DOI: 10.11817/j.ysxb.1004.0609.2020-35747

通孔式钛合金层强韧化Ti2AlC/TiAl基叠层复合板材

牛群飞1,艾桃桃1, 2,刘 洁1,邓志峰1, 2,冯小明1, 2,李文虎1, 2,袁新强1, 2,包维维1, 2,董洪峰1, 2

(1. 陕西理工大学 材料科学与工程学院,汉中 723000;

2. 陕西理工大学 矿渣综合利用环保技术国家地方联合工程实验室,汉中 723000)

摘 要:以通孔式结构TC4钛合金箔为增韧层,以TiC-Ti-Al混合粉末为反应体系,采用放电等离子烧结技术(SPS)制备TC4/Ti2AlC-TiAl基叠层结构复合板材。借助XRD、SEM等分析相组成和组织结构,并测量室温弯曲强度和断裂韧性。结果表明,叠层结构复合板材的力学性能呈各向异性;当Ti2AlC含量(质量分数)为15%时,断裂韧性在加载方向垂直于叠层方向时达到最大值18.81 MPa·m1/2,远高于无Ti2AlC的复合板材的断裂韧性。通孔叠层结构设计以及复合化手段构建了复杂的裂纹扩展路径,且钛合金韧化层可以吸收断裂能,对改善韧性具有重要作用,为金属复合板材研究提供了一种全新的设计思路。

关键词:叠层复合板材;金属间化合物;结构设计;力学性能

文章编号:1004-0609(2020)-04-0829-08 中图分类号:TB33 文献标志码:A

TiAl金属间化合物具有良好的耐腐蚀性、高温抗氧化性以及优越的力学性能,作为重要的结构材料可广泛用于航空航天、轮船和汽车工业等领域[1-5]。但由于TiAl金属间化合物具有本征脆性,使TiAl金属间化合物的推广应用较为缓慢。在尝试提高塑性的同时往往伴随着强度的降低,如何有效解决塑性-强度相互倒置的关系,成为各国研究人员面临的主要科学问题。贝壳是由珍珠层和特殊的蛋白质组成“三明治”结构,兼具较高的强度和韧性,一直被科研人员进行仿生复制。叠层结构复合材料力学性能不同于常规的复合材料,通过叠层结构设计,使得裂纹在扩展过程中断裂能量不断被层结构消耗,从而达到增韧的目的。OHASHI等[6]发现层压钢-黄铜复合材料在自身弯曲没有失效的情况下,拥有优异的延展性。SUN等[7]开发了Ti/Ti-Al层压复合材料,在室温下也显示出高耐损伤能力,且弯曲强度比拉伸性能要好。AI等[8]用放电等离子烧结技术制备TC4/Ti2AlC-TiAl复合板材,当Ti2AlC含量(质量分数)达到10%时,抗弯强度和断裂韧性高达1346.98 MPa和67.72 MPa·m1/2。ZHANG等[9]利用电子束物理气相沉积法成功制备出了TiAl/NiCoCrAl层压复合板材,三层微层压板在室温下综合性能最高。因此,创新叠层结构设计,研究其对力学性能的影响具有重要的意义。

此外,复合化技术通过引入合适的第二相(颗粒、晶须、纤维等)增强TiAl基合金的综合性能,也是研究人员关注的方向。但连续纤维和晶须增强TiAl基合金工艺复杂,纤维表面处理不当容易造成与基体合金发生脱粘,也是目前研究人员面临的问题。颗粒增强TiAl基合金具有各向异性、工艺简单等优点,逐渐受到重视。以三元化合物Ti2AlC最具代表性,Ti2AlC具有金属和陶瓷的双重优点,热膨胀系数和TiAl接近,是目前通过原位反应作为增强TiAl合金力学性能的重要增强相[10-14]。AI等[14]在研究Ti2AlC/TiAl基复合材料的力学性能时发现,由于Ti2AlC相加入,抗弯强度高达937.7 MPa;用反应热压法制备Ti2AlC/TiAl基复合材料,发现Ti2AlC相主要存在于基体晶粒边界上,细化了γ+α2晶粒[15];用Ti3AlC2分解生成Ti2AlC制备了Ti3AlC2-Ti2AlC/TiAl复合材料,系统揭示了Ti3AlC2-Ti2AlC组合增韧对裂纹延伸的影响[16]。

但是,纵观国内外相关文献发现,传统叠层结构复合板材在垂直叠层结构和平行叠层结构方向性能差距较大,制约了其应用。本文为了缩小不同方向的性能差距,对TC4钛合金箔增韧层进行开孔处理,以TiC-Ti-Al混合粉末为反应体系形成复合层,通过放电等离子烧结技术(SPS)制备通孔式结构钛合金层强韧化Ti2AlC/TiAl基叠层结构复合板材,研究特殊的叠层结构及Ti2AlC增强相双重耦合作用对复合板材力学性能的影响。

1 实验

以商用Ti粉(纯度≥99.5%,质量分数;平均粒度<35 μm),Al粉(纯度≥99.5%,平均粒度<55 μm),TiC粉(纯度≥99.5%,平均粒度<20 μm)作为原料,利用反应式(1+n)Ti+(1+n)Al+TiC=nTiAl+Ti2AlC,计算了Ti2AlC理论生成量为0%、10%、15%、20%和30%时对应的Ti、Al和TiC的质量分数。

表1 叠层结构复合板材的配方

Table 1 Formula of laminated composite sheets

按照表1设计配方准确称量粉末,然后将Ti粉、Al粉、TiC粉末放入球磨罐,用KQM-X4/B行星式球磨机球磨4 h,转速为150 r/min,球料比4:3,球磨完成后过筛备用。将打磨后的TC4钛合金箔(Ti-6Al-4V)用钻床进行钻孔,孔的直径为3 mm,孔与孔之间的距离为6 mm,如图1所示。将钻孔后的TC4钛合金箔进行酸洗腐蚀处理,除去表面的杂质及氧化层。将混合后的粉末和处理后的TC4钛合金箔以叠加的方式装入石墨模具中,通孔TC4钛合金箔的层数为5层,采用SPS技术进行固化烧结,压力值设定12.5 MPa。

用X射线衍射仪(XRD,D/max-2200PC,日本)分析相组成。通过扫描电镜(SEM,JSM-6700F,日本)结合能谱分析(EDS)观察样品的微观结构、裂纹延展路径及断口形貌。采用三点弯曲法测试材料的弯曲强度,跨距为30 mm,样品尺寸为44 mm×9 mm×7 mm。采用单边切口梁法测量断裂韧性,切口深度为3 mm,宽度为0.12 mm,跨距为26 mm,样品尺寸为33 mm×9 mm×7 mm。弯曲强度测试和断裂韧性测试压头下降速度均为0.75 mm/min。所有测试样品都已进行抛光处理,腐蚀液成分配比(体积分数)为5%HF和95%H2O。

图1 叠层结构工艺流程图

Fig. 1 Technological process of laminated structure

2 结果与讨论

2.1 结构分析

图2所示为Ti2AlC理论含量为20%对应的叠层复合板材的结构及EDS分析结果。由图2(a)可见,叠层结构中通孔结构特征明显,由于采取了手动打孔,孔的加工精度并不高,导致孔的尺寸并不均匀,且叠放过程层和层之间的孔洞呈错位分布。图2(b)所示为叠层结构的EDS线扫描结果。由图2(b)可见,增韧层和复合层之间因界面反应形成了新的界面层。分析发现,靠近TC4端Ti元素含量在增大,Al元素含量逐渐降低,初步判断界面层主要成分为Ti3Al相。界面层的存在增强了复合层和增韧层之间的粘结力,对改善复合板材的力学性能有利。对图2(b)复合层中的界面相进行EDS点分析,结果如图2(c)所示,表明该区域主要为增强相Ti2AlC以及少量的基体相Ti3Al。观察还发现Ti2AlC相呈不规则形貌,不同于文献[17]中呈菌棒类,主要是烧结工艺不同导致形貌差异。少量Ti2AlC相存在于复合层基体界面处,发挥了一定的颗粒强化作用。

2.2 相组成与结构分析

图2 Ti2AlC理论含量为20%对应叠层复合板材结构和EDS分析结果

Fig. 2 Microstructure(a) and EDS analysis((b), (c)) of laminated composite sheet with 20% Ti2AlC

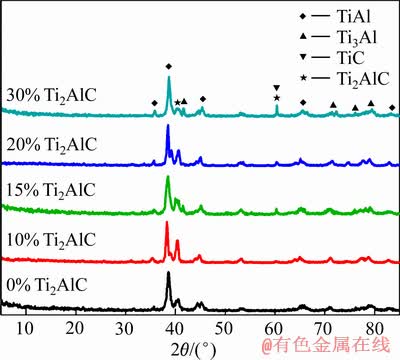

图3所示为叠层结构复合板材复合层的XRD谱。由图3可见,TiC-Ti-Al体系烧结后的产物主要为TiAl、Ti3Al、TiC、Ti2AlC相。结合Ti-Al二元相图,在Ti-Al之间生成的化合物有多种。在660 ℃的条件下,Ti→Al的扩散速度和Al→Ti的扩散速度分别为0.066 μm/s和0.075 μm/s[18]。因此在Al液中是Al原子向Ti原子扩散,即最初的生成相为TiAl3相。随着原位反应继续进行,TiAl3相和Ti生成吉布斯自由能更低的γ-TiAl和α2-Ti3Al相。当反应平衡后,最终产物为γ-TiAl和少量的α2-Ti3Al相。随着烧结温度的进一步升高,TiC和γ-TiAl生成Ti2AlC相。综上所述,烧结过程中发生的主要反应如下所示:

Ti+3Al=TiAl3 (1)

TiAl3+ 4Ti=2TiAl+ Ti3Al (2)

TiAl+TiC=Ti2AlC (3)

图3 叠层结构复合板材复合层的XRD谱

Fig. 3 XRD patterns of composite layers of laminated composite sheets

2.3 力学性能分析

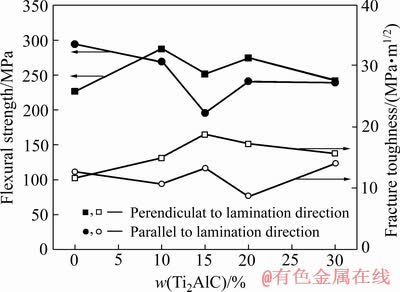

图4所示为TiAl叠层结构复合板材的力学性能。由图4可见,复合板材性能呈各向异性,即在垂直叠层和平行叠层结构方向性能有所差别。当Ti2AlC含量为0%时,加载方向垂直于增韧层方向时,叠层复合板材的弯曲强度和断裂韧性分别为226.53 MPa和11.73 MPa·m1/2;加载方向平行于增韧层方向时,复合板材的弯曲强度和断裂韧性分别为294.95 MPa和12.68 MPa·m1/2。随着Ti2AlC含量的增大,弯曲强度和断裂韧性基本呈增大趋势。当Ti2AlC含量达到10%时,加载方向垂直于叠层方向时,叠层复合板材的弯曲强度和断裂韧性分别达到287.08 MPa和14.94 MPa·m1/2,比Ti3AlC2三元陶瓷[19]的弯曲强度(245.86 MPa)和断裂韧性(6.63 MPa·m1/2)分别高出了16.77%和125.34%。当Ti2AlC含量达到15%时,综合断裂韧性较好,但弯曲强度降低,强度和韧性表现出倒置关系,但强度降低幅度并不大,且在加载方向垂直于叠层方向时,抗弯强度为251.25 MPa,断裂韧性达到最高为18.81 MPa·m1/2,比不含Ti2AlC增强相的TiAl叠层复合板材的抗弯强度和断裂韧性分别提高了10.91%和60.36%;在加载方向平行于叠层方向时,弯曲强度和断裂韧性分别为195.53 MPa和13.32 MPa·m1/2,比不含Ti2AlC增强相的TiAl基叠层复合板材抗弯强度有所降低,但断裂韧性提高了5.05%。分析认为,强度的降低与Ti2AlC增强相的含量及其团聚有一定的关系,合适的Ti2AlC增强相对改善综合性能有利,也与叠层结构数量有关,叠层数量会影响承载能力。当加载方向平行于叠层方向时,多层钛合金箔对强度发挥了主要作用,但由于钛合金箔厚度较薄,使得弯曲强度略低。由于通孔结构设计,较好地缩小了垂直叠层结构和平行叠层结构方向的性能差距。

图4 TiAl叠层结构复合板材力学性能

Fig. 4 Mechanical properties of TiAl laminated composite sheets

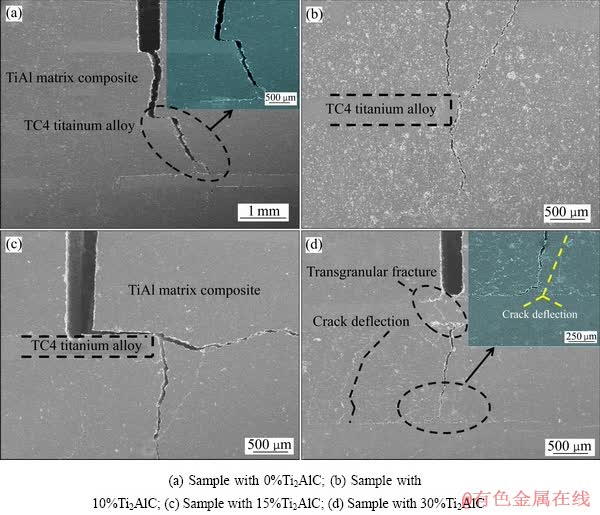

虽然对增韧层进行通孔设计是一种全新的思路,但较传统未开孔的层压复合板材,综合性能有所降低;一方面受通孔直径及孔分布的影响,另一方面也受叠层结构数量以及层层之间厚度的影响。图5所示为Ti2AlC/TiAl基叠层复合板材的断口断裂特征。由图5可见,裂纹扩展路径主要沿着增韧层与复合层的结合界面处延伸,到达通孔边缘处,裂纹会绕着通孔扩展,发生偏转,改变原裂纹扩展路径。裂纹沿通孔的边缘向相邻增韧层进行延展,到达相邻增韧层时又通过孔进行传递,以此类推,直至断裂能量消耗完毕。图5(a)所示为未原位形成Ti2AlC增强相的复合板材,裂纹主要沿着TC4钛合金层和TiAl合金层的结合处扩展,裂纹扩展宽度较小且扩展距离也较小,说明强度较高韧性一般。图5(b)所示为Ti2AlC含量为15%的复合板材,裂纹扩展宽度和长度增大,主要绕着钛合金层扩展以及向复合层扩展,扩展路径增大,预示着韧性增加,与图4所示韧性变化结果一致。随着Ti2AlC含量的继续增大,由于界面层厚度的增大,导致扩展裂纹沿着界面层和复合层结合处扩展,强度降低,韧性变差,如图5(c)所示。总体发现,该通孔结构设计使增韧层对裂纹延展能量吸收并不理想,对复合板材的力学性能提高幅度不明显,分析原因可能是通孔尺寸过大以及韧性层的错位分布所致。但是,从图5(d)可以看出,样品经力学性能测试后,并未发生断裂,说明叠层结构设计具有一定的优势。

图5 Ti2AlC/TiAl基叠层复合板材断裂特征

Fig. 5 Fracture morphologies of Ti2AlC/TiAl-based laminated composite sheets

图6所示为Ti2AlC/TiAl基叠层复合板材的裂纹扩展照片。由图6(a)可见,当未含有Ti2AlC时,裂纹在复合层扩展时,未发生明显的偏转,扩展路径较为平直,当到达增韧层时,沿着结合界面处扩展直至到通孔处,然后沿着通孔边缘扩展,进入相邻复合层,扩展路径较短。由图6(b)可见,当Ti2AlC含量为10%时,可以明显观察到裂纹偏转现象以及齿状扩展裂纹。裂纹在复合层扩展过程中,由于Ti2AlC颗粒的强化作用,其扩展驱动力越来越小,最终在复合层扩展终止,说明第二相Ti2AlC的生成发挥了重要的阻碍作用。由图6(c)可见,当Ti2AlC含量为15%时,裂纹由开槽口底端开始扩展,绕着复合层和增韧层结合处扩展,到达通孔边缘,裂纹会绕着增韧层和复合层及孔边缘继续扩展,到达新的复合层,发生裂纹分叉现象,而且裂纹在复合层扩展过程中发生明显的偏转现象。裂纹延伸的路径并且由宽变窄,说明裂纹驱动力减小,说明TC4钛合金箔作为增韧层和合适比例的Ti2AlC增强相对裂纹的延伸发挥了重要的阻碍作用。由图6(d)可见,裂纹穿过TC4增韧层在复合层中继续延伸,在裂纹尖端发生了尖端分叉现象,裂纹的扩展路径较其他几种复合板材明显减小,间接说明韧性变差。裂纹出现宽分叉现象后在尖端产生大量的裂纹尖点,尖点处应力场不能解耦,尖点之间由于相互交叉、干涉,导致应力集中因子骤降,使得应力场应力集中程度快速下降,裂纹的延展更加困难[20]。裂纹分叉后的应力强度与裂纹的扩展速度及分叉角有关,当分叉角越大,应力集中因子下降越明显,裂纹尖端会产生钝化越明显,裂纹在延伸过程中消耗的驱动力增加[21]。这也说明增韧层对裂纹起到了阻断作用,改变了裂纹的延展路径。

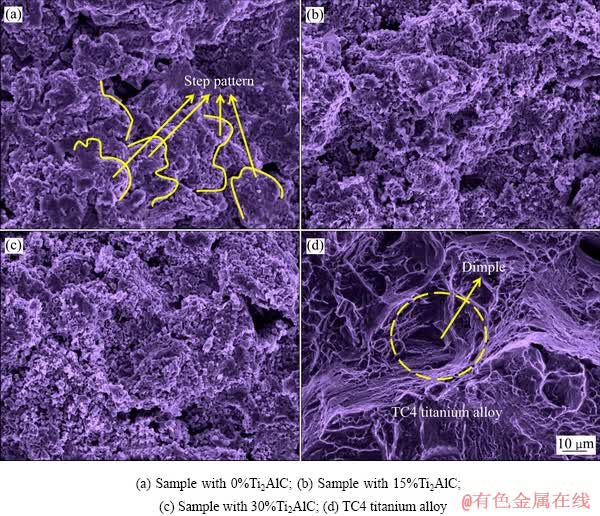

图7所示为复合板材复合层的断口形貌。从图7(a)可以看出,复合层断裂模式主要为脆性断裂,出现明显的解理断裂台阶。基体晶粒主要为层片状结构,晶粒大小不一,说明断裂方式为沿晶断裂和穿晶断裂两种模式。由于原位反应引入的孔隙和断裂过程中应力对复合层拉伸所产生的缺陷,导致晶粒层片之间存在大小不一的孔洞。在图7(b)和(c)中,无法观察到完整的层片状基体晶粒,但可以明显观察到许多细小的Ti2AlC颗粒, Ti2AlC颗粒主要存在基体晶粒晶界处,抑制了基体晶粒γTiAl-α2 Ti3Al相的长大,达到了细化晶粒的效果。当基体晶粒越细小时,晶界越多,位错的滑移和启动越困难,消耗的断裂能量就越大,也间接地提高了复合层的力学性能。图7(d)所示为TC4钛合金的断口形貌,从图中可以看出,断口表面存在着大小不一的韧窝,但撕裂脊表面光滑平整且断口形貌出现了河流花样,说明TC4钛合金的断裂是由韧性断裂和脆性断裂两种模式混合组成。

图6 Ti2AlC/TiAl基叠层复合板材裂纹扩展照片

Fig. 6 Crack propagation photos of Ti2AlC/TiAl-based laminated composite sheets

图7 复合板材复合层断口形貌

Fig. 7 Fracture morphologies of composite layers of composite sheets

3 结论

1) 采用SPS技术成功制备通孔式钛合金层强韧化Ti2AlC/TiAl基叠层结构复合板材。叠层结构主要由通孔TC4钛合金层和Ti2AlC/TiAl复合层交替构成,复合层相组成主要为TiAl、Ti3Al、TiC和Ti2AlC。

2) 通孔式叠层结构复合板材的力学性能具有各向异性特征,但是由于通孔结构设计,大大缩小了垂直叠层结构和平行叠层结构方向的性能差距。周期性通孔结构设计改变了裂纹的延展路径,可有效吸收断裂能量,同时原位Ti2AlC增强相可阻碍裂纹扩展,进而使断裂韧性有较大的提高。通孔式叠层结构设计为金属基复合板材研究提供了一种全新的设计思路。

REFERENCES

[1] 陈钰青, 王 岩, 罗世彬, 龚雪雯, 张 驰. TiB2对γ-TiAl基合金粉末放电等离子烧结行为的影响[J]. 中国有色金属学报, 2018, 28(1): 61-70.

CHEN Yu-qing, WANG Yan, LUO Shi-bin, GONG Xue-wen, ZHANG Chi. Effect of TiB2 on spark plasma sintering behavior of γ-TiAl based alloy powders[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(1): 61-70.

[2] 祁梓宸, 余 超, 肖 宏, 许 成. 异温轧制制备钛/铝复合板的变形协调性与复合性能[J]. 中国有色金属学报, 2018, 28 (6): 1120-1127.

QI Zi-chen, YU Chao, XIAO Hong, XU Cheng. Deformation coordination compatibility and bonding properties of Ti/Al composite plates prepared by different temperature rolling [J]. The Chinese Journal of Nonferrous Metals, 2018, 28(6): 1120-1127.

[3] 徐江宁, 刘秀波, 乔世杰, 翟永杰, 涂 溶. Ti6Al4V合金表面激光熔覆NiCrAlSi复合涂层的组织及高温抗氧化性能[J]. 中国有色金属学报, 2018, 28(1): 46-52.

XU Jiang-ning, LIU Xiu-bo, QIAO Shi-jie, ZHAI Yong-jie, TU Rong. Microstructure and high-temperature oxidation resistance of NiCrAlSi composite coating on Ti6Al4V alloy by laser cladding[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(1): 46-52.

[4] ZONG Ying-ying, WEN Dao-sheng, LIU Zu-yan, SHAN De-bin. γ-Phase transformation, dynamic recrystallization and texture of a forged TiAl-based alloy based on plane strain compression at elevated temperature[J]. Materials and Design, 2016, 91: 321-330.

[5] ERDELY P, STARON P, MAAWAD E, SCHELL N, KLOSE J, CLEMENS H, MAYER S. Design and control of microstructure and texture by thermomechanical processing of a multi-phase TiAl alloy[J]. Materials and Design, 2017, 131: 286-296.

[6] OHASHI Y, WOLFENSTINE J, KOCH R, SHERBY O D. Fracture behavior of a laminated steel-brass composite in bend tests[J]. Materials Science and Engineering A, 1992, 151(1): 37-44.

[7] SUN Yan-bao, CHEN Jing, MA Feng-mei, AMEYAMA Kei, XIAO Wen-long, MA Chao-li. Tensile and flexural properties of multilayered metal/intermetallics composites[J]. Materials Characterization, 2015, 102: 165-172.

[8] AI Tao-tao, FEI Yan-han, DENG Zhi-feng, LI Wen-hu, FENG Xiao-ming, YUAN Xin-qiang, NIU Qun-fei. Enhanced toughness and strength of multi-laminated TiAl composite sheets reinforced by periodic titanium alloy layers and carbides particles[J]. Materials Express, 2018, 8(4): 361-367.

[9] ZHANG Ru-bing, ZHANG Yao-yao, LIU Qiang, CHEN Gui-qing, ZHANG De-ming. Effect of a ductility layer on the tensile strength of TiAl-based multilayer composite sheets prepared by EB-PVD[J]. Materials Characterization, 2014, 95: 157-163.

[10] AI Tao-tao. High-temperature oxidation behavior of un-dense Ti3AlC2 material at 1000 ℃ in air[J]. Ceramics International, 2012, 38(3): 2537-2541.

[11] AI Tao-tao, LIU Fang, FENG Xiao-ming, YU Qi, YU Ning, RUAN Miao-miao, YUAN Xin-qiang, ZHANG Ying-tang. Processing, microstructural characterization and mechanical properties of in situ Ti3AlC2/TiAl3 composite by hot pressing[J]. Materials Science and Engineering A, 2014, 610(29): 297-300.

[12] LAPAUW T, VANMEENSEL K, LAMBRINOU K, VLEUGELS J. A new method to texture dense Mn+1AXn, ceramics by spark plasma deformation[J]. Scripta Materialia, 2016, 111: 98-101.

[13] SUN Hong-fei, LI Xue-wen, ZHANG Peng, FANG Wen-bin. The microstructure and tensile properties of the Ti2AlC reinforced TiAl composites fabricated by powder metallurgy[J]. Materials Science and Engineering A, 2014, 611(9): 257-262.

[14] AI T, YU Q, LI W. Design and strengthening behaviour of Ti2AlC/TiAl composite by low-temperature hot-pressing process[J]. Advances in Applied Ceramics: Structural, Functional and Bioceramics, 2016, 115: 190-192.

[15] AI Tao-tao, YU Ning, FENG Xiao-ming, XIE Nian-suo, LI Wen-hu, XIA Peng-ju. Low-temperature synthesis and characterization of Ti2AlC/TiAl in situ composites via a reaction Hot-Pressing Process in the Ti3AlC2-Ti-Al system[J]. Metals and Materials International, 2015, 21(1): 179-184.

[16] AI Tao-tao, WANG Fen, FENG Xiao-ming, RUAN Miao-miao. Microstructural and mechanical properties of dual Ti3AlC2-Ti2AlC reinforced TiAl composites fabricated by reaction hot pressing[J]. Ceramics International, 2014, 40(7): 9947-9953.

[17] LAPIN J, STAMBORSKA M, PELACHOVA T, BAJANA O. Fracture behaviour of cast in-situ TiAl matrix composite reinforced with carbide particles[J]. Materials Science and Engineering A, 2018, 721: 1-7.

[18] 艾桃桃, 费岩晗, 冯小明, 余 宁, 于 琦, 李文虎, 袁新强. SPS法制备Ti2AlC/TiAl基复合材料的力学性能[J]. 材料热处理学报, 2016, 37(8): 20-24.

AI Tao-tao, FEI Yan-han, FENG Xiao-ming, YU Ning, LI Wen-hu, YUAN Xin-qiang. Mechanical properties of Ti2AlC/TiAl composites prepared by SPS method[J]. Transactions of Materials and Heat Treatment, 2016, 37(8): 20-24.

[19] 王 维, 艾桃桃, 费岩晗. Ti3AlC2掺杂SPS法制备Ti2AlC/TiAl基复合材料的研究[J]. 稀有金属材料与工程, 2017, 46(S1): 1-4.

WANG Wei, AI Tao-tao, FEI Yan-han. Ti2AlC/TiAl Composites with Doped Ti3AlC2 by SPS[J]. Rare Metal Materials and Engineering, 2017, 46(S1): 1-4.

[20] 费岩晗, 艾桃桃, 袁新强, 冯小明. 放电等离子烧结制备TC4/Tin+1AlCn-TiAl叠层结构复合材料的组织和性能[J]. 材料热处理学报, 2017, 38(11): 1-7.

FEI Yan-han, AI Tao-tao, YUAN Xin-qiang, FENG Xiao-ming. Microstructure and properties of TC4/Tin+1AlCn- TiAl laminated composites prepared by spark plasma sintering[J]. Transactions of Materials and Heat Treatment, 2017, 38(11): 1-7.

[21] ADDA-BEDIA M, ARIAS R. Brittle fracture dynamics with arbitrary paths I. Kinking of a dynamic crack in general antiplane loading[J]. Journal of the Mechanics and Physics of Solids, 2003, 51(7): 1287-1304.

Ti2AlC/TiAl-based laminated composite sheets strengthened by titanium alloy layers with through-holes

NIU Qun-fei1, AI Tao-tao1, 2, LIU Jie1, DENG Zhi-feng1, 2, FENG Xiao-ming1, 2, LI Wen-hu1, 2, YUAN Xin-qiang1, 2, BAO Wei-wei1, 2, DONG Hong-feng1, 2

(1. School of Materials Science and Engineering, Shaanxi University of Technology, Hanzhong 723000, China;

2. National and Local Joint Engineering Laboratory for Slag Comprehensive Utilization and Environmental Technology, Shaanxi University of Technology, Hanzhong 723000, China)

Abstract: The TC4/Ti2AlC-TiAl based laminated composite sheets were prepared by the discharge plasma sintering technique (SPS), using TiC-Ti-Al system mixed powders as the reaction system and TC4 titanium alloy sheets with through-holes as the toughening layers. The phase composition and microstructure were analyzed by XRD and SEM, and the room temperature flexural strength and fracture toughness were also measured. The results indicate that the mechanical properties of the laminated composite sheets have anisotropy. When the content (mass fraction) of Ti2AlC is 15%, the fracture toughness reaches a maximum value of 18.81 MPa·m1/2 and it is much higher than that of the composite sheet without Ti2AlC, while the loading direction is perpendicular to the laminated structure. The through-hole laminated structure design and particle composite technology construct the complex crack propagation paths. Moreover, the titanium alloy toughening layers can absorb fracture energy, which play an important role in improving the toughness. Such design provides a new design idea for metal-based composite sheets.

Key words: laminated composite sheet; intermetallic compound; structural design; mechanical properties

Foundation item: Project(51671116) supported by the National Natural Science Foundation of China; Project (2016JZ016) supported by the Key Project of Natural Science Basic Research Plan in Shaanxi Province, China; Project(SLGQD1801) supported by the Scientific Research Startup Program for Introduced Talents of Shaanxi University of Technology, China

Received date: 2019-04-08; Accepted date: 2019-09-23

Corresponding author: AI Tao-tao; Tel: +86-18691612234; E-mail: aitaotao0116@126.com

(编辑 何学锋)

基金项目:国家自然科学基金资助项目(51671116);陕西省自然科学基金资助项目(2016JZ016);陕西理工大学人才项目(SLGQD1801)

收稿日期:2019-04-08;修订日期:2019-09-23

通信作者:艾桃桃,教授,博士;电话:18691612234;E-mail:aitaotao0116@126.com