DOI:10.19476/j.ysxb.1004.0609.2017.10.10

PREP工艺制造的镍基高温合金粉末中夹杂物

张 莹1, 2,张义文1, 2,吕日红3,黄虎豹1, 2,张国星1, 2,韩寿波1, 2,刘明东1, 2,孙志坤1, 2

(1. 钢铁研究总院 高温材料研究所,北京 100081;

2. 钢铁研究总院 高温合金新材料北京市重点实验室,北京 100081;

3. 贵州黎阳航空动力有限公司,安顺 561102)

摘 要:夹杂物是影响粉末冶金产品质量的主要因素之一。采用SEM、XRD、EPMA 等手段通过对等离子旋转电极制粉工艺(PREP)制取的镍基高温合金粉末中夹杂物的形貌特征、化学组成的研究,将不同工序处理后粉末中的夹杂物进行分类,统计分析其存在形式、尺寸、数量及分布。结果表明:粉末中的夹杂物按产生机制和来源主要分为陶瓷、熔渣、有机物、粉末粘连夹杂物或升华物形成的异常颗粒。经过筛分和静电处理后,残留在成品粉末中的陶瓷占夹杂物总数量的7%,熔渣占 53%,有机物占40%。筛分和静电分离去除各类夹杂物的能力主要与成品粉末的粒度和夹杂物的密度、介电常数及其尺寸、形态有关。

关键词:PREP 工艺;镍基高温合金粉末;夹杂物;粉末处理

文章编号:1004-0609(2017)-10-2037-09 中图分类号:TG132.32 文献标志码:A

镍基粉末冶金(PM)高温合金由于具备优异的高温性能,在PM高温合金领域得到了广泛的应用,并成为制造先进航空发动机高压涡轮盘等关键热端部件的必选材料[1-2]。近年来采用金属粉末3D打印零部件技术开始在航空航天领域获得了应用[3]。随着产品使用需求的提高,对合金粉末的质量提出了更严格的要求。夹杂物是影响PM高温合金发展和应用的主要因素之一。大量研究证明[1-2, 4-7],非金属夹杂物会破坏合金基体的连续性,造成应力集中,对PM高温合金产品的力学性能特别是低周疲劳性能产生极大的危害,甚至会造成盘件突然破裂而失效。文献[4]对镍基PM高温合金进行低周疲劳试验的研究结果表明,有80%的试样断裂起源于夹杂物。夹杂物与合金基体界面的结合强度以及对裂纹萌生、扩展、疲劳寿命的影响程度和夹杂物的类别、性质、尺寸、形貌及其在PM合金制件中的分布有着密切的关系。

夹杂物的研究一直是各国粉末冶金领域备受关注的问题[6-10]。人们试图通过等温锻造、挤压等热加工工艺破碎细化PM合金中的夹杂物,以改善产品的力学性能和提高使用寿命。同时也展开了改进母合金冶炼和制粉工艺的研究,以减少母合金中夹杂物数量和降低粉末的使用粒度[11-14]。然而与其他传统的成形工艺相同[15],夹杂物的存在尚不可避免。文献[6]对PREP工艺制取的EP741NP和EI698P合金粉末中的夹杂物进行了分析,指出在该类合金粉末中陶瓷、熔渣、有机物夹杂物数量分别占10%~16%、35%~44%、46%~49%。为减少粉末中夹杂物数量,人们在粉末处理工艺改进方面做了诸多研究[14, 16-17]。文献[17]通过静电分离电场中合金粉末和夹杂物的运动速度公式的推导,分析了不同粒子的尺寸、密度以及气体介质的粘滞度与其运动速度的关系,以及对静电分离去除夹杂物效果的影响,并报导目前正在深入该方面的研究。

PREP工艺是我国近20年来制造镍基高温合金粉末的主要手段之一。本文作者在对该类合金粉末多年的研究基础上,针对我国采用真空感应冶炼母合金+PREP 工艺制取的镍基高温合金粉末中的夹杂物,首次进行了系统分类,对其尺寸及分布状态进行统计分析;结合夹杂物的形貌特征和化学组成,分析各类夹杂物的来源、产生机制,并就其物理特性对去除效果的影响展开了讨论。这对改进PM高温合金的制造工艺、提高产品质量以及预测PM高温合金制件的使用寿命将提供有价值的科学依据。

1 实验

采用LEICAMZ6实体显微镜(OM)检测、提取不同工序处理后镍基高温合金粉末中的夹杂物,通过JSM-6480LV型扫描电镜(SEM)、APD-10 型X衍射仪(XRD)、JXA-8530型电子探针(EPMA)观察、分析夹杂物的形貌表征和化学组成,并进行计算统计和归类。

2 结果和分析

2.1 原始粉末中的夹杂物数量和尺寸

对PREP工艺制取的10炉批原始镍基高温合金粉末进行统计分析,得出粉末粒度与夹杂物分布的相对关系,由图1所示。当粒度在(50~150) μm的粉末为全粉质量的85%以上时,小于50 μm的粉末质量约占全粉质量的5%。尺寸在(50~150) μm的夹杂物数量(颗粒个数)占全粉中夹杂物总数量的55%,而小于50 μm的粉末中夹杂物占总数量的35%。

图1 原始粉末的粒度与夹杂物分布对应关系图

Fig. 1 Distribution of powder particles and inclusions in original powder

2.2 夹杂物的类型和数量

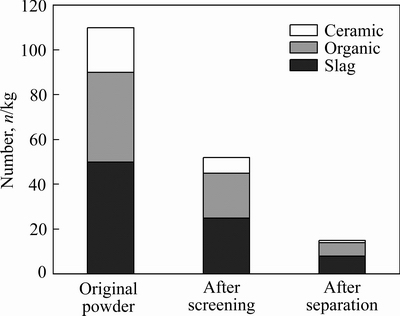

图2所示为原始以及筛分和静电处理后粉末试样中夹杂物的类型和数量。筛分处理后,夹杂物去除50%以上,经过静电处理,(50~150) μm范围1 kg粉样中的夹杂物少于15颗。其中陶瓷约占总数量的7%,熔渣占53%,有机物占40%。

图2 不同处理工序后1 kg粉样中夹杂物的类型和数量

Fig. 2 Type and number of inclusions in 1 kg powder sample after different treatment process

2.3 粉末中不同类型夹杂物的表征及产生机制

粉末中的夹杂物按来源分为陶瓷、熔渣、有机物、粉粘夹杂物异常颗粒4类。

2.3.1 陶瓷类

如图3所示,陶瓷类夹杂物呈球状(见图3(a))、液滴状(见图3(b))、有棱角多边形块状(见图3(c)),呈白、蓝、灰半透明色。根据EDS能谱分析,它们的主要成分是O、Si和Al(见图3(d))。

图4所示为浇注口耐火材料的XRD谱,结果显示,母合金熔炼炉浇注口的耐火材料是由3Al2O3·2SiO2(莫来石)、SiO2和Al2O3组成,其中莫来石含47.4%, SiO2含28.9%,Al2O3为23.7%。测试得知,本研究用真空感应熔炼炉的坩埚材质为MgO,并含有少量SiO2。由此分析,陶瓷类夹杂物主要来自浇注过程。极少量未能被过滤掉的炉衬渣及过滤网下方浇注口的耐火材料渣被卷入合金锭模中,属于外来夹杂物。

图5所示为典型球形Si、Al复合氧化物夹杂的SEM元素分析结果。这类夹杂物可能是合金原料在高温熔炼中生成的Al2O3、 SiO2或与炉衬的氧化硅渣聚集形成,归类为硅酸铝[18-19]陶瓷夹杂物。其反应式如下:

3/2Al2O3+SiO2=1/2(3Al2O3·2SiO2) (1)

在浇注凝固时由于冷却速度较快,液态的硅酸铝来不及结晶,通常以过冷液体玻璃态的形式存在,表面张力使其收缩而形成球状。或者是在雾化制粉过程中,高温等离子弧使母合金棒端面的陶瓷夹杂物以熔融态离心飞溅,然后在约1×104 ℃/s的速度冷却中形成球状。

图3 陶瓷夹杂物形貌及其EDS谱

Fig. 3 Ceramic inclusions morphologies and EDS spectrum

图4 浇注口耐火材料XRD谱

Fig. 4 XRD pattern of refractory material at sprue gate

2.3.2 熔渣类

图6所示为熔渣类夹杂物的形貌及其对应的EDS能谱。由图6可见,熔渣类夹杂物为多孔不透明、形状不规则且棱面光滑,呈黑色或灰色。图6(a′)、(b′)、(c′)所示为分别对应图6(a)、(c)、(e)的EDS分析结果。主要成分为Al、O(见图6(a))以及Al、Si和少量Mg、Ti、Cr、Fe的混合氧化物(见图6(c)、(e)),或粘连有合金基体,成分不均,局部存在合金枝晶组织(见图6(e))。

熔渣主要来源有:1) 合金原材料在熔炼过程中形成Al2O3等内生夹杂物;2) 原材料与坩埚材料发生化学反应形成氧化物;3) 浇注过程中多元反应生成的复杂氧化产物;4) 母合金棒中的夹杂物在雾化制粉时与熔融态的合金粘连。

由以上结果得知,熔渣类夹杂物主要是由氧化物组成。母合金在冶炼过程中的氧一方面来自原材料,另一方面来自炉衬材料的热分解。真空熔炼过程中坩埚炉衬与合金熔液接触,炉衬在高温下分解的氧直接进入熔池,与氧亲和力强的合金元素发生氧化反应:

2[Al]+3[O]=Al2O3 (2)

[Ti]+2[O]=TiO2 (3)

所研究的合金在真空感应冶炼过程中是通过碳进行脱氧:

[C]+[O]=CO (4)

但由于真空冶炼时Mg 的蒸汽压高而溶解度低,坩埚材料MgO分解的供氧速度MgO→[Mg]+[O]要大于[C]+[O]→CO反应的脱氧速度[20]。由此分析,坩埚与合金熔体中的Al发生如下反应,生成Al2O3夹杂物:

MgO+4/3[Al]=2/3Al2O3+2Mg (5)

所以,母合金冶炼时必须通过控制真空度和熔池温度以减少炉衬分解产生夹杂物。

图5 球形硅酸铝夹杂物的SEM元素分析图

Fig. 5 SEM elements analysis of spherical alumina silica inclusion

图6 熔渣类夹杂物的形貌及其对应的EDS谱

Fig. 6 Slag inclusions morphologies((a), (b), (c)) and corresponding EDS spectra((a′), (b′), (c′))

由于浇注过程与大气接触,因此,合金熔液中的Al等亲氧元素会发生二次氧化反应。同时合金熔液与炉渣、坩埚、分流器剥落的耐火材料之间发生多元反应[18],聚合形成以Al、Si、Mg为主的复杂氧化物夹杂,或与合金熔液粘连凝结,如图6(a′)、(b′)和(c′)所示。

2.3.3 有机类

有机夹杂物形貌表征如图7所示,形状不规则,多为半透明白、棕黄色及灰黑色,主要含C、O、Ca、Ti等元素。它们来自制粉和粉末处理系统,主要有棉丝、真空油蒸汽、灰尘、橡胶,及其在雾化室与熔融态的熔渣粘连形成混合夹杂物。

2.3.4 异常颗粒

如图8所示,在制粉过程中会形成一种合金粉末粘连升华物和夹杂物的异常颗粒,它们的形状、类型各异。

图7 有机夹杂物的形貌及其EDS谱

Fig. 7 Morphologies of organic inclusions and EDS results

图8 异常颗粒的形貌特征

Fig. 8 Abnormal particle morphologies

雾化制粉时,等离子流使母合金棒端部达到熔化的温度,在高温和惰性气体氛围下合金中低熔点的Mg、Cr、Al等元素相对蒸气压较高[21],极易蒸发,其升华物附着在未完全凝固的粉末表面,一般呈絮状或弥散状(见图8(a))。当雾化气氛中含有C、O时,便生成氧化物或碳氧化物粘附在粉末表面。图8(b)、(c)和(d)分别表示:雾化过程中离心飞射的合金液滴在未完全凝固时,与在2.3.1、2.3.2和2.3.3中所述的熔渣、陶瓷及有机夹杂物粘连形成的异常颗粒。夹杂物和熔融的合金液滴发生粘附(Adhesion),可用下式[22]表达:

(6)

(6)

式中:Wa为粘附力, 、

、 和

和 分别代表各自的表面张力及二者接触时质点间产生的界面张力)。Wa值越大,粘附越紧密。

分别代表各自的表面张力及二者接触时质点间产生的界面张力)。Wa值越大,粘附越紧密。

3 讨论

通过粉末处理去除夹杂物是获取高纯度粉末必不可少的工艺手段。目前,PREP工艺制取的高温合金粉末首先经过筛分获得所需的粒度范围,并筛去大尺寸和细小尺寸的夹杂物,然后再采用静电分离工艺去除夹杂物。

将图2中筛分与静电处理后相同粉末粒度范围的数据进行对比分析,发现静电后陶瓷夹杂物数量减少了86%,有机物减少70%,熔渣减少68%。

静电处理是在惰性气体保护下,被处理的粉末通过振动给料器均匀地撒到电晕极和沉淀极(辊筒)之间的电场中,利用电晕放电现象对金属粉末和夹杂物进行分离。如图9所示,在静电过程中合金及夹杂粒子受到电力和机械力的作用[23]。电力分别为:库仑力F1、界面吸力F2和作用极小的非均匀电场力F3。机械力 为重力F4和离心力F5。

在电晕电场中各类粒子所受电力的大小,取决于其荷电的能力。根据文献[23]中的公式推论,在电晕电场中合金及夹杂物粒子的荷电为

(7)

(7)

式中: 为粒子的介电常数;E为电场强度;r为粒子的尺寸。

为粒子的介电常数;E为电场强度;r为粒子的尺寸。

当离开电晕电场,粒子与辊筒接触释放电荷。粒子的剩余电荷可由公式表示:

(8)

(8)

式中:μ(R)为电阻系数。

图9 静电分离工艺示意图

Fig. 9 Electrostatic separation process diagram

这时作用在粒子的电力主要决定于剩余电荷。导电性能好的金属粉末μ(R)趋于0 ,一旦与辊筒接触,就释放电荷,剩余电荷QCR≈0,在重力和离心力的作用下从辊筒上脱落进入成品粉罐。导电性能差的非金属夹杂物可设μ(R)趋于1,则仍存在剩余电荷。夹杂物表面的剩余电荷使其受到辊筒的吸力作用,当夹杂物粒子上所受的力F1+F2+ >F5 +F3时,被吸附在辊筒表面,最终由清理刷将其刷入废粉罐内。

>F5 +F3时,被吸附在辊筒表面,最终由清理刷将其刷入废粉罐内。

由以上分析得知,各类夹杂物在静电场中受力的区别主要取决于它们的介电常数和密度。 在本研究合金粉末中常见的夹杂物主要含Al2O3、3Al2O3·2SiO2、SiO2、橡胶、聚四氟乙烯,它们的介电常数分别为9.5、6.5、3.78、2.6~2.9、2.0,密度分别为4.1、3.2、2.6、1.65、<2.3 g/cm3[22, 24]。设工作电压为40 kW,辊筒直径320 mm,转速60 r/min,将以上数据分别代入文献[16]的推导公式:

(9)

(9)

式中:d为夹杂物尺寸,E为电场强度,D为辊筒直径,n为辊筒转速,r为夹杂与辊筒的接触阻力, 为密度,

为密度, 为介电常数。

为介电常数。

计算分析对比得出,在相同工艺参数条件下,有机夹杂物应最易被去除,其次是SiO2、3Al2O3.2SiO2,然后是Al2O3。陶瓷类夹杂物主要含SiO2及其复合氧化物;熔渣较多是Al2O3为主的混合氧化物,所以陶瓷较熔渣易于去除。

小尺寸的夹杂物特别是有机物,由于本身剩余电荷和重力很小,加之与释放电荷快速流动的金属粉末撞击,很容易从辊筒上脱落被卷入成品粉罐。如图9所示,粘连夹杂颗粒落入成品粉罐中的概率还与其着落辊筒的方式有关。当该异常颗粒受辊筒的吸力大于离心力时,便会附着在辊筒上,被刷入废粉罐内;反之,则被卷入成品粉末中。

4 结论

1) 本研究采用真空感应熔炼母合金+PREP工艺生产的镍基高温合金原始粉末中大于150 μm的夹杂物占总数量的10%,(150~50) μm的占55%,小于50 μm的占 35%。

2) 本试验用粉末经筛分后,夹杂物减少了50%以上,通过静电分离处理,1 kg粒度为(50~150) μm试样中的夹杂物少于15颗。

3) 粉末中的夹杂物按来源分为:陶瓷、熔渣、有机夹杂物、粉末粘连夹杂物异形颗粒。

4) 与筛分处理后相同粒度的粉末比较,静电后陶瓷类减少了86%,有机物减少70%,熔渣减少68%;静电分离去除各类夹杂物的能力主要与夹杂物的密度和介电常数以及尺寸、形态有关。残留在成品粉末中的陶瓷占夹杂物总数的7%,熔渣占 53%,有机物占 40%。

REFERENCES

[1] 张义文, 刘建涛. 粉末高温合金研究进展[J]. 中国材料进展, 2013, 32(1): 1-11.

ZHANG Yi-wen, LIU Jian-tao. Development in powder metallurgy superalloy[J]. Materials China, 2013, 32(1): 1-11.

[2] GARIBOVG S, GRITS N M. The way of creatingnewhigh strengthpowder metallurgy superalloy forpromising aircraft engines[J]. Technologyof LightAlloys,2012(3): 35-43.

[3] 郑 增, 王联凤, 严 彪. 3D金属材料研究进展[J]. 上海有色金属, 2016, 37(1): 57-60.

ZHENG Zeng, WANG Lian-feng, YAN Biao. Research progress of metal materials for 3D printing[J]. Shanghai Nonferrous Metals, 2016, 37(1): 57-60.

[4] 张 莹, 张义文, 张 娜, 刘明东, 刘建涛. 粉末冶金高温合金FGH97的低周疲劳断裂特征[J]. 金属学报, 2010, 46(4): 444-450.

ZHANG Ying, ZHANG Yi-wen, ZHANG Na, LIU Ming-dong, LIU Jian-tao. Fracture character of low cycle fatigue of P/M superalloy FGH97[J]. Acta Metallurgica Sinica, 2010, 46(4): 444-450.

[5] 刘新灵, 陶春虎. 粉末高温合金缺陷特性及寿命预测方法研究进展和思考[J]. 材料导报, 2013, 27(专辑21): 92-96.

LIU Xin-ling, TAO Chun-hu. Research progress and analysis on defect characteristic and life estimation of powder metallurgy superalloy[J]. Materials Review, 2013, 27(special 21): 92-96.

[6] KOSHELEV V J, SHOROSHEV Y G.Study of nonmetallic inclusions in the powder particles of nickel base superallloy[J]. Technology of Light Alloys, 2005 (1/4): 78-82. (in Russian)

[7] 张 莹, 张义文, 宋璞生, 张凤戈, 陶 宇, 陈希春, 杨仕仲. 镍基粉末高温合金中的夹杂物[J]. 钢铁研究学报, 2003, 15(6): 71-73.

ZHANG Ying, ZHANG Yi-wen, SONG Pu-sheng, ZHANG Feng-ge, TAO Yu, CHENG Xi-cun, YANG Shi-zhong. Inclusion in PM nickel based superalloy[J]. Journal of Iron and Steel Research, 2003, 15(6): 71-73.

[8] 周晓明. 粉末高温合金中非金属夹杂物的遗传特征及损伤力学行为研究[D]. 北京: 北京航空材料研究院, 2006: 6-11, 24-44, 50-56.

ZHOU Xiao-ming. Genetic characteristic and damage mechanical behavior of non-metallic inclusions in P/M superalloy[D]. Beijing: Beijing Institute of Aeronautical Materials, 2006: 6-11, 24-44, 50-56.

[9] CHEBOTAREV M S.Defects in the PMdisksandtheir detectionmethods[J]. Technologyof Light Alloys, 2008(2): 44-48. (in Russian)

[10] 张敏聪, 方 爽, 陈由红, 孙 兴, 东赟鹏, 王淑云. FGH96合金挤压过程非金属夹杂物的变形行为[J]. 锻压技术, 2013, 38(6): 132-137.

ZHANG Min-cong, FANG Shuang, CHEN You-hong, SUN Xing, DONG Yun-peng, WANG Shu-yun. Deformation behavior of non-metallic inclusions of FGH96 alloy in extrusion process[J]. Forging & Stamping Technology, 2013, 38(6): 132-137.

[11] 陈希春, 付 锐, 任 昊, 冯 涤. 电渣重熔连续定向凝固FGH96合金非金属夹杂物研究[J]. 中国新技术新产品, 2011(10): 1-2.

CHEN Xi-chun, FU Rui, REN Hao, FENG Di. Study on nonmetallic inclusions of ESR-CDS FGH96 alloy[J]. China New Technologies and Products, 2011(10): 1-2.

[12] 王晓峰, 周晓明, 穆松林, 邹金文. 高温合金熔炼工艺讨论[J]. 材料导报, 2012, 26(4): 108-135.

WANG Xiao-feng, ZHOU Xiao-ming, MU Song-lin, ZOU Jin-wen. Discussion on melting process of superalloy[J]. Materials Review, 2012, 26(4): 108-135.

[13] 陶 宇, 冯 涤, 张义文, 国为民, 张 莹, 张凤戈, 陈生大. 优化等离子旋转电极工艺提高FGH95合金粉末的收得率[J]. 粉末冶金工业, 2003, 13(2): 33-36.

TAO Yu, FENG Di, ZHANG Yi-wen, GUO Wei-min, ZHANG Ying, ZHANG Feng-ge, CHEN Sheng-da. Study on improving the yield of FGH95 alloy powder in plasma rotating electrode process[J]. Powder Metallurgy Industry, 2003, 13(2): 33-36.

[14] VOSTRIKO A V, GARIBOVG S. Investigation in the field of physico-mechanical properties and a structure of new Ni-base superalloy powder[C]// Proceedings of 11th International Conference on Hot Isostatic Pressing. Stockholm Sweden: The Swedish Steel Producers’ Association Press, 2014: 427.

[15] 唐中杰, 郭铁明, 寇生中, 付 迎, 金 硕. 镍基高温合金K4169中夹杂物的特征及形成机理[J]. 中国有色金属学报, 2015, 25(9): 2403-2413.

TANG Zhong-jie, GUO Tie-ming, KOU Sheng-zhong, FU Ying, JIN Shuo. Feature and formation mechanism of inclusions in K4169 Ni-based superalloy [J]. The Chinese Journal of Nonferrous Metals, 2015, 25(9): 2403-2413.

[16] MESHALIN V S, KOSHELEV V I, MESENYSHIN A I. Clearing masses of powder Ni-based superalloy elimination non-metallic inclusions by electrostatic separation[C]// Metallurgy Powder No 6. Moscow: Moscow VILS Press, 1993: 246-251. (in Russian)

[17] GARIBOV G S, KAZBEROVIQ A M, KASATKIN V V, ROMANOV A I. The dynamics of movement of metallic granules and nonmetallic inclusions in electrostatic separation[J]. Technology of Light Alloys, 2007(4): 70-72.

[18] 姜锡山. 钢中非金属夹杂物[M]. 北京: 冶金工业出版社, 2011: 65-66, 214-216.

JIAN Xi-shan. Nonmetallic inclusions in steel[M]. Beijing: Metallurgical Industry Press, 2011: 65-66, 214-216.

[19] 陈肇友. 氧化物酸碱性强弱与复合氧化物的生成自由能[C]// 蒋明学, 李 勇, 陈开献. 耐火材料论文选. 北京: 冶金工业出版社, 2011: 1-13.

CHEN Zhao-you. The acidity and alkalinity of oxide and formation free energy of composite oxide[C]// JIANG Ming-xue, LI Yong, CHEN Kai-xian. Selected Papers on Refractories. Beijing: Metallurgical Industry Press, 2011: 1-13.

[20] 牛建平. 纯净钢及高温合金制备技术[M]. 北京: 冶金工业出版社, 2009: 173-175.

NIU Jian-ping. Purified steel and superalloy preparation technology[M]. Beijing: Metallurgical Industry Press, 2009: 173-175.

[21] 张 莹, 刘明东, 孙志坤, 张义文. 颗粒间断裂在P/M镍基高温合金低周疲劳断口上的特征[J]. 中国有色金属学报, 2013, 23(4): 987-996.

ZHANG Ying, LIU Ming-dong, SUN Zhi-kun, ZHANG Yi -wen. Characteristics of inter-particle rupture on LCF fractography of P/M nickel-based superalloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(4): 987-996.

[22] 陈家祥. 炼钢常用图表数据手册[M]. 北京: 冶金工业出版社, 2010: 38, 330.

CHEN Jia-xiang. Steelmaking common chart data handbook[M]. Beijing: Metallurgical Industry Press, 2010: 38, 330.

[23] 袁致涛, 王常任. 磁电选矿[M]. 北京: 冶金工业出版社, 2011: 258-265.

YUAN Zhi-tao, WANG Chang-ren. Magnetoelectricity separation[M]. Beijing: Metallurgical Industry Press, 2011: 258-265.

[24] 耿桂宏. 材料物理与性能学[M]. 北京: 北京大学出版社, 2010: 160.

GEN Gui-hong. Materials physics and properties science[M]. Beijing: Peking University Press, 2010: 160.

Inclusions in Ni-base superalloy powder by PREP

ZHANG Ying1, 2, ZHANG Yi-wen1, 2, Lü Ri-hong3, HUANG Hu-bao1, 2, ZHANG Guo-xing1, 2, HAN Shou-bo1, 2, LIU Ming-dong1, 2, SUN Zhi-kun1, 2

(1. High Temperature Material Institute, Central Iron and Steel Research Institute, Beijing 100081, China;

2. Beijing Key Laboratory of Advanced High Temperature Materials, Central Iron and Steel Research Institute, Beijing 100081, China;

3. Guizhou Liyang Aero Engine Co., Ltd., Anshun 561102, China)

Abstract: Inclusion is one of the main factors affecting the quality of powder metallurgy products. Scanning electron microscope (SEM), X-ray diffraction(XRD) and electron probe microanalysis (EPMA) were used to analyze morphology and composition of inclusions in nickel-base superalloy powder by plasma rotation electrode process(PREP). Inclusions in powder after different processing were assorted and analyzed their form, size, quantity and distribution statistically. The results show that inclusions in the powder can be divided into ceramics, slag, organic as well as abnormal particles adhering inclusions or sublimate by formation and source. The ceramic accounts for 7% of the residual inclusions in finished powder particles, 53% for slag, 40% for organic. The ability of removing inclusions by screening and electrostatic separation is associated with product particle size range and density, dielectric constant of inclusions, as well as their size and shape.

Key words: PREP; nickel-base superalloy powder; inclusions; powder processing

Foundation item: Project (2014DFR50330) supported by International Science and Technology Cooperation Program of China; Project(Z141100002814014) supported by Beijing Municipal Science and Technology Program, China

Received date: 2016-08-15; Accepted date: 2017-02-20

Corresponding author: ZHANG Ying; Tel: +86-10-62185157; E-mail: zyxqxn@hotmail.com

(编辑 何学锋)

基金项目:国家国际科技合作专项资助项目(2014DFR50330);北京市科技计划资助项目(Z141100002814014)

收稿日期:2016-08-15;修订日期:2017-02-20

通信作者:张 莹,教授级高级工程师;电话:010-62185157;E-mail: zyxqxn@hotmail.com