DOI:10.19476/j.ysxb.1004.0609.2017.10.07

基于旋转摩擦挤压法制备CNTs/Al复合材料的显微组织

邢 丽1,倪圆苹1, 2,徐卫平1,柯黎明1,简园园1

(1. 南昌航空大学,轻合金加工科学与技术国防重点学科实验室,南昌 330063;

2. 江西洪都航空工业股份有限公司,南昌 330024)

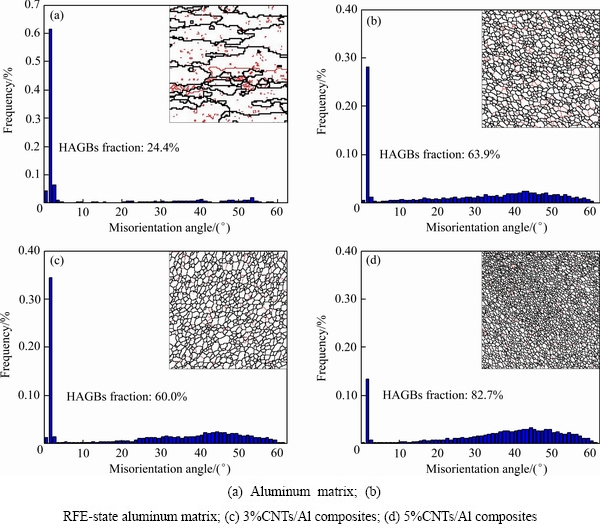

摘 要:采用旋转摩擦挤压法制备CNTs/2024Al复合材料,并利用电子背散射衍射技术对复合材料的晶体取向、晶粒尺寸、取向差分布和织构进行分析。结果表明:铝基材的组织为粗大的板条状,其平均晶粒尺寸为48.67 μm,大角度晶界含量为24.4%;经RFE加工后,铝基材变为动态再结晶后的细小等轴晶,平均晶粒尺寸减小为3.22 μm,大角度晶界含量增加至63.9%。当CNTs含量增加至5%时,CNTs/2024Al复合材料平均晶粒尺寸减小至1.97 μm,大角度晶界含量增加至82.7%,CNTs的加入阻止复合材料的晶粒长大。经RFE加工后,铝基材的最大极密度由10.8降低为4.18,轧制织构强度减弱;CNTs的加入对复合材料的织构强度具有弱化作用。

关键词:旋转摩擦挤压法;CNTs/2024Al复合材料;显微组织;大角度晶界含量;织构

文章编号:1004-0609(2017)-10-2012-08 中图分类号:TG331 文献标志码:A

碳纳米管(Carbon nanotubes, CNTs)具有独特的管状结构、高纵横比、良好的热稳定性、较低的热膨胀系数以及超强的力学性能,是复合材料的理想增强相。将CNTs加入铝基形成CNTs/Al复合材料,可进一步提高材料的综合性能,在航空、航天和交通运输工具等领域有重要的应用前景[1]。目前,制备CNTs/Al复合材料的方法有粉末冶金法、半固态搅拌铸造法、熔体浸渗法和搅拌摩擦加工法等,其中粉末冶金法的制备工艺复杂,制备的复合材料容易产生孔隙、裂纹等缺陷[2];半固态搅拌铸造法制备过程中,在凝固时复合材料易形成枝晶偏析[3];熔体浸渗法可制取高含量的复合材料,但基体与增强相之间的润湿性较差,复合材料显微组织不均匀[4];搅拌摩擦加工法制备出的复合材料只在搅拌摩擦区域形成,且搅拌摩擦加工难以一次性得到组织均匀、致密的复合材料[5]。

旋转摩擦挤压法[6](Rotational friction extrusion, RFE)是通过搅拌棒对待复合的材料施加摩擦挤压作用,实现增强相与金属材料复合的新工艺方法。此方法较其他方法制备过程简单,材料利用率高,可制备出不同尺寸的块体复合材料。刘德强等[7]采用RFE制备出CNTs/1060Al复合材料,与铝基体相比,发现CNTs能使复合材料晶粒细化,同时提高硬度和抗拉强度。林毛古等[8]采用RFE法制备出CNTs/1060Al复合材料,并对其界面结构进行研究时发现,经RFE加工后,CNTs和铝基体之间界面发生反应后会产生少量的Al4C3相,而少量的Al4C3薄层有润湿界面的作用,有利于CNTs与铝基体的界面结合;CNTs的加入有利于提高复合材料的抗拉强度和硬度。在RFE过程中,复合材料在摩擦产热和剧烈塑性变形作用下,会发生动态再结晶[9],其晶粒的取向和尺寸会发生变化[10],从而影响复合材料的组织和性能。

电子背散射衍射技术(Electron backscatter diffraction,EBSD)是一种新型的用于分析材料在形变过程中组织变化的方法。相对于TEM电镜,EBSD技术制样简便,且适用于大块试样的检测,该技术可同时确定材料的晶粒形貌、取向成像、晶粒尺寸、取向差分布及织构等较全面的晶体学信息,且结合高分辨率的场发射扫描电镜,可用于检测晶粒尺寸为纳米级别的纳米材料。丁汉林等[11]利用背散射电子衍射技术分析了Ca 的添加对镁合金热压缩变形后的显微组织、织构特征及再结晶晶粒特征。MORADI等[12]在室温下采用等通道转角挤压法(ECAP)对铸态A356铝合金进行了挤压实验,采用EBSD方法研究了ECAP变形后变形重熔后材料的组织演变及在挤压过程中A356铝合金的再结晶行为。

本文作者以2024-T4铝合金为基材,采用RFE方法制备CNTs/Al复合材料,用EBSD技术测定复合材料的取向成像、晶界和取向差分布、晶粒大小等,研究CNTs含量对CNTs/Al复合材料组织的影响。

1 实验

试验选用2024-T4铝合金为基体材料,增强相为长度10~30 μm、直径为20~30 nm的碳纳米管(Carbon nanotubes, CNTs)。将铝基材制成尺寸为90 mm×15 mm×12 mm的铝条,在铝条中心线上按一定的间距钻取直径为3~4 mm、孔深8 mm的盲孔,用超声波清洗机清洗后,将CNTs填充入盲孔内并压实,通过改变孔径来改变复合材料中CNTs添加量。

用自制的旋转摩擦挤压设备制备CNTs/Al复合材料,图1所示为RFE制备方法示意图,其工作原理:将待制备材料的试样分别从制备夹具两侧放入挤压型腔中,盖上压板,试样在两端挤压块的作用下与高速旋转的搅拌棒接触后,搅拌棒与试样材料摩擦产热使搅拌棒周围的试样材料金属达到塑化状态;塑化材料在搅拌棒和挤压块的共同作用下,沿出料口以块体的形式挤出,形成块体复合材料。

试验中搅拌棒的旋转速度(r)为315 r/min、挤压速度(v)为21 mm/min。研究中将2024-T4态铝合金简称为铝基材,经过RFE加工后的铝基体材料称为RFE态铝基材,而CNTs体积分数为1%的复合材料表示为1%CNTs/Al复合材料,以此类推。

图1 RFE加工示意图

Fig. 1 Schematic diagram of RFE

将制备出的棒状复合材料截取横截面试样,用Bruker D8 advance型X射线衍射仪(X-ray diffractometer,XRD)对CNTs/RFE复合材料进行物相分析。

截取厚度为3mm的横截面试样制备成EBSD试样,经机械研磨后,在DPF-2型电解抛光设备上进行电解抛光。电解抛光的电解液为25%硝酸+75%甲醇(体积分数),电压为15 V,时间为5~10 s,温度为室温。用SUPRA 55型扫描电子显微镜对试样进行EBSD试验。进行EBSD测量时,测试样品倾转70°,工作电压为20 kV。测得的EBSD数据用HKL Technology Channel 5图像处理软件中Tango程序测定试样的晶体取向、晶粒尺寸、晶界图和取向差分布,用Mambo程序得到的极图,分析测试样品的织构。

2 结果与分析

2.1 复合材料物相分析

图2所示为铝基材及CNTs/Al复合材料XRD谱。其中曲线1~4分别代表2024铝基材、RFE基材、CNTs含量为2%和5%(体积分数)的复合材料。在铝基材和RFE基材中,除了有Al的峰值外还有Al2CuMg和Al2Cu两种相的峰值;经过挤压后,材料中Al2CuMg和Al2Cu相的含量明显减少,说明RFE加工使铝基材中的部分第二相重新固溶到基体。而CNTs/Al复合材料中除了上述两种相,还增加了少量的Al4C3,且随CNTs含量的增加,Al4C3有增加的趋势。CI等[13]的研究表明,Al4C3是CNTs/Al复合材料中CNTs与Al基体结合的伴生物,以纳米尺度的形式存在于复合材料中,它与铝基体的结合有利于提高复合材料的强度。

图2 CNTs/Al复合材料的XRD谱

Fig. 2 XRD patterns of CNTs/Al composites

2.2 复合材料的取向成像及晶粒尺寸

图3所示为铝基材及CNTs/Al复合材料的取向成像图。图中颜色代表晶体取向,图3(d)右下角为反极图,晶体取向的色标中红色为<001>晶向,蓝色为<111>晶向,绿色为<101>晶向。图3(a)所示为铝基材的取向成像图。由图3(a)可见,铝基材晶粒粗大,显微组织为典型的拉长板条状,晶体取向主要为<001>和<111>晶向。图3(b)所示为RFE态铝基材的取向图,由图3(b)可见,经RFE加工后,铝基材晶粒变为细小的等轴晶,<101>晶向和<111>晶向较多,<001>晶向较少,表明铝基材中的<111>晶向继续保持,而<001>则向<101>晶向转变。图3(c)、(d)所示为不同CNTs含量时CNTs/Al复合材料的取向成像图,由图可见,添加CNTs后,CNTs/Al复合材料的晶粒变得更细小,且随CNTs含量增加,复合材料的晶粒进一步减小,晶体取向分布的随机性更大,<101>晶向、<111>晶向和<001>晶向均呈随机分布。

图4所示为铝基材及复合材料的晶粒尺寸分布。由图4(a)可知,铝基材中70%的晶粒尺寸为20~70 μm,尺寸小于11.28 μm的晶粒比例为5%,平均晶粒尺寸为48.67 μm。图4(b)所示为RFE态铝基材的晶粒尺寸分布。由图4(b)可知,经RFE加工后,铝基材中有40%的晶粒尺寸小于3 μm,其中仅有1%的晶粒尺寸为10.11 μm,晶粒的平均尺寸为3.22 μm,说明经RFE加工后的铝基材晶粒得到细化。图4(c)~(d)所示为不同CNTs含量时复合材料的晶粒尺寸分布,其中3%CNTs/Al复合材料中有53%的晶粒尺寸小于3 μm,平均晶粒尺寸为3.11 μm;CNTs含量为5%时,复合材料中尺寸小于3 μm的晶粒比例增加至92%,平均晶粒尺寸为1.97 μm,表明随CNTs含量的增加,复合材料中尺寸小于3 μm的晶粒比例显著增加,平均晶粒尺寸越来越小。

图3 CNTs/Al复合材料的取向成像图

Fig. 3 Orientation maps of CNTs/Al composites

图4 CNTs/Al复合材料的晶粒尺寸分布

Fig. 4 Grain size distributions of CNTs/Al composites

RFE态铝基材晶粒尺寸减小是由于在RFE加工过程中,铝基体在搅拌棒和挤压块的作用下,摩擦产热和剧烈塑性变形为动态再结晶提供了驱动力,铝基体通过动态再结晶使RFE态基材的晶粒细化[14-15]。而复合材料中的晶粒较RFE态基材更细小可能与复合材料中存在超细的分散相微粒有关。胡赓祥等[16]研究表明,如果材料中有分散相微粒,再结晶后这些微粒会与晶界进行交互作用而阻碍晶界的移动,从而阻碍晶粒的长大。在CNTs/Al复合材料中,弥散分布的CNTs微粒与晶界交互作用,阻止了再结晶后的晶粒长大,且随CNTs含量的增加,这种交互作用影响更大,因此,复合材料的晶粒比RFE态基材更细小。

2.3 复合材料的晶界和取向差

图5所示为CNTs/Al复合材料的晶界及对应的取向差分布。定义取向差为2°~10°的为小角度晶界(Low angle grain boundaries,LAGBs),在晶界图中用红色细线条表示;取向差大于15°为大角度晶界(High angle grain boundaries, HAGBs),在晶界图中用黑色粗线条表示。图5(a)和(b)所示分别为铝基材和RFE态铝基材的晶界及对应的取向差分布。由图5(a)和(b)可见,铝基材晶界图中的红线较多,表明其主要为小角度晶界,统计得到大角度晶界仅占24.4%。但经RFE加工后,RFE态铝基材晶粒的大角度晶界含量显著增加,从图5(b)右上角的晶界图可以看出,晶界中红线明显减少,小角度晶界大幅度降低,由铝基材的24.4%增至63.9%,说明RFE加工使铝基材中的晶粒由小角度晶界向大角度晶界转变,铝基材经RFE加工发生了动态再结晶[17-18]。

图5(c)~(d)所示为3%~5%CNTs/Al复合材料的晶界及取向差分布。由图5(c)~(d)可见,添加CNTs后,复合材料中的大角度晶界含量增加,3%CNTs/Al复合材料中的大角度晶界含量为60%;CNTs含量为5%时,复合材料中的大角度晶界含量增加至82.7%。

图5 CNTs/Al复合材料的晶界图和取向差分布

Fig. 5 Grain boundary diagrams and misorientation angle distributions of CNTs/Al composites

分析认为,RFE态铝基材大角度晶界含量增加的原因是在RFE加工过程中铝基体发生剧烈塑性变形,使晶粒内产生高密度位错,位错滑移和塞积在材料内部形成亚晶界,剧烈的塑性变形使原晶粒内和新生成的亚晶中形成位错墙和位错胞,取向差较小的小角度晶界上的位错转移到其他亚晶界使亚晶合并,合并之后生成的新亚晶通过晶界不断吸纳位错而成为大角度晶界[16],因此,RFE态铝基材中的大角度晶界含量显著增加。大角度晶界构成的再结晶晶核借助周围的大角度晶界移动生长,这种长大形成了由大角度晶界分界的再结晶晶粒,RFE态基材发生再结晶。完成动态再结晶后的RFE态基材中的晶粒会发生长大,而晶粒长大则会发生由大角度晶界向小角度晶界的转变,RFE态基材中大角度晶界的含量是其经历再结晶及晶粒长大后的结果。

在CNTs/Al复合材料中,同样经历了上述再结晶过程,不同的是复合材料中弥散分布的纳米级CNTs颗粒在晶粒长大的过程中阻碍了再结晶后的晶界迁移,使大角度晶界难以转变成小角度晶界,保持了已形成再结晶时的大角度晶界,因此,复合材料中大角度晶界的含量比RFE态铝基材多、且晶粒更细小。

2.4 复合材料的织构

结合图3可知,铝基材及CNTs/Al复合材料取向成像图中的晶体取向相近,说明其存在一定的织构。图6所示为对复合材料的织构进行分析得到的CNTs/Al复合材料{100}、{110}和{111}晶面上的极图(图中RD表示原试样的轧制方向,TD为棒状复合材料的法线方向)。图6(a)所示为铝基材的极图。由图6(a)可知,铝基材是典型的轧制织构,主要为铜型织构Copper {112}<111>和S型织构{123}<634>,最大极密度为10.8。图6(b)~(d)所示为RFE态铝基材和不同CNTs含量复合材料的极图。由图6(b)~(d)可以看出,相对于铝基材,RFE态铝基材的最大极密度由10.8降低为4.18,织构漫散程度较大,轧制织构强度减弱,说明RFE加工减弱了铝基材的轧制织构强度;添加CNTs后,当CNTs含量为3%时,复合材料的最大极密度为2.10,织构漫散程度更大,说明CNTs的加入使复合材料的织构强度弱化;当CNTs含量为5%时,复合材料的最大极密度降低为1.54。

这说明RFE加工促使铝基体发生动态再结晶而使铝基材的织构弱化,由于CNTs的加入阻碍了铝基体中再结晶晶粒的长大,使复合材料中的织构进一步弥漫,且随着CNTs含量的增加,最大极密度减小,织构强度减弱。

图6 复合材料的{100}、{110}和{111}极图

Fig. 6 {100}, {110} and {111} pole figures of CNTs/Al composites

3 结论

1) 铝基材的组织为粗大的板条状,平均晶粒尺寸为48.67 μm;经RFE加工后,铝基材晶粒得到细化,为细小等轴晶,其平均晶粒尺寸减小为3.22 μm;随CNTs含量增加,复合材料的晶粒变得更细小,当CNTs含量增加至5%时,平均晶粒尺寸为1.97 μm;CNTs 阻碍了复合材料晶粒的长大。

2) 经RFE加工后的铝基材中,晶体取向由<001>向<101>转变,最大极密度由10.8降低为4.18,织构漫散程度较大。当CNTs含量为3%和5%时,复合材料中的极密度分别为2.10和1.54,晶体取向的随机性变大,织构漫散程度也变大,CNTs对复合材料的织构强度具有弱化作用。

3) 经RFE加工后的铝基材晶粒的大角度晶界含量由24.4%增加至63.9%;随着CNTs含量增加,复合材料中的大角度晶界含量增加,当CNTs含量为5%时,复合材料中的大角度晶界含量增加至82.7%。

REFERENCES

[1] 郭 鲤, 蔡晓兰, 周 蕾, 易 峰, 李 铮. 碳纳米管增强铝基复合材料的研究进展[J]. 机械工程材料, 2014, 38(9): 1-5.

GUO Li, CAI Xiao-lan, ZHOU Lei, YI Feng, LI Zheng. Research progress on carbon nanotubes reinforced aluminum matrix composite[J]. Mechanical Engineering Materials, 2014, 38(9): 1-5.

[2] 姜金龙, 赵少俊, 杨 华, 李维学. 粉末冶金法制备纳米碳管/铝复合材料的力学性能[J]. 材料热处理学报, 2008, 29(3): 6-9.

JIANG Jin-long, ZHAO Shao-jun, YANG Hua, LI Wei-xue. Mechanical properties of Al matrix composites reinforced with carbon nanotubes prepared by powder metallurgy[J]. Journal of Materials Heat Treatment, 2008, 29(3): 6-9.

[3] ABBASIPOUR B, NIROUMAND B, MONIR V S M. Compocasting of A356-CNT composite[J]. Transactions of Nonferrous Metals Society of China, 2010, 20(9): 1561-1566.

[4] 张学习, 耿 林, 王德尊. 挤压铸造法制备碳纳米管增强铝合金复合材料: 中国, 201010300511[P]. 2010-01-21.

ZHANG Xue-xi, GENG Lin, WANG De-Zun. Preparation of CNTs/aluminium composites synthesised by squeeze casting: China patent, 201010300511[P]. 2010-01-21.

[5] LIU Q, KE L M, LIU F C, HUANG C P, XING L. Microstructure and mechanical property of multi-walled carbon nanotubes reinforced aluminum matrix composites fabricated by friction stir processing[J]. Materials and Design, 2013, 45(3): 343-348.

[6] 黄科辉, 柯黎明, 邢 丽, 陈玉华, 黄春平. 旋转摩擦挤压合金化法制备Al3Ti金属间化合物[J]. 稀有金属材料与工程, 2011, 40(10): 1812-1816.

HUANG Ke-hui, KE Li-ming, XING Li, CHEN Yu-hua, HUANG Chun-ping. Al3Ti intermetallic compounds fabricated by rotational extrusion alloying[J]. Rare Metal Materials and Engineering, 2011, 40(10): 1812-1816.

[7] 刘德强, 黄春平, 刘 强, 柯黎明, 邢 丽. 旋转摩擦挤压法制备CNTs/Al线材初探[J]. 热加工工艺, 2014, 43(2): 101-103.

LIU De-qiang, HUANG Chun-ping, LIU Qiang, KE Li-ming, XING Li. Research on preparation of CNTs/Al by rotating friction extrusion method[J]. Hot Working Process, 2014, 43(2): 101-103.

[8] 林毛古, 徐卫平, 柯黎明, 刘 强. 旋转摩擦挤压制备MWCNTs/Al复合材料的界面微观结构[J]. 中国有色金属学报, 2015, 25(1): 98-102.

LIN Mao-gu, XU Wei-ping, KE Li-ming, LIU Qiang. Interface microstructures of MWCNTs/Al composites prepared by rotational friction extrusion[J]. Chinese Journal of Nonferrous Metals, 2015, 25(1): 98-102.

[9] 赵 霞, 柯黎明, 徐卫平, 刘鸽平. 搅拌摩擦加工法制备碳纳米管增强铝基复合材料[J]. 复合材料学报, 2011, 28(2): 185-190.

ZHAO Xia, KE Li-ming, XU Wei-ping, LIU Ge-ping. Carbon nanotubes reinforced aluminum matrix composites by friction stir processing[J]. Journal of Composite Materials, 2011, 28(2): 185-190.

[10] 毛卫民, 赵新兵. 金属的再结晶与晶粒长大[M]. 北京: 冶金工业出版社, 1994: 201.

MAO Wei-min, ZHAO Xin-bing. Recrystallization and grain growth of metals[M]. Beijing: Metallurgical Industry Press, 1994: 201.

[11] 丁汉林, 王天一, 徐成志, 李殿凯. Ca添加及变形条件对Mg-Zn合金组织与织构的影响[J]. 中国有色金属学报, 2015, 25(5): 1142-1152.

DING Han-lin, WANG Tian-yi, XU Cheng-zhi, LI Dian-kai. Effects of Ca addition and deformation conditions on microstructure and texture of Mg-Zn alloy[J]. Chinese Journal of Nonferrous Metals, 2015, 25(5): 1142-1152

[12] MORADI M, NILI-AHMADABADI M, POORGANJI B, HEIDARIAN B, FURUHARA T. EBSD and DTA characterization of A356 alloy deformed by ECAP during reheating and partial Re-melting[J]. Metallurgical and Materials Transactions A, 2014, 45(3): 1540-1551.

[13] CI L, RYU Z, JIN-PHILLIPP N Y, RUHLE M. Investigation of the interfacial reaction between multi-walled carbon nanotubes and aluminum[J]. Acta Materialia, 2006, 54: 5367-5375

[14] XIONG Qi-ping, KE Li-ming, LIU Fen-cheng, LIU Qiang, CHEN Yu-hua, XING Li. Preparation and mechanical property of MWCNTs/Al composite wires by rotational friction extrusion processing[J]. Advanced Materials and Research, 2014, 833: 261-265.

[15] 简晓光, 柯黎明, 刘奋成, 邢 丽, 黄春平. 搅拌摩擦加工制备MWCNTs/AZ80复合材料的组织和力学性能[J]. 南昌航空大学学报: 自然科学版, 2013, 27(1): 8-13.

JIAN Xiao-guang, KE Li-ming, LIU Fen-cheng, XING Li, HUANG Chun-ping. Microstructure and mechanical properties of MWCNTs/AZ80 composite fabricated by friction stir processing[J]. Journal of Nanchang University of Aeronautics and Astronautics, 2013, 27(1): 8-13.

[16] 胡赓祥, 钱苗根. 金属学[M]. 上海: 上海科学技术出版社, 1980: 328-330.

HU Gen-xiang, QIAN Miao-gen. Metallography[M]. Shanghai: Shanghai Science & Technology Press, 1980: 328-330.

[17] MACKENZIE L W F, DAVIS B, HUMPHREYS F J, LORIMER G W. The deformation, recrystallisation and texture of three magnesium alloy extrusions[J]. Materials Science and Technology, 2007, 23(10): 1173-1180.

[18] 涂文斌, 柯黎明, 徐卫平. 搅拌摩擦加工制备MWCNTs/Al复合材料显微结构及硬度[J]. 复合材料学报, 2011, 28(6): 142-147.

TU Wen-bin, KE Li-ming , XU Wei-ping. Microstructure and hardness of MWCNTs/Al composite by friction stir processing[J]. Journal of Composite Materials, 2011, 28(6): 142-147.

Microstructure of CNTs/2024Al composites prepared by rotational friction extrusion

XING Li1, NI Yuan-ping1, 2, XU Wei-ping1, KE Li-ming1, JIAN Yuan-yuan1

(1. National Defense Key Disciplines Laboratory of Light Alloy Processing Science and Technology, Nanchang Hongkong University, Nanchang 330063, China;

2. Jiangxi Hongdu Aviation Industry Co., Ltd., Nanchang 330024, China)

Abstract: The carbon nanotubes (CNTs) reinforced 2024 Al matrix composites were fabricated by rotational friction extrusion (RFE).The crystal orientation, grain sizes, misorientation angle distributions and texture were analyzed by electron back scatter diffraction. The results show that the microstructure of aluminum matrix is the coarse strip, the average grain size is 48.67 μm and the large angle grain boundary content is 24.4%. After RFE, the microstructure of aluminum matrix becomes the fine equiaxed crystals by dynamic recrystallization. The average grain size of the RFE aluminum matrix decreases to 3.22 μm, and the large angle grain boundaries increases to 63.9%. With the increase of CNTs content, the average grain size of the CNTs/2024Al composites is gradually reduced to 1.97 μm and the ratio of large angle grain boundaries increases to 82.7% when the content of CNTs increases to 5%. CNTs can prevent the growth of the grains in the composites. The maximum pole density of aluminum matrix decreases from 10.8 to 4.18 and the rolling texture intensity decreases. The recrystallization textures of the composites are weakened by the addition of CNTs.

Key words: rotational friction extrusion; CNTs/2024Al composite; grain size; high angle grain boundary fraction; texture

Foundation item: Project(51364037) supported by the National Natural Science Foundation of China

Received date: 2016-07-26; Accepted date: 2016-12-28

Corresponding author: XING Li; Tel: +86-13576103681; E-mail: xingli_59@126.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51364037)

收稿日期:2016-07-26;修订日期:2016-12-28

通信作者:邢 丽,教授;电话:13576103681;E-mail: xingli_59@126.com