and opportunities[J]. Materials and Design, 2014, 56: 1078-1113.

[8] CHOUDHARY N, KAUR D. Shape memory alloy thin films and heterostructures for MEMS applications: A review[J]. Sensors & Actuators A Physical, 2016, 242: 162-181.

[9] 许仁波, 崔立山. TiNi合金冲蚀磨损行为及应用研究进展[J]. 材料导报, 2008, 22(5): 55-57.

XU Ren-bo, CUI Li-shan. Recent progress in research on erosion wear behaviors and application of TiNi alloy[J]. Materials Review, 2008, 22(5): 55-57.

[10] MIYAZAKI S, FU Y Q, HUANG W M. Thin film shape memory alloys: Fundamentals and device application[M]. Cambridge: Cambridge University Press, 2009: 409-423.

[11] QIU X M, LI M G, SUN D Q. Study on brazing of TiNi shape memory alloy with stainless steels[J]. Journal of Materials Processing Technology, 2006, 176: 8-12.

[12] 冯 辉, 贺志荣, 王 芳. 退火温度对Ti-51.1Ni形状记忆合金超弹性的影响[J]. 金属热处理, 2019, 44(3): 120-123.

FENG Hui, HE Zhi-rong, Wang Fang. Effects of annealing temperatures on superelasticity of Ti-51.1Ni shape memory alloy[J]. Heat Treatment of Metals, 2019, 44(3): 120-123.

[13] LIANG X, XIAO F, CHEN H, LI Z X, ZHU Li, JIN X J, FUKUDA T. Internal friction of the R-phase in single crystalline Ti-50.8 Ni (at.%) alloy containing controlled precipitate of Ti3Ni4[J]. Scripta Materialia, 2019, 166: 44-47.

[14] DAGHASH S M, OZBULUT O E. Characterization of superelastic shape memory alloy fiber-reinforced polymer composites under tensile cyclic loading[J]. Materials and Design, 2016, 111: 504-512.

[15] 刘洪涛, 周吉学, 刘 清, 刘运腾, 庄海华. Ni47Ti44Nb9形状记忆合金冲击过程形变行为分析[J]. 有色金属工程, 2016, 6(6): 9-13.

LIU Hong-tao, ZHOU Ji-xue, LIU Qing, LIU Yun-teng, ZHUANG Hai-hua. Deformation behavior of Ni Ni47Ti44Nb9 shape memory alloy under shock loading[J]. Nonferrous Metals Engineering, 2016, 6(6): 9-13.

[16] 李贵发, 孙益阳, 洪起虎. 热处理温度对NiTiNb5相变温度和组织的影响[J]. 特种铸造及有色合金, 2012, 32(3): 15-18.

LI Gui-fa, SUN Yi-yang, HONG Qi-hu. Influence of heat treatment temperature on phase transformation temperature and microstructure of NiTiNb5 alloy[J]. Special Casting and Nonferrous Alloys, 2012, 32(3): 15-18.

[17] WANG L, RONG L J, YAN D S. DSC study of the reverse martensitic transformation behavior in a shape memory alloy pipe-joint[J]. Intermetallics, 2005, 13(3): 403-407.

[18] 何向明, 戎利建, 闫德胜, 姜志民, 李依依. 形变对Ni47Ti44Nb9宽滞后形状记忆合金应力诱发马氏体相变行为的影响[J]. 金属学报, 2004, 40(7): 721-725.

HE Xiang-ming, RONG Li-jian, YAN De-sheng, JIANG Zhi-min, LI Yi-yi. Effect of deformation on the stress-induced martensitic transformation behavior of Ni47Ti44Nb9 wide hysteresis shape memory alloy[J]. Acta Metallurglca Sinica, 2004, 40(7): 721-725.

[19] 颜 莹, 金 伟, 曹名洲. Ni47Ti44Nb9形状记忆合金冷轧管材的组织、织构和相变[J]. 金属学报, 2008, 44(2): 139-144.

YAN Ying, JIN Wei, CAO Ming-zhou. Microstructure, texture and phase transformation of Ni47Ti44Nb9 shape memory alloy cold-rolled tube[J]. Acta Metallurglca Sinica, 2008, 44(2): 139-144.

[20] XIAO Fu, MA Guo-jun, ZHAO Xin-qing. Effects of Nb content on yield strength of NiTiNb alloys in martensite state[J]. Chinese Journal of Aeronautics, 2009, 22(6): 658-662.

[21] ZHAO Xin-qing. Mechanical properties and transformation behavior of NiTiNb shape memory alloys[J]. Chinese Journal of Aeronautics, 2009, 22(5): 540-543.

[22] 贺志荣, 刘康凯, 王 芳, 冯 辉, 杜雨青. 形变退火态Ti-50.8Ni-0.1Nb合金的相变和形状记忆行为[J]. 中国有色金属学报, 2019, 29(4): 742-748.

HE Zhi-rong, LIU Kang-kai, WANG Fang, Feng Hui, DU Yu-qing. Transformation and shape memory behaviors of deformed and annealed Ti-50.8Ni-0.1Nb alloy[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(4): 742-748.

[23] WANG Qi, HE Zhi-rong, LIU Man-qian, YANG Jun, LIU Yan. Effects of Ni content and solution-aging treatment on multi-stage transformations of TiNi shape memory alloys[J]. Rare Metal Materials and Engineering. 2011, 40(3): 395-398.

[24] YI Xiao-yang, SUN Kui-shan, GAO Wei-hong, WANG Hai-zhen, SUN Bin, YAO Wen, MENG Xiang-long, GAO Zhi-yong, CAI Wei. The precipitation behaviors, martensite transformation and superelasticity in the aged Ni-rich Ti-Ni alloy with the assist of super-high stress[J]. Intermetallics, 2019, 104: 8-15.

[25] CHEN H, XIAO F, LIANG X, LI Z X, LI Z, JIN X J, MIN N, FUKUDA T. Improvement of the stability of superelasticity and elastocaloric effect of a Ni-rich Ti-Ni alloy by precipitation and grain refinement[J]. Scripta Materialia, 2019, 162: 230-234.

[26] KAYA I, TOBE H, KARACA H E, BASARAN B, NAGASAKO M, KAINUMA R, CHUMLYAKOV Y. Effects of aging on the shape memory and superelasticity behavior of ultrahigh strength Ni54Ti46 alloys under compression[J]. Mater Sci Eng A, 2016, 678: 93-100.

[27] 贺志荣, 刘曼倩, 王 芳, 张永宏, 王永善. 时效工艺对Ti-Ni-V形状记忆合金组织和超弹性的影响[J]. 中国有色金属学报, 2013, 23(5): 1301-1306.

HE Zhi-rong, LIU Man-qian, WANG Fang, ZHANG Yong-hong, WANG Yong-shan. Effect of aging process on microstructure and superelasticity of Ti-Ni-V shape memory alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1301-1306.

[28] SHARIAT B S, MENG Q L, MAHMUD A S, WU Z G, BAKHTIARI R, ZHANG J S, MOTAZEDIAN F, YANG H, RIO G, NAM T H, LIU Y N. Functionally graded shape memory alloys: Design, fabrication and experimental evaluation[J]. Materials and Design, 2017, 124: 225-237.

[29] 贺志荣. Ti-Ni形状记忆合金多阶段可逆相变的类型及其演化过程[J]. 金属学报, 2007, 43(4): 353-357.

HE Zhi-rong. Multi-stage reversible transformation types and their evolving processes of Ti-Ni shape memory alloys[J]. Acta Metallurglca Sinica, 2007, 43(4): 353-357.

[30] ATLI K C. The effect of tensile deformation on the damping capacity of NiTi shape memory alloy[J]. Journal of Alloys and Compounds, 2016, 679: 260-267.

[31] 商泽进, 王忠民, 尹冠生, 郑碧玉. 循环加载条件下TiNi形状记忆合金棒材的超弹性行为[J]. 实验力学, 2008, 23(4): 305-310.

SHANG Ze-jin, WANG Zhong-min, YIN Guan-sheng, ZHENG Bi-yu. Superelastic behavior under cyclic loading for TiNi shape memory alloy bars[J]. Journal of Experimental Mechanics, 2008, 23(4): 305-310.

[32] 贺志荣,王芳. Ti-Ni-V形状记忆合金的循环形变特性[J]. 中国有色金属学报, 2013, 23(7): 1866-1872.

HE Zhi-rong, WANG Fang. Cyclic deformation characteristics of Ti-Ni-V shape memory alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1866-1872.

Effect of aging temperature on phase transformation and shape memory behaviors of Ti-50.8Ni-0.1Nb alloy

LIU Kang-kai, HE Zhi-rong, FENG Hui, DU Yu-qing, JI Rong-yao

(School of Materials Science and Engineering, Shaanxi University of Technology, Hanzhong 723001, China)

Abstract: The effect of aging temperature (tag) on the phase transformation, microstructure, and shape memory behaviors of Ti-50.8Ni-0.1Nb shape memory alloy aged at 300, 400, 500 and 600 ℃ for 1 h, respectively, were investigated by means of X-ray diffractometry, differential scanning calorimetry, laser scanning confocal microscope, TEM and tensile test. The results show that the phase compositions of Ti-50.8Ni-0.1Nb alloy aged at 300-600 ℃ are B2 and B19′. With increasing tag, the transformation types of the alloy change from A→R→M/M→R→A to A→M/M→A (A—parent phase B2, CsCl; R—R phase, rhombohedral; M—martensite B19′, monoclinic) upon cooling/heating; the R phase transition temperature increases first and then decreases, and the M transition temperature decreases first, then increases and then decreases; the R and M temperature hysteresis change in the range of 3.8-12.0 ℃ and 8.7-131.7 ℃, respectively. With increasing tag, the morphology of Ti3Ni4 precipitates in the alloy changes from granular → acicular → lenticular → flaky. The tensile strength of the alloy aged at 400 ℃ and 500 ℃ is higher than that of the alloy aged at 300 ℃ and 600 ℃, while the percentage elongation of the former is lower than that of the latter. The alloys aged at 300, 400, 600 ℃ show superelasticity, and the alloy annealed at 500 ℃ shows shape memory effect. With increasing stress-strain cycling number, the platform stress in the stress-strain curve of the alloy decreases. The stability of the superelasticity in the alloy aged at 300 ℃ and 400 ℃ is excellent.

Key words: Ti-50.8Ni-0.1Nb alloy; shape memory alloy; aging temperature; phase transformation; shape memory behavior

Foundation item: Project(2016YFE0111400) supported by the National Program on Key Basic Research

Received date: 2018-12-23; Accepted date: 2020-06-22

Corresponding author: HE Zhi-rong; Tel: +86-13892611307; E-mail: hezhirong01@163.com

(编辑 何学锋)

基金项目:国家重点研发计划资助项目(2016YFE0111400)

收稿日期:2018-12-23;修订日期:2020-06-22

通信作者:贺志荣,教授,博士;电话:13892611307;E-mail:hezhirong01@163.com