DOI:10.11817/j.ysxb.1004.0609.2020-37479

Ti2AlNb合金超塑性能及四层立筋结构超塑成形/扩散连接工艺

李保永1, 2,蒋少松1

(1. 哈尔滨工业大学 金属精密热加工国家级重点实验室,哈尔滨 150001;

2. 北京航星机器制造有限公司,北京 100013)

摘 要:对Ti-22Al-27Nb合金四层结构件SPF/DB组合工艺进行试验研究,对Ti-22Al-27Nb合金的超塑性能及扩散连接性能进行探究。拉伸实验表明,当变形温度为960 ℃、应变速率为1×10-4 s-1时,材料伸长率达到最大,为230%。对温度、保温时间和扩散压力对Ti-22Al-27Nb合金接头质量的影响进行研究,结果表明Ti-22Al-27Nb合金扩散连接的最佳工艺参数为(960 ℃,10 MPa,2 h)。根据高温拉伸试验结果,利用有限元模拟软件对中空四层结构件超塑成形过程进行模拟。通过SPF/DB组合工艺成形得到外观质量良好的Ti-22Al-27Nb合金中空四层结构件,成形构件壁厚分布均匀。

关键词:Ti-22Al-27Nb;扩散连接;超塑成形;四层结构

文章编号:1004-0609(2020)-01-0103-09 中图分类号:TG301 文献标志码:A

随着航空航天领域对轻质结构材料需求的增加,Ti2AlNb基合金凭借着优异的高温强度,较低的密度、良好的抗氧化性而日异受到航空航天制造业的青睐。Ti2AlNb基合金是指Nb的摩尔分数在25%左右的Ti-Al-Nb系合金,与Nb含量较低的Ti3Al-Nb合金相比具有更好的力学性能[1]。Ti2AlNb基合金的成分通常在Ti-(18%~30%)Al-(12.5%~30%)Nb(摩尔分数),并含有少量的其他合金元素,如V,Ta等。根据Nb含量的不同,可将Ti2AlNb基合金分为第一代O相合金和第二代O相合金。一般认为第一代O相合金为Nb含量低于25%(摩尔分数) Ti2AlNb基合金,在三相区热处理获得的组织为α2+B2+O三相,第一代O相合金的代表产品有Ti-25Al-17Nb、Ti-21Al-22Nb和Ti-22Al-23Nb;第二代O相合金为Nb含量不低于25%的合金,在两相区热处理获得的组织为B2+O两相,代表产品Ti-22Al-25Nb、Ti-22Al-27Nb。研究表明,第二代O相合金的性能要明显的优于第一代O相合金,第二代O相合金是该类合金研究的重点[2]。

对于一些形状复杂的结构件,Ti2AlNb基合金的成形需要在900 ℃以上的高温条件下进行。合适成形工艺的选择对于促进Ti2AlNb基合金的推广应用具有重要意义。对于常温难变形材料(如Ti合金)复杂结构件,通常采用超塑性成形工艺成形[3]。这是由于在超塑成形条件下材料具有良好的塑性和低流动应力,且制造的构件无回弹等缺陷[4]。因而,超塑性成形工艺是适合于Ti2AlNb基合金的理想成形工艺。超塑性成形工艺充分利用了材料的超塑性,研究Ti2AlNb基合金超塑成形工艺的前提即为研究Ti2AlNb基合金的超塑性能。目前,国内外很多学者对Ti2AlNb基合金的超塑性能进行了研究[5-13]。研究表明:Ti2AlNb基合金具有超塑性的温度范围和应变速率范围分别为900~980 ℃和1×10-5~1×10-3 s-1,而由于研究者使用的Ti2AlNb基合金成分和热力学处理方法的不同,使得制备的Ti2AlNb基合金的最大伸长率从刚刚达到超塑性条件的217%到具有良好超塑性的1570%不等[11-12]。由此可知不同成分和热力学处理的Ti2AlNb基合金的超塑性能在伸长率上差别很大,在应用Ti2AlNb基合金的超塑性时,要首先确定所使用的Ti2AlNb基合金的超塑性能。

为了促进Ti2AlNb基合金及其成形结构件的推广应用,除了需要具有良好的成形性能之外,还需要具有良好的焊接性能。良好的焊接性能不仅指材料本身的可焊性良好,也包括Ti2AlNb基合金能与其他目前常用的轻质高温结构材料Ti合金、TiAl基合金以及Ni基高温合金等形成良好的连接,这样才能使得Ti2AlNb基合金成为有应用价值的轻质高强结构材料。目前,已有很多学者对Ti2AlNb基合金自身以及与其他材料的焊接性能进行了研究,这些焊接方法包括电子束焊,固态扩散焊等多种焊接方法。对于Ti2AlNb基合金自身扩散连接技术,目前主要是国内的学者进行了研究。邹贵生等[14]在Gleeble 1500D模拟试验机上研究了Ti-22Al-25Nb合金无中间层的直接扩散连接,研究表明当连接温度θ≥970 ℃、连接压力p≥7MPa、连接时间t≥0.5 h时,获得的接头强度较高(最大接头强度达到母材强度的91%)且界面结合良好。当连接温度高于1000 ℃时,虽然接头的强度提高了,但使得B2相粗化,O相减少。李贝贝等[15-16]在真空热压的条件下研究了Ti2AlNb基合金的固态扩散连接,发现较好的扩散连接工艺参数为θ=950 ℃,p=10~15 MPa,t=120 min,此时界面处结合良好。

Ti-22Al-27Nb合金的三层板和四层板结构件广泛应用在航空航天领域,它们的传统制造方法是通过铆接或胶接来成形,因而其整体性和连接强度均未达到最佳程度[17]。超塑成形技术与扩散连接技术即SPF/DB组合技术,把超塑成形和扩散连接的优点集中于一身,可以生产复杂的多层结构件,采用SPF/DB技术制造的多层结构件在减轻结构质量,降低生产成本方面具有极大的优越性[18-19]。

本文主要针对典型的多层结构热防护结构和弹翼对于耐高温和轻质化的双重要求,以研发Ti2AlNb基合金超塑成形/连接组合技术为基础,掌握其热塑性成形/连接组合工艺条件下变形及组织演变规律,实现钛铝系合金多层结构微观组织、力学性能和三维型面精确控制,推动该类材料在耐热结构件中的应用。

1 实验

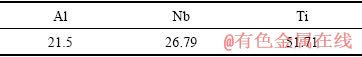

使用的Ti2AlNb基合金是由钢研院提供的厚度为1 mm的热轧板材,名义成分为Ti-22Al-27Nb(摩尔分数,%),表1所列为Ti-22Al-27Nb合金的具体化学成分。

表1 Ti2AlNb基合金的化学成分

Table 1 Chemical composition of Ti2AlNb based alloy (mole fraction, %)

Ti2AlNb基合金高温拉伸试验在Instron 5569R电子万能拉伸试验机上进行,通过拉伸试验机调节横梁的移动速度控制拉伸应变速率。对于Ti2AlNb基合金高温拉伸,拉伸试样标距长为18 mm,标距宽6 mm;试验温度为920 ℃、940 ℃、960 ℃,初始应变速率依次为1×10-3 s-1、5×10-4 s-1和1×10-4 s-1,拉伸方向为板材的轧制方向。

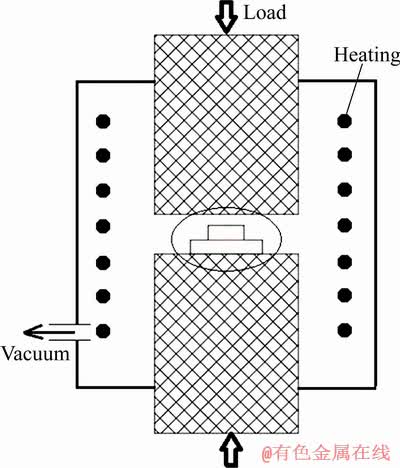

Ti2AlNb合金的扩散连接工艺在真空热压烧结炉内进行,如图1所示,连接过程中真空度为5×10-3 Pa,用于扩散连接的试样尺寸分别为8 mm×40 mm×3 mm和5 mm×40 mm×3 mm。这些试样的表面经过240#~1200# SiC砂纸依次打磨,然后在丙酮中超声清洗5 min,加热过程升温速率为15 ℃/min,扩散连接工艺的示意图如图2所示。针对Ti-22Al-27Nb合金的扩散连接,扩散连接温度为940 ℃和960 ℃,扩散连接压力选择10 MPa和15 MPa,连接时间为1 h和2 h。

图1 ZRY55型真空热压烧结炉

Fig. 1 ZRY55 vacuum hot pressing sintering furnace

图2 扩散连接示意图

Fig. 2 Schematic illustration of diffusion bonding devices

扩散连接试样及基体材料的剪切强度测试同样在Instron 5569R型万能拉伸试验机上进行,试验条件为室温,压头下降的速度为0.5 mm/min。为了保证测量接头剪切强度的准确性,每个参数下的扩散连接接头至少测试3个,用平均值来作为连接接头的最终强度。

Ti-22Al-27Nb合金板材四层结构的超塑成形/扩散连接工艺试验在2000 kN超塑成形试验机上进行,压力机提供成形的压边力和扩散连接的压力。实验中通过FEI Quanta 200F型扫描电镜对材料的扩散连接界面进行表征。

2 结果与讨论

2.1 Ti2AlNb合金的超塑性能

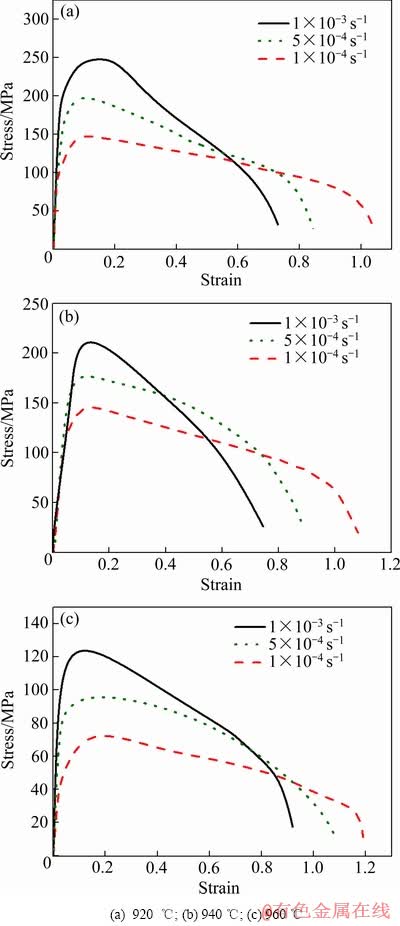

图3所示为Ti-22Al-27Nb合金不同温度不同应变速率下的拉伸曲线。从图3可以看出,Ti-22Al-27Nb合金板材在960 ℃,应变速率为1×10-4 s-1条件下的最大伸长率为230%。随着温度的升高,合金的流动应力降低。变形开始阶段,材料的流动应力急剧上升,此时材料内部位错的塞积,缠结、割阶所引起的加工硬化起主导作用,材料内部发生的动态回复和部分动态再结晶的软化作用远低于硬化作用。随拉伸过程的进行,动态回复和动态再结晶的软化作用增强,对应于拉伸曲线斜率逐渐降低。从图3可以看出,随着应变速率的降低,合金的流动应力降低。

这可以用Backofen方程来解释:

(1)

(1)

式中: 为流动应力,MPa;K为常数;

为流动应力,MPa;K为常数; 为应变速率,s-1;m为应变速率敏感性指数。

为应变速率,s-1;m为应变速率敏感性指数。

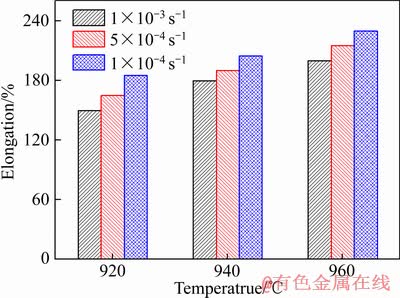

图4所示为伸长率与温度及应变速率关系,920 ℃时候伸长率小,材料在该温度下显示出超塑性。随着温度的升高,材料的伸长率也呈增加趋势,主要是因为温度升高可以降低临界切变应力并提高原子的自由能,促进晶界的滑移。在940 ℃、960 ℃时,伸长率随着应变速率降低而增加,在960 ℃低应变速率下拉伸,其最高应变量可达到230%。

2.2 扩散连接接头的剪切强度和微观形貌

扩散连接时的连结温度、连接压力、连接时间、表面粗糙度以及真空度均对扩散连接最终质量有影响。在本次扩散连接试验中,所有扩散连接试样表面均经过相同的机械处理且扩散连接工艺在具有相同真空度的热压烧结炉内进行,因此表面粗糙度以及和真空度对扩散连接的影响可以忽略。因此,对于本实验连接温度、连接压力、连接时间是主要影响剪切强度和连接界面微观组织的主要因素。从前面已知,Ti-22Al-27Nb在940~960 ℃,应变速率1×10-4 s-1下表现出良好的塑性。通常情况下,在超塑成形/扩散连接工艺中扩散连接温度与超塑成形温度相同。因此,本文重点研究该合金在940 ℃和960 ℃下的扩散连接性能。

图3 Ti-22Al-27Nb合金真应力-真应变曲线

Fig. 3 True stress-strain curves of Ti-22Al-27Nb alloy at strain rates ranging from 1×10-4-1×10-3 s-1: (a) 920 ℃; (b) 940 ℃; (c) 960 ℃

图4 Ti-22Al-27Nb合金的伸长率与温度和应变速率的关系

Fig. 4 Elongation of Ti-22Al-27Nb alloy at different temperatures and strain rates

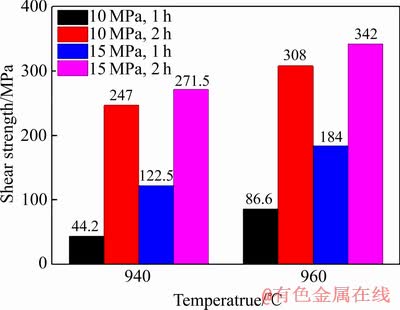

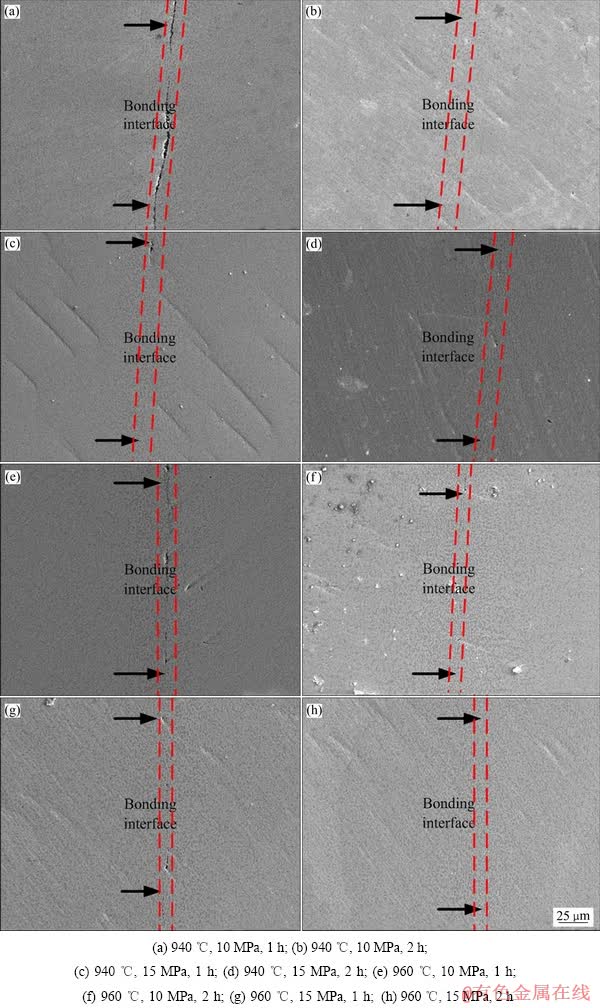

在室温条件下测试了连接接头的抗剪切强度,剪切强度与连接参数之间的关系如图5所示。连接温度、连接压力和连接时间影响接头的抗剪切强度。当连接压力和连接时间相同时,在960 ℃条件下得到的接头的剪切强度要大于940 ℃时得到的接头剪切强度。另外,高的连接压力和长的扩散连接时间均将引起相应接头剪切强度的增加。每种实验参数相对应的微观组织和连接界面如图6所示,连接质量可通过剪切强度测量评价。

图5 不同连接参数下获得接头的剪切强度

Fig. 5 Shear strength of alloy under different diffusion bonding conditions

温度影响接触界面的局部塑性变形和扩散行为,在低温条件下微区塑性变形不充分,会影响扩散连接的质量。对比图6(a)和6(e)中,明显可以看到连接界面在图6(e)的连接区域更大且强度更高,高温促进扩散连接工艺。

增加扩散连接压力可以提高局部塑性变形减少界面处的微观孔洞。当连接压力从10 MPa增加到15 MPa时,基体之间的连接面积增大,960 ℃下剪切强度从88.6 MPa增加184 MPa。高的连接压力可以得到高强度的接头,但连接压力过大会造成基体严重的变形影响最终构件的精度。因此,连接压力的选择要合适。

延长连接时间可以有效地提高元素的扩散和增加连接面积以及抗剪切强度。对比图6,可以发现后者在界面处的微观孔洞基本消失,连接时间2 h对于获得良好的接头是很有必要的。在(960 ℃,10 MPa,2 h)和(960 ℃,15 MPa,2 h)条件下得到的接头剪切强度超过300 MPa。基于扩散连接实验,扩散工艺参数选择为(960 ℃,10 MPa,2 h)。

2.3 四层结构的有限元模拟

本试验以四层结构件为有限元分析目标,板料的尺寸为175 mm×350 mm×1 mm,有限元模型包括成形模具模型以及板料模型,模具模型和板料模型经过简化后可直接在MSC.MARC中建立。对于本试验的研究的两种四层结构以及成形所需的模具,结构均具有对称性,在保证不影响计算结果的前提下对有限元模型进行一定的简化,以保证有限元分析结果可更直观的呈现和计算速度的加快。因而,采用1/4模型进行有限元分析,即为两层板料及同侧模具的一半作为有限元分析的模型。

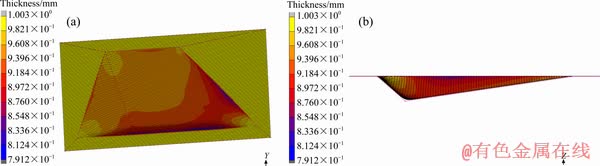

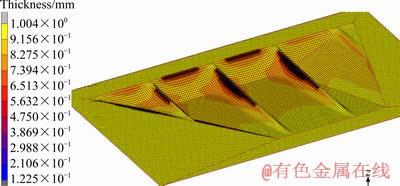

图7所示为面板成形的最终厚度分布图,由图7可以看出,对于面板成形,最薄部位的厚度在0.79 mm左右,材料的性能能够满足这种厚度变化。

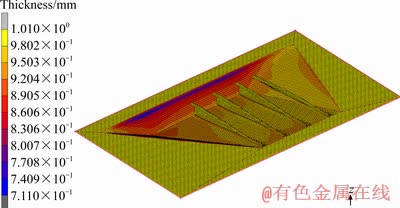

根据模型尺寸及要求,进行了网格尺寸宽度为50 mm,扩散连接宽度为4 mm的有限元分析,得到最终的厚度分布结果如图8所示,由于成形的网格宽度较小,且高度最大的部位为最后成形部位,在直立筋部位减薄严重,最薄厚度不足0.1 mm。增加网格的宽度,图9所示为网格宽度80 mm时的成形厚度分布结果,图9中为成形过程中板材部分贴模时的厚度分布,最小厚度也在0.12 mm,而此时直立部位的成形并未完全完成,对于目前Ti2AlNb合金该减薄量过大,将产生破裂。

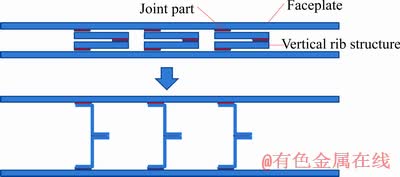

根据分析结果,可以确定对于目前的材料性能,进行这种结构的成形由于受到成形高度的限制,结构件的成形极易出现破裂,造成结构件的失效。针对该种情况,对结构件的成形方法进行改进,利用内部放置直立筋以代替芯板变形的方法来实现该种结构件的成形,采用放置直立筋的成形方法,直立筋部位的主要变形为弯曲变形,面板成形和扩散连接是关键,已经对面板成形进行分析,减薄量小,易于成形,放置直立筋的成形示意图如下图10所示。

图6 连接参数对连接界面微观组织的影响

Fig. 6 Microstructures of diffusion bonding interfaces under different conditions

图7 面板成形厚度分布图

Fig. 7 Thickness values of face-sheet

图8 芯板成形厚度分布(网格50 mm)

Fig. 8 Thickness distribution of core sheet (mesh 50 mm)

图9 芯板成形厚度分布(网格80 mm)

Fig. 9 Thickness distribution of core sheet (mesh 80 mm)

图10 直立筋结构成形示意图

Fig. 10 Schematic diagram of forming process of cross- section profiles for vertical rib structure

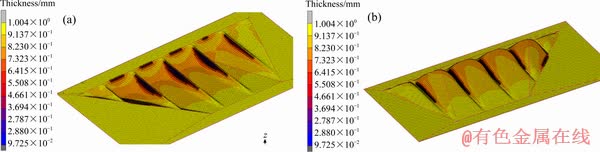

在原始模具模型的基础上,在模具的中间部位放置4条直立筋,其中一条直立筋要与两个不同的平面扩散连接,变形不同于其他3条直立筋,直立筋的布置及最终成形结果如图11所示。由图11可以看出,面板的厚度仍旧在0.7 mm以上,而直立筋的厚度基本不发生变化,直立筋的主要变形为弯曲变形。3条直立筋在垂直方向上拉直效果较明显,而与两个平面相连接的直立筋由于形状尺寸和另外3条相同。

2.4 中空四层结构SPF/DB成形

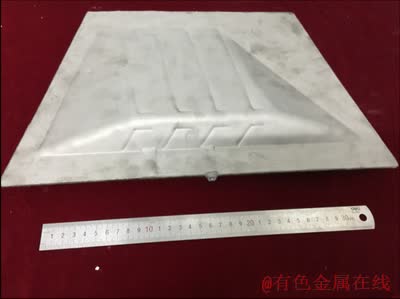

立筋四层结构芯板形状如图12所示。

对预扩散区域首先进行机械打磨,首先采用粗砂纸对芯板和面板表面进行打磨,后采用细砂纸800#或1000#的砂纸进行打磨。化学处理采用酸洗,酸洗液成分体积配比:V(HF):V(HNO3):V(H2O)=1:3:7。酸洗时间10 min左右,在酸洗过程中使用毛刷不断刷去酸洗表面反应生成的残留物,酸洗完后采用酒精清洗板材的表面,在干燥通风处将酸洗后的芯板和面板晾干。

图11 直立筋的超塑成形模拟结果

Fig. 11 Simulation results of vertical ribs by superplastic forming process

图12 立筋结构芯板实物图

Fig. 12 Picture of vertical ribs structure

对于接触面板与芯板以及芯板与芯板之间非扩散部位涂抹止焊剂。对于四层结构将阻焊剂主要涂抹在两层芯板的上、下表面,面板内表面可不涂抹止焊剂。

对于四层结构的面板和芯板,芯板的尺寸同面板相比小很多,除了等腰梯形面板的上底边处为四层板料,其他三个边上均只有两层面板而无多余的芯板结构,因而需要在边缘部位放置两层与芯板厚度相同的Ti2AlNb合金板料,沿其他三个边的边缘放置,保证封边焊区域均为4层结构。

封边焊接之后,在加热之前即开始抽真空,真空度至2×10-2 MPa,持续抽真空到扩散连接实验结束。扩散连接前在板材上下放置两块略小的面板的高温合金板(2 mm左右),置于封边焊焊缝轮廓的内部,不与焊缝接触。保证扩散过程中压力分布的均匀和压边区域的扩散连接,另外止焊剂有一定厚度,在多层结构需扩散部位面板上、下各放置一层或两层Ti箔,抵消止焊剂带来的厚度差。

扩散连接过程中持续抽真空,由于芯板的尺寸小于面板尺寸,在无芯板的区域面板受到外部压力的作用有一定程度的向内变形,该部分两层面板会有一定的接触连接,但由于Ti2AlNb合金扩散连接所需的压力较大,接触连接部分在随后的胀形过程中一定气压条件下会分开。

加热到温度后,保温1 h,以保证模具和板料的温度达到设定温度。保温过程中即可施加一定的压力,模具热胀使得压力在保温过程中逐渐增大,扩散连接参数为(960 ℃,10 MPa,2 h),压力机指示在50 t左右,而钛箔总面积约为12000 mm2,计算平均压力在40 MPa左右。可实现Ti2AlNb基合金四层结构面板与芯板以及芯板间的良好扩散连接。

待温度下降后取件更换模具,成形模具尺寸略小于板料,梯形板料上下底边的焊缝均在模具外侧,露出2 mm左右,之后装炉加热。

成形温度选择970 ℃,待温度升高至指定温度后,通入氩气进行面板的超塑成形,气体压力缓慢增加,大约5 min气体压力增加0.1 MPa,待气压增值1 MPa之后,可加快增压速度,20~30 min内增加至2~2.5 MPa,保压1 h左右。图13所示为成形后的Ti2AlNb合金多层结构。成形轮廓贴模良好,表面质量较好。

图13 成形后的Ti2AlNb合金多层结构

Fig. 13 Hollow four-layer structure of Ti2AlNb alloy

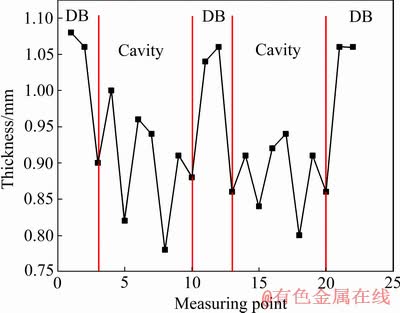

成形后零件壁厚分布曲线如图14所示。零件壁厚的主要减薄区域为直立筋弯曲部位之间的区域,但此处壁厚分布仍在0.7 mm以上。从图14中可以看到,零件的最大减薄率为25%左右,同模拟结果较为吻合。

图14 四层结构壁厚分布曲线

Fig. 14 Thickness distribution of four-layer structure

图15所示为成形后的Ti2AlNb合金多层结构剖开照片,可见直立筋成形到位,无破裂,成形效果较好。

图15 剖开后的多层结构内部特征

Fig. 15 Cross-section of hollow four-layer structure

3 结论

1) 当变形温度为960 ℃,应变速率为1×10-4 s-1时,材料伸长率可以达到最大值,为230%,表现出超塑性。

2) Ti-22Al-27Nb扩散连接接头的焊合率随着温度、保温时间、保温压力的增加而增加,在(960 ℃,10 MPa,2 h) 和(960 ℃,15 MPa,2 h)条件下得到的接头剪切强度超过300 MPa。

3) 在960 ℃,利用SPF/DB组合工艺可以成形出外观质量良好的Ti-22Al-27Nb合金中空四层结构件,构件蒙皮壁厚分布均匀,且直立筋厚度基本不发生变化。

REFERENCES

[1] 陈 静, 姜国政, 林 鑫, 黄卫东. 激光立体成形 Ti2AINb 基合金的组织和相结构[J]. 中国激光, 2010(2): 593-598.

CHEN Jing, JIAN Guo-zheng, LIN Xin, HUANG Wei-dong. Microstructure and phase structure of laser solid forming Ti2AlNb-based alloy[J]. Chinese Journal of Lasers, 2010(2): 593-598.

[2] 司玉锋, 孟丽华, 陈玉勇. Ti2AlNb基合金的研究进展[J]. 宇航材料工艺, 2006: 10-13.

SI Yu-feng, MENG Li-hua, CHEN Yu-yong. Progress in the study of Ti2AlNb-based alloy[J]. Aerospace Materials and Technology, 2006: 10-13.

[3] SIENIAWSKI J, MOTYKA M. Superplasticity in titanium alloys[J]. Journal of Achievements in Materials and Manufacturing Engineering, 2007, 24(1): 123-130.

[4] 窦健敏, 白秉哲. 我国钛合金超塑性研究的现状及进展[J]. 锻压技术, 1991, 16(3): 33-37.

DOU Jian-min, BAI Bin-zhe. Progress in the study of titanium superplasticity in China[J]. Forging & Stamping Technology, 1991, 16(3): 33-37.

[5] LIU Y, YAO Z, LUO X, CAO L. Superplastic properties and microstructural evolution during superplastic tension of Ti-24Al-15Nb-1.5 Mo alloy[J]. Rare Metal Materials and Engineering, 2008, 37(1): 14-18.

[6] ROSENBERG Y, MUKHERJEE A K. The superplastic properties of a Ti AlNb alloy[J]. Materials Science and Engineering A, 1995, 192: 788-792.

[7] SHAGIEV M R, GALEYEV R M, VALIAKHMETOV O R. Improved mechanical properties of Ti2AlNb-based intermetallic alloys and composites[C]// Advanced Materials Research. Spain: Trans Tech Publications, Ltd., 2008: 105-108.

[8] PENG J, MAO Y, LI Shi-qiong. Microstructure controlling by heat treatment and complex processing for Ti2AlNb based alloys[J]. Materials Science and Engineering A, 2001, 299(1/2): 75-80.

[9] ZHU H L, LI Z Q, SHANG B S. Superplasticity of a Ti-24A1-14Nb-3V-0.5 Mo intermetallic alloy[J]. Journal of Materials Science & Technology, 2001, 17(1): 119-120.

[10] 付明杰, 韩秀全, 吴 为, 张建伟. Ti-23Al-17Nb 合金板材超塑性研究[J]. 金属学报, 2014, 50(8): 955-961.

FU Ming-jie, HAN Xiu-quan, WU wei, ZHANG Jian-wei. Superplasticity Researchof Ti-23Al-17NbAlloy Sheet[J]. Acta Metallurgica Sinica, 2014, 50(8): 955-961.

[11] LIN P, HE Z, YUAN S. Tensile deformation behavior of Ti-22Al-25Nb alloy at elevated temperatures[J]. Materials Science and Engineering A, 2012, 556: 617-624.

[12] WANG C, ZHAO T, WANG G. Superplastic forming and diffusion bonding of Ti-22Al-24Nb alloy[J]. Journal of Materials Processing Technology, 2015, 222: 122-127.

[13] 张久文, 陈国清, 周文龙, 郭和平, 李志强. 热轧态 Ti2AlNb合金超塑性变形行为的研究[J]. 航空制造技术, 2007(z1): 449-453.

ZHANG Jiu-wen, CHEN Guo-qing, ZHOU Wen-long, GUO He-ping, LI Zhi-qiang. Superplastic behavior of hot rolled Ti2AlNb sheets[J]. Aeronautical Manufacturing Technology, 2007(z1): 449-453.

[14] 邹贵生, 白海林, 谢二虎. O相合金Ti-22Al-25Nb固态扩散连接[J]. 中国有色金属学报, 2008, 18(4): 577-582.

ZOU Gui-sheng, BAI Hai-ling, XIE Er-hu. Solid diffusion bonding of Ti-22Al-25Nb O phase alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(4): 577-582.

[15] 李贝贝, 王 斌, 李 萍. Ti2AlNb 基合金固态扩散连接工艺[J]. 中国有色金属学报, 2015, 25(3): 662-667.

LI Bei-bei, WANG Bin, LI Ping. Solid diffusion bonding of Ti 2AlNb-based alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(3): 662-667.

[16] 李贝贝. Ti2AlNb基合金固态扩散连接工艺研究[D]. 合肥: 合肥工业大学, 2015.

LI Bei-bei. Study on solid diffusion bonding of Ti2AlNb alloy[D]. Hefei: Hefei University of Technology, 2015.

[17] 张凯锋, 王国峰. 先进材料超塑成形技术[M]. 北京: 科学出版社, 2012.

ZHANG Kai-feng, WANG Guo-feng. Superplasticity in advanced materials[M]. Beijing: China Science Press, 2012.

[18] KAIBYSHEV O A. Superplasticity in metals and ceramics[J]. Materials Science Forum, 2001, 357/359: 73-82.

[19] 程文礼, 袁 超, 邱启艳. 航空用蜂窝夹层结构及制造工艺[J]. 航空制造技术, 2015, 476(7): 94-98.

CHENG Wen-li, YUAN Chao, QIU Qi-yan. Honeycomb sandwich structure and manufacturing process in aviation industry[J]. Aeronautical Manufacturing Technology, 2015, 476(7): 94-98.

Superplastic forming/diffusion bonding of Ti-22Al-27Nb alloy hollow four-layer structure

LI Bao-yong1, 2, JIANG Shao-song1

(1. Harbin Institute of Technology, National Key Laboratory for Precision Hot Processing of Metals, Harbin 150001, China;

2. Beijing Hangxing Machine Manufacturing, Beijing 100013, China)

Abstract: The hollow four-layer structure of Ti-22Al-27Nb alloy was fabricated by SPF/DB process. The characteristics and mechanism of Ti-22Al-27Nb alloy with respect to superplasticity and diffusion bonding were investigated. Tensile tests show that the optimal elongation of tensile specimens is 230% at the temperature of 960 ℃ and the strain rate of 1×10-4 s-1. Effect of the bonding pressure, bonding temperature and bonding time to determine the microstructure and mechanical properties of diffusion bonding joints was investigated, and the optimum bonding parameters are (960 ℃, 10 MPa, 2 h). Through the finite element simulation, it could be found that the SPF/DB process of hollow four-layer structure is feasible. The hollow four-layer structure of Ti-22Al-27Nb alloy is manufactured, showing that the thickness distribution of the bonding area is uniform.

Key words: Ti-22Al-27Nb; diffusion bonding; superplastic forming; four-layer structure

Foundation item: Projects(51775135, 51675125) supported by the National Natural Science Foundation of China

Received date: 2018-12-07; Accepted date: 2019-06-24

Corresponding author: JIANG Shao-song; Tel: +86-13936690628; E-mail: jiangss600_2005@163.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51775135; 51675125)

收稿日期:2018-12-07;修订日期:2019-06-24

通信作者:蒋少松,副教授,博士;电话:13936690628;E-mail:jiangss600_2005@163.com