文章编号:1004-0609(2013)11-3196-06

纳米Ni颗粒对时效过程中钎焊界面组织的影响

甘贵生1,杜长华1,许惠斌1,甘树德1,王卫生2,李镇康1,刘 斌1

(1. 重庆理工大学 材料科学与工程学院,重庆 400054;

2. 重庆平伟科技(集团)有限公司,重庆 400026)

摘 要:分别采用低温搅拌钎焊和润湿平衡法对Sn-Cu-Ag亚共晶钎料及其纳米复合钎料进行钎焊,并对其进行时效处理。结果发现:纳米Ni颗粒有利于金属间化合物(IMC)的形成,在钎焊界面形成孔洞状的(CuxNi1-x)6Sn5;采用低温搅拌钎焊工艺时,时效过程中两种接头的IMC厚度与时效时间 的拟合直线完全重合,纳米颗粒对IMC结构的改变作用不明显;采用润湿反应钎焊工艺,添加颗粒后钎料中元素互扩散系数降低一个数量级,纳米颗粒对时效过程中IMC的生长有明显的抑制作用。

的拟合直线完全重合,纳米颗粒对IMC结构的改变作用不明显;采用润湿反应钎焊工艺,添加颗粒后钎料中元素互扩散系数降低一个数量级,纳米颗粒对时效过程中IMC的生长有明显的抑制作用。

关键词: 纳米颗粒;搅拌钎焊;IMC;润湿平衡;时效处理

中图分类号:TG425.1 文献标志码:A

Effect of Ni nanoparticles on soldering interfacial microstructure during aging treatment

GAN Gui-sheng1, DU Chang-hua1, XU Hui-bin1, GAN Shu-de1, WANG Wei-sheng2, LI Zhen-kang1, LIU Bin1

(1. School of Materials Science and Engineering, Chongqing University of Technology, Chongqing 400054, China;

2. Chongqing Pingwei Technology (Group) Co., Ltd., Chongqing 400026, China)

Abstract: Soldering with Sn-Cu-Ag eutectic solder or its composite solder by low-temperature stirring soldering and wetting balance method were implemented respectively, and the aging treatments were performed. The results show that the nano-Ni particles are beneficial to the formation of IMC, and the hole shape (CuxNi1-x)6Sn5 forms in the soldering interface. With low-temperature soldering process, the fitting line of the IMC thickness and aging time  is totally coincident in two soldering joint, and the structural change of the IMC due to adding nano-particles is not obvious. With the wetting balance test method, the mutual diffusion coefficient reduces by an order of magnitude after adding nanoparticles, the nano-Ni particles are beneficial to inhibiting the growth of IMC.

is totally coincident in two soldering joint, and the structural change of the IMC due to adding nano-particles is not obvious. With the wetting balance test method, the mutual diffusion coefficient reduces by an order of magnitude after adding nanoparticles, the nano-Ni particles are beneficial to inhibiting the growth of IMC.

Key words: nanoparticle; stirring soldering; IMC; wetting balance; aging treatment

Sn-Ag-Cu共晶钎料因其优异的性能而被公认为最有可能代替Sn-37Pb的无铅钎料合金[1-4],但在该钎料合金的凝固过程中,β-Sn存在较大的过冷度, 会形成粗大的板条状Ag3Sn初晶。在随后的服役过程中, 板条状Ag3Sn会进一步粗化,导致钎料合金抗冲击及抗跌落(高应变速率条件)性能明显降低。同时,较高的Ag含量使初生β-Sn含量降低,共晶相含量增加,同样导致更多粗大的板条状Ag3Sn存在,致使钎料合金强度指标增加,塑性指标降低,从而降低了焊点的可靠性[5-6]。

焊接界面处金属间化合物(IMC)的形成、生长和演变对焊点的可靠性起着非常重要的作用。一些研究表明[7-10],添加适量金属或惰性纳米颗粒对界面IMC层的生长一般均有明显抑制作用。文献[11-18]研究了Ni颗粒对无铅钎料工艺性能的影响,但对其在服役行为研究较少。因此,本文作者以近年热点低银Sn-0.68Cu-0.45Ag(以下简称SCA)亚共晶钎料为研究对象,添加纳米Ni颗粒,采用低温搅拌钎焊和润湿平衡法对SCA钎料及其复合钎料进行钎焊,研究IMC在时效过程中的演变规律。

1 实验

将基体SCA钎料置于坩埚中,快速升温至250 ℃,将粒径约80 nm的Ni颗粒浸渍特殊的表面活性剂后加入到基体钎料中,在表面敷以松香保护,快速机械搅拌10 min后,浇注成3 mm厚的含1%Ni(质量分数)的Sn-0.68Cu-0.45Ag复合钎料(以下简称Ni-SCA)。

采用搅拌辅助工艺对两种钎料进行低温钎焊,装置如图1所示。DSC研究发现,钎料及复合钎料的熔化开始温度分别为216.6和215.9 ℃,熔化结束温度为227.6和229.3 ℃。选取222℃作为操作温度使钎焊在固液两相区进行,搅拌头尺寸为d1.8 mm的螺旋状,转速为1 570 r/min,搅拌头横向移动速度为15 mm/min。搅拌头自动在被焊件槽中边搅拌边横向移动,走完20 mm长的焊缝即为搅拌一次,往返搅拌各一次后保温3 min,空冷即得到搅拌辅助接头试样。采用润湿平衡法在240 ℃下对两种钎料进行钎焊,浸入深度为3 mm,浸入速度为20 mm/s,浸入时间为10 s。两种工艺均选用75 g异丙醇+25 g松香+0.39 g二乙胺盐酸盐混合物为钎剂,钎焊母材为铜板。

将所得试样分别在150和125 ℃进行老化处理,在不同时效时间取样,经过镶嵌、打磨、抛光、腐蚀之后,在QUANTA200型扫描电镜下进行界面组织的观察,并用EDX进行成分分析。

采用Photoshop对拍摄的金相图片进行处理,每个试样的图片选取6个区域,分别计算IMC层的面积,再除以IMC长度,得到每个区域IMC厚度,最后将6个区域的厚度加以平均,即能得到一张图片的IMC厚度的平均厚度。

2 结果与讨论

2.1 搅拌辅助低温钎焊界面IMC时效过程组织演变

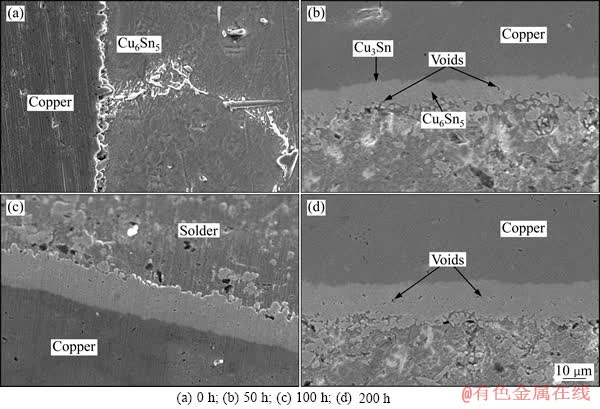

图2和3所示分别为两种钎料搅拌辅助低温钎焊后在150℃时效所得界面IMC。从图2可以看出,SCA/Cu界面的IMC主要由扇贝状Cu6Sn5组成。由于机械搅拌钎焊温度为222℃,焊缝中是固液共存的浆料,搅拌强迫熔体流动,引入部分气体在低温下难以及时溢出,而在焊接界面和基体中留下气孔。随着时效时间的延长,在Cu和Sn原子的扩散作用下,IMC逐渐趋于平整,同时,在靠近Cu基板一侧出现了Cu3Sn;Cu6Sn5层和Cu3Sn层不断增厚,时效200 h时,IMC厚度从4.62 μm增加到13.67 μm。

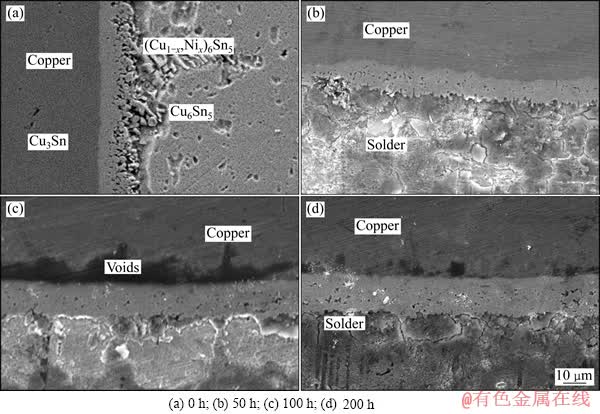

图3所示为搅拌辅助低温钎焊Ni-SCA /Cu界面150 ℃时效时的界面IMC。由于在界面处形成的孔洞状(CuxNi1-x)6Sn5可作为界面上各元素的扩散通道,使得Cu可以充分地通过管道扩散到钎料内部,加速了IMC的生长。同时,Sn通过疏松的IMC扩散到基板上,在靠近Cu基板一侧生成了很薄的Cu3Sn层。IMC由Cu6Sn5、Cu3Sn和孔洞状的(CuxNi1-x)6Sn5组成。随着时效时间的延长,IMC厚度增大,但趋势减缓,200 h时IMC 厚度为13.67 μm。

2.2 润湿反应钎焊界面IMC时效过程组织演变

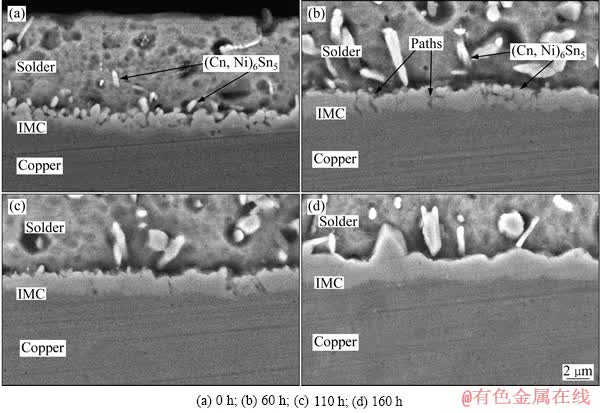

图4和5所示分别为两种钎料在240 ℃下润湿反应钎焊后125 ℃时效所得界面IMC。从图4可以看出,随着时效时间的延长,不均匀扇贝状IMC不断增厚,趋于平整,厚度从0.87 μm增加到2.50 μm,并且只出现少量孔洞。

图1 低温搅拌钎焊试验装置(包括钎焊试样)和SAT-5100可焊性测试仪

Fig. 1 Schematic diagram of low-temperature stirring soldering test (a) and solderability checker SAT-5100 (b)

图2 搅拌辅助低温钎焊SCA/Cu界面150 ℃时效时的组织演变

Fig. 2 Microstructure evolution of SCA/Cu interface after aging at 150 ℃ with stirring soldering

图3 搅拌辅助低温钎焊Ni-SCA /Cu界面150 ℃时效时的组织演变

Fig. 3 Microstructure evolution of Ni-SCA/Cu interface after aging at 150 ℃ with stirring soldering

图4 润湿反应钎焊SCA/Cu界面125℃时效时的组织演变

Fig. 4 Microstructure evolution of SCA/Cu interface after aging at 125 ℃ with wetting reactive soldering

图5所示为Ni-SCA复合钎料在240 ℃下润湿反应钎焊后125 ℃时效所得界面IMC。由图5可以看出,随着纳米Ni颗粒的添加,界面IMC层的形貌并未以扇贝状出现,而是分布均匀平缓的层状界面层。加入1%的纳米Ni颗粒之后,IMC层厚度增加到1.39 μm,在界面IMC靠近钎料的一侧中存在大量细小的向日葵状突起。根据EDX分析发现,粒状突起中含有5%左右的Ni。分析认为,纳米Ni颗粒因其表面很容易吸附在界面IMC层上,在制料和钎焊过程中会有少部分的溶解,易在界面处形成(CuxNi1-x)6Sn5,呈孔洞状,其反应式如下:

Cu6Sn5+6(1-x)Ni=(CuxNi1-x)6Sn5+6(1-x)Cu (1)

文献[12]指出,在界面处形成的孔洞状 (CuxNi1-x)6Sn5可作为界面上Sn、Cu元素的扩散通道,使得Cu可以充分地通过管道扩散到钎料内部,而Cu基板也能获得足够多的Sn,故复合钎料IMC层的厚度也更厚。而随着时效时间的延长,界面IMC层的厚度增加,时效160 h时IMC层的厚度增加到1.94 μm。

2.3 纳米颗粒在不同钎焊工艺中的作用

根据传统动力学理论的描述,固相焊点中界面金属间化合物的生长规律通常以扩散生长为主,其生长速度由互扩散控制而不是由组元间的反应控制[19]。金属间化合物层的厚度与老化时间通常遵循以下经验关系:

(2)

(2)

式中:d为金属间化合物层的厚度;d0为金属间化合物层的初始厚度;D为扩散系数;t为老化时间。扩散系数D与老化温度之间的关系可以用Arrhenius方程式表示如下:

(3)

(3)

式中:D为某扩散体统的扩散系数;D0为扩散常数;Q为溶质原子的扩散激活能;T为反应温度。其中,扩散激活能Q和扩散常数D0与温度T无关。

图5 润湿反应钎焊Ni-SCA/Cu界面125 ℃时效时的组织演变

Fig. 5 Microstructure evolution of Ni-SCA/Cu interface after aging at 125 ℃ with wetting reactive soldering

图6所示为低温搅拌钎焊后时效过程中IMC层厚度与时效时间 的关系。由图6可以看出,两种钎料拟合直线完全重合,计算得到D=0.423 53 μm2/h,说明添加纳米Ni颗粒对IMC的扩散系数没有影响,IMC层厚度随时效时间的变化只与钎焊工艺有关(搅拌形成的疏松IMC控制扩散过程,纳米Ni颗粒对改变IMC结构作用不明显)。当时效时间到达200 h,两种钎料的IMC层厚度相同。

的关系。由图6可以看出,两种钎料拟合直线完全重合,计算得到D=0.423 53 μm2/h,说明添加纳米Ni颗粒对IMC的扩散系数没有影响,IMC层厚度随时效时间的变化只与钎焊工艺有关(搅拌形成的疏松IMC控制扩散过程,纳米Ni颗粒对改变IMC结构作用不明显)。当时效时间到达200 h,两种钎料的IMC层厚度相同。

图7所示为润湿反应钎焊后时效过程中IMC层厚度与时效时间 的关系。由图7可以看出,由两种钎料拟合直线计算得到DSCA=0.015 22 μm2/h和DNi/SCA= 0.001 549 μm2/h;随时效时间延长,添加Ni颗粒后IMC的致密性明显提高,钎料中元素的互扩散系数明显降低,IMC层厚度没有出现明显的增长。

的关系。由图7可以看出,由两种钎料拟合直线计算得到DSCA=0.015 22 μm2/h和DNi/SCA= 0.001 549 μm2/h;随时效时间延长,添加Ni颗粒后IMC的致密性明显提高,钎料中元素的互扩散系数明显降低,IMC层厚度没有出现明显的增长。

图6 150℃时效时IMC厚度与 的关系

的关系

Fig. 6 Relationship between IMC thickness and square root of aging time after aging at 150 ℃

图7 125 ℃时效时IMC厚度与 的关系

的关系

Fig. 7 Relationship between IMC thickness and square root of aging time after aging at 125 ℃

3 结论

1) 添加纳米Ni颗粒有利于IMC的形成和增厚。复合材料低温搅拌钎焊界面IMC由Cu6Sn5、Cu3Sn和孔洞状的(CuxNi1-x)6Sn5组成,润湿反应钎焊界面IMC由Cu6Sn5和孔洞状的(CuxNi1-x)6Sn5组成。

2) 采用低温搅拌钎焊工艺时,随着时效时间延长,IMC层厚度均增加,两种钎料在时效200 h时的IMC层厚度几乎相同。时效过程中两种钎料钎焊界面IMC层厚度与时效时间 的拟合直线完全重合,Ni颗粒的添加对基体IMC的扩散系数没有明显影响,IMC层厚度随时效时间的变化只与钎焊工艺有关。

的拟合直线完全重合,Ni颗粒的添加对基体IMC的扩散系数没有明显影响,IMC层厚度随时效时间的变化只与钎焊工艺有关。

3) 采用润湿反应钎焊工艺时,两种钎料在125 ℃时的扩散系数分别为DSCA=0.015 22 μm2/h和DNi/SCA=0.001 549 μm2/h,添加Ni颗粒后钎料中元素的互扩散系数降低了1个数量级,纳米Ni颗粒对时效过程中IMC的生长有一定的抑制作用。

REFERENCES

[1] 许天旱, 赵麦群, 刘新华. Sn-Ag-Cu系无铅焊锡成分的优化研究[J]. 电子元件与材料, 2004, 23(8): 14-16.

XU Tian-han, ZHAO Mai-qun, LIU Xin-hua. Study on the optimal free-lead solder alloy of Sn-Ag-Cu system[J]. Electronic Components and Materials, 2004, 23(8): 14-16.

[2] 张曙光, 何礼君, 张少明, 石力开. 绿色无铅电子焊料的研究与应用进展[J]. 材料导报, 2004, 18(6): 72-75.

ZHANG Shu-guang, HE Li-jun, ZHANG Shao-ming, SHI Li-kai. Progress of research and application of lead-free solder[J]. Materials Review, 2004, 18(6): 72-75.

[3] SHEN J, PENG C F, YIN H G, CHEN J. Influence of minor POSS molecules additions on the microstructure and hardness of Sn3Ag0.5Cu-xPOSS composite solders[J]. Journal of Materials Science: Materials in Electronics, 2012, 23(9): 1640-1646.

[4] CHANG S Y, TSAO L C, WU M W, CHEN C W. The morphology and kinetic evolution of intermetallic compounds at Sn-Ag-Cu solder/Cu and Sn–Ag–Cu-0.5Al2O3 composite solder/Cu interface during soldering reaction[J]. Journal of Materials Science: Materials in Electronics, 2012, 23(1): 100-107.

[5] SEO S K, KANG S K, SHIH D Y, LEE H M. An investigation of microstructure and microhardness of Sn-Cu and Sn-Ag solders as functions of alloy composition and coolin g rate[J]. Journal of Electronic Materials, 2009, 38(2): 257-265.

[6] HENRY Y LU, HALUK BALKAN, K Y SIMON N G. Microstructure evolution of the Sn-Ag-y %Cu interconnect[J]. Microelectronics Reliability, 2006, 46(7): 1058-1070.

[7] LEONG J C, TSAO L C, FANG C J, CHU C P. Effect of nano-TiO2 addition on the microstructure and bonding strengths of Sn3.5Ag0.5Cu composite solder BGA packages with immersion Sn surface finish[J]. Journal of Materials Science: Materials in Electronics, 2011, 22(9): 1443-1449.

[8] GAIN A K, FOUZDER T, CHAN Y C, YUNG W K. Microstructure, kinetic analysis and hardness of Sn-Ag-Cu-1wt.% nano-ZrO2 composite solder on OSP-Cu pads[J]. Journal of Alloys and Compounds, 2011, 509(7): 3319-3325.

[9] TSAO L C, WANG B C, CHANG C W, WU M W. Effect of Nano-TiO2 addition on wettability and Interfacial reactions of Sn0.7Cu composite solder/Cu solder joints[C]//Proceedings of 11th International Conference on Electronic Packaging Technology & High Density Packaging. Taiwan, China, 2010.

[10] CHOI S, LUCAS J P, SUBRAMANIAN K N, BIELER T R. Reactions of Sn0.7Cu Composite Solder/Cu solder joints formation and growth of interfacial intermetallic layers in eutectic Sn-Ag solder and its composite solder joints[J]. Journal of Materials Science: Materials in Electronics, 2000, 11(6): 497-502.

[11] 徐金华, 吴佳佳, 陈 胜, 马 鑫. 低银Sn-Ag-Cu无铅钎料的性能研究[J]. 电子工艺技术, 2010, 31(3): 141-144.

XU Jin-hua, WU Jia-jia, CHEN Sheng, MA Xin. Study on properties of low-silver-content Sn-Ag-Cu lead-free solders[J]. Electronics Process Technology, 2010, 31(3): 141-144.

[12] 聂京凯, 郭 福, 郑菡晶, 邰 枫, 夏志东. Ni颗粒增强无铅复合钎料中IMC形态之演变[J]. 电子元件与材料, 2007, 26(9): 43-46.

NIEJing-kai, GUOFu, ZHENGHan-jing, TAIFeng, XIAZhi-dong. Morphology evolution of intermetallic compounds in nickel particle reinforced lead-free composite solder[J]. Electronic Components&Materials 2007, 26(9): 43-46.

[13] 徐广臣, 何洪文, 聂京凯, 郭 福. Ni颗粒对SnBi焊点电迁移的抑制作用[J]. 电子元件与材, 2008, 27(11): 60-63.

XUGuang-chen,HEHong-wen,NIEJing-kai,GUOFu.Electromigration suppressing effect of Ni particle on SnBi soldering point[J]. Electronic Components & Materials, 2008, 27(11): 60-63.

[14] 聂京凯, 张冰冰, 郭 福, 夏志东, 雷永平. 热输入及掺Ni对Sn-Ag钎料强度的影响[J]. 电子元件与材料, 2008, 27(1): 29-31.

NIE Jing-kai, ZHANG Bing-bing, GUO Fu, XIA Zhi-dong, LEI Yong-ping. Effect of thermal input and Ni doping on strength in Sn-Ag solder[J]. Electronic Components & Materials, 2008, 27(1): 29-31.

[15] LEE J G, CHEN K C, SUBRAMANIAN K N. Formation and growth of intermetallics around metallic particles in eutectic Sn-Ag solder[J]. Journal of Electronic Materials, 2003, 32: 1240-1248.

[16] 刘 朋, 郭 福, 何洪文, 夏志东, 史耀武. 颗粒增强Sn-Ag基无铅复合钎料显微组织与性能[J]. 电子元件与材料, 2007, 26(6): 28-30.

LIU Peng, GUO Fu, HE Hong-wen, XIA Zhi-dong, SHI Yao-wu. Microstructure and properties of particle reinforced Sn-Ag based lead-free composite solders[J]. Electronic Components & Materials, 2007, 26(6): 28-30.

[17] 邰 枫, 郭 福, 申 灏, 韩孟婷. 升温速率对复合钎料显微组织和力学性能的影响[J]. 焊接学报, 2008, 29(9): 79-83.

TAI Feng, GUO Fu, SHEN Hao, HAN Meng-ting. Effect of heating rate on microstructure and mechanical properties of composite solder joints[J]. Transactions of the China Welding Institution, 2008, 29(9): 79-83.

[18] 杨 莉. 增强颗粒对Sn0.7Cu基复合钎料铺展性能的影响[J]. 热加工工艺, 2010, 39(1): 29-32.

LI Yang. Effect of particle-reinforced on spreading property of Sn-0.7Cu based composite solders[J]. Hot Working Technology, 2010, 39(1): 29-32.

[19] ZENG K, TU K N. Six cases of reliability study of Pb-free solder joints in electronic packaging technology[J]. Materials Science and Engineering, 2002, 38: 55-105.

(编辑 何学锋)

基金项目:重庆高校优秀成果转化资助重大项目(KJZH11215);国家自然科学基金资助项目(50975303);重庆市教委科技研究一般项目(KJ130813);重庆理工大学科研启动基金资助项目(2012ZD12)

收稿日期:2011-11-16;修订日期:2013-05-26

通信作者:甘贵生,博士;电话:15213450861;E-mail:ggs@cqut.edu.cn