DOI: 10.11817/j.ysxb.1004.0609.2020-36479

镍基高温合金DD5、DD10和DSM11热腐蚀行为比较

李艳明,刘 欢,乔 志,韩振宇,薛志博

(中国航发沈阳发动机研究所,沈阳 110015)

摘 要:镍基高温合金DD5、DD10和DSM11在涂覆10%NaCl+90%Na2SO4(质量分数)混合盐膜后进行(850 ℃,200 h)热腐蚀实验,并利用扫描电子显微镜(SEM)、能谱仪(EDS)和X射线衍射仪(XRD)等分析手段,对腐蚀200 h后的合金进行热腐蚀行为对比分析。结果表明:DD10和DSM11合金成分中含有较高含量的Cr和Ti,在表面易生成保护性Cr2O3和TiO2氧化膜,氧化膜遇到熔盐中的O2-会优先在表面发生溶解,保证内部Al2O3氧化膜的稳定生长,进一步抑制热腐蚀反应的进行,提高合金的抗热腐蚀性能。DD5合金中Cr和Al含量较少且相差不大,在合金表面形成Cr2O3和Al2O3混合型氧化物,导致内部元素的贫化,不易形成连续致密性氧化膜,基体会进一步遭受到腐蚀。

关键词:镍基高温合金;DD5;DD10;DSM11;热腐蚀;氧化膜

文章编号:1004-0609(2020)-09-2105-11 中图分类号:TG146.1 文献标志码:A

镍基高温合金具有抗氧化、抗腐蚀、强度高和韧性好等优异的综合性能,广泛地应用于先进发动机的热端部件[1-4]。海洋环境中具有大量的NaCl和CaCl2等盐粒子,且发动机燃油在燃烧过程中会产生大量的含硫燃气,两者发生作用会在热端部件表面沉积一层混合(NaCl、CaCl2和Na2SO4等)型盐膜,使得热端部件表面在熔融盐的作用下发生热腐蚀[5-7]。镍基高温合金的热腐蚀行为及机理研究成为相关合金设计与零部件选材的重要依据,受到国内外研究者关注。

镍基高温合金热腐蚀行为的主要影响因素包括腐蚀环境、合金元素和热处理工艺[8-9]。镍基高温合金产生腐蚀作用的腐蚀介质主要为NaCl、KCl、CaCl2和Na2SO4等氯化物或硫酸盐或两者的混合物,与其所在工作环境有关。LU等[10]研究表明,熔融NaCl可引起镍基高温合金沿晶界腐蚀。杨君宝等[11]揭示了在高温硫酸盐中含钛镍基合金的氧化和硫化现象。张铁邦等[12]发现在混合熔盐(Na2SO4+NaCl)中Ni-20Cr-18W高温合金热腐蚀速度随着腐蚀温度的增加而迅速加快。管秀荣等[13-14]研究Ru、Cr含量对高温合金热腐蚀行为影响时发现,增加Ru会增强合金基体和腐蚀层结合力,从而提高了合金的热腐蚀能力;Cr可促使保护性Cr2O3层的形成,阻止热腐蚀进程。李维杰等[15]研究结果表明,随着Al含量的增加,表面易形成连续致密的Al2O3保护膜,合金表现为优异抗热腐蚀性能。WENG等[16]认为添加Nb元素能够形成Nb2O5保护层,合金的热腐蚀性能显著提高。于忠锋等[17]研究DZ68和K438G合金在Na2SO4+NaCl的混合熔盐热腐蚀行为时发现,合金成分和组织均匀的合金腐蚀过程缓慢。宁礼奎等[18]对DZ68和K438合金的抗热腐蚀性能比较后认为,热处理后组织均匀的DZ68合金的抗热腐蚀性能略好于K438合金。

上述研究为认识镍基高温合金在不同成分和环境下的熔盐腐蚀提供了参考。相比于多晶材料,定向凝固和单晶材料由于特定晶粒取向以及晶界的减少,其耐蚀性明显提高,是目前高性能先进发动机热端部件材料制造与选材的方向发展[19]。对系列定向凝固和单晶镍基高温合金的热腐蚀行为及机理的比较分析,成为相关先进发动机制造选材中的关键,相关研究鲜有报道。

本文作者在单晶高温合金DD5、单晶高温合金DD10和定向凝固高温合金DSM11表面涂覆NaCl和Na2SO4混合盐膜,然后对3种合金进行(850 ℃,200 h)热腐蚀实验;结合扫描电子显微镜(SEM)、能谱仪(EDS)和X射线衍射仪(XRD)等分析手段,研究3种合金样品表面形貌、物相组成、元素分布和腐蚀产物层的分布情况,进行热腐蚀机理研究和对比分析,以期研究成果为先进发动机热端部件的选材和生产使用提供技术基础。

1 实验

1.1 实验样品

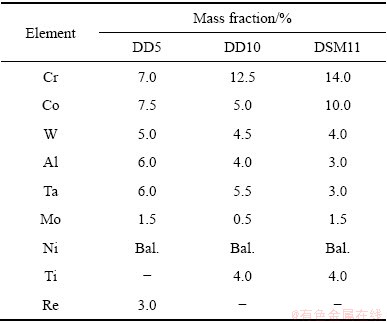

单晶高温合金DD5、单晶高温合金DD10和定向凝固高温合金DSM11样品主要化学成分如表1所示。3种合金样品均被切割成直径为20 mm、厚度为2 mm的圆柱形。样品表面通过砂纸进行抛光处理,采用丙酮或酒精进行超声清洗,进而保持表面光滑,达到去除表面油污效果。

表1 DD5、DD10和DSM11合金样品主要化学成分

Table 1 Chemical composition of DD5, DD10 and DSM11

1.2 实验方法

实验采用NaCl和Na2SO4用混合盐膜,将配置的10%NaCl+90%Na2SO4(质量分数)混合盐溶液充分雾化后均匀地沉积在镍基高温合金DD5、DD10和DSM11样品表面,样品烘干后保证盐的沉积量为(30±5) g/m2。沉积盐的合金样品在850 ℃条件下进行热腐蚀实验,以25 h为1个周期,共进行8个周期。每个周期结束后取出样品冷却到室温。

采用称重方法研究3种合金的腐蚀动力学。采用精度为0.1 mg电子分析天平对3种合金沉积盐膜前的质量作为原始质量。将腐蚀后样品用沸水清洗样品表面剩余盐并烘干,在干燥器皿中静置一段时间后称量腐蚀后样品质量,由此计算单位面积的腐蚀质量损失。

采用附带牛津X-MAMN能谱仪的Sigma 500场发射扫描电镜对腐蚀产物的表面形貌、截面形貌和元素分布进行表征。采用UltimalV型X射线衍射仪对腐蚀产物物相进行表征。

2 实验结果

2.1 腐蚀动力学曲线

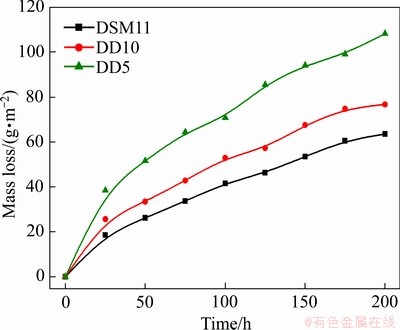

采用失重法绘制镍基高温合金DD5、DD10和DSM11的腐蚀动力学曲线,结果如图1所示。DD5合金样品质量变化较大,随着实验时间的增加,质量呈现下降趋势,前25 h之内的质量损失最明显;DD10和DSM11合金样品质量变化较小,随着实验时间的增加,质量呈现先减少后趋于平稳趋势,前25 h之内的质量损失也较为明显。

图1 DD5、DD10和DSM11合金样品腐蚀动力学曲线

Fig. 1 Corrosion kinetics curves of DD5, DD10 and DSM11

2.2 腐蚀层物相分析

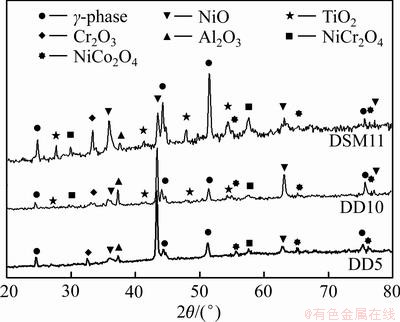

DD5、DD10和DSM11合金样品涂盐腐蚀200 h后,表面腐蚀层XRD谱如图2所示,腐蚀层均以氧化物为主。DD5合金样品表面腐蚀层物相主要由NiO、Cr2O3和Al2O3氧化物组成,还含有少量的NiCr2O4和NiCo2O4等尖晶石型氧化物。DD10和DSM11合金样品表面腐蚀层物相主要由NiO、Cr2O3、TiO2和Al2O3氧化物组成,还含有少量的NiCr2O4和NiCo2O4等尖晶石型氧化物;DD10和DSM11合金成分中含有Ti元素,所以腐蚀物中存在TiO2。XRD由于测试精度和范围有限,只检测到外层的腐蚀产物类型,检测结果中未发现硫化物,可能是硫进入内部发生反应或硫化物含量较少的原因。

图2 DD5、DD10和DSM11合金样品腐蚀产物XRD谱

Fig. 2 XRD patterns of DD5, DD10 and DSM11 corrosion products

2.3 腐蚀层表面形貌分析

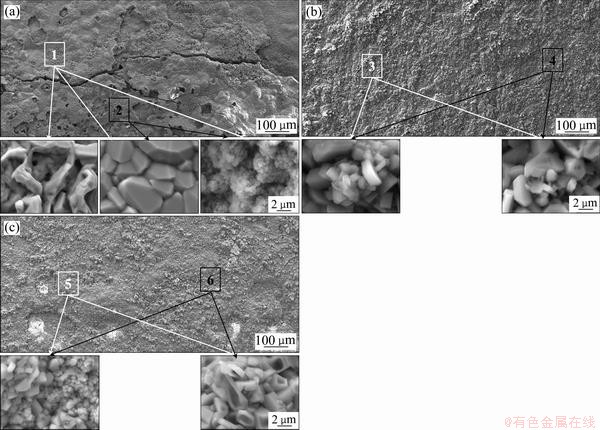

DD5、DD10和DSM11合金样品涂盐腐蚀200 h后,腐蚀层表面形貌如图3所示。DD5合金样品涂盐腐蚀200 h后,合金表面腐蚀较严重,呈现裂纹和孔洞;区域1微观形貌包括颗粒状、球状和絮状物质;区域2微观形貌包括颗粒状和球状物质,此区域的孔洞应为表面絮状物质发生脱落而产生的。DD10合金样品涂盐腐蚀200 h后,表面形貌较一致,无明显裂纹和孔洞,区域3和区域4微观形貌都为颗粒状和球状物质。DSM11合金样品涂盐腐蚀200 h后,表面形貌较一致,无明显裂纹和孔洞,区域5和区域6微观形貌都为颗粒状和球状物质。

2.4 腐蚀产物截面分析

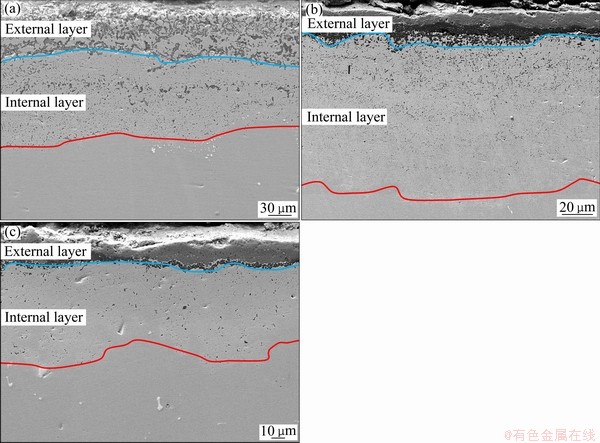

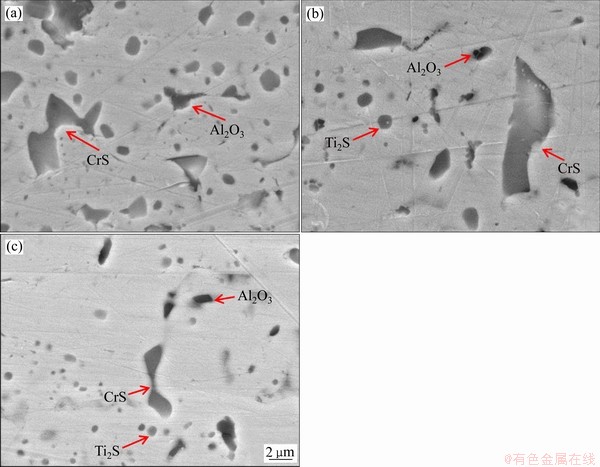

DD5、DD10和DSM11合金样品涂盐腐蚀200 h后,腐蚀产物截面形貌如图4和5所示,其中红色实线上方为腐蚀层。腐蚀层均可分为两个区域。DD5合金样品腐蚀产物外腐蚀区黑色和浅灰色腐蚀产物混合分布,内腐蚀区分布颗粒状腐蚀产物,内腐蚀区灰色颗粒主要以CrS为主,黑色颗粒主要以Al2O3为主。DD10和DSM11合金样品腐蚀产物外腐蚀区深灰色和黑色产物呈层状连续分布,内腐蚀区分布颗粒状腐蚀产物,内腐蚀区灰色颗粒主要以CrS和Ti2S为主,黑色颗粒主要以Al2O3为主。硫化物和氧化物的产生,表明DD5、DD10和DSM11合金样品涂盐腐蚀后发生内硫化和内氧化反应。

图3 DD5、DD10和DSM11合金样品腐蚀产物表面形貌

Fig. 3 Corrosion products surface morphologies of DD5(a), DD10(b) and DSM11(c)

图4 DD5、DD10和DSM11合金样品腐蚀产物截面形貌

Fig. 4 Corrosion products section morphologies of DD5(a), DD10(b) and DSM11(c)

图5 DD5、DD10和DSM11合金样品内腐蚀区截面形貌

Fig. 5 Internal corrosion products section morphologies of DD5(a), DD10(b) and DSM11(c)

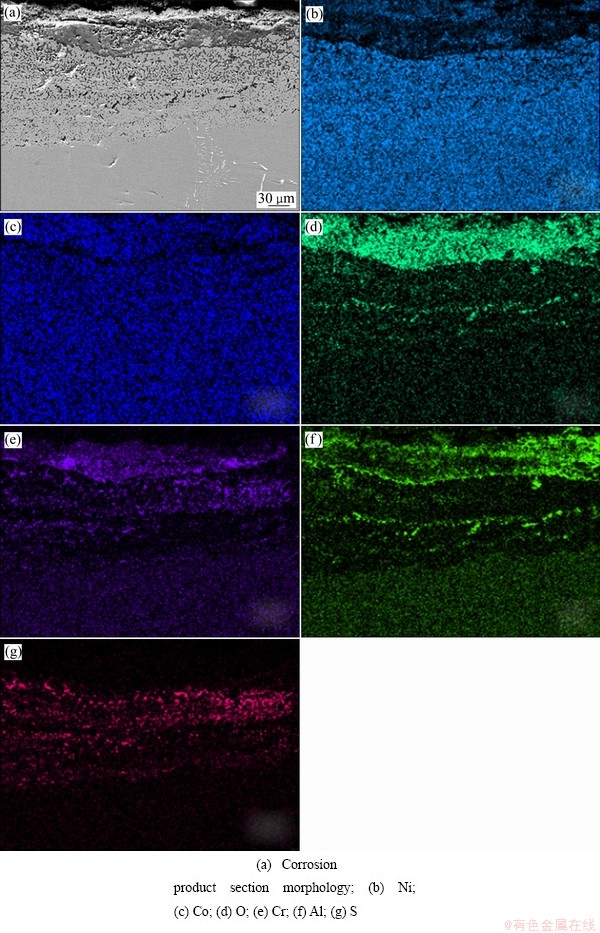

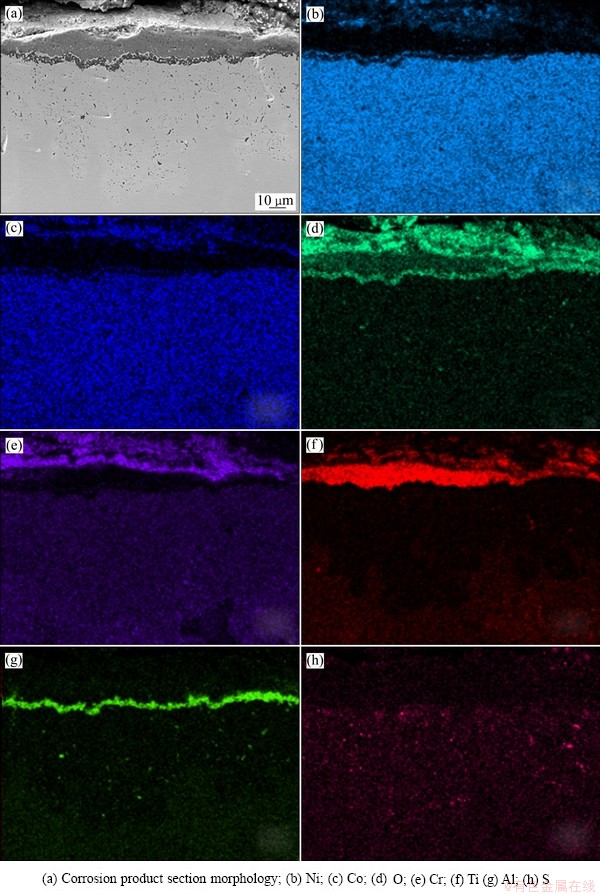

DD5合金样品涂盐腐蚀200 h后,样品腐蚀层截面面扫描结果见图6,O富集于整个外腐蚀区,Ni、Co、Cr和Al也散布于外腐蚀区,结合XRD分析结果表明腐蚀产物主要为NiO、Cr2O3、Al2O3、NiCr2O4和NiCo2O4;S散布于内腐蚀区,内腐蚀区也含有少量的Cr、Al和O,腐蚀产物主要为CrS和Al2O3。

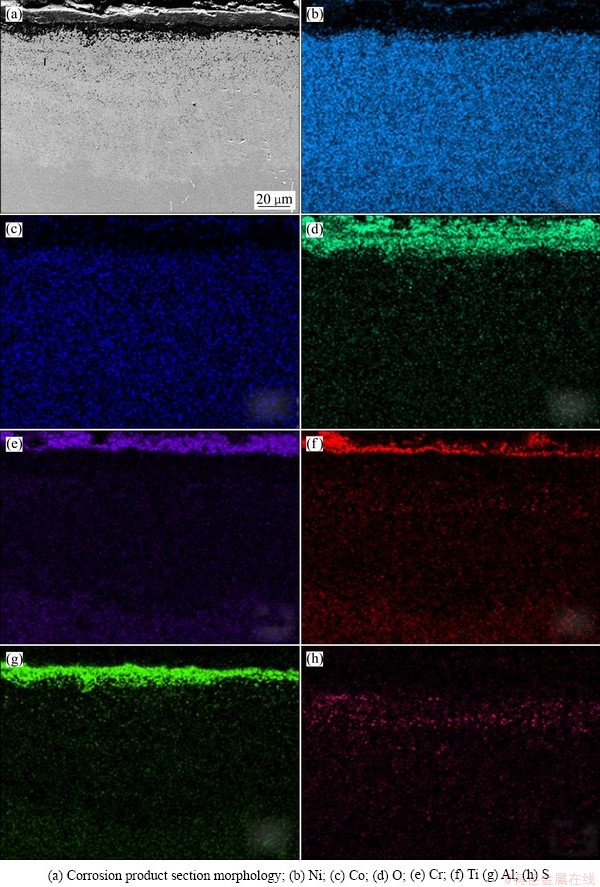

DD10和DSM11合金样品涂盐腐蚀200 h后,样品腐蚀层截面面扫描结果见图7和8所示。O富集于整个外腐蚀区,外腐蚀区为多层氧化物组成,外腐蚀区的外侧较疏松、不连续,主要为Ni、Co、Cr和Ti,结合XRD分析结果表明腐蚀产物主要为NiO、Cr2O3、TiO2、NiCr2O4和NiCo2O4;外腐蚀区中间较致密,连续性好,形成了主要以Cr和Ti为主的过渡性氧化物层,腐蚀产物主要应为Cr2O3和TiO2;外腐蚀区的内侧较致密,连续性好,主要为Al,腐蚀产物应为Al2O3。S散布于内腐蚀层,内腐蚀区也含有少量的Cr、Ti、Al和O,腐蚀产物主要为Ti2S、CrS和Al2O3。

综上所述,DD5、DD10和DSM11合金样品腐蚀层面扫描图分析可知,DD5合金样品腐蚀层内部Cr2O3、TiO2和Al2O3等氧化物分散性较大、不连续;DD10和DSM11合金样品腐蚀层具有连续层状分布的Cr2O3、TiO2和Al2O3保护性氧化膜。

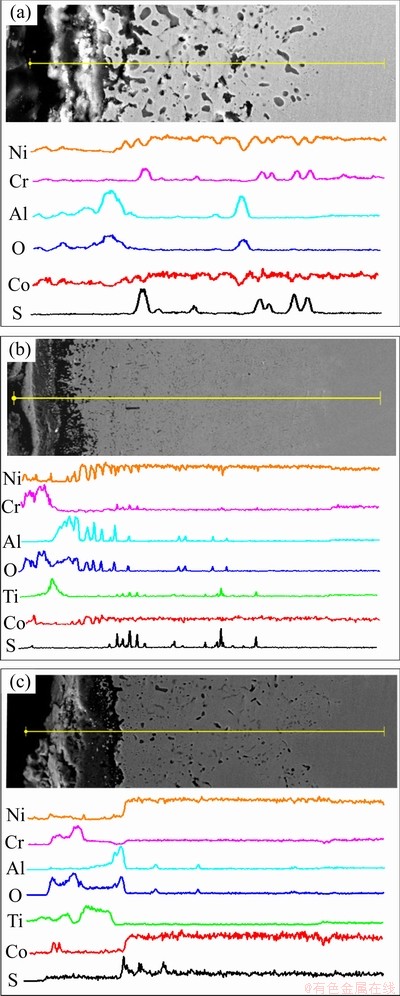

DD5、DD10和DSM11合金样品涂盐腐蚀200 h后,腐蚀层截面线扫描如图9所示。DD5合金样品在热腐蚀过程中,O、Cr和Al元素均富集在腐蚀层的表面,表明Cr和Al元素由合金基体向表面迁移,与O接触生成了Cr2O3和Al2O3,与XRD检测结果一致。DD10和DSM11合金样品腐蚀层表面均出现了O、Cr、Ti和Al元素的富集,也进一步证明Cr、Ti和Al向合金表面迁移并形成了Cr2O3、TiO2和Al2O3。3种合金腐蚀层的内层中,Al和O的分布对应较好,也说明内腐蚀层中的氧化物为Al2O3。

图6 DD5合金样品腐蚀层截面面扫描

Fig. 6 Cross section scanning results of DD5 corrosion products

图7 DD10合金样品腐蚀层截面面扫描

Fig. 7 Cross section scanning results of DD10 corrosion products

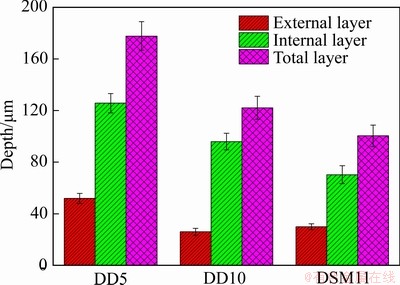

对DD5、DD10和DSM11合金样品腐蚀层的外腐蚀区、内腐蚀区和总腐蚀区的深度进行测量,结果如图10所示。DD5合金的外腐蚀区和内腐蚀区的深度均大于DD10和DSM11合金腐蚀区的深度,且DD5合金的外腐蚀区和内腐蚀区均匀性较差,腐蚀程度差异较大。根据前文分析,DD10和DSM11合金在内部易生成保护性的氧化膜,两者的腐蚀层腐蚀深度会少于DD5的腐蚀层深度。

图8 DSM11合金样品腐蚀产物截面面扫描

Fig. 8 Cross section scanning results of DSM11 corrosion products

3 分析与讨论

DD5、DD10和DSM11合金样品在经历了850 ℃腐蚀200 h的过程后,均发生了明显的热腐蚀现象。腐蚀层外腐蚀区由多层氧化物组成,内腐蚀区为硫化物和氧化物组成,综合判断均发生了“酸碱熔融模型”机制的热腐蚀反应[20]。合金在发生热腐蚀时,在熔盐作用下表面形成的氧化膜不断沉积、溶解和破坏,致使材料加速腐蚀。DD5合金外腐蚀区形成大量混合的氧化物,未在内部形成连续的氧化膜,对基体保护性较差,抗热腐蚀性较差。DD10和DSM11合金腐蚀层的内部形成了层状致密连续的Cr2O3、TiO2和Al2O3膜,对基体存在一定保护作用,合金具有一定的抗热腐蚀性能。

图9 DD5、DD10和DSM11合金样品腐蚀层截面线扫描

Fig. 9 Cross section line scanning results of DD5(a), DD10(b) and DSM11(c) corrosion layers

图10 DD5、DD10和DSM11合金样品腐蚀层深度测量结果

Fig. 10 Corrosion layer depth measurement results of DD5, DD10 and DSM11

以DD10合金为例,热腐蚀过程主要分为以下4个进程:

1) 氧化膜形成

本实验合金中Al元素的含量仅为4.0%(质量分数),并且抑制Al在合金中迁移扩散的难熔元素Ta和W等含量较高,导致合金表面不能形成单一的Al2O3膜。合金中Cr元素高达12.5%(质量分数),Ti元素约为4.0%(质量分数),并且合金中Cr和Ti元素的沿晶界扩散能力会高于Al元素,在热腐蚀的初期阶段,Cr元素优先氧化为Cr2O3,在表面形成一层Cr2O3膜,逐一再形成TiO2和Al2O3等氧化物膜,与实验中腐蚀层截面面扫描结果大致相同。熔盐中溶解的氧和硫酸盐在高温下分解的氧促进合金元素的氧化。

=O2+2SO2+2O2- (1)

=O2+2SO2+2O2- (1)

2) 氧化膜溶解

氧化膜的形成消耗了O2,导致合金/熔盐界面的局部O2-的活度升高,表面的NiO、Cr2O3和TiO2氧化膜发生碱性溶解反应,生成的 、

、 和

和 等离子,由合金/熔盐界面向熔盐/气体界面扩散。这些离子具有不稳定特性,扩散至熔盐/气体界面后,会发生分解并进一步析出疏松的金属氧化物[21]。

等离子,由合金/熔盐界面向熔盐/气体界面扩散。这些离子具有不稳定特性,扩散至熔盐/气体界面后,会发生分解并进一步析出疏松的金属氧化物[21]。

2Cr2O3+4O2-+3O2= (2)

(2)

TiO2+O2-= (3)

(3)

4NiO+2O2-+O2= (4)

(4)

同时,由于混合盐中存在NaCl、Cl-与氧化物发生反应,生成较强挥发性的产物,使氧化膜局部溶解,进而破坏其表面氧化物的连续性[22]。

2Cr2O3+3O2+4Cl-=2CrO2Cl2+ (5)

(5)

NiO还会与Cr2O3、CoO等氧化物发生固相反应,形成NiCr2O4和NiCo2O4等尖晶石类物质,增加原有氧化膜的溶解程度。

NiO+Cr2O3=NiCr2O4 (6)

表面的NiO、Cr2O3和TiO2等氧化物逐渐溶解,而内部的Al2O3氧化膜相应地受到了保护,可保证Al2O3稳定的生长。NiCr2O4和NiCo2O4等尖晶石类产物与O2-不发生反应,也会聚集在表面。

3) 氧化膜破裂

随着腐蚀反应的进行,合金表面逐渐生成由多种氧化物组成的氧化膜。在相同温度的作用下,不同的氧化物之间会发生不同程度的体积膨胀,因此,在合金基体和氧化膜界面、不同氧化物相互之间会产生由于体积膨胀而引起的局部应力。局部应力增加到一定程度,会导致合金表面的氧化膜疏松分层且产生开裂。

Cl-与金属元素发生反应会生成挥发性的氯化物,当氯化物聚集到一定程度时发生扩散作用,会从氧化膜的空隙中扩散出去,进一步引起氧化膜的开裂。

4) 内氧化和内硫化过程

随着腐蚀过程的进行,熔盐内的O不断被消耗,导致在合金基体/熔盐界面的O分压不断减小,界面的S分压相反地不断上升,导致腐蚀产物/基体界面之间形成S的正活度梯度,使S原子通过微裂纹及氧化物晶界扩散至基体,与合金中金属元素发生反应,在内层区不断形成内硫化物[23-24]。

3Ni+2S=Ni3S2 (7)

Cr+S=CrS (8)

2Ti+S=Ti2S (9)

2Cr+Ni3S2=2CrS+3Ni (10)

同理,少量O也会扩散进入基体,与基体元素和内硫化物反应生成内氧化物。由截面成分分析和线扫描结果表明,内氧化物以Al2O3为主。这一现象可能是因为Al元素与氧的结合能力较强,并且Al2O3具有热力学最稳定性的特点,在内腐蚀区域中的氧含量较少条件下,最终导致主要的氧化产物为Al2O3。另外,气态氯化物的挥发也会导致腐蚀层发生开裂和剥落,促使S和O向基体方向扩散,进一步加快了腐蚀,形成了内氧化和内硫化区。

综合分析可知,DD5、DD10和DSM11合金中Al、Cr和Ti的含量有所差别。在DD10和DSM11合金中,Cr含量都远高于DD5的含量,并且合金中添加有Ti元素,在表面易生成保护性Cr2O3和TiO2的氧化膜。当表面Cr2O3和TiO2等氧化物遇到熔盐中O2-时,会优先在表面发生溶解反应,而内部的Al2O3氧化膜相应地受到了保护,进一步保证Al2O3的稳定生长,保护合金内部不受熔盐、O和S的作用而进一步产生氧化和热腐蚀[25]。对于DD5而言,Cr和Al含量较少且相差不大,在热腐蚀过程中,Cr和Al在表面均可形成氧化物,形成了混合型氧化物,导致内部元素的贫化,不易形成层状连续分布的氧化膜,基体会进一步遭受腐蚀。因此,DD5合金抗热腐蚀性较差,DD10和DSM11合金具有一定的抗热腐蚀性能。

4 结论

1) DD5合金涂盐腐蚀后质量变化较大,随着实验时间的增加,质量呈现下降趋势,前25 h之内,合金的质量损失最明显;DD10和DSM11合金样品质量变化较小,随着实验时间的增加,质量呈现先减少后趋于平稳趋势,前25 h之内的质量损失也较为明显。

2) DD5合金腐蚀层大致可分为2个区域:外腐蚀区由NiO、Cr2O3、Al2O3、NiCo2O4和NiCr2O4组成;内腐蚀区由颗粒状CrS和Al2O3组成。DD10和DSM11合金的腐蚀产物大致可分为2个区域:外腐蚀区的外层主要成分为NiO、Cr2O3、TiO2、NiCo2O4和NiCr2O4,较薄且呈现不连续性;外腐蚀区的中间层主要成分为Cr2O3和TiO2 为主的过渡氧化层;外腐蚀区的内侧主要以Al2O3为主的连续且致密的氧化层。内腐蚀区由颗粒状Ti2S和CrS组成,还含有少量的Al2O3。

3) 热腐蚀机理主要为合金表面形成Cr2O3、TiO2和Al2O3等氧化膜,不断经历沉积、溶解和破坏过程。DD5合金腐蚀产物内部Cr2O3和Al2O3等氧化物分散性较大、不连续,对基体保护性较差。DD10和DSM11合金腐蚀产物内部呈现连续层状分布Cr2O3、TiO2和Al2O3保护性氧化膜,对基体保护性较好,具有一定的抗热腐蚀性能。

REFERENCES

[1] 安 宁. 先进涡轮发动机用镍基高温合金的化学组成、显微组织和性能[J]. 金属材料研究, 2017, 43(2): 39-54.

AN Ning. Chemical composition, microstructure and performance of high temperature nickel-base alloy for advanced turbine engine with[J]. Research on Metallic Materials, 2017, 43(2): 39-54.

[2] ERIC S, HURON R C, REED M C, HARDY M J, MILLS R E, MONTERO P D, PORTELLA J T. AD730TM—A new nickel-based superalloy for high temperature engine rotative parts[M]. New Jersey: John Wiley & Sons, 2012.

[3] 毕中南, 董建新, 张麦仓, 郑 磊, 章清泉. 一种航空发动机密封用镍基合金组织稳定性的实验研究及理论计 算[J]. 航空学报, 2010, 31(3): 643-649.

BI Zhong-nan, DONG Jian-xin, ZHANG Mai-cang, ZHENG Lei, ZHANG Qing-quan. Experimental study and theoretical calculation on structure stability of a nickel-based superalloy for seals in aero-engine[J]. Acta Aeronautica et Astronautica Ainica, 2010, 31(3): 643-649.

[4] RAISSON G, GUEDOU J Y, GUICHARD D, RONGVAUX J M. Production of net-shape static parts by direct HIPing of nickel base superalloy prealloyed powders[J]. Advanced Materials Research, 2011, 278: 277-282.

[5] 李 云. 五种镍基高温合金的高温氧化、热腐蚀及其防护涂层的研究[D]. 沈阳: 东北大学, 2004.

Li Yun. High-temperature oxidation, hot corrosion of five Ni-base superalloys and their protection[D]. Shenyang: Northeastern University, 2004.

[6] DEODESHMUKH V P. Evaluating the hot corrosion behavior of high-temperature alloys for gas turbine engine components[J]. JOM, 2015, 67(11): 2608-2614.

[7] 李 云, 郭建亭, 袁 超, 杨洪才, 徐 宁, 申志明. 镍基铸造高温合金K35的热腐蚀行为[J]. 中国腐蚀与防护学报, 2005, 25(4): 250-255.

LI Yun,GUO Jian-ting,YUAN Chao,YANG Hong-cai, XU Ning, SHEN Zhi-ming. Hot corrosion of nickel-base cast superalloy K35 at 800 ℃[J]. Journal of Chinese Society for Corrosion and Protection, 2005, 25(4): 250-255.

[8] 余竹焕, 王盼航, 张 洋, 刘蓓蕾. 高温合金热腐蚀性能影响因素的研究进展[J]. 铸造技术, 2018, 39(1): 226-231.

YU Zhu-huan, WANG Pan-hang, ZHANG Yang, LIU Bei-lei. Research progress on factors affecting hot corrosion of superalloy[J]. Foundry Technology, 2018, 39(1): 226-231.

[9] 蔡文博, 孙海霞. 高温合金热腐蚀性能影响因素的研究[J]. 中国科技信息, 2018, 591(19): 89-90.

CAI Wen-bo, SUN Hai-xia. Research of hot corrosion influence factors on High temperature alloy[J]. China Science and Technology Information, 2018, 591(19): 89-90.

[10] LU Yang, CHENG Bo, WANG Jun-wei, WANG Zhi-ping, LI Wen-sheng. Corrosion behavior of Cr, Fe and Ni based superalloy in molten NaCl[J]. Rare Metal Materials & Engineering, 2014, 43(1): 17-23.

[11] 杨君宝, 邱克强, 卢旭东. 含钛镍基合金在850 ℃和950 ℃的热腐蚀行为[J]. 材料热处理学报, 2015, 36(10): 218-223.

YANG Jun-bao, QIU Ke-qiang, LU Xu-dong. Hot corrosion behavior of a Ni-base superalloy containing Ti in molten sulfate at 850 ℃ and 950 ℃[J]. Transactions of Materials and Heat Treatment, 2015, 36(10): 218-223.

[12] ZHANG T B, DONG R F, HU R. Hot corrosion characteristics of Ni-20Cr-18W superalloy in molten salt[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(11): 3840-3846.

[13] 管秀荣, 关英双, 纪慧思, 刘恩泽, 郑 志, 佟 健. 不同Ru含量的镍基高温合金热腐蚀研究[J]. 材料科学与工艺, 2013, 21(2): 108-112.

GUAN Xiu-rong, GUAN Ying-shuang, JI Hui-si, LIU En-ze, ZHENG Zhi, TONG Jian. Study on hot corrosion of Ni-based superalloy with different Cr content[J]. Materials Science & Technology, 2013, 21(2): 108-112.

[14] 管秀荣, 关英双, 纪慧思, 郑 志, 佟 健, 刘恩泽. 不同Cr含量对镍基高温合金抗热腐蚀性能的影响[J]. 材料热处理学报, 2014, 35(s1): 58-61.

GUAN Xiu-rong, GUAN Ying-shuang, JI Hui-si, ZHENG Zhi, TONG Jian, LIU En-ze. Effect of different Cr content on hot corrosion resistance of Ni-base superalloy[J]. Transactions of Materials and Heat Treatment, 2014, 35(s1): 58-61.

[15] LI Wei-jie, LIU Y, WANG Y, HAN C, TANG H P. Hot corrosion behavior of Ni-16Cr-xAl based alloys in mixture of Na2SO4-NaCl at 600 ℃[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(12): 2617-2625.

[16] WENG F, YU H, WAN K, CHEN C Z. The influence of Nb on hot corrosion behavior of Ni-based superalloy at 800 ℃ in a mixture of Na2SO4-NaCl[J]. Journal of Materials Research, 2014, 29(21): 2596-2603.

[17] 于忠锋, 郑 志, 刘恩泽, 于永泗, 朱耀宵. 两种低偏析镍基高温合金抗热腐蚀性能的研究[J]. 中国腐蚀与防护学报, 2008, 28(5): 277-281.

YU Zhong-feng, ZHENG Zhi, LIU En-ze, YU Yong-si, ZHU Yao-xiao. Hot corrosion behavior of Ni-based superalloy DZ68 and K438G with low segregation[J]. Journal of Chinese Society for Corrosion and Protection, 2008, 28(5): 277-281.

[18] 宁礼奎, 郑 志, 谭 毅, 刘恩泽, 佟 健, 于永泗, 王 华. 一种新型定向凝固镍基高温合金抗热腐蚀性能的研究[J]. 金属学报, 2009, 45(2): 161-166.

NING Li-kui, ZHENG Zhi, TAN Yi, LIU En-ze, TONG Jian, YU Yong-si, WANG Hua. Study on hot corrosion resistance of a new directional solidification Ni-based superalloy[J]. Acta Metallurgica Sinica, 2009, 45(2): 161-166.

[19] 王会阳, 安云岐, 李承宇, 晁 兵, 倪 雅, 刘国彬, 李 萍. 镍基高温合金材料的研究进展[J]. 材料导报, 2011, 25(2): 482-486.

WANG Hui-yang, AN Yun-qi, LI Cheng-yu, CHAO Bing, NI Ya, LIU Guo-bin, LI Ping. Research progress of Ni-based superalloys[J]. Materials Reports, 2011, 25(2): 482-486.

[20] 黄 烁, 王 磊, 黄 炎, 李俊涛. 定向凝固镍基DZ792及DZ792G合金的热腐蚀行为[J]. 东北大学学报, 2013, 34(11): 1580-1584.

HUANG Shuo, WANG Lei, HUANG Yan, LI Jun-tao. High temperature hot corrosion behaviors of directional solidification Ni-base superalloy DZ792 and DZ792G[J]. Journal of Northeastern University, 2013, 34(11): 1580-1584.

[21] 黄 烁, 王 磊, 黄 炎, 刘 杨, 吴剑涛, 燕 平, 李俊涛. 定向凝固DZ792镍基高温合金900 ℃下的热腐蚀行为[J]. 钢铁研究学报, 2011, 23(2): 385-388.

HUANG Shuo, WANG Lei, HUANG Yan, LIU Yang, WU Jian-tao, YAN Ping, LI Jun-tao. Hot corrosion behaviors of Ni-base directional solidification DZ792 superalloy at 900 ℃[J]. Journal of Iron and Steel Research, 2011, 23(2): 385-388.

[22] 郭贵芬. Fe、Cr、Ni及其氧化物在NaCl、KCl熔盐中的腐蚀及机理[D]. 大连: 大连理工大学, 2005.

GUO Gui-fen. The corrosion and mechanism of Fe, Cr, Ni and their oxide in NaCl, KCl molten salt[D]. Dalian: Dalian University of Technology, 2005.

[23] BAO Q H, YE B, JIANG H Y, XIE C, DING W J. Research progress on the corrosion resistance of nickel-based superalloy[J]. Mater Rev, 2015, 29(17): 132-138.

[24] 陈 涛. 含铼镍基合金的高温氧化和热腐蚀研究[D]. 沈阳: 沈阳理工大学, 2014.

CHEN Tao. Study on oxidation and thermal corrosion of rhenium-nick-based alloys at high temperature[D]. Shenyang: Shenyang Ligong University, 2014.

[25] 鲍庆煌, 叶 兵, 蒋海燕, 谢超英, 丁文江. 镍基高温合金耐腐蚀性能的研究进展[J]. 材料导报, 2015(17): 128-134.

BAO Qing-huang, YE Bing, JIANG Hai-yan, XIE Chao-ying, DING Wen-jiang. Research progress on the resistance of Ni-base superalloy[J]. Materials Review, 2015(17): 128-134.

Comparison on hot corrosion behaviors of Ni-base superalloy DD5, DD10 and DSM11

LI Yan-ming, LIU Huan, QIAO Zhi, HAN Zhen-yu, XUE Zhi-bo

(Shenyang Aeroengine Research Institute, Aero Engine Corporation of China, Shenyang 110015, China)

Abstract: The hot corrosion behaviors of Ni-base superalloy DD5, DD10 and DSM11 in the presence of 10%NaCl+90%Na2SO4 (mass fraction) salt film after corrosion at 850 ℃ for 200 h were tested by scanning electron microscopy(SEM), energy disperse spectroscopy(EDS) and X-ray diffraction(XRD). The results show that O2- in molten salt preferentially reacts with the outside Cr2O3 and TiO2 layer at surface of the alloys DD10 and DSM11 owing to the high Cr and Ti contents. DD10 and DSM11 have excellent thermal corrosion resistance, the further corrosion of alloy enable to be inhibited because of stable growth of Al2O3. The outside Cr2O3 and Al2O3 layer at surface of the alloy DD5 owing to the fewer and similar Cr and Al contents can cause the dilution of internal alloy elements. The alloy DD5 cannot form a continuous oxidation film, the base metal will suffer further corrosion.

Key words: Ni-base superalloy; DD5; DD10; DSM11; hot corrosion; oxidation film

Received date: 2019-10-21; Accepted date: 2020-06-27

Corresponding author: LI Yan-ming; Tel: +86-15298372885; E-mail: 260535498@qq.com

(编辑 李艳红)

收稿日期:2019-10-21;修订日期:2020-06-27

通信作者:李艳明,工程师,硕士;电话:15298372885;E-mail:260535498@qq.com