文章编号:1004-0609(2011)05-1178-08

在H2SO4-HCl-H2O复合体系中

氧化浸出镍钼矿冶炼烟尘中的硒

侯晓川1, 2, 高丛堦1, 肖连生1, 张启修1, 曾 理1, 曹佐英1

(1. 中南大学 冶金科学与工程学院,长沙 410083;2. 金川有色金属公司,金昌 737100)

摘 要:对在H2SO4-HCl-H2O复合体系中氧化浸出镍钼矿冶炼烟尘中的硒进行热力学分析,确定从镍钼矿冶炼烟尘中浸出硒的新工艺及其最优技术参数。采用XRD对镍钼矿冶炼烟尘及其浸出渣进行表征。结果表明:在最佳技术条件下,硒浸出率达到98%,浸出渣含硒0.16%(质量分数);冶炼烟尘中硒以单质形式存在,未见硒及其化合物出现,表明烟尘中的硒浸出较完全;浸出渣主要由SiO2、CaSO4、Al2SiO5、As2O3和KAlSi3O8组成。

关键词:镍钼矿;硒;烟尘;氧化浸出;热力学

中图分类号:TF843.5 文献标志码:A

Oxidized leaching selenium from Ni-Mo ore smelter dust in mixing solution system of H2SO4-HCl-H2O

HOU Xiao-chuan1, 2, GAO Cong-jie1, XIAO Lian-sheng1, ZHANG Qi-xiu1, ZENG Li1, CAO Zuo-ying1

(1. School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China;

2. Jinchuan Nonferrous Metals Corporation, Jinchang 737100, China)

Abstract: The thermodynamics of oxidized leaching selenium from Ni-Mo ore smelter dust in mixing solution system of H2SO4-HCl-H2O was analyzed, and a novel process and its optimum parameters for leaching selenium from Ni-Mo ore smelter were determined. Both Ni-Mo ore smelter dust and its leaching residue were characterized by XRD. The results show that, under the optimum conditions, the leaching rate of selenium reaches 98%, and the selenium in leaching residue is only 0.16% (mass fraction). The selenium in smelter dust exists in the form of elemental selenium, but no selenium and its compounds are detected in leaching residue. The leaching residue is mainly composed of SiO2, CaSO4, Al2SiO5, As2O3 and KAlSi3O8, which indicates that the leaching of selenium is almost complete.

Key words: Ni-Mo ore; selenium; smelter dust; oxidized leaching; thermodynamics

随着现代冶金工业的快速发展,镍和钼的应用领域不断扩大,导致对镍、钼需求量逐年增加。而独立的镍、钼矿床较少,并逐渐枯竭。镍钼矿是一种富含镍、钼的多金属复合矿,广泛分布于我国的贵州、湖南、云南和浙江等地区[1-2]。由于其储量巨大和有价金属镍、钼含量较高(Ni 0.7% ~7.7%、Mo 2% ~11%),从而引起了国内外冶金工作者的高度关注。据北京大学的董允杰和缪加坦[3]估算,镍钼矿中含钼5 220万t、镍4 515万t、金510 t、银10 800 t、钯480 t、稀有金属501 t。因此,开发和利用镍钼矿具有重要的意义。

镍钼矿的处理主要采用火法冶金与湿法冶金相结合的生产工艺,在氧化焙烧过程中,硒和砷分别被氧化为SeO2和砷的氧化物,此类氧化物挥发进入烟气。在湿式收尘过程中,绝大部分SeO2被烟气中的SO2还原为元素Se,从而沉降在冶炼烟尘中,致使烟尘中有价元素Se的含量高于5%,而有害元素As的含量高达18%。长期以来,这些生产厂家缺乏有效的处理镍钼矿冶炼烟尘的工艺,导致这些厂家的冶炼烟尘多年堆积,经常受风吹雨淋,导致有害的元素硒和砷流入江河湖泊,或渗透进入土壤,对环境产生极大的污染。同时,有价元素硒大量流失,未能得到综合回收利用。

硒是人体和动物生命活动必需的微量元素[4],缺乏硒就会导致多种疾病[5],但过量摄入硒会产生硒中毒[6-7]。因此,为了消除硒对人类及其生存环境的不良影响,达到综合利用资源和保护环境的目的,对从镍钼矿冶炼烟尘中提取硒的工艺进行研究具有十分重要的意义。目前,提取硒的主要原料为电解精炼铜、镍和铅的阳极泥,以及硫酸和纸浆生产中产生的酸泥等原料。传统提取硒的工艺流程为氧化焙烧含硒原料,用水吸收SeO2,用SO2还原吸收液中的亚硒酸,最后得到硒粉[8]。然而,传统氧化焙烧工艺中,硒的回收率较低,焙烧过程中会产生SO2、SeO2和As2O3等易于泄露的有毒气体,还存在粉尘污染环境的弊端。

迄今为止,虽然有从煤灰和阳极泥中浸出硒的研究[9-10],但尚未有从镍钼矿冶炼烟尘中浸出、提取硒的工艺报道。本文作者以盐酸和硫酸为浸出体系,采用氧化剂将镍钼矿冶炼烟尘中的硒氧化浸出,通过还原剂将浸出液中的亚硒酸还原为金属硒粉。该工艺全过程为湿法处理,硒的浸出效率高,可实现清洁冶金目的。对从镍钼矿冶炼烟尘中提取硒的新工艺进行研究,可为其工业应用提供理论依据。

1 实验

1.1 实验原料

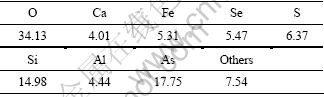

实验所用原料为国内某厂镍钼矿冶炼烟尘,其主要化学成分如表1所示,其XRD谱如图1所示。

表1 镍钼矿冶炼烟尘的主要成分

Table 1 Main components of Ni-Mo ore smelter dust (mass fraction, %)

从图1可以看出,该烟尘主要由SiO2、As2O3、CaSO4、Se、FeS2和KAl2Si3AlO10(OH)2组成。其中As和Se主要以As2O3和单质Se的形态存在,未见较高价态的As2O5和SeO2的衍射峰出现。这主要是由于镍钼矿氧化焙烧时,硒化物及硫化物中的Se和S分别被氧化为SeO2和SO2。在湿法收尘过程中,SO2将高价态的As2O5还原为低价态的As2O3;SeO2溶解于水中生成的H2SeO3被烟气中的SO2还原为单质Se。

图1 镍钼矿冶炼烟尘的XRD谱

Fig.1 XRD pattern of Ni-Mo ore smelter dust

1.2 烟尘的SEM-EDS表征

图2(a)所示为镍钼矿冶炼烟尘的SEM像,图2(b)~(d)所示分别为对应于图2(a)中A、B、C点的EDS谱。

从图2(b)可以看出,图2(a)中银白色部分主要由Se、Hg等元素组成(A点),由冶炼烟尘的XRD谱可知,烟尘中Se主要由单质Se组成;从图2(c)可以看出,图2(a)中烟尘中浅色部分主要由Si、O、S、As和Ca等元素组成(B点),根据冶炼烟尘的XRD谱可以推断出,烟尘中该部分主要由CaSO4和As2O3组成;从图2(d)可以看出,图2(a)中暗灰色部分主要由Si、O、S和Ca等元素组成(C点),可推断烟尘中该部分主要由SiO2、CaSO4组成。从图2(a)可见,烟尘中绝大多数的Se以单质Se形态附着在烟尘表面,极少部分镶嵌在烟尘较浅部位。因此,为了提高烟尘中Se的浸出率,在预处理时,只需将烟尘稍加研磨即可。

1.3 实验方法

将镍钼矿冶炼烟尘(每次试验加入的烟尘质量均为20 g)和实验要求的硫酸与盐酸混合溶液,按实验所需量以一定液固比加入到反应容器中。随后启动搅拌,以一定的搅拌转速搅拌浸出体系;同时,加热反应体系,达到实验要求的浸出温度后,用蠕动泵以一定的流速向浸出体系加入实验要求浓度的氧化剂溶液。恒温氧化浸出一段时间,定时取样,真空抽滤进行液固分离,分别计量浸出渣(干基)的质量和浸出液的体积。采用美国Baird公司生产的PS-6型电感耦合等离子发射光谱(ICP),分析元素Se,并计算Se的浸出率。

图2 镍钼矿冶炼烟尘的SEM像和EDS谱

Fig.2 SEM image and EDS spectra of Ni-Mo ore smelter dust: (a) SEM image; (b) EDS, point A; (c) EDS, point B; (d) EDS, point C

2 实验基本原理

从冶炼烟尘物相分析结果可知,Se主要以单质的形态存在。烟尘中的Se在浸出的过程中,可能存在如表2所列的化学反应,根据热力学数据[11]可计算出其?GΘ,结果也列入了表2。

从表2热力学数据可以看出,化学反应(2)和(3)的?GΘ均大于0,表明在标准状态下,单独采用硫酸或盐酸浸出冶炼烟尘中的Se在热力学上难于自发进行;而化学反应(1)、(4)、(6)和(7)的?GΘ均小于0,说明在硫酸和盐酸的复合体系中,采用氧化剂氧化浸出冶炼烟尘中的Se,在热力学上易于自发进行。因此,本研究中采用氧化剂氧化浸出冶炼烟尘中的Se,符合热力学原理。

表2 氧化浸出镍钼矿冶炼烟尘中Se可能存在的主要化学反应

Table 2 Main chemical reactions of oxidized leaching selenium from Ni-Mo ore smelter dust

3 结果与讨论

3.1 搅拌速度对烟尘中Se浸出率的影响

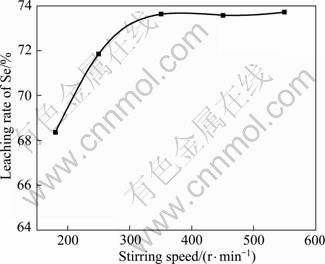

实验条件如下:固定烟灰粒度小于0.15 mm、起始酸度为6 mol/L、加入的盐酸与硫酸的摩尔比为1?1,液固比为5?1,浸出时间为150 min,浸出温度为85 ℃,氧化剂加入系数(氧化剂与烟尘中Se的摩尔比)为2.22;氧化剂加入速度为40 mg/min。在此条件下,考察搅拌速度对烟尘中Se浸出率的影响,结果如图3所示。

图3 搅拌速率对Se浸出率的影响

Fig.3 Effects of stiring speed on leaching rate of Se

从图3可以看出,随着搅拌速度的增大,镍钼矿冶炼烟尘中Se浸出率呈逐渐增大的趋势。搅拌速度在180~350 r/min的范围内,Se浸出率的增大幅度较大;而在350~550 r/min的范围内,搅拌速度对Se浸出率的影响不明显。其原因是在一定的搅拌速度范围内,提高搅拌速度可减小扩散层的厚度,增大浸出剂与浸出物的接触比表面积,有利于浸出速度的提高;但搅拌对浸出反应速度的提高是有限度的,靠近浸出物的溶液层与浸出物之间存在牢固的附着力。当液体处于相对剧烈的紊流状态时,固体表面层附近的液体仍然处于层流状态,即固体表面上存在液体表面层,即使强烈搅拌也不能消除。因此,搅拌速度达到一定程度后,再增加搅拌速度,并不能增加离子或分子的扩散速度,无益于浸出速度和浸出率的提高[12]。因此,浸出搅拌速度确定为350 r/min。

3.2 起始酸度对烟尘中Se浸出率的影响

在浸出的搅拌速度为350 r/min、其余实验条件同3.1节的条件下进行试验,考察浸出起始酸度对烟尘中Se浸出率的影响,结果如图4所示。

从图4可以看出,Se浸出率随起始酸度的增加而提高。当浸出液中H+的浓度高于8 mol/L时,Se浸出率趋于稳定。若继续增加浸出的酸度,不仅使浸出液中游离酸的浓度增大,而且还会加速烟尘中杂质离子的浸出,给浸出液的后续处理带来更大的负担。因此,确定浸出酸度为8 mol/L。

图4 起始H+浓度对Se浸出率的影响

Fig.4 Effects of initial [H+] on leaching rate of Se

3.3 盐酸与硫酸的摩尔比对烟尘中Se浸出率的影响

在浸出剂酸度为8 mol/L、其余实验条件同3.2节的条件下进行试验,考察盐酸与硫酸的摩尔比β对烟尘中Se浸出率的影响,结果如图5所示。

图5 系数β对Se浸出率的影响

Fig.5 Effects of coefficient β on leaching rate of Se

从图5可以看出,当β在0.4~1.5范围内时,Se浸出率随β增大而增大。主要是由于随着β的增大,浸出剂中盐酸的量相对增加,在氧化剂的作用下,浸出液中的Cl-被氧化为氯气的量也增加。浸出的Fe2+被新生态的、具有高活性的氯气氧化成Fe3+,Fe3+/Fe2+电偶起着传递电子的作用[13],将氯气与矿浆在气、液、固三相界面的反应转变为氯气与Fe2+间的气-液反应和Fe3+与烟尘的液-固反应,进一步改善了浸出反应的动力学条件,提高了盐酸和氯气的利用率。而当β大于1.5时,Se浸出率随β的增大而降低。主要原因是随着β不断增大,溶液中的Cl-被氧化为氯气的量也急剧增加,生成的部分氯气来不及与烟尘中的Se反应就溢出浸出体系;另一方面,由于盐酸为低沸点酸,随着盐酸浓度的增加和浸出系统温度的升高,HCl气体挥发加剧,使浸出体系的酸度减少,导致浸出体系中氧化剂和盐酸实际利用率降低,从而使烟尘的Se浸出率降低。因此,β选择1.5为宜。

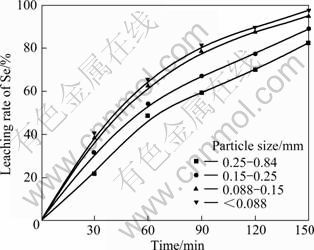

3.4 烟尘粒度对Se浸出率的影响

在β为1.5、其他实验条件同3.3节的条件下进行试验,考察粒度对烟尘中Se浸出率的影响,结果如图6所示。

图6 烟尘的粒度对Se浸出率的影响

Fig.6 Effects of particle size on leaching rate of Se

从图6可以看出,烟尘粒度越小,Se浸出率越高。这是由于烟尘细磨后,固体颗粒与浸出剂和氧化剂接触的比表面积增加;同时,在烟尘细磨过程中,固体颗粒也得到不同程度的机械活化[14-15],强化浸出扩散的传质过程;此外,细磨烟尘使被包裹的Se裸露出来,Se易于被氧化浸出进入溶液。而烟尘粒度达到0.15 mm后,粒度对Se浸出率的影响不太显著。因此,烟尘浸出粒度确定为小于0.15 mm。

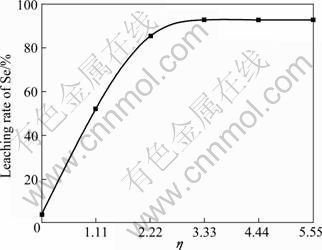

3.5 氧化剂加入系数对Se浸出率的影响

在烟尘粒度小于0.15 mm,其他实验条件同3.4节的条件下,考察氧化剂加入系数η(氧化剂与烟尘中Se的摩尔比)对烟尘的Se浸出率的影响,实验结果如图7所示。

从图7可以看出,当浸出体系中不加氧化剂时,对应的Se浸出率只有3.69%。浸出过程中,主要是以SeO2存在的Se被浸出;同时,可能有极少量的单质Se被浸出。因此,Se浸出率很低。这与图1所示烟尘的物相分析结果相吻合。此时,浸出体系中主要发生化学反应(1)、(2)和(3);当η在0~3.33范围内时,随着η的增大,Se浸出率也逐渐增高。此时,烟尘中的Se发生了剧烈的氧化还原反应,大量的单质Se被氧化为H2SeO3进入浸出液。同时,产生大量的反应热,推动浸出反应快速进行。此时,除发生化学反应(1)、(2)和(3)外,还发生化学反应(4)、(6)和(7);当η大于3.33时,Se浸出率趋于稳定,此时体系达到浸出平衡状态。加入的氧化剂足以将烟尘中的Se全部氧化浸出。因此,氧化剂的加入系数确定为3.33。

图7 系数η对Se浸出率影响

Fig.7 Effects of coefficient η on leaching rate of Se

3.6 氧化剂加入速度对Se浸出率的影响

在氧化剂的加入系数η为3.33,其他实验条件同3.5节的条件下,考察氧化剂加入速度对烟尘的Se浸出率的影响,实验结果如图8所示。

图8 氧化剂加入速度对Se浸出率的影响

Fig.8 Effects of speed of adding oxidant on leaching rate of Se

从图8可以看出,当氧化剂加入速率在30~35 mg/min时,Se浸出率随着氧化剂加入速度的增加而逐渐增大;当氧化剂加入速度在35~55 mg/min时,Se浸出率随着氧化剂加入速度的增加而逐渐减小。其主要原因是随着氧化剂加入速度的增加,单位时间内加入到浸出体系中氧化剂的质量增加。此时,浸出体系发生剧烈的氧化还原反应,加入的氧化剂将Se氧化浸出,同时,浸出过程中产生大量的反应热,使浸出体系在一个较长的时间内维持浸出反应所需的温度;随着氧化剂加入速度的进一步提高,致使单位时间内会产生相对过剩的氯气,部分过剩的氯气还未来得及反应就从浸出体系中逸出,从而使氧化剂的有效利用率降低,Se浸出率下降。因此,实验中氧化剂加入速度确定为35 mg/min。

3.7 浸出温度对Se浸出率的影响

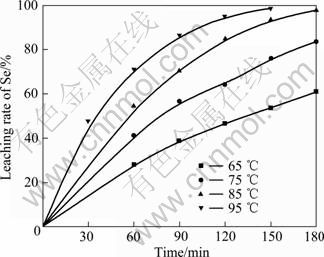

在氧化剂加入速度为35 mg/min、其他实验条件同3.6节的条件下进行试验,考察浸出温度对烟尘的Se浸出率的影响,结果如图9所示。

从图9可以看出,温度对硒的浸出率影响较大。在相同的浸出时间内,95 ℃与65 ℃时对应的Se浸出率相差45%左右。浸出过程中,温度升高,分子运动平均速度增加,分子间碰撞频率上升,有利于化学反应的进行。更为重要的是,升高温度会使能量较低的分子获得能量转变为活化分子,增加活化分子的含量,宏观上表现为反应物活度增加,有利于浸出反应速度的提高。

图9 浸出温度对Se浸出率的影响

Fig.9 Effects of leaching temperature on leaching rate of Se

化学反应受控于不同的控制步骤时,温度对化学反应速度的影响是不相同的。当反应受化学反应控制时,随温度升高,反应速度急剧增加;当受扩散控制时,反应速度正比于扩散系数,而温度对扩散系数的影响远不及对化学反应速度的影响,因而在受扩散控制时,温度对浸出率的影响没有受化学反应控制时显著[16]。在Se的浸出过程中,由于搅拌速度对Se浸出率的影响较小,而温度对Se浸出率的影响很大,由此可推断,Se的浸出反应为化学反应控制,该结论在其动力学研究中得到证明[17]。

3.8 在最优综合条件下的试验

实验研究确定的最优综合条件如下:烟尘粒度小于0.15 mm,酸度8 mol/L,加入盐酸与硫酸的摩尔比3?2,液固比5?1,浸出时间150 min,浸出温度95 ℃,氧化剂加入系数3.33;氧化剂加入速率35 mg/min。在最优综合条件下,进行试验,结果如表3和4所示。

表3 综合条件下浸出液的主要成分

Table 3 Main compositions of leaching solution under comprehensive conditions(g/L)

表4 在综合条件下从镍钼矿冶炼烟尘浸出Se的试验结果

Table 4 Experimental results of leaching selenium from Ni-Mo ore smelter dust under comprehensive conditions

从表4可以看出,在实验确定的最优浸出条件下,冶炼烟尘的Se浸出率为98%,平均渣率为32.62%,表明冶炼烟尘中的Se被浸出较完全。

3.9 浸出渣的表征

3.9.1 浸出渣的化学组成

在实验研究确定的最优浸出条件下,所得浸出渣的化学成分如表5所列。

表5 镍钼矿冶炼烟尘浸出渣的主要成分

Table 5 Main components of leaching residue from Ni-Mo ore smelter dust (mass fraction, %)

从表5可见,镍钼矿冶炼烟尘浸出渣中,主要成分为O、Si、Ca和S,而有价元素Se的含量(质量分数)仅有0.16%。因此,烟尘中的Se浸出较完全。

3.9.2 烟尘浸出渣的XRD 分析

浸出渣的XRD分析结果如图10所示。

图10 镍钼矿冶炼烟尘浸出渣的XRD谱

Fig.10 XRD pattern of leaching residue from Ni-Mo ore smelter dust

从图10可以看出,该浸出渣物相组成主要由SiO2、CaSO4、Al2SiO5、As2O3和KAlSi3O8组成,未见Se及其化合物的衍射峰出现。表明烟尘在氧化浸出过程中,有价元素Se被浸出进入浸出液。

4 结论

1) 通过实验研究,确定了从镍钼矿冶炼烟尘中浸出Se的工艺,即在H2SO4-HCl-H2O复合体系中,采用氧化剂可将冶炼烟尘中的绝大部分Se浸出,Se的浸出率大于98%,浸出渣的Se含量仅为0.16%。

2) 确定了从镍钼矿冶炼烟尘中浸出Se的最优浸出参数:烟灰粒度小于0.15 mm,搅拌速度350 r/min,浸出酸度[H+]8 mol/L,浸出液中盐酸与硫酸的摩尔比3?2,浸出时间150 min,液固比5?1,氧化剂加入系数3.33,氧化剂加入速度35 mg/min,浸出温度95℃。

3) 采用XRD对镍钼矿冶炼烟尘及其浸出渣进行了表征。XRD结果表明,冶炼烟尘中Se以单质的形式存在,而浸出渣主要由SiO2、CaSO4、Al2SiO5、As2O3和KAlSi3O8组成,未见Se及其化合物的特征谱线存在。

REFERENCES

[1] 王志坚. 硫酸化焙烧处理镍钼矿的工艺研究[J]. 湖南有色金属, 2009, 25(2): 25-27.

WANG Zhi-jian. Progress research on Ni-Mo ore by sulfate roasting[J]. Hunan Nonferrous Metals, 2009, 25(2): 25-27.

[2] 游先军, 戴塔根, 罗 卫, 彭学勤, 鲍振襄, 包觉敏. 湘西北黑色岩系中的镍钼矿床及其贵金属矿物特征[J]. 地质找矿论丛, 2009, 24(1): 15-22.

YOU Xian-jun, DAI Ta-gen, LUO Wei, PENG Xue-qing, BAO Zhen-xiang, BAO Xue-min. Ni-Mo ore and mineral characteristics of its precious metals in the black rock series in the northwest of Hunan province[J]. Geological Prospecting Essays, 2009, 24(1): 15-22.

[3] 董允杰, 缪加坦. 我国镍钼矿及生产现状[J]. 中国钼业, 2008, 32(2): 60-60.

DONG Yun-jie, MIAO Jia-tan. Ni-Mo ore and production status in China[J]. China Molybdenum Industry, 2008, 32(2): 60-60.

[4] HUANG Shun-sheng, HUA Ming, FENG Jin-shun, ZHONG Xin-yong, JIN Yang, ZHU Bai-wan, LU Hua. Assessment of selenium pollution in agricultural soils in the Xuzhou District, Northwest Jiangsu, China[J]. Journal of Environmental Sciences, 2009, 21: 481-487.

[5] MARIA M B, MARIAJ D M, ELISA B G, ALFREDO S M. Evaluation of different sample extraction strategies for selenium determination in selenium-enriched plants (Allium sativum and Brassica juncea) and Se speciation by HPLC-ICP-MS[J]. Talanta, 2006, 68: 1287-1293.

[6] ORSKOV L, FLYBJERG A. Selenium and human health[J]. Lancet, 2000, 356: 942-943.

[7] 王大鹏. 硒与人体健康及其分析方法[J]. 世界元素医学, 2008, 15(4): 44-46.

WANG Da-peng. Selenium and human health and the analytical methods[J]. World Elemental Medicine, 2008, 15(4): 44-46.

[8] 周令治, 陈少纯. 稀散金属提取冶金[M]. 北京: 冶金工业出版社, 2008: 285-292.

ZHOU Ling-zhi, CHEN Shao-chun. Scattered metal extraction metallurgy[M]. Beijing: Metallurgical Industry Press, 2008: 285-292.

[9] 张博亚, 王吉坤. 加压酸浸预处理铜阳极泥的工艺研究[J]. 矿冶过程, 2007, 27(5): 41-43.

ZHANG Bo-ya, WANG Ji-kun. Process for copper anode slime by pressure acid pretreatment[J]. Mining Process, 2007, 27(5): 41-43.

[10] JOSE R O, MARIA J M, JORGE M, ELIA A, SOLEDAD M, PURIFICACION L,DARIO P. Influence of several experimental parameters on As and Se leaching from coal fly ash samples[J]. Analytica Chimica Acta, 2005, 531(2): 299-305.

[11] 杨显万, 何蔼平, 袁宝州. 高温水溶液热力学数据计算手册[M]. 北京: 冶金工业出版社, 1983: 1-684.

YANG Xian-wan, HE Ai-ping, YUAN Bao-zhou. The manual of thermodynamic data of high-temperature solution[M]. Beijing: Metallurgical Industry Press, 1983: 1-684.

[12] BAHAR B, ORAL L, HANIFI S. Kinetic study on the leaching of calcined magnesite in gluconic acid solutions[J]. Journal of Industrial and Engineering Chemistry, 2010, 16: 479-484.

[13] IGNASI S, JOSE A G, ROSA M R, ENRIC B, NIHAL O, MEHMET A O. Catalytic behavior of the Fe3+/Fe2+ system in the electro-fenton degradation of the antimicrobial chlorophene[J]. Applied Catalysis B: Environmental, 2007, 72: 382-394.

[14] LI Chun, LIANG Bin, WU Zi-bin, GUO Ling-hong. Efect of mechanical activation on the dissolution of Panzhihua ilmenite[J]. Minerals Engineering, 2006, 19(14): 1430-1438.

[15] LI Chun, LIANG Bin. Dissolution of mechanically activated Panzhihua ilmenite in dilute solutions of sulfuric acid[J]. Hydrometallurgy, 2007, 89(1/2): 1-10.

[16] 李洪桂. 湿法冶金学[M]. 长沙: 中南大学出版社, 2002: 74-75.

LI Hong-gui. Hydrometallurgy[M]. Changsha: Central South University Press, 2002: 74-75.

[17] HOU X C, XIAO L S, GAO C J, ZHANG Q X, ZENG L. Kinetics of leaching selenium from Ni-Mo ore smelter dust using sodium chlorate in a mixture of hydrochloric and sulfuric acids[J]. Hydrometallurgy, 2010, 104(1): 76-80.

(编辑 何学锋)

基金项目:国家高技术研究发展计划资助项目(2007AA06Z129)

收稿日期:2010-05-04;修订日期:2010-09-19

通信作者:肖连生, 教授, 博士; 电话: 13975694859; E-mail: xls1211@sina.com