文章编号:1004-0609(2010)09-1686-06

热处理工艺对单辊搅拌冷却成形Al-Mg-Sc合金

组织和力学性能的影响

张雪飞1, 周天国1, 温景林2

(1. 沈阳大学 机械工程学院, 沈阳 110044;2. 东北大学 材料与冶金学院,沈阳 110004)

摘 要:采用单辊搅拌冷却技术(Shearing-cooling-rolling,简称SCR技术)和在线固溶处理方法制备Al-3Mg-0.5Sc合金线材,研究不同热处理工艺对合金线材的微观组织和力学性能的影响。结果表明: SCR技术对合金线材产生强烈的单辊剪切塑性变形,在铝基体中产生大量的位错及初生Al3Sc强化相粒子,初生Al3Sc强化相粒子与热处理过程中沉淀析出的大量更为细小的次生Al3Sc强化相粒子共同与位错交互作用。当合金线材采用T6(SCR成形、在线固溶并人工时效)热处理制度时,320 ℃时效2 h后合金线材的抗拉强度为353 MPa;当采用T8(SCR成形、在线固溶、冷拔加工并人工时效)热处理制度时,合金材料的抗拉强度为378 MPa;当采用T9(SCR成形、在线固溶、人工时效并冷拔加工)热处理制度时,合金线材的抗拉强度为435 MPa。

关键词:Al-Mg-Sc合金;时效;单辊搅拌冷却(SCR);力学性能

中图分类号:TG355.12;TG146.2 文献标志码:A

Effects of heat treatment on microstructures and

mechanical properties of Al-Mg-Sc alloy wire formed by shearing-cooling-rolling technology

ZHANG Xue-fei1, ZHOU Tian-guo1, WEN Jing-lin2

(1. School of Mechanical Engineering, Shenyang University, Shenyang 110044, China;

(2. School of Materials and Metallurgy, Northeastern University, Shenyang 110004, China)

Abstract: Al-3Mg-0.5Sc alloys wires were prepared by shearing-cooling-rolling (SCR) and on-line solution, the effects of heat treatment on the microstructures and mechanical properties of those alloy wires formed by SCR were studied. The results show that primary Al3Sc and dislocation are formed in alloy wire by SCR deformation, and the finer secondary Al3Sc dispersoids precipitated from the supersaturated solution in the treatment can effectively pin dislocation. After T6(SCR forming, on-line solution, aging) treatment at 320 ℃ for 2 h, the tensile strength is 353 MPa. After T8(SCR forming, on-line solution, drawing, aging) treatment, the tensile strength is 378 MPa. After T9 (SCR forming, on-line solution, aging, drawing) treatment, the tensile strength is 435 MPa.

Key words: Al-Mg-Sc alloy; aging; shearing-cooling-rolling (SCR); mechanical property

Al-Mg合金中添加微量Sc,由于镁的固溶强化及热处理过程中析出的Al3Sc粒子的沉淀强化作用,使合金具有较高的强度和韧性、良好的耐蚀性和可焊 性[1-3]。俄罗斯、乌克兰、美国等在开发铝钪系合金方面已经取得很大进展并在航空领域得到应用[4-7]。我国对铝钪合金的研究尚处于研发阶段[8],而且主要是关于铝钪合金板材的研究,所研究合金采用传统轧制工艺制备。近几年虽已开始了铝钪合金棒材的研究[9-10],但所研究合金均采用铸造-均化-挤压工艺制备而成,该工艺与传统轧制工艺相比,生产周期较长,而且成本高。单辊搅拌冷却(SCR, shearing-cooling-rolling)技术[11]是一种连续浇注与连续成形一体化的有色金属高效、节能半固态成形新技术,具有短流程、净成形、产品长度不受限制、易于在线固溶等优点,适于铝钪合金线材的生产。目前,对于采用SCR技术制备的Al-Mg-Sc合金的组织及性能的研究报道还较少[12],而对于采用该技术制备的合金在热处理工艺方面的研究则更少见报道。

因此,本文作者主要研究不同热处理条件对Al-3Mg-0.5Sc合金线材的微观组织与性能及断口形貌的影响,为SCR成形Al-Mg-Sc合金线材的组织控制和热处理工艺优化及新产品的开发提供理论依据。

1 实验

采用SCR技术制备实验合金。合金成分为3%Mg(质量分数),0.5% Sc,其余为Al。在熔炼合金时,Al、Mg以纯金属的形式加入,Sc以Al-2%Sc中间合金的形式加入。根据文献[11, 13]确定SCR工艺成型,合金线材的工艺如下:浇注温度755~760 ℃,冷却强度15~18 L/min,在线固溶温度520 ℃,淬火冷却速度50 ℃/s;将线材按标准(L=10 d)制成拉伸试样。研究该合金线材在4种状态下的组织与性能,这4种状态分别是:SCR成形并在线固溶、T6(SCR成形、在线固溶并人工时效)、T8(SCR成形、在线固溶、冷拔加工并人工时效)和T9(SCR成形、在线固溶、人工时效并冷拔加工)。采用INSTRON4206材料拉伸试验机测试合金线材的抗拉强度和伸长率;采用扫描电镜观察不同状态下合金线材的拉伸断口形貌;采用透射电镜观察合金不同状态下的显微组织结构。透射电镜样品由机械预磨后双喷电解减薄制得,电解液为33%硝酸甲醇溶液。

2 结果与讨论

2.1 热处理工艺对合金线材力学性能的影响

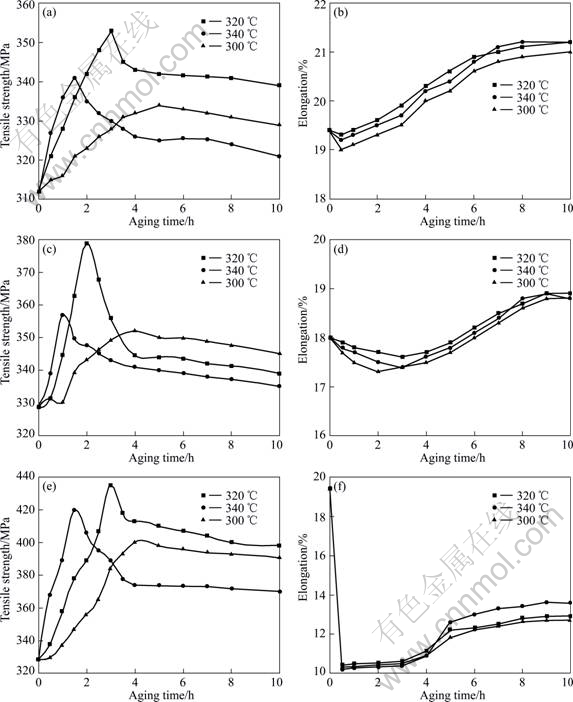

Al-3Mg-0.5Sc合金线材SCR成形并在线固溶处理后,抗拉强度为312 MPa,伸长率为23.8%。图1所示为合金线材的力学性能与人工时效时间的关系曲线。从图1可以看出,合金线材的抗拉强度与时效时间呈现先升后降的趋势,并且随时效温度的升高,合金线材的峰值抗拉强度呈下降趋势。在T6状态热处理过程中(见如图1(a)和(b)),伸长率变化幅度不大,在19%~21%;在320 ℃人工时效3 h时,合金线材出现峰值抗拉强度(353 MPa);在340 ℃人工时效1.5 h时,合金线材出现峰值抗拉强度(341 MPa);在300 ℃人工时效5 h时,合金线材出现峰值抗拉强度(334 MPa)。这是因为随着时效温度的降低,时效进程缓慢,因而需要更长的时间才能达到峰值抗拉强度,时效温度升高后,原子扩散加快,析出相的析出加快,同时析出相的粗化程度加大,因此,在340 ℃时效时,达到峰值抗拉强度的时间缩短,但峰值抗拉强度下降。从图1(c)和(d)可以看出,T8状态合金线材的抗拉强度与T6状态合金线材的抗拉强度相比有了明显的提高;在T8热处理状态,合金线材320 ℃人工时效2 h,达到峰值抗拉强度(378 MPa); 340 ℃人工时效1 h,达到峰值抗拉强度(356 MPa);300 ℃人工时效4 h,达到峰值抗拉强度(351 MPa)。在整个时效过程中,合金线材的伸长率变化不大。对比图1(a)和(c),T8状态合金线材经历不同的时效温度时效处理后,合金线材达到峰值抗拉强度所需的时间与T6状态合金线材所需时间相比,前者所用时间要短些。

从图1(e)可以看出,合金线材T9状态的峰值抗拉强度较T8状态的峰值抗拉强度有了显著提高。这是由于先经过人工时效后,合金线材因沉淀强化作用,具有较高的抗拉强度,在此基础上合金线材经冷加工变形又产生加工硬化作用,所以最终抗拉强度有了显著提高。合金线材在320 ℃人工时效3 h后再冷加工,达到峰值抗拉强度(435 MPa);在340 ℃人工时效1.5 h后再冷加工,达到峰值抗拉强度(420 MPa);在300 ℃人工时效5 h后再冷加工,达到峰值抗拉强度(400 MPa)。从图1(f)可见,在时效初期,合金线材的伸长率从冷加工状态时的19.4%下降到10.4%。

2.2 热处理工艺对合金线材微观组织的影响

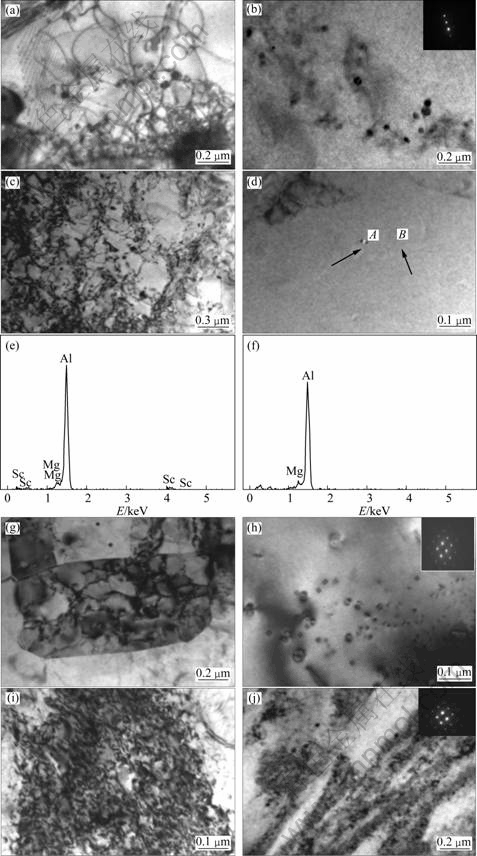

图2所示为不同状态合金线材的TEM像,可以看出:在铸态合金线材的组织中,存在较多的位错(见图2(a))及细小的第二相粒子(见图2(b))。这是由于在SCR成形过程中,合金经历了动态凝固-半固态变形-塑性变形3个阶段的连续过程,强烈的单辊剪切塑性变形使合金线材产生大量位错。第二相粒子尺寸为20~50 nm,其对应选区的电子衍射花样(见图1(b)),可见具有共格的超点阵衍射斑点;另外,粒子衬度呈双叶花瓣状及粒子中间的无衬度带也表明,这种第二相粒子与Al(α)基体共格,该粒子为初生Al3Sc粒子,可以作为良好的非均质晶核细化合金晶粒[13]。在SCR

图1 不同状态下合金线材的力学性能与时效时间的关系

Fig.1 Relationships between mechanical properties and aging time at different states: (a), (b)T6; (c), (d)T8; (e), (f)T9

成形过程中产生的部分位错,由于受到初生细小的Al3Sc粒子的钉扎和阻碍而无法移动,在时效(T6状态)过程中,可以看出这些位错的周围有更为细小的第二相粒子析出(见图2(c)),粒子尺寸为8~20 nm。这种细小的强化相粒子与位错交互作用,阻碍位错的运动;同时,在基体中也有这种细小的强化相粒子析出,但是数量不是很多。观察这种细小第二相粒子(见图2(d)),粒子衬度呈双叶花瓣状及粒子中间的无衬度带表明这种第二相粒子与Al(α)基体共格。对该粒子和其周围局部采用OXFORD INCA X-sight能谱分析。图2(d)中A,B点所对应的成分分析如图2(e)和2(f)所示,可以看出该粒子是含有Al和Sc的化合物。参考相关文献[8,13-15]可知,该细小的第二相粒子为次生Al3Sc强化相。正是由于这种细小的次生Al3Sc粒子的沉淀

图2 不同状态下Al-3Mg-0.5Sc合金线材的TEM像以及EDS分析

Fig.2 TEM images and EDS of alloys at different states: (a), (b) SCR; (c), (d), (e), (f) T6; (g), (h) T8; (i), (j) T9

析出,经过T6状态处理的合金线材较铸态合金线材的抗拉强度提高了41 MPa。采用T8状态处理合金线材时,由于合金线材在时效前经历大变形量的冷拉变形,因此,组织中形成了大量的位错缠结和位错缠结胞状组织,这些组织经过短时间时效后发生回复。图2(g)和(h)所示为合金线材T8状态的TEM像,可以看出,胞壁中的位错逐渐形成规则、清晰的低能态位错网络。经过冷拉变形的合金线材,当加热到时效温度时,在线固溶时保留在合金中的过饱和固溶体的脱溶和回复同时发生,这种脱溶过程因为冷加工塑性变形而加速,这与T8状态合金线材达到峰值抗拉强度所需的时间较T6状态合金线材所需时间相比较短的实验结果相吻合。同时,脱溶相质点(第二相质点)因冷变形而更加弥散(见图2(h)),可以看出大量弥散的第二相质点。从其电子衍射花样可见,有超点阵衍射斑点,表明时效析出的大量细小的Al3Sc强化相粒子与基体共格;另外,粒子衬度呈双叶花瓣状,粒子中间无衬度带,表明该粒子与Al(α)基体共格,粒子尺寸为5~17 nm。T8状态合金线材较T6状态合金线材的抗拉强度提高了25 MPa。

图2(i)和(j)所示为合金线材T9状态的TEM像,可以看出:合金线材经过人工时效后进行较大变形量的冷拉加工,合金组织中出现了大量的位错缠结(见图2(i));由于人工时效沉淀析出大量强化相粒子,位错运动更加困难,位错组织变得密度很高,而且更为复杂,在合金中出现大量间距很小的变形带(见图2(j)),同时在变形带的周围分布着一些细小的强化相粒子。但是从图2(j)中可以观察到,合金线材人工时效后经过冷拉变形,在产生大量位错缠结的同时,强化相质点的双叶花瓣状共格衬度像不再出现,但观察图2(j)对应的衍射谱,可以清楚地看出超点阵衍射斑点的存在,说明时效后冷拉状态下合金组织内仍存在大量的共格第二相粒子,只是这些共格粒子未能显示出其双叶花瓣状共格衬度而已,分析其原因如下:这是由于较大的冷拉变形量在合金组织内产生了大的应变场,以致原来的强化相质点的共格应变场显得微不足道而被掩盖,因此,在透射电子显微组织中未能显示出其特有的双叶花瓣状共格衬度特征。T9状态合金线材较T8状态合金线材的抗拉强度提高了57 MPa。可见采用不同的热处理,对于合金线材的抗拉强度产生很大的影响。

2.3 合金线材的断口形貌

不同热处理状态Al-3Mg-0.5Sc合金线材断口扫描形貌如图3所示。从图3(a)可以看出断口中存在大量韧窝,韧窝大小均匀且韧窝较深,这与该状态的合金线材具有良好的塑性(23.8%)相符。从图3(b)可以观察到在断口上也有大量的韧窝,韧窝较深,但与图3(a)

图3 不同状态下合金线材的断口形貌

Fig.3 Fracture morphologies of alloy wires at different states: (a) SCR; (b) T6; (c) T8; (d)T9

相比韧窝大小不均匀,这也与铸态合金线材的塑性优于T6状态合金线材相吻合。从图3可以观察到在断口上也有大量的韧窝,这些韧窝比图3(d)(合金线材T9状态拉伸断口形貌)中显示的韧窝相比大些,数量更少,同样符合T9热处理状态合金线材的塑性与T8热处理状态合金线材的塑性相比要差这一实验结果。对不同状态实验合金线材拉伸断口中的韧窝进行成分扫描,发现有含Fe的夹杂物,但并没有测出第二相粒子的存在,可能是这种第二相粒子太小,通过扫描电镜没有办法检测。

3 结论

1) SCR技术对Al-3Mg-0.5Sc合金线材具有剪切细化功能,在铝基体中产生大量的位错,时效析出大量细小的Al3Sc强化相粒子与位错交互作用。

2) 合金线材的抗拉强度与时效时间呈现先上升后下降的趋势,并且随时效温度的升高,合金线材的峰值抗拉强度呈现下降的趋势。

3) 当合金线材采用T6热处理制度时,320 ℃时效2 h合金线材的峰值抗拉强度为353 MPa;采用T8热处理制度时,合金线材的峰值抗拉强度为378 MPa;采用T9热处理制度时,合金线材的峰值抗拉强度为435 MPa。

REFERENCES

[1] DAVYDOV V G, ROSTOVA T D, ZAKHAROV V V, FILATOV, YELAGIN V I. Scientific principles of making an alloying addition of scandium to aluminum alloys[J]. Materials Science and Engineering A, 2000, 280(1): 30-36.

[2] LATHABAI S, LOYD P G. The effect of scandium on the microstructure, mechanical properties and weld ability of a cast Al-Mg alloy[J]. Acta Materials, 2002, 50(17): 4275-4292.

[3] WOO K D, KIM S W. Effects size on high temperature deformation behavior of Al-4Mg-0.4Sc alloy[J]. Materials Letters, 2003, 57: 1903-1909.

[4] EMMANUELLE A M, DAVID N S. Effect of Mg addition on the creep and yield behavior of an Al-Sc alloy[J]. Acta Materialia, 2003, 51(16): 4751-4760.

[5] RIDDLE Y W, SANDERS T H. A study of coarsening, recrystallization, and morphology of microstructure in Al-Sc-(Zr)-Mg alloy[J]. Metallurgical and Materials Transactions A, 2004, 35(1): 341-350.

[6] ROYSET J, RYUM N. Kinetics and mechanisms of precipitation in an Al-0.2wt% Sc alloy[J]. Materials Science and Engineering A, 2005, 396: 409-422.

[7] VINOGRADOV A, WASHIKITA A. Fatigue life of fine-grain Al-Mg-Sc alloys produced by equal-channel angular pressing[J]. Materials Science and Engineering A, 2003, 349: 318-326.

[8] 潘青林, 尹志民, 邹景霞, 陈显明, 张传福. 微量Sc在Al-Mg合金中的作用[J]. 金属学报, 2001, 37(7): 750-753.

PAN Qing-lin, YIN Zhi-min, ZOU Jing-xia, CHEN Xian-ming, ZHANG Chuan-fu. Effect of minor Sc addition on microstructure and tensile property of Al-Mg alloy[J]. Acta Metallurgica Sinica, 2001, 37(7): 750-753.

[9] DAI Xiao-yuan, XIA Chang-qing, PENG Xiao-min, MA Ke. Structure and properties of an ultra-high strength 7xxx aluminum alloy contained Sc and Zr[J]. Journal of University of Science and Technology Beijing, 2008, 15(3): 276-279.

[10] LIU Zhong-xia, LI Zi-jiong, WANG Ming-xing, WENG Yong-gang. Effect of complex alloying of Sc, Zr and Ti on the microstructure and mechanical properties of Al-5Mg alloys[J]. Materials Science and Engineering A, 2008, 483/484: 120-122.

[11] 管仁国, 陈彦博, 温景林. 单辊剪切/冷却工艺对LY11半固态合金组织的影响[J]. 中国有色金属学报, 2001, 11(s1): 5-8.

GUAN Ren-guo, CHEN Yan-bo, WEN Jing-lin. Effects of processing factors on microstructure of semi-solid LY11 alloy during single-roll shearing/cooling process[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(s1): 5-8.

[12] 张雪飞, 王顺成, 石 路, 李俊鹏, 李 罡, 温景林. SCR成形Al-3Mg-0.4Sc 合金线材的组织与性能[J]. 中国有色金属学报, 2006, 16(8): 1423-1428.

ZHANG Xue-fei, WANG Shun-cheng, SHI Lu, LI Jun-peng, LI Gang, WEN Jing-lin. Microstructure and property of Al-3Mg-0.4Sc alloy wire formed by SCR technology[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(8): 1423-1428.

[13] DRITS M E, TOROPOVA L S, BYKOV YU G., GUSHCHINA F L, ELAGIN V I, FILATOV YU A. The grain refinement of Al-Sc alloy[J]. Russ Metal, 1983(1): 150-157.

[14] NORMAN A F, PRANGNELLA P B, McEWENB R S. The solidification behavior of dilute aluminum-scandium alloys[J]. Acta Materialia A, 1998, 46(16): 5715-5732.

[15] ELAGIN V I, ZAKHAROV, V V, ROSTOVA T D. Scandium-alloyed aluminum alloys [J]. Metal Science and Heat Treatment, 1992, 34(1): 37-44.

(编辑 杨 华)

基金项目:国家自然科学基金与上海宝钢集团联合资助项目(50274020)

收稿日期:2009-03-31;修订日期:2010-06-30

通信作者:张雪飞,讲师,博士;电话:024-81038636, 15242483928;E-mail: zxfzxm@163.com