TiB2颗粒增强铜基复合材料的研究

来源期刊:中南大学学报(自然科学版)2001年第3期

论文作者:熊拥军 邓至谦 凌兴珠 江玲 敖晖

文章页码:294 - 297

关键词:铜基复合材料;机械合金化; TiB2

Key words:copper matrix composite; mechanical alloying; TiB2

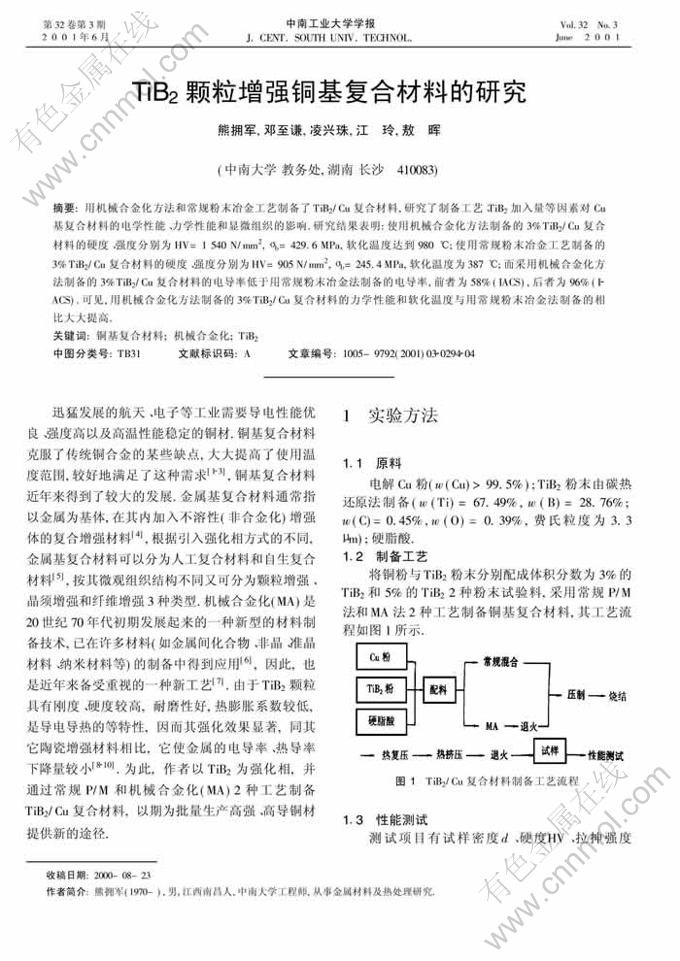

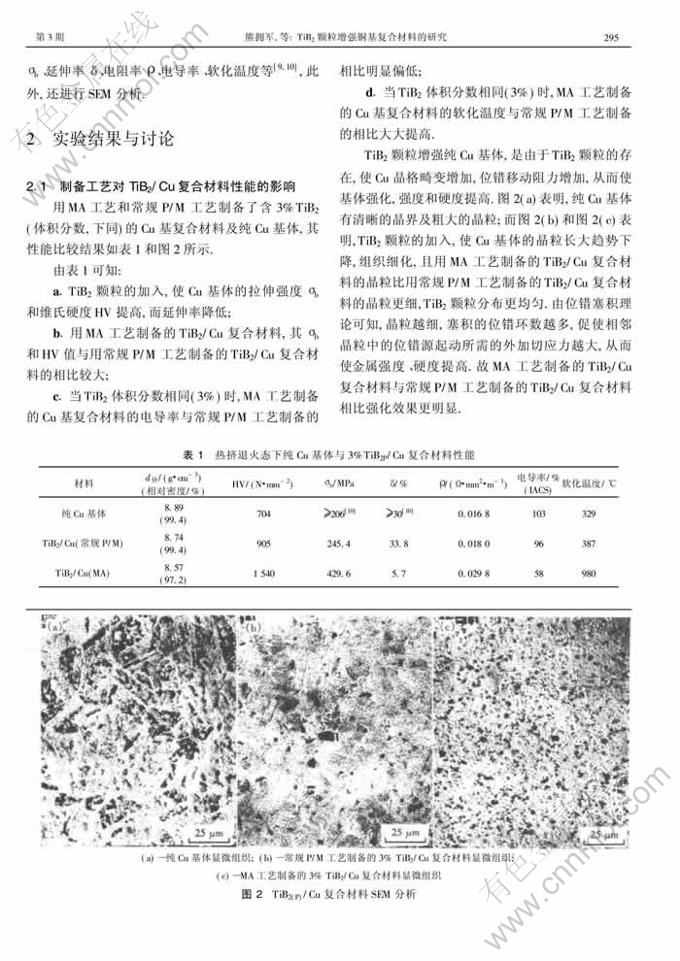

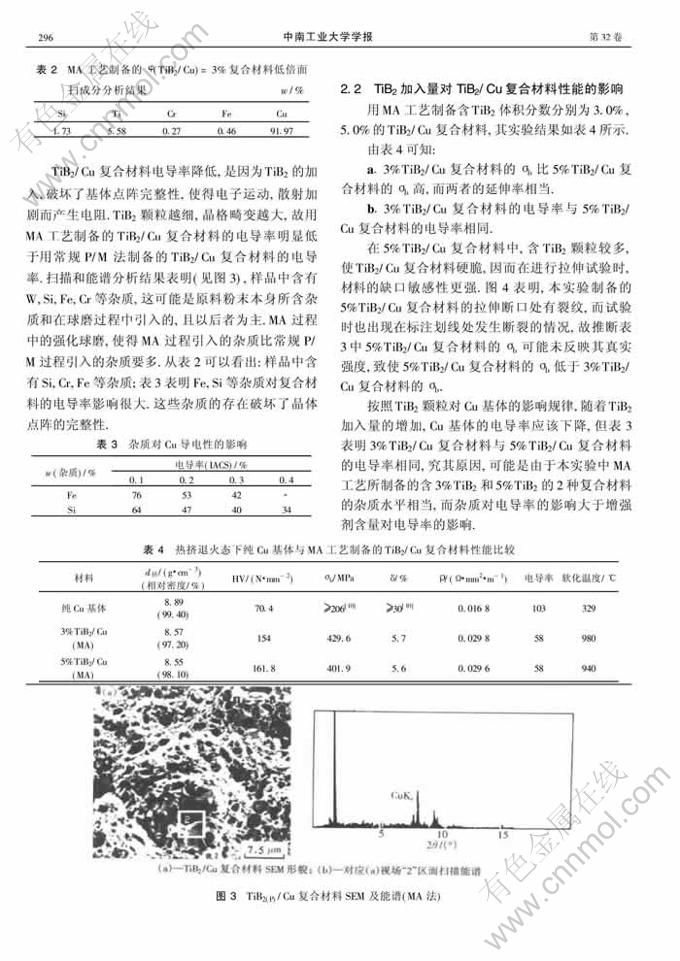

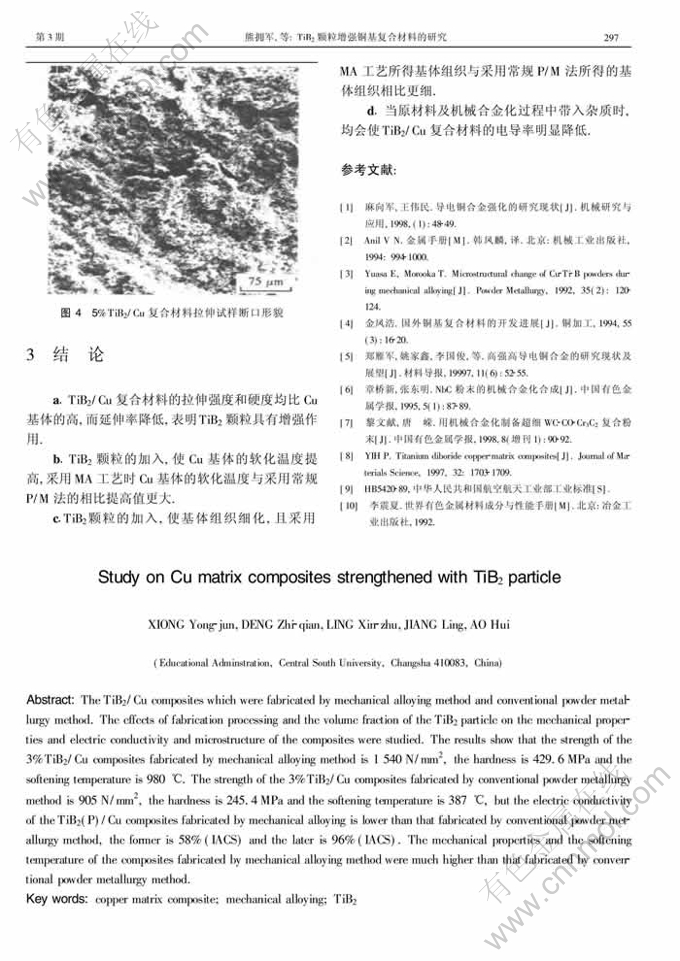

摘 要:用机械合金化方法和常规粉末冶金工艺制备了TiB2/Cu复合材料,研究了制备工艺、TiB2加入量等因素对Cu基复合材料的电学性能、力学性能和显微组织的影响.研究结果表明:使用机械合金化方法制备的3%TiB2/Cu复合材料的硬度、强度分别为HV=1 540 N/mm2,σb=429.6 MPa,软化温度达到980℃;使用常规粉末冶金工艺制备的3%TiB2/Cu复合材料的硬度、强度分别为HV=905 N/mm2,σb=245.4 MPa,软化温度为387℃;而采用机械合金化方 法制备的3%TiB2/Cu复合材料的电导率低于用常规粉末冶金法制备的电导率,前者为58%(IACS),后者为96%(I-ACS).可见,用机械合金化方法制备的3%TiB2/Cu复合材料的力学性能和软化温度与用常规粉末冶金法制备的相比大大提高.

Abstract: TheTiB2/Cu composites which were fabricated by mechanical alloying method and conventional powder metallurgy method. The effects of fabrication processing and the volume fraction of the TiB2 particle on the mechanical properties and electric conductivity and microstructure of the composites were studied. The results show that the strength of the 3%TiB2/Cu composites fabricated by mechanical alloying method is 1 540 N/mm2, the hardness is 429.6 MPa and the softening temperature is 980℃. The strength of the 3%TiB2/Cu composites fabricated by conventional powder metallurgy method is 905 N/mm2, the hardness is 245.4MPa and the softening temperature is 387℃, but the electric conductivity of theTiB2 (P)/Cu composites fabricated by mechanical alloying is lower than that fabricated by conventional powdermetallurgy method, the former is 58%(IACS) and the later is 96%(IACS). The mechanical properties and the softening temperature of the composites fabricated by mechanical alloying method were much higher than that fabricated by conventional powder metallurgy method.