文章编号:1004-0609(2010)S1-s0770-05

BTi-62421S高温钛合金的热成形及超塑成形性能

史 科,郭晓琳,王猛团

(北京航星机器制造公司, 北京 100013)

摘 要:对新型高温钛合金BTi-62421S进行卷圆、冷/热冲压成形、热涨性、热成形等实验研究,获得了该合金的热成形性能;通过高温超塑性拉伸试验,获得了该合金超塑性成形的最佳工艺参数,并进行该合金框架、舵面零件的超塑性成形试验。结果表明:BTi-62421S钛合金在(620±10)℃下保温20~25 min可实现筒形件的热涨形,在750 ℃左右可实现口框类零件的热成形,但热成形性能存在各向异性;该合金在温度为920 ℃,应变速率为1.0×10-3 s-1时具有最佳超塑性能,伸长率达到448.5%,在此条件下可成形出满足设计要求的舵面及框架样件。

关键词:BTi-62421S钛合金;热涨形;热成形;超塑成形

中图分类号:TG457.19 文献标志码:A

Hot forming and superplastic forming performance of high-temperature BTi-62421S titanium alloy

SHI Ke, GUO Xiao-lin, WANG Meng-tuan

(Beijing Hangxing Machinery Manufacturing Co., Beijing 100013, China)

Abstract: Experiments including crimping, cold pressing, hot pressing, hot bulging, hot forming were carried out to achieve the hot deforming performance of BTi-62421S alloy. The tensile tests under superplastic temperature were also carried out to determine the optimum parameters of superplastic forming. Furthermore, a BTi-62421S alloy frame and a rudder were superplastic deformed. The results show BTi-62421S alloy tube can be hot-bulged at (620±10) ℃for 20-25 min, and a big cage part can be hot-formed at about 750 ℃ although the alloy is anisotropic. BTi-62421S alloy has the optimal superplastic performance with the elongation of 448.5% when being deformed at the temperature of 920℃ and the strain rate of 1.5×10-4 s-1. A BTi-62421S titanium alloy frame and a rudder satisfying with the design requirements can be formed successfully under this condition.

Key words: BTi-62421S titanium alloy; hot bulging; hot forming; superplastic deformation

钛合金因其密度小、强度高,具有良好的耐热、抗腐蚀性能,在航空航天等领域得到广泛应用[1]。随着航空航天事业的发展,钛合金的使用温度逐步提高,迫切需要550 ℃以上的新型高温钛合金材料[2-4]。目前,国际先进的高温钛合金主要有:美国的Ti-6242S和Ti-1100,英国的IMI829和IMI834,俄罗斯的BT18y和BT36,以及中国的Ti-55、Ti-60和Ti-600等合 金[5-14]。但由于高温钛合金比一般钛合金变形抗力更大、塑性更低,其板材的成形比一般钛合金更困难,因此,关于这方面的研究报道较少。BTi-62421S合金是宝钛公司研制的一种新型高温钛合金,属于Al-Sn-Zr-Nb-Mo-Si系近α型钛合金,使用温度到550 ℃甚至更高,对该材料的性能尤其是热加工性能尚未见公开报道,无法满足工程化应用需要。

为此,本文作者研究了新型高温钛合金BTi- 62421S冷成形、热涨形及热成形性能。通过高温拉伸力学实验研究了该合金的最佳超塑变形工艺参数,并在该条件下成形出满足设计要求的钛合金框架及舵面零件,为该合金的工程化应用及航空航天构件的精密成形提供了依据。

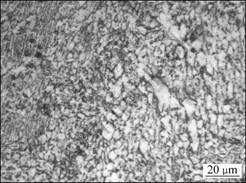

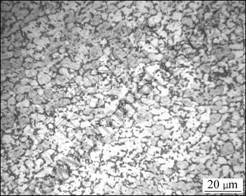

1 实验

实验材料是由宝钛集团有限公司生产的厚度为1.5 mm的BTi-62421S钛合金热轧板材,其名义成分为Al 6%,Sn 2%,Zr 4%,Nb 2%,Mo 1%。该合金沿轧制方向的微观组织形貌如图1所示,由图1可见:该材料的原始组织晶粒尺寸不太均匀,既有被拉伸的细长晶粒,又有等轴的晶粒。采用德国Netzch公司生产的STA-449C型同步热分析仪测得该合金的相转变温度为975 ℃。

对该材料进行圆筒及锥筒的室温精密卷圆试验,结合涨胎模具及热处理炉进行热涨校形试验,并且在500 t热成形/超塑成形机上完成大口框热成形及舵面和框架的超塑成形实验。

图1 BTi-62421S原始组织形貌

Fig.1 Initial microstructure of BTi-62421S alloy

2 结果与分析

2.1 冷成形实验

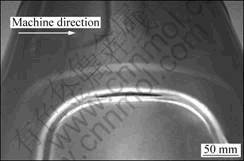

观察BTi-62421S钛合金采用剪板机下料后的断口形貌发现,该合金在剪切方向(沿纤维方向)断口不平整、较脆。该钛板经法国JAMMS 1503型精密卷圆机冷卷圆后回弹严重,最终只能卷成半圆或大半圆,经夹具夹持后在自动氩弧焊机上焊纵缝,焊后显示焊缝处存在明显的直边段,如图2所示。采用冲压模对其在常温下进行冲压实验,冲后产生明显裂纹,如图3所示。这些实验表明:BTi-62421S钛合金的冷成形性能较差,一般不适合采用室温条件下的拉伸、冲压等加工手段。

图2 冷卷圆零件

Fig.2 Cold crimping pressed tube

图3 冷冲压成形钛板

Fig.3 Cold stamped BTi-62421S alloy sheet

2.2 热涨形实验

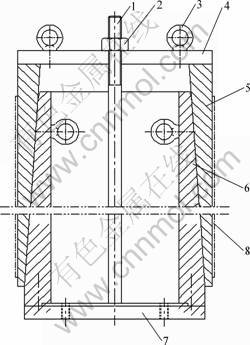

BTi-62421S钛合金板通过卷圆成形、焊接纵缝后成为一个闭合的筒体,筒体的外形与设计所要求的外形几何尺寸存在差距,钛合金筒形件需经涨胎校形。工艺过程如下:常温下在钛合金筒体表面涂高温防氧化保护涂料,将涨胎(结构如图4所示)放入筒体内,施加压力将涨胎涨紧,然后在加热炉内加热,当筒体被加热至(620±10) ℃时,保温20~25 min,筒体具有一定的塑性,达到应力松弛状态,消除了内应力,从而使筒体具有稳定圆弧尺寸。卸下涨胎后获得的筒体零件如图5所示,焊缝处直边段已消除,经检测外径尺寸符合要求。

2.3 热成形实验

由以上研究得知:BTi-62421S钛合金钣材室温塑性低、变形回弹大、对裂纹敏感易开裂。在此研究基础上对某航天用钛合金大口框零件进行高温热冲压成形(简称热成形)实验。钛合金热成形通常采用550~750 ℃的工艺参数[15],鉴于BTi-62421S钛合金比一般钛合金更耐高温,高温强度更高,因此,采用成形温度范

图4 涨胎模具结构图

Fig.4 Structural pattern of hot bulged die: 1—Tie rod; 2—Nut; 3—Hanging ring; 4—Platen; 5—Body mold; 6—Mould core; 7—Bed; 8—Sheet

图5 BTi-62421S合金锥筒

Fig.5 BTi-62421S alloy taper tube

围上限为720~750 ℃。实验在500 t热/超塑成形机上进行,采用工艺参数为:保温15 min,保压5 min,施加吨位为30 t。在此条件下按图示顺纤维方向热成形获得的复杂形状大口框零件如图6所示,经检测各部分成形完整,表面没有缺陷,尺寸符合要求,表明该合金热成形性能良好。而对坯料进行垂直纤维方向热成形时可能出现裂纹,如图7所示。实验结果显示通过调整温度等参数也不易消除裂纹,表明该材料热成形性能存在较明显的各向异性,横向塑形性能低于纵向塑形性能,这与坯料的微观组织与轧制方向性 相关。

图6 热成形口框

Fig.6 Hot formed cage part

图7 热成形裂纹

Fig.7 Crack during hot forming

2.4 超塑性能及工艺

2.4.1 超塑拉伸实验

超塑拉伸实验在INSTRON 5582型电子万能实验机上进行,所用板材厚度为1.5 mm,顺板材轧制方向用线切割方法切取样坯。

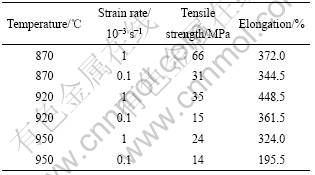

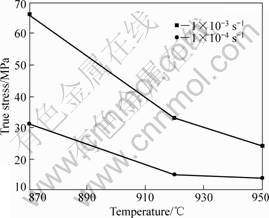

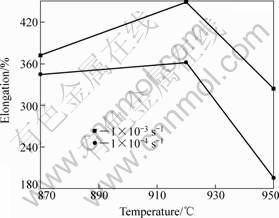

以恒应变速率1×10-3 s-1和1×10-4 s-1,在870、920和950 ℃对试样进行高温拉伸,实验结果见表1。结果显示:当温度为920 ℃,应变速率为1×10-3 s-1时,BTi-62421S合金的伸长率达到最大值,448.5%,且流变应力只有35 MPa。这一结果对开发BTi-62421S钛合金超塑性的工程应用具有重要意义。

图8所示为不同应变速率下真应力与温度的关系。由图8可见:BTi-62421S钛合金的变形抗力随着变形温度的升高和应变速率的降低而下降,但当温度超过920 ℃时变形抗力下降趋势变缓。图9所示为不同应变速率下伸长率与温度的关系。可见,该合金的伸长率对温度与应变速率都比较敏感,在相同温度条件下,伸长率随应变速率的降低而下降,在相同的应

表1 超塑性拉伸结果

Table 1 Results of superplastic tensile forming

图8 真应力与温度的关系

Fig.8 Relationship between true stress and temperature

图9 伸长率与温度的关系

Fig.9 Relationship between elongation and temperature

变速率下都在变形温度为920 ℃时达到峰值。

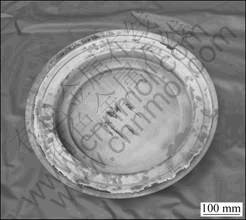

2.4.2 超塑成形工艺

根据以上研究,确定了钛合金BTi-62421S的超塑成形工艺参数为:920 ℃,1×10-3 s-1,在此条件下进行航天用某舵面样件的超塑成形。设置模具闭合压力为30 t,分阶段加载气压以保证超塑成形稳定性并尽可能保证成形速率控制在超塑性应变速率范围内。为使模具的拐角处充分贴模,在气压达到最大值1 MPa时保压10 min,最终在3 min内完成卸载,成形时间共计60 min。最终获得的钛合金舵面样件如图10所示,经检测其外观尺寸及壁厚符合设计要求。图11所示为舵面超塑成形零件的金相组织,与该合金原始组织相比(图1)可知:超塑成形后的组织中晶粒没有明显长大,而且尺寸及分布更为均匀。采用超塑成形工艺加工的航天用框架零件如图12所示。

图10 超塑成形舵面样件

Fig.10 Superplastic formed rudder

图11 舵面超塑成形零件的金相组织

Fig.11 Metallograph of superplastic formed rudder

图12 超塑成形框架零件

Fig.12 Superplastic formed frame

3 结论

1) BTi-62421S钛合金在温度为750 ℃左右时可实现口框类零件的热成形,但热成形性能存在方向性;利用涨胎模在温度为620 ℃左右时可实现筒形件的热涨形。

2) BTi-62421S钛合金最佳超塑变形工艺参数为920 ℃,1×10-3 s-1,在该变形条件下,极限伸长率为448.5%。

3) 在超塑性成形工艺条件下,BTi-62421S钛合金可成形出质量合格的舵面样件及框架,成形后合金的显微组织、尺寸及分布比变形前更加均匀。

REFERENCES

[1] 李 梁, 孙建科, 孟祥军. 钛合金超塑性研究及应用现状[J]. 材料开发与应用, 2004,19(6): 34-38.

LI Liang, SUN Jian-ke, MENG Xiang-jun. Research progress and application of superplasticity of titanium alloys[J]. Development and Application of Materials, 2004, 19(6): 34-38.

[2] 许国栋, 王凤娥. 高温钛合金的发展和应用[J]. 稀有金属, 2008, 32(6): 774-780.

XU Guo-dong, WANG Feng-e. Development and application of high temperature titanium alloys[J]. Chinese Journal of Rare Metals, 2008, 32(6): 774-780.

[3] 付艳艳, 宋月清, 惠松骁, 米绪军. 航空用钛合金的研究与应用进展[J]. 稀有金属, 2006, 30(6): 850-856.

FU Yan-yan, SONG Yue-qing, HUI Song-xiao, MI Xu-jun. Research and application of typical aerospace titanium alloy[J]. Chinese Journal of Rare Metals, 2006, 30(6): 850-856.

[4] 钱九红. 航空航天用新型钛合金的研究发展及应用[J]. 稀有金属, 2000, 24(3): 218-223.

QIAN Jiu-hong. Application and development of new titanium alloys for aerospace[J]. Chinese Journal of Rare Metals, 2000, 24(3): 218-223.

[5] 蔡建明, 李臻熙, 马济民, 黄 旭, 曹春晓. 航空发动机用600 ℃高温钛合金的研究与发展[J]. 材料导报, 2005, 19(1): 50-53.

CAI Jian-ming, LI Zhen-xi, MA Ji-ming, HUANG Xu, CAO Chun-xiao. Research and development of 600 ℃ high temperature titanium alloys for aeroengine[J]. Materials Review, 2005, 19(1): 50-53.

[6] 萧今声, 许国栋. 提高高温钛合金性能的途径[J]. 中国有色金属学报, 1997, 7(4): 97-105.

XIAO Jin-sheng, XU Guo-dong. Several ways to improve mechanical properties of high-temperature Ti-based alloys[J]. The Chinese Journal of Nonferrous Metals, 1997, 7(4): 97-105.

[7] 魏寿庸, 何 瑜, 王青江, 刘羽寅. 俄航空发动机用高温钛合金发展综述[J]. 航空发动机, 2005, 31(1): 52-58.

WEI Shou-yong, HE Yu, WANG Qing-jiang, LIU Yu-yin. Development of the aeroengine heat- resisting titanium alloys in russia[J]. Aeroengine, 2005, 31(1): 52-58.

[8] 洪 权, 戚运莲, 刘 向, 赵永庆. Ti600合金板材的轧制工艺与电子束焊接性能研究[J]. 航空材料学报, 2006, 26(5): 31-34.

HONG Quan, QI Yun-lian, LIU Xiang, ZHAO Yong-qing. Effects of rolling process on microstructure and properties of Ti600 alloy plates[J]. Journal of Aeronautical Materials, 2006, 26(5): 31-34.

[9] 杨 义, 黄爱军, 徐 峰, 李阁平. BT18y钛合金等轴组织与全片层组织的室温拉伸塑性[J]. 中国有色金属学报, 2005, 15(5): 768-774.

YANG Yi, HUANG Ai-jun, XU Feng, LI Ge-ping. Room-temperature tensile plasticity of BT18y titanium alloy with equiaxed structure and fully lamellar structure[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(5): 768-774.

[10] CHEN Y X, WAN X J, LI F, WANG Q J, LIU Y Y. The behavior of hydrogen in high temperature titanium alloy Ti-60[J]. Materials Science and Engineering A, 2007, 466: 156-159.

[11] 洪 权, 戚运莲, 赵永庆, 杨冠军. 加工工艺对Ti-600合金板材组织性能的影响[J]. 稀有金属材料与工程, 2005, 34(8): 1334-1337.

HONG Quan, QI Yun-lian, ZHAO Yong-qing, YANG Guan-jun. Effect of rolling process on microstructure and properties of Ti600 alloy plates[J]. Rare Metal Materials and Engineering, 2005, 34(8): 1334-1337.

[12] LEI J F, WANG Z G, LI D, HU Z Q. Fatigue crack initiation in Ti-5Al-4Sn-2Zr-1Mo-0.7Nd-0.25Si high temperature titanium alloy[J]. International Journal of Fatigue, 1997, 19(s): s95-s98.

[13] HAMOUDA G. Microstructure and fatigue crack growth mechanisms in high temperature titanium alloys[J]. International Journal of Fatigue, 2010, 32: 1448-1460.

[14] NIU Y, HOU H L, LI M Q, LI Z Q. High temperature deformation behavior of a near alpha Ti600 titanium alloy[J]. Materials Science and Engineering A, 2008, 492: 24-28.

[15] 尚建勤. 钛合金TC1整流内罩热成形工艺研究[J]. 锻压技术, 2000(2): 17-18.

SHANG Jian-qin. Research on hot-forming technology for TC1 fairing internal cap[J]. Forging and Stamping Technology, 2000(2): 17-18.

(编辑 陈卫萍)

通信作者:史 科,工程师,博士;电话:010-88103425;E-mail:shike239@sina.com