文章编号:1004-0609(2007)07-1058-05

双级时效处理对喷射沉积Al-Zn-Mg-Cu合金

微观组织和力学性能的影响

王 锋,熊柏青,张永安,朱宝宏,刘红伟,何小青

(北京有色金属研究总院 有色金属材料制备加工国家重点实验室,北京 100088)

摘 要:利用喷射成形技术制备Al-10.8Zn-2.8Mg-1.9Cu合金。借助透射电镜、高分辨电子显微镜和拉伸性能测试等手段研究双级时效处理对喷射沉积Al-Zn-Mg-Cu合金微观组织和力学性能的影响。结果表明,合金经120 ℃, 16 h+150 ℃, 2 h双级时效后,晶内析出相略有长大,此时合金的强化机制是GP区和h′相的综合强化。与峰时效条件相比,双级时效后合金的抗拉强度和屈服强度分别降低4.5%和3.5%,但合金组织中的晶界析出相完全断开,这对提高合金的抗应力腐蚀能力具有重要意义。

关键词:Al-Zn-Mg-Cu合金;喷射成形;双级时效;微观组织;力学性能

中图分类号:TG 146.2 文献标识码:A

Effect of two-step aging treatment on microstructure and mechanical properties of spray-deposited Al-10.8Zn-2.8Mg-1.9Cu alloy

WANG Feng, XIONG Bai-qing, ZHANG Yong-an, ZHU Bao-hong, LIU Hong-wei, HE Xiao-qing

(State Key Laboratory for Fabrication and Processing of Nonferrous Metals,

General Research Institute for Nonferrous Metals, Beijing 100088, China)

Abstract: Al-10.8Zn-2.8Mg-1.9Cu alloy was fabricated by spray atomization and deposition technique. The microstructure and mechanical properties of spray-deposited Al-10.8Zn-2.8Mg-1.9Cu alloy after two-step aging treatment at 110 ℃ and 150 ℃ were investigated using transmission electron microscopy (TEM), high-resolution electron microscopy (HREM) and tensile tests. The results indicate that the GP zones and h′ phase are major precipitates for the alloy under two-step aging condition. The discontinuous grain boundary precipitates are favorable to SCC resistance at over-aged condition, which reduces its ultimate tensile strength and yield strength by about 4.5% and 3.5% compared with those under peak-aged condition, respectively.

Key words: Al-Zn-Mg-Cu alloy; spray deposition; two-step aging treatment; microstructure; mechanical properties

7000系铝合金因其具有高强、高韧、低密度等优良性能在航空航天领域被广泛应用,在新一代轻质高强材料中占有重要的地位[1-2]。然而,高锌含量的Al-Zn-Mg-Cu 合金普遍存在着应力腐蚀现象[3]。合金微观组织对应力腐蚀的敏感性主要取决于材料的化学成分和热处理工艺[4-6]。双级时效处理可以降低Al-Zn-Mg-Cu 合金的应力腐蚀敏感性,但这种热处理制度会导致合金的强度下降[7-10]。

7000系铝合金作为一种典型的热处理时效强化型合金,长期以来,发达国家通过优化合金中各种添加元素并不断改进铸造、变形加工和后续热处理工艺来提高铝合金的综合性能,相继开发了7075、7049、7050、7055、7076、B95和B96等性能更高的合金,使合金的抗拉强度达到680 MPa[11-13]。20世纪80年代,日本住友轻金属公司利用快速凝固技术(平流铸造)在实验室里成功制备出极限抗拉强度超过700 MPa的铝合金。20世纪90年代,随着以喷射成形为代表的新一代快速凝固技术走向大规模实用化,使得以规模生产制备各种超高强7000系铝合金变为现实。利用喷射成形技术制备的材料可在一次冶金操作中完成,克服了传统快凝粉末冶金工艺复杂和氧化严重的缺点。

本文作者主要研究了双级时效处理对喷射成形Al-10.8Zn-2.8Mg-1.9Cu合金微观组织和力学性能的影响,分析了双级时效后合金的强化机制。

1 实验

实验所用合金的化学成分为:10.8% Zn, 2.8% Mg, 1.9% Cu, 0.16% Zr, 其余为Al (质量分数)。喷射成形实验是在北京有色金属研究总院自行研制的SF-200型设备上完成的,雾化气体为氮气,雾化温度为800~ 900 ℃,雾化压力为0.5~0.8 MPa,沉积距离为400~ 500 mm。合金沉积坯在415 ℃下挤压成直径20 mm的棒材,挤压比为39?1,挤压后棒材空冷。热处理实验采用双级固溶:450 ℃,1 h + 475 ℃,1.5 h后试样水淬至室温。合金的时效工艺选择如下2种不同的制度:1) T6峰时效(120 ℃,16 h);2) T7双级时效(120 ℃,16 h + 150 ℃,1,2,3,4 h)。采用JEM-2000FX型透射电镜和 JEM-2100型高分辨电镜对材料的微观组织进行分析和观察,材料的拉伸性能在 MTS-810型万能试验机上测定,拉伸速度为0.5 mm/min。

2 结果和讨论

2.1 微观组织

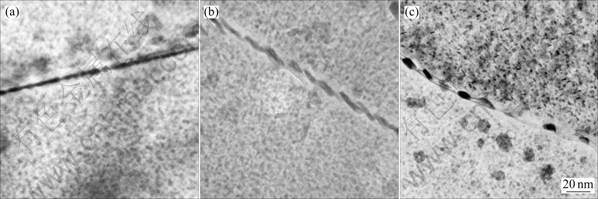

图1所示为喷射成形Al-10.8Zn-2.8Mg-1.9Cu合金在(120 ℃,16 h),(120 ℃,16 h+150 ℃,1 h)和(120 ℃,16 h+150 ℃,2 h)时效后的TEM像。很明显,合金基体上析出了细小弥散的颗粒状第二相,经峰时效条件下,晶界析出物呈完全连续状(图1(a));经120 ℃, 16 h+150 ℃,1 h时效后,晶界析出物呈断续状(图1(b))。上述二种时效制度下,合金组织中没有形成明显的晶界无析出带。图1(c)所示为合金经120 ℃,16 h+ 150 ℃,2 h时效后的TEM像,可以看到,晶内析出物与图1(a)和(b)相比略有长大,除了颗粒状的析出相外,沿着一定的晶体学取向析出了片状的第二相。晶界析出物已完全断开,同时出现了很窄(2~3 nm)的晶界无析出带。从显微组织方面来看,断开的晶界析出物对提高合金的抗应力腐蚀性能十分有利。

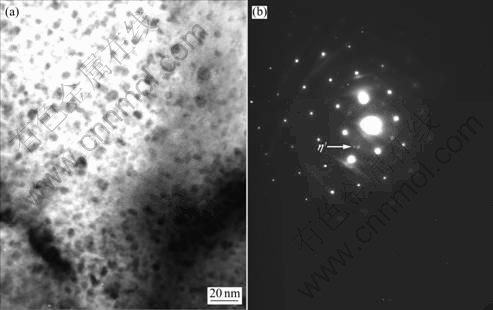

图2所示为合金经120 ℃,16 h+150 ℃,2 h时效后的TEM像和选区电子衍射图。可以看到,在基体的[100]衍射方向上,位于1/3, 2/3(220)处出现h′相的散射弱斑点,证实了此时合金基体上析出了h′强化相。

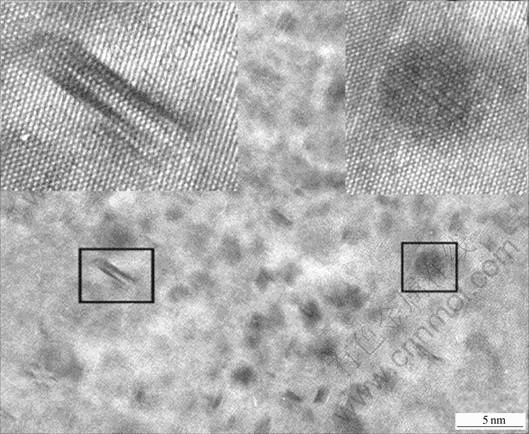

图3所示为喷射成形Al-10.8Zn-2.8Mg-1.9Cu合金经120 ℃,16 h+150 ℃,2 h时效后的高分辨图像。可以看到,合金基体上析出了球状和片状二种析出相,高分辨图像表明球状相和片状相分别与Al基体呈共格和半共格关系,这与GP区和h′相的共格特征相对应,说明此时合金的强化相是GP区和h′相,合金的强化机制是GP区和h′相的联合强化。

图1 喷射成形Al-10.8Zn-2.8Mg-1.9Cu合金在不同时效条件下的TEM像

Fig.1 TEM photographs of spray-deposited Al-10.8Zn- 2.8Mg-1.9Cu alloy after different aging treatments: (a) For 16 h at 120 ℃; (b) For 16 h at 120 ℃ plus for 1 h at 150 ℃; (c) For 16 h at 120 ℃ plus for 2 h at 150 ℃

图2 喷射成形Al-10.8Zn-2.8Mg-1.9Cu合金经120 ℃,16 h+150 ℃,2 h时效后的TEM像

Fig.2 TEM photograph of spray-deposited Al-10.8Zn- 2.8Mg-1.9Cu alloy aged for 16h at 120℃ plus for 2h at 150℃: (a) Bright-field image; (b) Selected area electron diffraction pattern

图3 喷射成形Al-10.8Zn-2.8Mg-1.9Cu合金经120 ℃,16 h+150 ℃,2 h时效后的HREM图像

Fig.3 HREM image of spray-deposited Al-10.8Zn-2.8Mg-1.9Cu alloy aged for 16 h at 120 ℃ plus for 2 h at 150 ℃

2.2 力学性能

图4所示为喷射成型合金在T6峰时效后,第二级在150℃下时效不同时间对合金力学性能的影响。随着第二级时效时间的延长,材料的抗拉强度和屈服强度在0~3 h略有波动,但变化不大,而伸长率基本呈下降趋势。材料在150 ℃时效1 h时材料的强度、伸长率均较理想,抗拉强度为795 MPa,屈服强度为770 MPa,伸长率为8.9%。透射电镜观察表明,在 150 ℃时效1 h时,晶界已经开始断开,但部分晶界析出相仍然连续或者是没有完全断开。合金在150 ℃时效2 h后,晶界析出相已经完全断开。完全断开的晶界析出相能够阻碍合金在应力腐蚀过程中所谓的阳极通道的形成,有利于合金获得良好的抗应力腐蚀性能。因此,为获得较高的抗应力腐蚀性能,第二级选用150 ℃时效2 h为最佳方案。

图4 第二级时效时间对合金力学性能的影响

Fig.4 Mechanical properties of spray-deposited Al-10.8Zn- 2.8Mg-1.9Cu alloy aged for 16 h at 120 ℃ plus for various aging time at 150 ℃

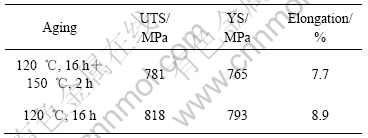

表1所列为合金双级时效和单级峰时效条件下力学性能的比较。可以看到,合金经120 ℃,16 h+150 ℃,2 h时效处理后,与峰时效性能相比,抗拉强度下降了37 MPa (4.5%),屈服强度下降了28 MPa (3.5%)。

表1 合金双级时效和单级峰时效条件下力学性能的比较

Table 1 Comparison of mechanical properties of spray- deposited Al-10.8Zn-2.8Mg-1.9Cu alloy under two-step aging and peak-aging condition

3 结论

1) 喷射成形Al-10.8Zn-2.8Mg-1.9Cu合金经 120 ℃,16 h+150 ℃,2 h双级时效后,晶内析出相与峰时效的相比略有长大,晶界析出相完全断开,此时合金的强化机制是GP区和h′相的综合强化。

2) 合金在双级时效制度(120 ℃,16 h+150 ℃, 2 h)下,其抗拉强度和屈服强度分别比峰时效值下降4.5%和3.5%。由于晶界析出相完全断开,这对提高合金的抗应力腐蚀能力具有重要意义。

REFERENCES

[1] 陈昌麒. 超高强铝合金的发展[J]. 中国有色金属学报, 2002, 12(Al Special): 22-27.

CHEN Chang-qi. Development of ultra-high strength Al alloy[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(Al Special): 22-27

[2] De Sanctis M. Structure and properties of rapidly solidified ultrahigh strength Al-Zn-Mg-Cu alloys produced by spray deposition[J]. Mater Sci Eng A, 1991, A141: 103-110.

[3] Ramgopal T, Gouma P I, Frankel G S. Role of grain-boundary precipitates and solute-depleted zone on the intergranular corrosion of aluminum alloy 7150[J]. Corrosion, 2002, 58(8): 687-697.

[4] Puiggali M, Zielinski A, Olive J M, Renauld E, Desjarding D, Cid M. Effect of microstructure on stress corrosion cracking of an Al-Zn-Mg-Cu alloy[J]. Corrosion Science, 1998, 40: 805-819.

[5] Singh P M, Lewandowski J J. Effects of heat treatment on stress corrosion cracking of a discontinuously reinforced aluminium 7××× alloy during slow strain rate testing[J]. Scripta Materialia, 1995, 33(9): 1393-1399.

[6] Engdahl T, Hansen V, Warren P J, Stiller K. Investigation of fine scale precipitates in Al-Zn-Mg alloys after various heat treatments[J]. Mater Sci Eng A, 2002, A327: 59-64.

[7] ZENG Yu, YIN Zhi-min, ZHU Yuan-zhi, CUI Jian-zhong. Microstructure investigation of a new type super high strength aluminium alloy at different heat-treated conditions[J]. Rare Metals, 2004, 23(4): 377-384.

[8] Stiller K, Warren P J, Hansen Angenete J, Gjonnes J. Investigation of precipitation in an Al-Zn-Mg alloy after two-step ageing treatment at 100 and 150 ℃[J]. Mater Sci Eng A, 1999, A207: 55-63.

[9] Nicolas M, Deschamps A. Characterisation and modeling of precipitate evolution in an Al-Zn-Mg alloy during non-isothermal heat treatments[J]. Acta Materialia, 2003, 51: 6077-6094.

[10] Deshais G, Newcomb S B. The influence of microstructure on the formation of stress corrosion cracks in 7××× series aluminium alloys[J]. Materials Science Forum, 2000, 313/317: 1635-1640.

[11] 韦 强, 熊柏青, 张永安, 朱宝宏, 石力开. 喷射成形Al-Zn-Mg-Cu系高强铝合金的组织与性能[J]. 中国有色金属学报, 2001, 11(2): 279-282.

WEI Qiang, XIONG Bai-qing, ZHANG Yong-an, ZHU Bao-hong, SHI Li-kai. Microstructure and mechanical properties of spray formed Al-Zn-Mg-Cu alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(2): 279-282.

[12] Srivatsan T S. Microstructure, tensile properties and fracture behaviour of aluminum alloy 7150[J]. J Mater Sci, 1992, 27(17): 4772-4781.

[13] Park J K, Ardell A J. Microstructures of the commercial 7075 Al alloy in the T651 and T7 tempers[J]. Metall Trans A, 1983, A14: 1957-1965.

(编辑 袁赛前)

基金项目:国家重点基础研究发展计划资助项目(2005CB623704)

收稿日期:2006-07-03;修订日期:2007-06-06

通讯作者:王 锋,高级工程师;电话:010-82241162-206;E-mail: wfbs@263.net