铸态铝镁钪合金的热塑性

徐国富1, 3,王 森1,牟申周1,蒋蓉蓉1,聂 波1, 2,尹志民1, 3

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 东北轻合金有限责任公司,黑龙江 哈尔滨,150060;

3. 有色金属材料科学与工程教育部重点实验室,湖南 长沙,410083)

摘 要:采用半连续铸锭冶金法制备一种成分为Al-6Mg-0.4(Sc+Zr)的合金,铸锭样品经均匀化退火后,测试其在250,300,350,400,450,475和500 ℃时的瞬时拉伸力学性能,借助扫描电镜(SEM)和透射电镜(TEM)的观察和分析,研究该合金的高温变形及断裂行为。结果表明:合金抗拉强度和屈服强度随温度的升高而降低,而其伸长率随温度的升高而增大;合金在300 ℃以下拉伸,断口为穿晶断裂型;在300 ℃以上拉伸,断口由穿晶断裂逐步向沿晶断裂转变;在400 ℃以上拉伸,断口基本上是沿晶断裂。在400 ℃以上变形,晶界区域有大量的强滑移带;在400 ℃以上晶内强度高于晶界强度,拉伸时变形优先在晶界区域发生,变形不均匀的结果导致铸坯热加工过程中开裂。Al-6Mg-0.4(Sc+Zr)合金铸坯的最佳热加工温度范围为350~400 ℃,在此条件下,合金的变形抗力较低,热塑性较好,又不出现热裂纹。

关键词:Al-Mg-Sc合金;热塑性;变形;断裂

中图分类号:TG146 文献标识码:A 文章编号:1672-7207(2009)02-0383-06

Thermoplastic of Al-Mg-Sc casted alloy

XU Guo-fu1, 3, WANG Sen1, MOU Shen-zhou1, JIANG Rong-rong1, NIE Bo1, 2, YIN Zhi-min1, 3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Northeast Light Alloy Co. Ltd., Harbin 150060, China;

3. Key Laboratory of Nonferrous Metal Materials Science and Engineering,

Ministry of Education, Changsha 410083, China)

Abstract: An Al-6Mg-0.4(Sc+Zr) alloy was prepared by semicontinuous ingot metallurgy method. In order to determine the best thermal process technics, the thermoplastic of Al-6Mg casted alloy was studied. The tensile properties of the casted sample were tested at 250, 300, 350, 400, 450, 475 and 500 ℃, respectively, after homogenizing annealing treatment. The high temperature deformation and fracture behavior of the alloy was investigated by scanning electron microscopy (SEM) and transmission electron microscopy (TEM). The results show that its tensile strength and yield strength decrease, while the elongation increases with the increase of temperature. The results of SEM fracture analysis show that the tensile fracture is transgranular below 300 ℃, the morphology changes gradually from transgranular fracture to a fracture appearance with the intergranular, and the fracture is intergranular above 400 ℃. TEM results also indicate that after deforming above 400 ℃, a large number of slip bands occur in grain boundary region. Over 400 ℃,the strength of the crystal is higher than that of the grain boundary and tensile deformation occurs firstly in the grain boundary region. Inhomogeneous deformation leads to casting thermal processing cracking. The best thermal processing temperature of Al-Mg-Sc casting alloy is between 350-400 ℃. Under these conditions, the deformation resistance of the alloy is lower and thermoplastic is better, so thermal crack will not arise.

Key words: Al-Mg-Sc alloy; thermoplastic; deformation; fracture

Al-Mg系合金具有良好的耐蚀性、导电性、导热性,并能长时间保持光亮的表面,具有较强的塑性和较大的比强度,焊接性能良好,该合金是热处理不可强化合金[1-2]。而与传统铝镁合金相比,铝镁钪合金具有较高的常温和低温力学性能以及较高的耐损伤容限,并具有优异的焊接性能、抗腐蚀性能和天然超塑成形性能,俄罗斯已成功地将铝镁钪合金应用在航天飞行器、新型战机和新型舰船上。目前,公开报道的关于Al-Mg合金的研究多集中于低镁含量的合金,并主要研究稀土元素对其性能的影响,对其高温性能及热轧工艺前期研究的报道不多,且多集中于高温压缩变形的研究,一些铝合金热变形流变应力方面的研究已有报道[3-8],其热加工时微观组织的变化已成为许多研究者的目标[9-11]。铝镁钪合金中由于添加了钪,其热加工性能大大改善,但仍存在Al-Mg系合金的一系列加工工艺缺点,即变形温度区间窄,道次变形量低,形变不均匀,容易出现局部应力集中导致热加工开裂等。在高温变形条件下, 由于晶界强度低于晶内强度, 合金的断裂形式一般表现为晶间断裂[12-16]。本文作者通过研究Al-6Mg合金的热塑性,分析铸态Al-6Mg合金在热变形过程中的变形行为,探索热加工条件下材料的动态性能与组织变化规律,以便为该材料热加工工艺的正确制定提供理论与实验依据。

1 实 验

1.1 实验材料

研究合金的化学成分为(质量分数):Mg 5.3%~ 6.3%,Mn 0.2%~0.6%,Sc+Zr 0.25%~0.4%,Ti 0.01%~ 0.05%,采用半连续铸造冶金法制备该合金的铸锭,铸锭均匀化退火后,经机加工成高温拉伸用棒材。

1.2 实验方法

拉伸实验在Instron8032拉伸机上进行,实验过程按照GB/T 4338—1995《金属高温拉伸试验方法》的有关规定进行,试样保温时间为15 min,拉伸速度为2 mm/min。分别测试了该合金在250,300,350,400,450,475和500 ℃时棒材的拉伸力学性能。在每个温度下对3个试样进行实验,取其平均值作为该状态下的测定值。

断口扫描在FEI公司生产的Sirion200场发射扫描电镜上进行。透射电镜试样经机械减薄至100 μm后冲成直径为3 mm的圆片,然后,在MTP-1双喷电解减薄仪上进行双喷减薄、穿孔。电解液为硝酸+甲醇,体积比为1?3,温度为-20~-30 ℃,电流为50 mA左右,在FEI公司生产的Tecnai G2 20ST型透射电子显微镜上进行显微组织结构的观察与分析。

2 实验结果

2.1 铸态合金不同温度下的力学性能

该合金不同温度时的拉伸力学性能见图1。可见,其抗拉强度随温度的升高而降低,屈服强度随温度的升高而降低,伸长率随温度的升高而增大。合金强度在250~300 ℃时下降得最快,在350~ 400 ℃时下降也较快。

1—σb; 2—σ0.2; 3—δ

图1 不同温度下铸态合金的力学性能

Fig.1 Mechanical properties of as-cast alloy at different temperatures

2.2 断口形貌

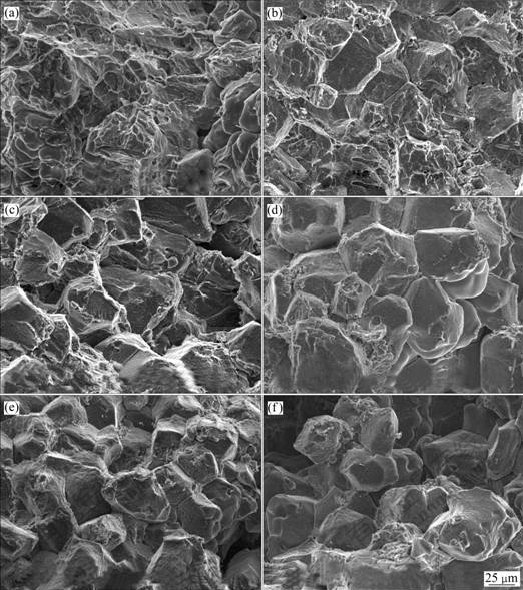

图2所示分别为铸态合金棒材在250,300,350,400,450和500 ℃时拉伸断口的SEM像。从图2可观察到,250 ℃时有明显的韧窝(图2(a)),属于晶内断裂;300 ℃时,既有扁平的韧窝,又有较明显的晶粒,大约各占一半(图2(b)),属于混合断裂;当温度超过350 ℃时,断口形貌表现为明显的沿晶断裂,能够清晰地观察到铸态晶粒,不同的是,随着温度的升高,所观察到的表面晶粒逐渐趋向于圆角化,表面变得光滑,晶粒与晶粒之间有微小的裂缝。

温度/℃: (a) 250; (b) 300; (c) 350; (d) 400; (e) 450; (d) 500

图2 不同温度下合金拉伸断口的SEM形貌

Fig.2 SEM morphologies of alloy at different temperatures

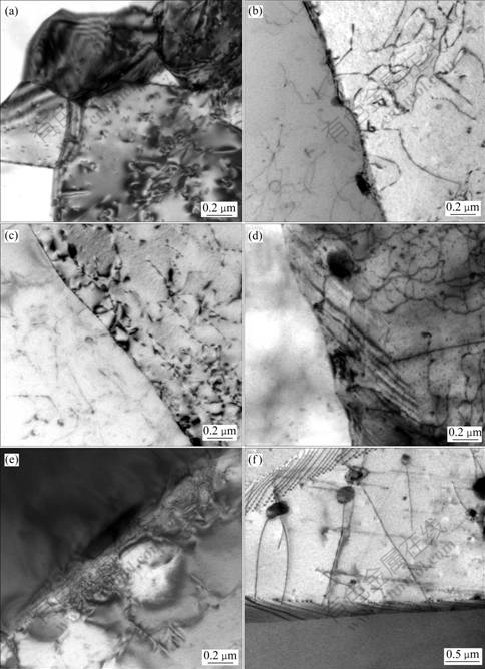

2.3 TEM显微组织

图3所示分别为铸态合金棒材在250,300,350,400,450和500 ℃时拉断后变形区的TEM像。可见,在350 ℃以下拉伸,变形区域的晶界比较平直,并有少量位错线缠结在晶界上;在400 ℃及以上温度拉伸时,在变形区晶界区域有大量的强滑移带(图3(d)~(f))。

温度/℃: (a) 250; (b) 300; (c) 350; (d) 400; (e) 450; (d) 500

图3 高温拉伸变形区的TEM像

Fig.3 TEM images of deformed area at high temperatures

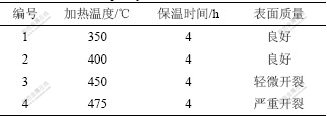

2.4 合金铸锭加热制度的确定

铝镁钪合金铸锭加热制度对板材质量的影响见表1。结果表明,铸锭在400 ℃及以下加热、轧制可以得到质量良好的板材,随着铸锭加热温度的升高,轧制开裂的倾向严重。

表1 铝镁钪合金铸锭加热制度对板材质量的影响

Table 1 Effect of heating system of Al-Mg-Sc ingot on quality of sheet metal

3 分析与讨论

3.1 拉伸温度对合金力学性能的影响

实验合金抗拉强度随温度的升高而降低,其屈服强度随温度的升高而降低,伸长率随温度的升高而增大。这是因为随着温度升高,热激活的作用增强,原子间的动能增大,原子间的临界切应力减弱,此外,动态回复及少量动态再结晶引起的软化程度也随温度的升高而增大,从而导致合金的应力降低。金属在较高温度下塑性变形时, 同时存在着加工硬化和动态软化2个过程。加工硬化是由于在外加应力下使位错密度增加, 位错之间互相交割, 以致于许多位错互相纠缠并被钉扎而难以运动。动态软化则是高温下使位错密度降低和位错重新排列成低能量状态的组织,使晶体的强度降低。在高温拉伸下动态软化的程度要比加工硬化程度更加明显,而且软化程度随温度的升高而增大,所以,合金的强度随温度升高而降低,伸长率随温度升高而升高。

合金强度在250~300 ℃时下降最快,这是由于在此温度转变时,其拉伸断裂的方式也发生了变化,由穿晶断裂向沿晶断裂转变(图2)。在300 ℃时,合金晶界的强度相对晶内强度已经大幅度下降,已有半数沿晶断裂,这使得合金的整体强度突然大幅度下降。该结果与实验结果一致。同样,在350~400 ℃时,又是由于混合断裂向沿晶断裂转变,导致强度下降较快。

3.2 拉伸温度对合金显微组织的影响

在250 ℃拉伸时有明显的韧窝,属于晶内断裂;在300 ℃时,既有扁平的韧窝,又有较明显的晶粒,大约各占一半,属于混合断裂;当温度超过350 ℃时,断口形貌表现为明显的沿晶断裂,这是由于晶粒内部位错、层错等缺陷,使晶粒内部的强度低于晶界强度,所以,在较低的温度拉伸出现的断裂都是晶内断裂;而随着拉伸温度升高,热激活作用增强,原子间的动能增大,使得晶粒内部的缺陷减少,强度随温度的升高下降的幅度比其在晶界下降的幅度要小得多,所以,晶内强度逐渐高于晶界强度,以致在较高温度发生沿晶断裂;而在300 ℃,晶内强度正好与晶界强度相当,故发生混合断裂。

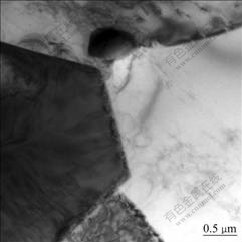

变形一般都是通过滑移进行的,沿每一个滑移面的滑行距离为几个原子到几千个原子的厚度。滑移不是一个连续过程,只有当应力达到临界应力后,才突然开始滑移,在滑移过程中,晶界和亚晶界都是运动的障碍,这些障碍造成位错堆积、晶格歪扭,最后在晶界发生运动。合金在高温拉伸时就发生了晶内、晶间滑移(图4)和晶体转动现象。

图4 450 ℃时拉伸变形区晶间滑移的TEM像

Fig.4 TEM image of intergranular slip of deformed area at 450 ℃

从TEM像来看,在低于350 ℃时晶界比较平直、光滑,有少量位错堆积,说明晶界没有发生明显的变形;而在400 ℃时,图3(d)中的晶界附近有大量的强滑移带,说明此时晶界发生运动,也就是晶界先于晶内运动,从而造成先在晶界处发生断裂形成沿晶断 裂,当温度更高时,此种情形一样明显,如图3(e)和(f)所示。

铸锭热轧最重要的就是铸锭加热温度的确定。过高的加热温度可能引起热脆、过烧或导致热轧粘辊,热轧塑性下降。若温度过低,则可能引起不均匀变形,变形抗力增大,铸锭开裂,热轧过程难以进行。通过以上分析可知,Al-6Mg-0.4(Sc+Zr)合金铸坯的最佳热加工温度范围应为350~400 ℃,在此条件下,合金的变形抗力较低,热塑性较好,又不出现热裂纹。

4 结 论

a. Al-6Mg-0.4(Sc+Zr)合金的抗拉强度和屈服强度随温度的升高而降低,最大差值?σb=171 MPa, ?σ0.2=149 MPa;其伸长率也随温度的升高而增大,最大差值?δ=9.7%。

b. Al-6Mg-0.4(Sc+Zr)合金在300 ℃以下拉伸,断口为穿晶型断裂;在300 ℃以上拉伸时,断口由穿晶型断裂逐步向沿晶型断裂转变;在400 ℃以上拉伸时,断口基本上是沿晶断裂,此时,晶内强度高于晶界强度,拉伸时变形优先在晶界区域发生。

c. Al-6Mg-0.4(Sc+Zr)合金铸坯的最佳热加工温度范围为350~400 ℃,在此条件下,合金的变形抗力较低,热塑性较好,又不出现热裂纹。

参考文献:

[1] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南大学出版社, 2005: 292.

WANG Zhu-tang, TIAN Rong-zhang. Manual of aluminium alloys and it’s processes[M]. Changsha: Central South University Press, 2005: 292.

[2] Filatov Y A, Yelagin V I, Zakharov V V. New Al-Mg-Sc alloys[J]. Materials Science and Engineering A, 2000, A280: 97-101.

[3] 沈 健. AA7050 铝合金的热加工变形特征[J]. 中国有色金属学报, 2001, 11(4): 593-597.

SHEN Jian. Hot deformation behaviors of AA7005 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(4): 593-597.

[4] 林高用, 张 辉, 郭武超, 等. 7075 铝合金热压缩变形流变应力[J]. 中国有色金属学报, 2001, 11(3): 412-415.

LIN Gao-yong, ZHANG Hui, GUO Wu-chao, et al. Flow stress of 7075 aluminum alloy during hot compression deformation[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(3): 412-415.

[5] 沈 健. 2091铝锂合金高温塑性变形行为研究[D]. 长沙: 中南工业大学材料科学与工程学院, 1996.

SHEN Jian. Study on the plastic deformation behavior of 2091 Al-Li alloy at elevated temperatures[D]. Changsha: School of Materials Science and Engineering, Central South University of Technology, 1996.

[6] Cho J R, Baeb W B, Hwang W J, et al. A study on the hot-deformation behavior and dynamic recrystallization of Al-5wt.%Mg alloy[J]. Journal of Materials Processing Technology, 2001, 118: 356-361.

[7] XU Guo-fu, MOU Shen-zhou, YIN Zhi-min, et al. Effect of trace rare earth element ER on Al-Zn-Mg alloy[J]. Transaction of Nonferrous Metals Society of China, 2006, 16(3): 598-603.

[8] 柏振海, 罗兵辉, 谭敦强. Al-Mg-Sc合金退火组织和性能[J]. 中南工业大学学报: 自然科学版, 2002, 33(6): 600-603.

BAI Zhen-hai, LUO Bing-hui, TAN Dun-qiang. Tempering on the microstructure and properties of Al-Mg-(Sc) alloy[J]. Journal of Central South University of Technology: Natural Science, 2002, 33(6): 600-603.

[9] Baxter G J, Zhu Q, Sellars C M. Effect of magnesium content on hot deformation and subsequent recrystallization behaviour of aluminum-magnesium alloys[C]//Proceedings of the Sixth International Conference on Aluminum Alloys. Toyohashi, 1998: 1233-1239.

[10] 张新明, 肖 蓉, 杜予暄, 等. 1420铝锂合金的温压变形及动态再结晶行为[J]. 中南大学学报: 自然科学版, 2006, 37(4): 629-634.

ZHANG Xin-ming, XIAO Rong, DU Yu-xuan, et al. Dynamic recrystallization mechanism during warm deformation in 1420 alloy[J]. Journal of Central South University: Science and Technology, 2006, 37(4): 629-634.

[11] Cho S H, Kim Y S, Yoo Y C, et al. The prediction of deformation resistance of Al6061 during hot deformation[J]. J Kor Inst Met Mater, 1998, 36(4): 502-508.

[12] Vedani M, Errico F D, Gariboldi E. Mechanical and fracture behaviour of aluminium-based discontinuously reinforced composites at hot working temperatures[J]. Composites Science and Technology, 2006, 66: 343-349.

[13] Raj R, Ashby M F. Intergranular fracture at elevated temperature[J]. Acta Metall, 1975, 23: 653-666.

[14] NIAN Zhang, WEI Tong. An experimental study on grain deformation and interactions in an Al-0.5%Mg multicrystal[J]. International Journal of Plasticity, 2004, 20: 523-542.

[15] Beere W, Speight M V. Creep cavitation by vacancy diffusion in plastically deforming solids[J]. Met Sci, 1978, 12: 172-176.

[16] Needeman A, Rice J R. Plastic creep flow effects in the diffusive cavitation of grain boundaries[J]. Acta Metall, 1980, 28(10): 1315-1332.

收稿日期:2008-01-16;修回日期:2008-03-25

基金项目:国家重点基础研究发展规划资助项目(2005CB623705);总装预研资助项目(51312010402)

通信作者:尹志民(1946-),男,湖南湘乡人,教授,博士,从事先进有色金属材料及其微观结构研究;电话:0731-8830262;E-mail: zmyin @mail.csu.edu.cn