粉末冶金自润滑Cu/MoS2复合材料的摩擦行为

来源期刊:中国有色金属学报(英文版)2018年第5期

论文作者:Mohammad MOAZAMI-GOUDARZI Aram NEMATI

文章页码:946 - 956

关键词:铜基复合材料;显微组织;摩擦因数;磨损机制

Key words:copper matrix composite; microstructure; coefficient of friction; wear mechanism

摘 要:研究MoS2 含量对纯铜的显微组织、密度、硬度和耐磨性能的影响。采用纯铜粉和MoS2粉末,通过机械球磨和热压法,制备含0~10% (质量分数) MoS2颗粒的铜基复合材料。在干滑动摩擦条件下,采用销-盘式磨损实验装置,测试材料的耐磨性能,固定滑动速率为0.2 m/s。硬度测试结果显示,MoS2含量为2.5% 的复合材料的硬度达到峰值。当载荷一定时,Cu/2.5MoS2复合材料具有最低的摩擦因数和磨损量。当载荷从1 N增加到4 N,不同含量增强相复合材料的摩擦因数均减小,同时,磨损量增大。磨损表面和磨屑的SEM照片显示,Cu/MoS2复合材料的磨损机理由纯铜的粘着磨损为主转变为磨粒磨损和剥层磨损相结合的机制。

Abstract: The effects of MoS2 content on microstructure, density, hardness and wear resistance of pure copper were studied. Copper-based composites containing 0-10% (mass fraction) MoS2 particles were fabricated by mechanical milling and hot pressing from pure copper and MoS2 powders. Wear resistance was evaluated in dry sliding condition using a pin on disk configuration at a constant sliding speed of 0.2 m/s. Hardness measurements showed a critical MoS2 content of 2.5% at which a hardness peak was attained. Regardless of the applied normal load, the lowest coefficient of friction and wear loss were attained for Cu/2.5MoS2 composite. While coefficient of friction decreased when the applied normal load was raised from 1 to 4 N at any reinforcement content, the wear volume increased with increasing normal load. SEM micrographs from the worn surfaces and debris revealed that the wear mechanism was changed from mainly adhesion in pure copper to a combination of abrasion and delamination in Cu/MoS2 composites.

Trans. Nonferrous Met. Soc. China 28(2018) 946-956

Mohammad MOAZAMI-GOUDARZI, Aram NEMATI

Department of Materials Engineering, Science and Research Branch, Islamic Azad University, Tehran, Iran

Received 25 March 2017; accepted 30 September 2017

Abstract: The effects of MoS2 content on microstructure, density, hardness and wear resistance of pure copper were studied. Copper-based composites containing 0-10% (mass fraction) MoS2 particles were fabricated by mechanical milling and hot pressing from pure copper and MoS2 powders. Wear resistance was evaluated in dry sliding condition using a pin on disk configuration at a constant sliding speed of 0.2 m/s. Hardness measurements showed a critical MoS2 content of 2.5% at which a hardness peak was attained. Regardless of the applied normal load, the lowest coefficient of friction and wear loss were attained for Cu/2.5MoS2 composite. While coefficient of friction decreased when the applied normal load was raised from 1 to 4 N at any reinforcement content, the wear volume increased with increasing normal load. SEM micrographs from the worn surfaces and debris revealed that the wear mechanism was changed from mainly adhesion in pure copper to a combination of abrasion and delamination in Cu/MoS2 composites.

Key words: copper matrix composite; microstructure; coefficient of friction; wear mechanism

1 Introduction

Lubricants are widely applied between contacting surfaces to minimize friction and wear. While liquid lubricants are typically used in most of industrial and engineering applications, solid lubricants such as graphite and molybdenum disulfide (MoS2) are employed in tribosystems when liquid lubrication is limited by operational or environmental considerations. In this respect, solid lubricants may be used in space technology, ultra-high vacuum or automotive transport [1,2]. However, the effective performance of solid lubricants requires a continuous supply of them between contacting surfaces. This is usually achieved by incorporation of solid lubricant material within a metallic matrix and creating a composite material. In this regard, metal matrix composites (MMCs) reinforced with solid lubricant particles are being used as self-lubricating materials for various engineering applications [2].

While both graphite and MoS2 have low shear strength due to lamellar structure and reduce friction in tribo-interfaces, most of the investigations in this field are focused on MMCs reinforced with graphite particles. This might be due to higher cost and complexities in processing of MoS2 reinforced MMCs. Both liquid and solid metallurgy processing routes are widely used to synthesize self lubricating Cu/graphite composite [3]. However, liquid metallurgy processing method such as stir casting could not be utilized to fabricate Cu/MoS2 composites owing to high reactivity of MoS2 particles with molten copper. Conventional powder metallurgy (PM), as the most widely used solid processing method, has been successfully applied to a large number of metal/non-metal combinations. However, agglomeration of MoS2 particles during process of mixing and their dissociation during solid state sintering are among the problems encountered in fabrication of Cu/MoS2 composites using PM method [3,4].

MoS2 offers better lubrication than graphite under extreme condition of load in dry and vacuum environments [2,5]. It is reported that impregnating MoS2 into sintered bronze provides even a greater improvement in friction and wear life than impregnation with graphite [6]. Therefore, it would be influential to study the tribological behavior of copper-based composites containing various amounts of embedded MoS2 particles.

BAO et al [7] reported the reduced coefficient of friction of Cu/MoS2 composite against a bronze counterface under electrical sliding by increasing of MoS2 content. SENTHIL KUMAR et al [8,9] studied the effect of MoS2 addition on the wear behavior of Cu-Sn matrix composites and reported MoS2 as a potential solid lubricant for the sintered copper-based composites. Contradictory results especially at higher reinforcement contents were reported by others [10] expressing that MoS2 is an ineffective solid lubricant in sintered Cu-Sn composites due to its reactivity with the matrix at the sintering temperature. KOVALCHENKO et al [11] described the influence of incorporated MoS2 particles within a copper matrix on prevention of scuffing damage against a sliding copper counterface.

In addition, the improved wear resistances of Ni [12], Mo [13], Al [14-16], Mg [17,18] and Fe [19] based composites by incorporation of MoS2 particles in the matrix have also been reported. However, because of difficulties in embedding and uniformly distributing MoS2 particles within a metallic matrix such as copper, this type of solid lubricant is often utilized on metallic substrates by different coating methods. For example, the improved sliding wear performance of Cu/MoS2 composite coatings fabricated by cold spray method was recently reported by ZHANG et al [20]. Nevertheless, the working period of a PM self lubricating material is much longer than a composite coating because solid lubricants are uniformly distributed within the whole bulk material [11].

Addition of high amount of MoS2 (20%-40%, volume fraction) to copper alloys was reported to lead to very high wear rates [10]. Therefore, in the present work, the effect of lower contents of MoS2 (i.e., 0-10%, mass fraction) on friction and wear behavior of self lubricated copper matrix composites is evaluated. More specifically, the relation between microstructure and hardness of Cu/MoS2 composites with their wear resistance is discussed. In order to alleviate the aforementioned problems in processing of Cu/MoS2 composites through the PM method, mechanical milling and hot pressing were respectively used for mixing and consolidation of copper and MoS2 powders.

2 Experimental

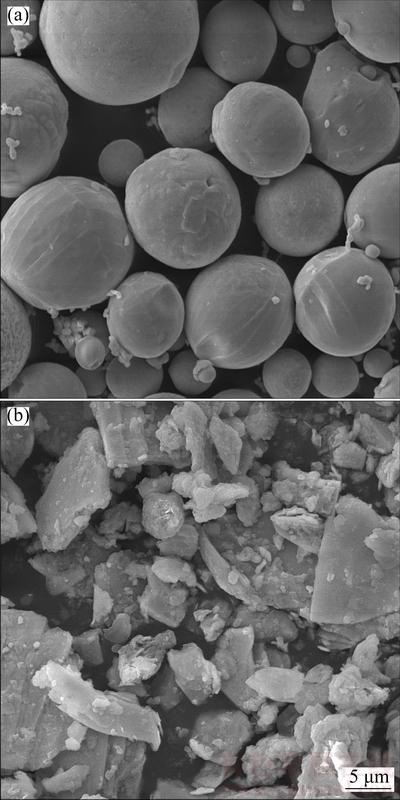

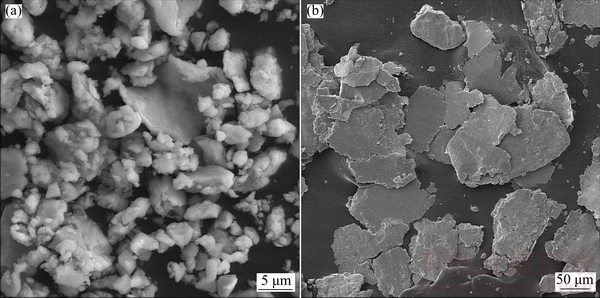

In the present work, copper and MoS2 powders were used as the matrix and reinforcement, respectively. The SEM images of as-received copper (99% in purity and 8 μm in size) and MoS2 (98% in purity and 5 μm in size) particles are shown in Fig. 1. As observed, copper powders were spherical in shape and MoS2 particles possessed sheet-like structure. The pure copper and copper matrix composites containing 2.5%, 5% and 10% (mass fraction) of MoS2 (equivalent to 4%, 8% and 16%, volume fraction, respectively) were fabricated by a powder metallurgy route including ball milling (mixing) and hot pressing. The copper and MoS2 powders were mixed together in an attrition ball mill using a plastic container and steel balls at 20 r/min for 20 min. The balls were 6 mm in diameter and ball to charge ratio was 5:1. These milling setup and parameters were chosen to minimize any work hardening effect during the mixing stage. The powder mixtures were consolidated in a hot work tool steel die at a constant temperature of 370 °C under 500 MPa for 20 min. Since the oxidation rate of MoS2 in air is very low at temperatures below 370 °C [21,22], the powder compaction was carried out at this constant temperature. The hot-pressed compacts were cylindrical in shape with 25 mm in diameter and about 10 mm in height.

Fig. 1 SEM micrographs of as-received copper powders (a) and MoS2 particles (b)

In order to investigate the possibility of formation of new deleterious products during the fabrication process, X-ray diffraction (XRD) studies were performed on both ball milled Cu/MoS2 powders and hot consolidated samples using a Philips PW-1730 diffractometer. The target was Cu Kα (λ=0.154 nm) and the tests were carried out with a scanning speed of 2 (°)/min.

Microstructural studies were performed on polished samples using an Olympus BX51M optical microscope. Density of consolidated compacts was measured using Archimedes’ method. Vickers hardness of hot-pressed samples was obtained by applying 300 N load using the ESE WAY hardness tester device.

Coefficient of friction and wear loss of prepared samples were measured using a pin on disk tribometer. The wear tests were carried out on rotating disk samples under normal loads of 1, 2 and 4 N at a constant sliding speed of 0.2 m/s for a sliding distance of 1000 m at room temperature (24 °C). The disks were polished to the surface roughness (Ra) of about 0.2 μm. The counterface was round ended AISI 52100 steel pin, 3 mm in diameter and 15 mm in height with a hardness of HRC 62. The wear tests were carried out in the atmosphere with relative humidity of (40±2)%. Prior to each test, the samples and disks were cleaned in acetone using an ultrasonic device. The wear of the specimens and the counterface was determined by measuring their mass loss using an electric balance with the precision of 0.1 mg. The wear volume was calculated using the mass loss and the known density of each sample. The worn surfaces and generated debris were observed and analyzed with a Tescan VEGA-LMU scanning electron microscope (SEM) equipped with an energy dispersive spectrometer (EDS).

3 Results and discussion

3.1 Microstructure, density and hardness

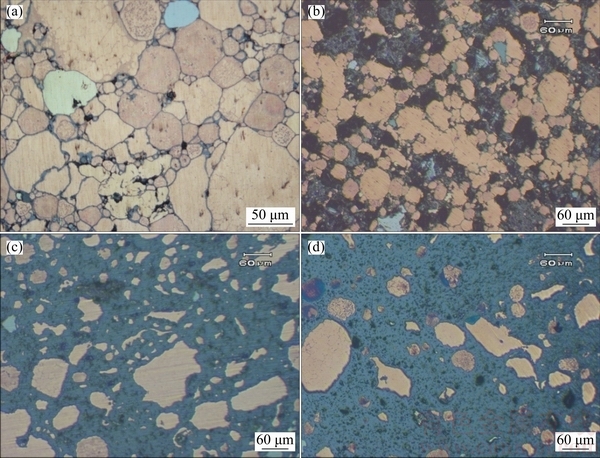

Figure 2 shows the optical microstructures of hot pressed copper and Cu/MoS2 composites. The microstructure of pure copper sample shown in Fig. 2(a) includes some microporosities which are typical in powder metallurgy processed parts. The microstructure of Cu/2.5MoS2 composite exhibits dark particles of MoS2 dispersed in the light matrix of copper, as shown in Fig. 2(b). Some voids are also observed which are probably generated by removing of loose MoS2 particles in the polishing stage. Such a microstructure in which solid lubricant reinforcements are reasonably distributed within the matrix phase is anticipated to provide self lubricating property. When the mass fraction of MoS2 was 5% or higher, the continuous matrix phase in the microstructure changed from metallic copper to MoS2, as shown in Figs. 2(c) and (d). These microstructures resemble to those containing much higher content of solid lubricant particles. This is mainly due to smearing of copper powders with finely divided MoS2 particles during mechanical milling in powder mixing process. In fact, while Cu/2.5MoS2 is a copper matrix composite reinforced with soft MoS2 particles, Cu/5MoS2 and Cu/10MoS2 are a kind of MoS2 matrix composite reinforced with hard copper particles. Similar microstructures were reported for Cu/WS2 composites by other authors [23].

Fig. 2 Optical micrographs of hot-pressed pure copper (a) and Cu/MoS2 composites containing 2.5% (b), 5% (c) and 10% (d) of MoS2

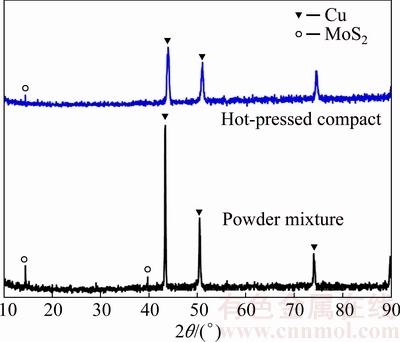

The results of X-ray diffraction studies on Cu/5MoS2 powder mixture and the hot-pressed composite are shown in Fig. 3. The analyses show the presence of Cu and MoS2 diffraction peaks for both the powder mixture and the consolidated compact. The absence of copper oxide, molybdenum oxide, mixed copper and molybdenum sulfides (Cu-Mo-S compounds) or other related peaks indicates that no oxidation or dissociation reaction has taken place during hot pressing.

Fig. 3 XRD patterns for Cu/5MoS2 powder mixture and hot-pressed composite

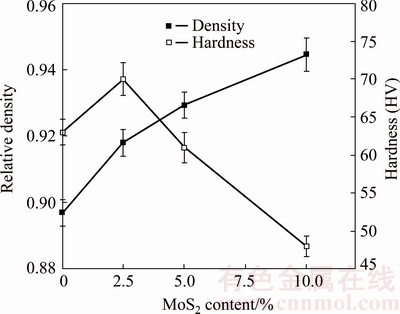

Figure 4 shows the variation of relative density and hardness of hot pressed samples with MoS2 content. It is found that relative density of the compacts increases with MoS2 content. Generally, compaction process of powders consists of rearrangement and movement of particles followed by their plastic deformation [24]. Since all the samples were compacted at a constant applied pressure, the contribution of plastic deformation in the achieved densification would be nearly the same for all the tested materials. However, MoS2 reduces the internal friction among copper particles sliding against each other under the applied pressure. Therefore, particle sliding of compacting powders increases with increasing MoS2 content. As a result, the improved densification of powder mixtures with MoS2 content could be mainly attributed to the enhanced particle rearrangement arisen from lubricating effect of MoS2 particles.

The Vickers hardness of various specimens is also presented in Fig. 4. It is found that the hardness of Cu/2.5MoS2 composite is 11% higher than that of pure copper compact produced by hot pressing of the milled powders. This is due to enhanced densification which compensates any possible reduction of hardness due to the addition of soft MoS2 particles to the powder compact. However, when the MoS2 content exceeds this threshold value, the hardness is decreased by further MoS2 addition. This reversed trend in hardness variation results from microstructural changes in the composites, as previously shown in Fig. 2. The MoS2 phase covers a larger area than copper phase in the microstructure of the composites containing 5% and 10% of soft MoS2 particles. The softer matrix imposes lower constraint against indentation and thereby results in reduction of hardness.

Fig. 4 Variation of relative density and hardness with MoS2 content

3.2 Tribological behavior

3.2.1 Friction

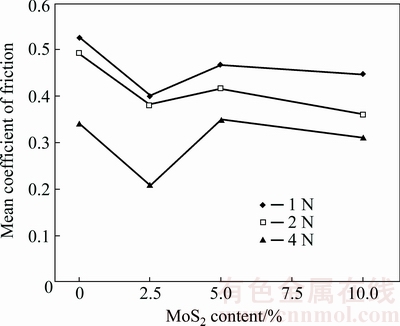

Figure 5 shows the average coefficient of friction as a function of MoS2 content under different applied normal loads. It is found that at all the applied loads the composite containing 2.5% of MoS2 particles exhibits the least coefficient of friction. For the pure copper, the mean coefficient of friction varies between 0.34 and 0.53, while it fluctuates between 0.20 and 0.40 in 2.5% MoS2 composite at various normal loads. Friction rises when the content of solid lubricant particles increases from 2.5% to 5% and then remains nearly constant. However, most of reports in this field indicate that coefficient of friction decreases initially with percentage of solid lubricating particles and then levels off without any subsequent increase [25-28]. The decrease of coefficient of friction with addition of 2.5% of MoS2 to the base copper is related to lubricating characteristic of MoS2 particles. The MoS2 particles incorporated within the copper matrix shear on the mating surfaces during sliding and decrease metal to metal contact area, which results in reduction of coefficient of friction. However, it is reported that overall effectiveness of solid lubricating particles depends on the ability of the sheared material layers to adhere to the sliding surfaces [29]. In fact, properties of the substrate material affect the lubricating characteristic of the sheared layer. When a thin film is deposited on a harder substrate, the coefficient of friction (f) could be expressed as [30]

(1)

(1)

where Sf is the shear strength of the film material and Hs is the hardness of the substrate. This equation suggests that coefficient of friction is inversely related to the hardness of substrate material. Therefore, the increased coefficient of friction by increasing MoS2 content from 2.5% to 5% (Fig. 5) could be attributed to the reduced hardness value (Fig. 4) which in turn is affected by microstructure of the material.

Fig. 5 Variation of coefficient of friction with MoS2 content at different normal loads

It is also clear from Fig. 5 that the coefficients of friction of both base copper and Cu/MoS2 composites decrease with increase in the applied normal load from 1 to 4 N. Similar trends for reduced coefficient of friction by increasing of normal load have been reported by other researchers [31-33]. For pure copper, the increased applied load is accompanied with increased frictional heating which in turn softens the surface asperities. In this condition, local bonds formed due to welding in contacting surface asperities are easily broken. Therefore, lower tangential force is needed to shear these adhesive bonds leading to a lower friction. In addition, higher normal load introduces higher tendency of oxidation, which prevents metal-metal contact and therefore reduces friction coefficient. Moreover, higher normal load leads to heavier work hardening, resulting in a harder tribolayer and thus reducing the friction according to Eq. (1). In the case of Cu/MoS2 composites, reduction of coefficient of friction could be attributed to the enhanced squeezing-out of MoS2 particles from the matrix at higher normal loads. As a result, a wider part of the contact area is covered with the lubricating film and metal to metal contact is effectively reduced leading to a lower coefficient of friction. Moreover, the effect of applied normal pressure (P) on coefficient of friction for thin film lubrication is given by [3]

(2)

(2)

where α is a constant of film material. As the normal pressure increases, the contribution of the first term in Eq. (2) is reduced and the coefficient of friction approaches to the constant value of α, a characteristic of MoS2 lubricating film.

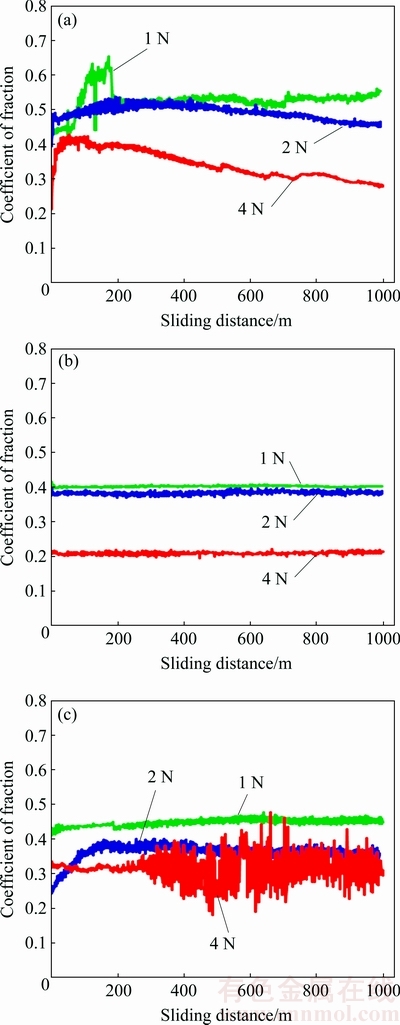

Generally, the coefficient of friction is to be minimized for system efficiency [5]. However, the fluctuation level of friction is also of special importance since it affects frictional behavior in tribosystems. Figure 6 shows the variation of coefficient of friction with sliding distance for the base copper and Cu/MoS2 composites. For pure copper, it is found that the coefficient of friction exhibits a fluctuant trend at all the normal loads (Fig. 6(a)). It is evident from Fig. 6(b) that Cu/2.5MoS2 composite has reasonably stable frictional traces. This is typical of lubricated sliding ensuring the formation of a stable lubricating film between the mating surfaces. The friction traces of Cu/10MoS2 composite (Fig. 6(c)) show unsteady data particularly at higher normal loads. This could be attributed to the instability of lubricating film due to the reduced hardness of substrate material at high MoS2 content. A higher fluctuation of the coefficient of friction for copper matrix composites containing higher solid lubricant contents was previously reported by other authors [11].

Fig. 6 Variation of coefficient of friction versus sliding distance for pure copper (a), Cu/2.5MoS2 (b) and Cu/10MoS2 (c) composites under different normal loads

3.2.2 Wear loss

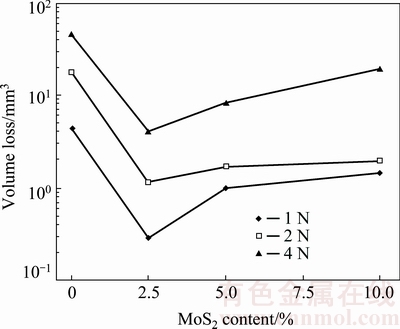

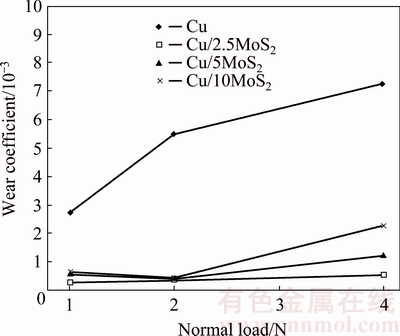

Figure 7 shows the wear loss of pure copper and Cu/MoS2 composite disks as a function of MoS2 mass fraction under different applied normal loads. As observed, the volume loss of disk samples at a constant applied load follows almost the same tendency of the coefficient of friction (Fig. 5). A critical MoS2 content of 2.5% (mass fraction) is found in which the lowest wear loss occurred at a constant normal load. Further increase in amount of solid lubricating reinforcement resulted in a higher wear loss. The reduced wear loss of 2.5% MoS2 composite as compared to that of the pure copper is attributed to the antifriction properties of solid lubricating film of MoS2 as discussed before. The subsequent increase in volume loss of composite disks with further addition of MoS2 particles is associated with the deteriorated mechanical properties of the substrate material (Fig. 4). The results presented in Fig. 7 also indicate that the wear loss increases with increasing normal load regardless of the MoS2 content of substrate material. These results might be interesting considering that the coefficient of friction decreased with normal load as shown in Fig. 5. The effect of normal load (N) on volume loss per unit sliding distance (V) is given by Archard wear equation [34]:

(3)

(3)

where K is wear coefficient indicating the severity of the wear process. The variations of wear coefficient with applied normal load for pure copper and self lubricating Cu/MoS2 composites are presented in Fig. 8. It is found that the wear coefficient for pure copper significantly increased with normal load, indicating deterioration of tribological performance of the copper at high normal loads. However, the wear coefficients of Cu/MoS2 composites show little changes with normal load. The wear coefficient of Cu/2.5MoS2 composite, in particular, is almost constant through the entire range of the applied load. This suggests that properly selected and processed self lubricating Cu/MoS2 composites have high potentials to be utilized in applications requiring high load carrying capacity.

Fig. 7 Wear loss of pure copper and Cu/MoS2 composites at different applied loads

Fig. 8 Variation of wear coefficient with normal load for pure copper and Cu/MoS2 composites

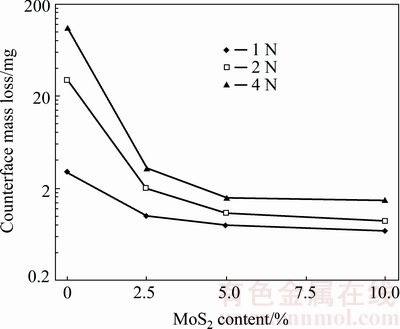

The mass loss of the counterfaces running against pure copper and composite disks as a function of MoS2 content is shown in Fig. 9. It is evident that the addition of MoS2 particles into the copper matrix decreases the mass loss of counterfaces at all the applied normal loads. The decrease of mass loss of the counterfaces reaches the minimum at 5% MoS2 content and remains almost constant with further increase of MoS2 content. The smearing of MoS2 particles on the composite surface and formation of a separating film between the mating surfaces, i.e. transfer layer, govern the wear loss of both composites and the counter material. This layer is continuously replenished by MoS2 dispersoids within the composite compacts. The formed transfer layer protects the surface of the counter material from further wear damage through avoiding metal to metal contact of the rubbing surfaces. In addition, the reduced hardness of composite disks with addition of MoS2 particles affects the wear of counterface pins. That is why the minimum mass loss for the counterface material is found to occur at 5% or 10% mass fraction of MoS2 particles.

Fig. 9 Mass loss of counterface pins as function of MoS2 content worn at different applied loads

From above results, it may be concluded that MoS2 particles enclosed in a copper matrix provide effective lubrication of the material surfaces in contact. At an optimum content of MoS2, i.e. 2.5%, friction surfaces are always covered with a lubricating MoS2 film which separates the mating surfaces effectively. This results in a low and stable coefficient of friction together with improved wear resistance of the tribosystems. However, in a similar work by KOVALCHENKO et al [11], it was reported that a minimum content of 5% (mass fraction) MoS2 in the copper matrix is needed to obtain the best lubricating effect. These different results may arise from using of different synthesizing processes. In the present work, ball milling was utilized to mix pure copper with MoS2 particles. The soft MoS2 powders are easily sheared and fractured to very fine particles during mechanical milling. It would be easier for these well dispersed and finely powdered particles to emerge from the copper matrix. As a result, the milled MoS2 particles could be efficiently smeared on the surface of composite compacts during the sliding wear. In addition, no decomposition of MoS2 was found due to utilizing of hot pressing as the consolidating process in synthesizing of the Cu/MoS2 composites. Consequently, all the added MoS2 particles (i.e. 2.5%) were effectively used for the self lubricating purpose. Therefore, it is evident that even an addition of as low content as 2.5% MoS2 results in a high level of lubrication.

3.2.3 Wear mechanism

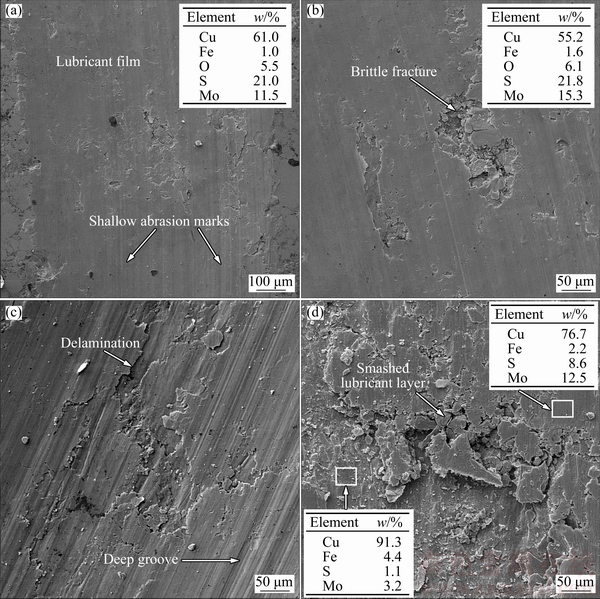

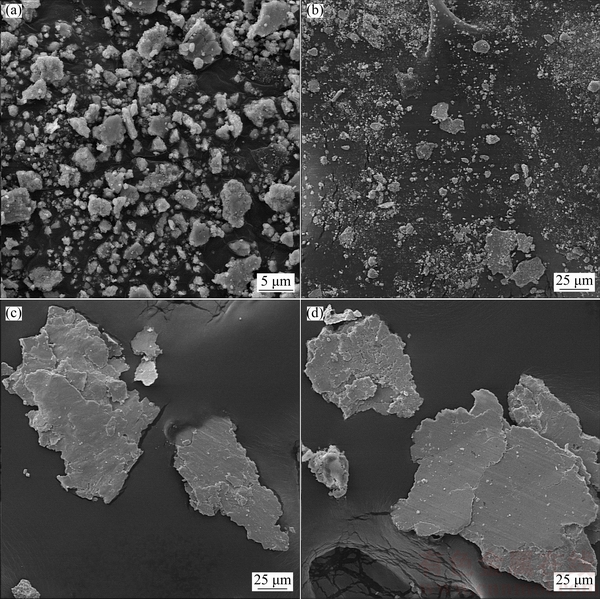

The worn surfaces of pure copper disks and their corresponding wear debris are shown in Figs. 10 and 11, respectively. The results of EDS analysis performed on those surfaces are also inserted. Figure 10(a) shows minor plastic deformation for pure copper loaded with 1 N, indicating the domination of adhesive wear. The EDS analysis of the surface shows only copper element. A characteristic of adhesive wear is large unstable coefficient of friction [35], as presented in Fig. 6(a). Figure 11(a) shows differently shaped fine wear particles produced in wear test of pure copper sample under normal load of 1 N.

Fig. 10 SEM images of wear surface of pure copper under normal load of 1 N (a) and 4 N (b) together with results of their corresponding EDS analyses

Figure 10(b) shows massive plastic deformation in surface of the pure copper disk worn under normal load of 4 N. The region marked with dashed lines shows a wearing out particle developing on the disk surface due to the adhesive action of the counterface. As a result of adhesive wear, irregular large wear fragments are generated, as shown in Fig. 11(b). The presence of iron and oxygen on the wear surface as confirmed by EDS analysis might indicate the material transfer from the counterface and formation of oxides, respectively. Increasing the normal load in sliding wear from 1 to 4 N leads to a temperature rise of contacting asperities especially in steel counterface with lower heat conduction than the copper disc. Therefore, the thermal softening of asperities in steel counterface and consequently the material transfer occur. In addition, the formation of metallic oxides on the mating surfaces decreases the coefficient of friction between sliding surfaces [36,37]. This results in the reduction of coefficient of friction with increasing of normal load for pure copper samples, as previously shown in Fig. 5.

Fig. 11 SEM images from wear debris of pure copper disks worn under normal load of 1 N (a) and 4 N (b)

Fig. 12 SEM images of wear surface of Cu/2.5MoS2 (a, b) and Cu/10MoS2 (c, d) composites under normal load of 1 N (a, c) and 4 N (b, d) together with results of their corresponding EDS analyses

Figure 12 shows the wear surface and results of EDS analysis for Cu/MoS2 composites. It is observed that the surface of Cu/2.5MoS2 composite worn under normal load of 1 N (Fig. 12(a)) is relatively smooth and covered with a dark and continuous film of MoS2 confirmed by EDS analysis. This solid lubricating film is created by transferring of MoS2 particles from the bulk of composite to the surface under the applied normal load. Since no signs of adhesion are observed, it can be concluded that the main role of a solid lubricant film is to suppress or decrease the adhesive wear between sliding surfaces. Instead, some shallow scratches are evident indicating the dominating abrasion marks. This wear mechanism results in formation of fine powder like debris and some approximately equiaxed particles smaller than 5 μm in size as presented in Fig. 13(a). However, the wear surface of the same composite under the applied load of 4 N (Fig. 12(b)) reveals brittle fracture of the lubricant film which results in formation of both fine powdery and coarse irregularly shaped wear debris (Fig. 13(b)). Similar wear debris morphology was observed for Al/9Gr composite disks sliding against a steel counterface by other researchers [28]. The formation of pits by brittle fracture on the worn surface might suggest the activation of fatigue wear mechanism in the absence of the adhesive wear due to the well lubricated contacts.

As MoS2 content in the composite disk loaded with 1 N increased from 2.5% to 10%, the morphology of the wear surface changed from fine scratches (Fig. 12(a)) to deep grooves (Fig. 12(c)) indicating sever abrasive wear mechanism. This could be explained by the reduced hardness of the composite disks with increasing MoS2 content leading to lowered abrasion resistance of the materials. In addition, delamination is observed to be operative during sliding wear of 10% MoS2 composite loaded with 1 N, as shown in Fig. 12(c). This could be attributed to the fact that microcracks propagate more easily in high lubricant content composites than in those containing less lubricant [38].

Fig. 13 SEM images from wear debris of Cu/2.5MoS2 (a, b) and Cu/10MoS2 (c, d) composite disks worn under normal load of 1 N (a, c) and 4 N (b, d)

Figure 12(d) shows the morphology of the wear surface of Cu/10MoS2 composite disk worn under normal load of 4 N. It is observed that solid lubricant film is smashed into particles up to 100 μm in diameter at this normal load. As a result, in some regions, the fresh uncoated composite surface is exposed to the steel counterface leading to a highly fluctuant friction, as illustrated in Fig. 6(c). The load-carrying capacity of coated systems generally decreases with decreasing hardness of substrate material [39]. Therefore, the smashing of solid lubricant film under normal load of 4 N could be attributed to the low hardness of substrate composite containing 10% MoS2 particles, as presented in Fig. 4. This wear mechanism generates irregular large wear debris, as shown in Fig. 13(d).

4 Conclusions

The effects of MoS2 content (0-10%, mass fraction) on microstructure, density, hardness and wear behavior of the pure copper synthesized by mechanical milling and hot pressing of powder particles were studied. Microstructural studies showed that the continuous matrix phase changed from copper to MoS2 when MoS2 content increased from 2.5% to 5% in the composites. While the relative density of the fabricated samples increased continuously with MoS2 content, their hardness values showed a peak at 2.5% MoS2. Results of the wear tests demonstrated that with increasing MoS2 content to the critical content of 2.5%, both the coefficient of friction and the wear loss decreased at all the applied normal loads. This was attributed to the formation of an intact lubricant film of MoS2 on the composite surface. Higher contents of MoS2, however, contributed to the reduction of wear resistance due to the reduced hardness of the materials. In the case of Cu/10MoS2 composite, a sever fragmentation of solid lubricant layer was observed on the surface worn at normal load of 4 N causing instability and increasing of coefficient of friction. It was also confirmed that increasing the normal load in wear tests led to reduction of coefficient of friction regardless of MoS2 mass fraction. Nevertheless, wear volume loss increased with increasing applied loads. The wear mechanism was found to be mostly adhesive in pure copper and a mixture of abrasive and delamination wear in Cu/MoS2 composites.

References

[1] CHHOWALLA M, AMARATUNGA G A J. Thin films of fullerene-like MoS2 nanoparticles with ultra-low friction and wear [J]. Nature, 2000, 407: 164-167.

[2] MENEZES P, NOSONOVSKY M, INGOLE S P, KAILAS S V, LOVELL M R. Tribology for scientists and engineers: From basics to advanced concepts [M]. New York: Springer, 2013.

[3] ROHATGI P K, RAY S, LIU Y. Tribological properties of metal matrix-graphite particle composites [J]. International Materials Reviews, 1992, 37: 129-152.

[4] CHEN S X, FENG Y, LI S, XIE Y J. Influences of MoS2 contents on sintering process and properties of Cu-MoS2 composites [J]. Journal of Materials Science and Engineering, 2008, 2: 7-12.

[5] BHUSHAN B. Modern tribology handbook [M]. USA: CRC Press, 2000.

[6] CLAUSS F J. Solid lubricants and self-lubricating solids [M]. New York: Academic Press, 1972.

[7] BAO S, YONGZHEN Z, JIANDONG X, LEMIN S, DAOCHUN H, MING Q. Effects of content of MoS2 on sliding tribological behavior of copper-based powder metallurgy materials under electrical current [C]//LUO J, MENG Y, SHAO T, ZHAO Q. Advanced Tribology: Proceedings of CIST2008 & ITS-IFToMM2008. Berlin, Heidelberg: Springer Berlin Heidelberg, 2010: 239-241.

[8] SENTHIL KUMAR P, MANISEKAR K. Prediction of effect of MoS2 content on wear behavior of sintered Cu-Sn composite using Taguchi analysis and artificial neural network [J]. Indian Journal of Engineering and Materials Sciences, 2014, 21: 657-671.

[9] SENTHIL KUMAR P, MANISEKAR K, SUBRAMANIAN E, NARAYANASAMY R. Dry sliding friction and wear characteristics of Cu-Sn alloy containing molybdenum disulfide [J]. Tribology Transactions, 2013, 56: 857-866.

[10] KATO H, TAKAMA M, IWAI Y, WASHIDA K, SASAKI Y. Wear and mechanical properties of sintered copper–tin composites containing graphite or molybdenum disulfide [J]. Wear, 2003, 255: 573-578.

[11] KOVALCHENKO A M, FUSHCHICH O I, DANYLUK S. The tribological properties and mechanism of wear of Cu-based sintered powder materials containing molybdenum disulfide and molybdenum diselenite under unlubricated sliding against copper [J]. Wear, 2012, 290-291: 106-123.

[12] DANGSHENG X. Lubrication behavior of Ni-Cr-based alloys containing MoS2 at high temperature [J]. Wear, 2001, 251: 1094-1099.

[13] TKACHENKO Y G, KOVAL'CHENKO M S, YULYUGIN V K, BOVKUN G A, YURCHENKO D Z. Lubricating action of MoS2 on rubbing sintered materials [J]. Soviet Powder Metallurgy and Metal Ceramics, 1978, 17: 552-555.

[14] ALIDOKHT S A, ABDOLLAH-ZADEH A, ASSADI H. Effect of applied load on the dry sliding wear behaviour and the subsurface deformation on hybrid metal matrix composite [J]. Wear, 2013, 305: 291-298.

[15] KANTHAVEL K, SUMESH K R, SARAVANAKUMAR P. Study of tribological properties on Al/Al2O3/MoS2 hybrid composite processed by powder metallurgy [J]. Alexandria Engineering Journal, 2016, 55: 13-17.

[16] JANBOZORGI M, SHAMANIAN M, SADEGHIAN M, SEPEHRINIA P. Improving tribological behavior of friction stir processed A413/SiCp surface composite using MoS2 lubricant particles [J]. Transactions of Nonferrous Metals Society of China, 2017, 27: 298-304.

[17] NARAYANASAMY P, SELVAKUMAR N. Tensile, compressive and wear behaviour of self-lubricating sintered magnesium based composites [J]. Transactions of Nonferrous Metals Society of China, 2017, 27: 312-323.

[18] NARAYANASAMY P, SELVAKUMAR N, BALASUNDAR P. Effect of hybridizing MoS2 on the tribological behaviour of Mg-TiC composites [J]. Transactions of the Indian Institute of Metals, 2015, 68: 911-925.

[19] DHANASEKARAN S, GNANAMOORTHY R. Dry sliding friction and wear characteristics of Fe-C-Cu alloy containing molybdenum disulphide [J]. Materials & Design, 2007, 28: 1135-1141.

[20] ZHANG Y, MICHAEL SHOCKLEY J, VO P, CHROMIK R R. Tribological behavior of a cold-sprayed Cu-MoS2 composite coating during dry sliding wear [J]. Tribology Letters, 2016, 62: 1-12.

[21] FARR J P G. Molybdenum disulphide in lubrication: A review [J]. Wear, 1975, 35: 1-22.

[22] WINER W O. Molybdenum disulfide as a lubricant: A review of the fundamental knowledge [J]. Wear, 1967, 10: 422-452.

[23] TSUYA Y, SHIMURA H, UMEDA K. A study of the properties of copper and copper-tin base self-lubricating composites [J]. Wear, 1972, 22: 143-162.

[24] MOAZAMI-GOUDARZI M, AKHLAGHI F. Effect of nanosized SiC particles addition to CP Al and Al-Mg powders on their compaction behavior [J]. Powder Technology, 2013, 245: 126-133.

[25] AKHLAGHI F, ZARE-BIDAKI A. Influence of graphite content on the dry sliding and oil impregnated sliding wear behavior of Al 2024–graphite composites produced by in situ powder metallurgy method [J]. Wear, 2009, 266: 37-45.

[26] GUO M L T, TSAO C Y A. Tribological behavior of self-lubricating aluminium/SiC/graphite hybrid composites synthesized by the semi-solid powder-densification method [J]. Composites Science and Technology, 2000, 60: 65-74.

[27]  L U. Effect of composition on friction coefficient of Cu–graphite composites [J]. Wear, 2008, 265: 417-421.

L U. Effect of composition on friction coefficient of Cu–graphite composites [J]. Wear, 2008, 265: 417-421.

[28] MAHDAVI S, AKHLAGHI F. Effect of the graphite content on the tribological behavior of Al/Gr and Al/30SiC/Gr composites processed by in situ powder metallurgy (IPM) method [J]. Tribology Letters, 2011, 44: 1-12.

[29] JHA A K, PRASAD S V, UPADHYAYA G S. Sintered 6061 aluminium alloy—solid lubricant particle composites: Sliding wear and mechanisms of lubrication [J]. Wear, 1989, 133: 163-172.

[30] LANSDOWN A R. Molybdenum disulphide lubrication [M]. Amsterdam: Elsevier, 1999.

[31] KESTURSATYA M, KIM J K, ROHATGI P K. Friction and wear behavior of a centrifugally cast lead-free copper alloy containing graphite particles [J]. Metallurgical and Materials Transactions A, 2001, 32: 2115-2125.

[32] KESTURSATYA M, KIM J K, ROHATGI P K. Wear performance of copper–graphite composite and a leaded copper alloy [J]. Materials Science and Engineering A, 2003, 339: 150-158.

[33] RAMESH C S, NOOR AHMED R, MUJEEBU M A, ABDULLAH M Z. Development and performance analysis of novel cast copper–SiC-Gr hybrid composites [J]. Materials & Design, 2009, 30: 1957-1965.

[34] HUTCHINGS I M. Tribology: Friction and wear of engineering materials [M]. London: Edward Arnold, 1992.

[35] STACHOWIAK G W, BATCHELOR A W. Engineering tribology [M]. 3rd ed. Burlington: Butterworth–Heinemann, 2005.

[36] LI X Y, TANDON K N. Mechanical mixing induced by sliding wear of an Al-Si alloy against M2 steel [J]. Wear, 1999, 225-229(Part 1): 640-648.

[37] MOAZAMI-GOUDARZI M, AKHLAGHI F. Wear behavior of Al 5252 alloy reinforced with micrometric and nanometric SiC particles [J]. Tribology International, 2016, 102: 28-37.

[38] ZHAN Y, ZHANG G. Friction and wear behavior of copper matrix composites reinforced with SiC and graphite particles [J]. Tribology Letters, 2004, 17: 91-98.

[39] RONKAINEN H, KOSKINEN J, VARJUS S, HOLMBERG K. Load-carrying capacity evaluation of coating/substrate systems for hydrogen-free and hydrogenated diamond-like carbon films [J]. Tribology Letters, 1999, 6: 63-73.

Mohammad MOAZAMI-GOUDARZI, Aram NEMATI

Department of Materials Engineering, Science and Research Branch, Islamic Azad University, Tehran, Iran

摘 要:研究MoS2 含量对纯铜的显微组织、密度、硬度和耐磨性能的影响。采用纯铜粉和MoS2粉末,通过机械球磨和热压法,制备含0~10% (质量分数) MoS2颗粒的铜基复合材料。在干滑动摩擦条件下,采用销-盘式磨损实验装置,测试材料的耐磨性能,固定滑动速率为0.2 m/s。硬度测试结果显示,MoS2含量为2.5% 的复合材料的硬度达到峰值。当载荷一定时,Cu/2.5MoS2复合材料具有最低的摩擦因数和磨损量。当载荷从1 N增加到4 N,不同含量增强相复合材料的摩擦因数均减小,同时,磨损量增大。磨损表面和磨屑的SEM照片显示,Cu/MoS2复合材料的磨损机理由纯铜的粘着磨损为主转变为磨粒磨损和剥层磨损相结合的机制。

关键词:铜基复合材料;显微组织;摩擦因数;磨损机制

(Edited by Bing YANG)

Corresponding author: Mohammad MOAZAMI-GOUDARZI; E-mail: moazami@srbiau.ac.ir

DOI: 10.1016/S1003-6326(18)64729-6