文章编号:1004-0609(2007)11-1792-06

Al-Mg-Sc合金热塑性和热轧工艺

聂 波1, 2,尹志民1,徐国富1,牟申周1,蒋蓉蓉1,丛福官2

(1. 中南大学 材料科学与工程学院,长沙 410083;

2. 东北轻合金有限责任公司,哈尔滨 150060)

摘 要:采用高温瞬时拉伸试验和电子显微镜研究Al-Mg-Sc合金在高温下的塑性变形特征。结果表明,随试验温度升高,合金高温瞬时拉伸强度下降,而塑性增加,350~400 ℃实验温度下合金的变形抗力相对较低,热塑性较好。大生产条件下的热加工工艺验证试验也表明,350~470 ℃实验温度范围内铸锭热加工温度越高,轧制开裂的几率越大,Al-Mg-Sc合金适宜的热轧温度为350~420 ℃。另外,大生产条件下还应严格控制热加工道次和道次变形量,开始轧制时道次压下量和轧制速度不宜过大,轧制变形量超过25%后,应逐渐加大道次压下量和提高轧制速度,使变形深透到整个轧件厚度。

关键词:Al-Mg-Sc合金;热塑性;热轧工艺;显微组织

中图分类号:TG 111.7 文献标识码:A

Thermo-plasticity and heat rolling processing of Al-Mg-Sc alloy

NIE Bo1, 2, YIN Zhi-min1, XU Guo-fu1, MU Shen-zhou1, JIANG Rong-rong1, CONG Fu-guan2

(1. School of Materials Science and Technology, Central South University, Changsha 410083, China;

2. Northeast Light Alloy Co. Ltd., Harbin 150060, China)

Abstract: The flow behavior of Al-Mg-Sc alloy during high temperature plastic deformation was studied by high temperature tensile test and electronic microstructure analysis. The results show that the strength decreases and the plasticity increases with the increase of tensile testing temperature. The strength is lower and the hot plasticity is better when the test temperature is 350?400 ℃. The heat rolling processing at industrial production condition also shows that the rolling crack is easily formed when the heat processing temperature is higher. The best rolling temperature of Al-Mg-Sc alloy is 350?420 ℃. In addition, at the industrial production condition the heat processing pass and pass deformation ratio should be controlled. The pass deformation amount and rolling velocity should not be large at beginning. When deformation ratio is beyond 25%, the pass deformation ratio and rolling velocity should be gradually enhanced.

Key words: Al-Mg-Sc aluminum alloy; thermo-plasticity; hot rolling; microstructure

Al-Mg-Sc合金是新一代中强可焊耐蚀铝合 金[1?4]。由于钪的添加,其热加工性能有所改善,但仍存在Al-Mg系合金的一系列热加工工艺缺点,即变形温度区间窄、道次变形量较低、形变不均匀、容易出现局部应力集中导致热加工开裂等。文献[5?7]针对上述特点研究了Al-Mg系合金的轧制工艺,吕新宇[5]对5083合金板材轧制工艺的研究表明,铸锭在450~ 480 ℃和合理的道次压下量进行轧制,可获得形状、表面质量良好的板材。迟志坤等[6]研究了5A06铝合金热轧时的断裂行为,研究表明,5A06合金在高温轧制时,容易产生断裂,断口表现为解理和沿晶混合型。但对于Al-Mg-Sc合金热加工工艺的研究,尤其是大生产条件下的研究,国内还鲜见报道。本文作者首先通过热塑性试验,考察不同实验温度下Al-Mg-Sc合金的变形抗力和热塑性变化规律,在此基础上,针对大规格板材的具体性能要求,并结合生产技术条件,最终确定该合金的热加工工艺参数,旨在为新合金的研制和开发提供理论和实验依据。

1 实验

采用半连铸技术制备Al-Mg-Sc合金铸锭,铸锭尺寸为300 mm×1 000 mm,化学成分见表1。

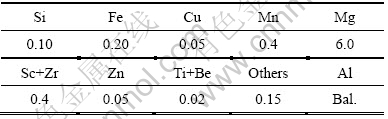

表1 Al-Mg-Sc合金的化学成分

Table 1 Chemical composition of studied alloy (mass fraction, %)

铸锭经350 ℃,8 h均匀化退火,取样车削成系列棒状试样。热塑性试验温度为250、300、350、400、450、475、500和550 ℃,热塑性拉伸试验在Instron8032拉伸机上进行,试样保温时间为15 min,拉伸速度为2 mm/min。每个温度做3个试样,取其平均值作为该状态下的测定值。为了防止断口氧化和保留热塑性拉伸过程的组织特征,将拉伸断口快速转入水冷的无水乙醇中,之后在Sirion?200扫描电子显微镜上进行断口分析,透射样品取自紧靠断口的区域。

大生产条件下的热加工工艺主要研究铸锭热轧前的加热温度、道次变形量和总变形量等工艺参数对热轧板坯工艺性能的影响。采用300 mm×1 000 mm铸锭,在热塑性的研究结果基础上,选择不同的热加工温度(350~470 ℃)和不同的轧制参数在四重可逆式热轧机上进行热轧,探索实际的最佳热加工工艺,热轧总变形率大于70%。

2 实验结果

2.1 Al-Mg-Sc合金热塑性实验

1) Al-Mg-Sc合金高温瞬时拉伸力学性能

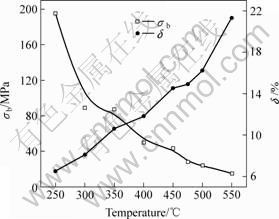

Al-Mg-Sc合金在不同温度下的拉伸力学性能见图1。结果表明,Al-Mg-Sc合金铸锭高温瞬时拉伸时抗拉强度随温度的升高而降低,延伸率和断面收缩率则随温度的升高而增大。350~400 ℃实验温度下合金的变形抗力相对较低,热塑性较好。

图1 不同温度下Al-Mg-Sc合金的拉伸力学性能

Fig.1 Tensile properties of Al-Mg-Sc alloy at different test temperatures

2) Al-Mg-Sc合金高温瞬时拉伸断口特征

不同实验温度下合金瞬时拉伸断口特征见图2。可见不同温度下合金的断口特征明显不同。较低实验温度下,断口呈穿晶断裂特征;升高实验温度,断口呈典型的沿晶断裂特征,表明高温下晶界被弱化,棒状试样侧面肉眼可观察到热裂纹,说明在此条件下合金的热塑性很差。

图2 不同温度下Al-Mg-Sc合金的断口特征

Fig.2 Fractograph of Al-Mg-Sc alloy at different test temperatures: (a) 250 ℃; (b) 400 ℃

3) 不同温度下合金的透射电子显微组织

不同实验温度下试样上靠近断口的变形区域的透射电子显微组织见图3。结果表明,较低温度下,除了晶内位错亚结构以外,试样上接近断口变形区域的晶内和晶界特征与拉伸变形前没有太大的区别。升高实验温度,试样上接近断口的变形区域的晶界附近存在密集的位错亚结构和明显的晶界强滑移带(如图3中箭头所示),表明高温下晶界被弱化,变形集中在晶界区域。

图3 不同实验温度下Al-Mg-Sc合金的透射电子显微组织

Fig.3 TEM images of Al-Mg-Sc alloy at different temperatures: (a), (b) 250 ℃; (c), (d) 400 ℃; (c) Within grain; (d) Intensive sliding bands

2.2 大生产条件下的热轧工艺

2.2.1 Al-Mg-Sc合金铸锭加热温度的确定

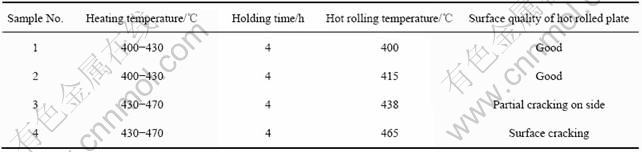

大生产条件下Al-Mg-Sc合金铸锭热轧加工过程加热制度对板材质量的影响见表2。结果表明,在实验温度范围内,铸锭在420 ℃以下热轧,效果较好,可以得到质量良好的热轧板坯,随着热加工温度的升高,热轧开裂的倾向变严重。

表2 Al-Mg-Sc合金铸锭加热温度对热轧板材质量的影响

Table 2 Effect of heating processing of ingot on surface quality of hot rolled plate

2.2.2 Al-Mg-Sc合金道次加工率的确定

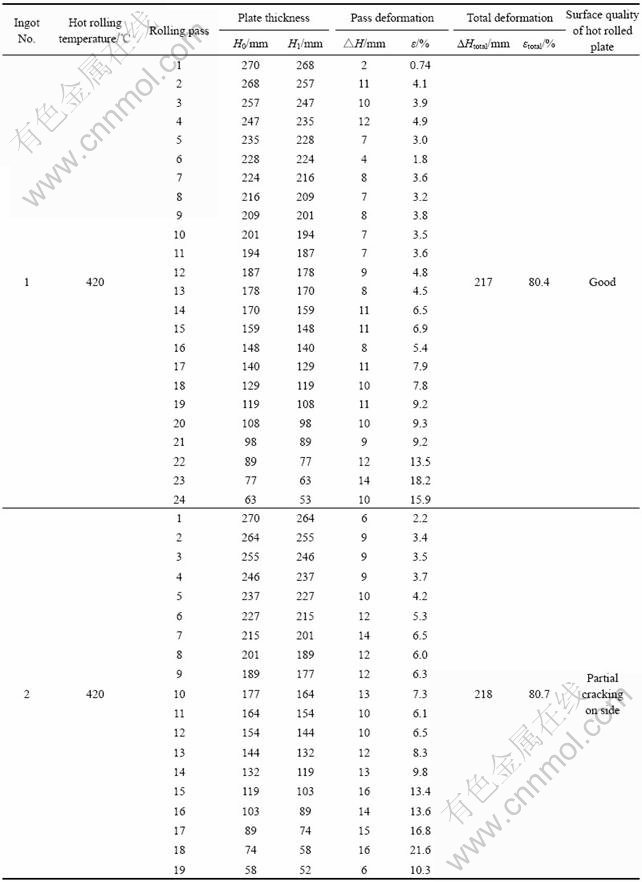

道次变形量是影响板材轧制质量的重要因素之 一[8?11]。大生产条件下Al-Mg-Sc合金道次变形量对板材轧制质量的影响见表3。结果表明,同等温度区间内,道次压下量的变化会明显影响板材的表面质量。

表3 道次变形量对板材轧制质量的影响

Table 3 Effect of pass deformation on surface quality of Al-Mg-Sc alloy hot rolled plate

Al-Mg-Sc合金轧制应逐步加大道次压下量,采用多道次小压下量的轧制工艺。开始道次变形只发生在试样表层,试样中部未发生明显的塑性变形,仍保留为均匀化处理后的铸态组织结构,加工率不宜过大,控制在3%~5%;轧制中期,随着变形道次增加,变形温度不断降低,而应变速率不断增加,晶粒开始破碎并被拉长,形成亚结构,这时应加大道次加工率,使轧件尽快越过易碎区,道次加工率应控制在5%~10%;在轧制后期,为了弥补轧制的热损失,同时为了保证热轧产品最终的组织和性能,可采用10%~20%的道次加工率。

3 分析与讨论

3.1 Al-Mg-Sc合金适宜的热加工温度范围

铸锭热轧最重要的就是确定铸锭加热温度,过高的加热温度可能引起热脆、过烧或导致热轧粘辊,热轧塑性下降;温度过低则可能引起不均匀变形,变形抗力增大,铸锭开裂,热轧过程难以进行。通常热轧温度是根据已有的相图、塑性图、变形抗力图和第二类结晶图来确定。对于新型合金的热加工特性,只能通过高温瞬时拉伸试验和生产现场验证试验来确定。

Al-Mg-Sc合金热变形过程中的流变应力与变形体内的位错组态密切相关[12?15]。变形初期,需要较高的能量来启动位错,随着变形程度的加大,易于形成位错缠结,而这种位错缠结有效阻碍金属变形,因此变形抗力增大。与此同时,位错由于热激活程度的不同而发生动态回复或者再结晶,加工硬化效应减弱或消除,合金的热塑性提高,流变进入稳态变形。图1所示的热塑性曲线表明:变形温度越高,变形抗力越小,但是变形温度达到一定值时,由于高温下产生晶界的弱化,使晶界发生滑动,这时材料无法承受较大的轧制力,坯料在热轧过程中容易开裂。大生产条件下的热加工工艺试验也表明:铸锭在420 ℃以下热轧,热轧效果较好;继续升高热加工温度,热轧板坯就会开裂。因此Al-Mg-Sc适宜的热加工温度范围应当在350~420 ℃之间。

3.2 Al-Mg-Sc合金适宜的热加工道次和道次加工率

合金热轧时,内外层金属流动不均匀,外层流动快,内层流动慢,内层金属会受到外层金属的拉应力作用。当开始轧制时,由于外摩擦和变形区形状因子的影响,造成沿试样厚度的变形极不均匀,变形只发生在试样表层而不深入,试样中部未发生明显的塑性变形,仍保留为均匀化处理后的铸态组织结构,其塑性比同种合金变形组织的低得多。这时,若突然加大道次压下量,心部铸造组织层承受不了外层金属的强大拉应力作用,则产生不均匀变形,形成紊流,出现大量强烈变形带,并在变形带上产生小裂口。随着变形道次增加,变形温度不断降低,而应变速率不断增加,晶粒开始破碎并被拉长,形成亚结构,中心部位变形量达到进入稳态流变的应变值,这时可逐渐加大道次变形量,使心部得到充分变形。因此Al-Mg-Sc合金热轧过程中要综合考虑热轧温度、热轧速度和道次加工率,铸块在开始轧制时为铸造组织,塑性较差,所以在开始轧制的几个道次,道次压下量和轧制速度不宜过大。之后轧件从铸造组织逐渐过渡到加工变形组织,应逐渐加大道次压下量和提高轧制速度,使变形深透到整个轧件厚度。本实验研究结果表明,在350~420 ℃热加工温度范围内,Al-Mg-Sc合金轧制应逐步加大道次压下量,采用多道次小压下量的轧制工艺。轧制初期,道次加工率控制在3%~5%;轧制中期,道次加工率应控制在5%~10%;轧制后期,可采用10%~20%的道次加工率。该热加工道次和道次加工率工艺特点与Al-Mg系合金变形温度区间窄、道次变形量较低、形变不均匀、容易出现局部应力集中导致热加工开裂的特点相一致。

4 结论

1) 随着热塑性实验温度的升高,Al-Mg-Sc合金的高温瞬时强度不断降低,塑性升高,350~400 ℃变形抗力较低,热塑性较好。

2) 热加工温度越高,轧制开裂的几率越大,Al-Mg-Sc合金适宜的热轧温度为350~420 ℃。

3) 大生产条件下,应严格控制道次和道次变形量,开始轧制时道次压下量和轧制速度不宜过大,轧制变形量超过25%后,应逐渐加大道次压下量和提高轧制速度,使变形深透到整个轧件厚度。

REFERENCES

[1] Filator Y A, Yelagin V I, Zakharov. New Al-Mg-Sc alloy[J]. Mater Sci Eng A, 2000, 289(1): 97?101.

[2] 张永红. Al-Mg-Sc-Zr合金再结晶行为的研究[J]. 铝加工, 2001, 24(6): 42?44.

ZHANG Yong-hong. Study on action of recrystallization of Al-Mg-Sc-Zr alloy[J]. Aluminium Fabrication, 2001, 24(6): 42?44.

[3] Ahmad Z. The corrosion behavior of scandium alloying A15052 in neutral sodium chloride solution[J]. Corrosion Science, 2001, 43: 1227?1243.

[4] Davydov V G. Scientific principles making an alloying addition of scandium to aluminum alloys[J]. Mater Sci Eng, 2000, 280(1): 30?36.

[5] 吕新宇. 5083铝合金热轧板研究[J]. 轻合金加工技术, 2002, 30(3): 15?19.

L? Xin-yu. Study on 5083 aluminium alloy hot rolling plate[J]. Light Alloy Fabrication Technology, 2002, 30(3): 15?19.

[6] 迟志坤, 唐明君, 吉泽升, 江志邦. 微量元素对5A06铝合金热轧时断裂行为的影响[J]. 轻合金加工技术, 2005, 33(6): 16?21.

CHI Zhi-kun, TANG Ming-jun, JI Ze-sheng, JIANG Zhi-bang. Effect of minor element on fracture of 5A06 alumiunm alloy hot rolling[J]. Light Alloy Fabrication Technology, 2005, 33(6): 16?21.

[7] Deschamps A, Péron S, Bréchent Y. High temperature cleavage fracture in 5383 aluminium alloy[J]. Mater Sci Eng, 2001, 319?321: 583?586.

[8] 唐 伟, 陈丽君, 王立波. 6082-T651铝合金厚板拉伸断裂原因分析[J]. 轻合金加工技术, 2003, 31(11): 17?19.

TANG Wei, CHEN Li-jun, WANG Li-bo. Cause and analysis for 6082-T651 aluminium alloy streched plate of the crack[J]. Light Alloy Fabrication Technology, 2003, 31(1): 17?19.

[9] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 长沙: 中南大学出版社, 2005: 505?506.

WANG Zhu-tang, TIAN Rong-zhang. Handbook of aluminum alloy and processing[M]. Changsha: Central South University Press, 2005: 505?506.

[10] 肖亚庆. 铝加工技术实用手册[M]. 北京: 冶金工业出版社, 2005: 349?370.

XIAO Yia-qing. Practical handbook of aluminum fabrication technology[M]. Beijing: Metallurgical Industry Press, 2005: 349?370.

[11] 赵永军, 师雪飞, 张景学, 马英义. 5A06-H34厚板生产工艺研究[J]. 轻合金加工技术, 2005, 33(5): 29?32.

ZHAO Yong-jun, SHI Xue-fei, ZHANG Jing-xue, MA Ying-yi. Research about production technology of 5A06-H34 aluminium alloy plate[J]. Light Alloy Fabrication Technology, 2005, 33(5): 29?32.

[12] 张 辉, 彭大暑, 杨立斌, 孟力平. 铝合金多道次热轧流变应力的研究[J]. 热加工工艺, 2000(5): 6?8.

ZHANG Hui, PENG Da-shu, YANG Li-bin, MENG Li-ping. The study of flow stress for multipass hot rolling of aluminium alloys[J]. Hot Working Technology, 2000(5): 6?8.

[13] Poirier J P, 关德林. 晶体的高温塑性变形[M]. 大连: 大连理工大学出版社, 1989.

Poirier J P, GUAN De-lin. High temperature plastic deformation of crystals[M]. Dalian: Dalian University of Technology Press, 1989.

[14] 沈 健. AA7005铝合金的热加工变形特性[J]. 中国有色金属学报, 2001, 11(4): 593?597.

SHEN Jian. Hot deformation behaviours of AA7005 aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(4): 593?597.

[15] 余 琨, 黎文献, 王日初, 马正青, 赵 俊, 孟力平. Mg-5.6Zn-0.7Zr-0.8Nd合金高温塑性变形的热/力模拟研究[J]. 金属学报, 2003, 39(5): 492?498.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing, ZHAO Jun, MENG Li-ping. Hot compressive deformation simulation of Mg-5.6Zn-0.7Zr-0.8Nd alloy at elevated temperature[J]. Acta Metallurgica, 2003, 39(5): 492?498.

基金项目:国家十五科技攻关资助项目(MKPT-2004-16ZD);国家重点基础研究发展计划资助项目(2005CB623705)

收稿日期:2007-07-23;修订日期:2007-10-08

通讯作者:尹志民,教授;电话:0731-8830262;E-mail: zmyin@163.com

(编辑 杨 兵)