DOI: 10.11817/j.issn.1672-7207.2016.01.002

烧结竖罐床层内的空隙率分布特性

冯军胜1,董辉1,曹峥2,王爱华1

(1. 东北大学 国家环境保护生态工业重点实验室,辽宁 沈阳,110819;

2. 鞍钢股份有限公司,辽宁 鞍山,114000)

摘要:采用注水法并结合断层图像分析法对烧结矿床层内平均空隙率和径向空隙率分布规律进行研究,考察床层几何因子对床层平均空隙率的影响,以及在不同床层几何因子条件下,床层径向空隙率分布规律。研究结果表明:影响床层空隙率分布的主要因素为烧结矿颗粒直径和竖罐直径。其中,在较小床层几何因子(D/dp<120)条件下,烧结矿颗粒直径不变时,床层平均空隙率随床层直径的增大而减小;反之,床层平均空隙率不随颗粒直径和罐体直径的变化而变化;床层空隙率在壁面处达到最大值,并向床层中心衰减,在床层中心处达到最小值。

关键词:烧结矿;填充床;固定床;床层几何因子;空隙率

中图分类号:TK11+5 文献标志码:A 文章编号:1672-7207(2016)01-0008-06

Voidage distribution properties of bed layer in sinter vertical tank

FENG Junsheng1, DONG Hui1, CAO Zheng2, WANG Aihua1

(1. SEPA Key Laboratory on Eco-industry, Northeastern University, Shenyang 110819, China;

2. Angang steel Co. Ltd., Anshan 114000, China)

Abstract: Water flood method and tomographic image analysis method were used to investigate sinter bed layer average voidage and radial voidage distribution. The effect of bed layer geometric factor on bed layer average voidage was studied, and the bed layer radial voidage distribution was also studied under the condition of different bed geometrical factors. The results show that the main factors that influence the bed layer voidage distribution are the sinter particle diameter and bed layer diameter of vertical tank. Among them, the bed layer average voidage decreases with the increase of bed layer geometric factor for a given sinter particle diameter under the condition of smaller bed geometrical factor (D/dp<120). On the contrary, the bed layer average voidage does not vary with the change of particle diameter or bed layer diameter. Bed layer voidage is the largest at the inner wall surface, then decays to the center of bed layer, and finally reaches the minimum value in the center of bed layer.

Key words: sinter mineral; packed bed; fixed bed; bed layer geometric factor; voidage

烧结过程余热资源高效回收与利用是降低烧结工序能耗的主要途径之一[1-2]。烧结余热竖罐式回收是针对于传统烧结余热回收系统的弊端[3],借鉴干熄焦炉的结构和工艺提出的一种烧结矿余热高效回收方式[4-5],其具有漏风率低、气固热交换充分、出口热载体能级高等优点。就结构特点而言,烧结余热回收竖罐是一种散料床式气固逆流热交换装置,竖罐床层内气流阻力特性和气固传热特性是决定烧结余热罐式回收可行性的2个关键问题,而床层空隙率分布是影响床层内气体流动,进而影响气流阻力特性和气固传热特性的核心因素。近年来,许多学者为探索床层内空隙率分布规律进行大量工作。GOVINDARAO等[6]采取几何计算的方法来预测空隙率分布;MUELLER[7]对前人的研究成果进行了总结,得到了仅包含1个方程的经验模型,该模型考虑了空隙率的衰减分布,并引入了床层几何因子(D/dp,其中,D为床层直径,dp为颗粒平均粒径),即考虑床层直径与颗粒粒径的比值对空隙率变化的影响。随后MUELLER[8]又通过实验提出了1个经验公式,但该公式不能与床层边缘附近的空隙率波动很好地吻合;NGUYEN等[9]采用核磁共振成像技术测定均匀颗粒条件下填充床内空隙率分布;KUBIE[10]研究了非均匀颗粒条件下随机填充床壁面区域的空隙率分布。此外,一些学者还采用其他方法对床层空隙率分布进行了研究[11-14]。由于烧结矿形状的严重不均匀性,造成了烧结矿颗粒形状因子(球形度)较小,而烧结竖罐内径较大,使得罐体内床层几何因子(床层直径与颗粒粒径之比)也较大,这2种情况给研究烧结矿床层空隙率分布规律增加了很大的难度。迄今为止,有关固定床层内空隙率分布的研究对象主要为球体或者形状均匀的颗粒,关于烧结矿这种形状严重不均匀,颗粒形状因子较小,同时罐体床层几何因子较大的床层空隙率分布研究较少,为此,本文作者通过实验的手段,研究烧结床层内平均空隙率和径向空隙率的分布规律,得出床层几何因子对床层平均空隙率和径向空隙率分布的影响规律,并在此基础上,拟合出描述罐体内床层空隙率的实验关联式,以便为研究罐体内气流阻力特性和气固传热特性提供参考。

1 实验方法及过程

1.1 实验方法

采用注水法和断层图像分析法研究罐体内床层平均空隙率和径向空隙率分布规律。断面图像分析法的基本原理是将不同粒径的烧结矿随机落入不同直径的圆管之中,然后向圆管内注入与烧结矿颜色形成强烈对比的淀粉溶液,待溶液达到一定高度后,利用高清相机对圆管断面进行拍照,而后利用图片裁剪和Image J处理软件对所拍相片进行处理和分析,得到空隙部分面积所占整体截面面积的百分比,即床层截面的平均空隙率,最后再对该相片进行径向剖分和后续处理,得到床层径向空隙率分布规律。

淀粉溶液达到的高度将由对该组实验采用称质量法所得到的整体空隙率决定。称质量法的基本原理是将已浸泡至饱和状态的烧结矿随机落入不同直径的圆管中,加入清水使之达到溢出的临界状态。通过称量加水前后的质量差,求得烧结矿之间的空隙体积,再根据圆管直径和烧结矿床层高度,计算出床层体积,空隙体积与床层体积之比即为床层整体平均空隙率。由于采用称质量法得到的实验结果与实际床层空隙率相差不大,因此,可以将采用断层图像分析法所得到床层截面平均空隙率与采用称质量法得到的床层整体平均空隙率进行对比,确定淀粉溶液的实际高度,以便于后续研究床层径向空隙率分布规律。

断层图像分析法有效地避免了对烧结矿颗粒的切割,同时继续沿用剖分法中的分析过程,其主要研究的是烧结矿床层径向空隙率分布,暂不考虑高度上的空隙率变化。因此,只分析表层断面,对烧结矿的堆积高度无过多要求,但每次实验只能得到1组数据,这样就需要多次重复试验来代替剖分效果,且此方法受人为偶然因素影响较大,同样需要多次重复测量以减小误差。

1.2 实验过程

本实验所研究的烧结矿为不同粒径且形状不规则的颗粒。实验中将烧结矿分为筛分料和未筛分料。筛分烧结矿每组粒径范围为0~10,10~20和20~30 mm。未筛分烧结矿主要由未经过筛分的烧结矿颗粒组成,粒径分布较广,范围为0~30 mm,平均粒径约20 mm。将筛分后的烧结矿分组编号,用清水浸泡一段时间。计算床层几何因子(D/dp)时前3组粒径分别按各自的平均直径计算,未筛分料不予计算。实验中模拟床层的管道采用6种不同管径PVC管(310,348,450,470,510和600 mm),管子高度为200~300 mm。

实验内容分为床层平均空隙率和床层径向空隙率分布2部分。首先对断面平均空隙率进行测量,确定最佳的淀粉溶液高度,然后对测量后的图片进行后续处理分析,得到床层径向空隙率分布规律。具体过程如下。

1) 将不同粒径的烧结矿依次装入10种不同直径的管子内,形成随机填充结构。将最上层颗粒所在的床层高度按颗粒粒径划分为5~10等份,然后将淀粉溶液按顺序注入不同等份高度处。

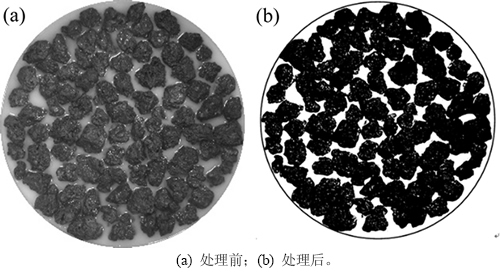

2) 用相机对每个等份时的截面进行拍照,得出不同等份高度时的床层断面平均空隙率。利用Image J软件先将所得照片改为8位像素即黑白照片以排除部分颜色对实验结果的影响,而后通过此软件的Type工具将图片处理成灰度图,调整为适合观察的灰度,然后使用Threshold工具将深颜色部分覆盖。由于照片质量存在差异且部分照片烧结矿位置上存在一些反光点,覆盖前还需对灰度图的补偿率进行适当调整,来补偿因照片中反光点以及亮点造成的误差。处理前后的图片对比如图1所示,图1中黑色部分为烧结矿,白色部分为淀粉溶液。

图1 床层断面图片处理对比示意图

Fig. 1 Comparison schematics of bed layer image processing

3) 通过Image J软件中的Analyze Particles工具对所得图片进行分析计算,得出黑色部分面积占整个图片面积的百分比,再计算得到白色部分占整个部分的百分比,即床层断面空隙率。

4) 将不同等份高度时的床层断面空隙率与采用称质量法得到的床层整体空隙率进行对比,越接近床层整体空隙率的等份高度,就是所要确定的最佳淀粉溶液高度。

5) 对每组最佳淀粉溶液高度所对应的图片沿径向进行分段剖分,将圆形的床层截面划分为若干个环形区域,每个同心圆的大小由管径和颗粒粒径决定,白线为剖分曲线,如图2所示,根据每个环形区域空隙率的变化情况即可得到床层断面径向空隙率变化规律。

6) 对以上5个过程进行大量重复性实验,直到实验结果达到可重复性,即实验数据之间变化很小,然后对所得实验数据取平均值。最后利用Origin软件对得出的空隙率平均值进行进一步计算分析。

图2 径向剖分示意图

Fig. 2 Schematic of radial subdivision

2 实验结果及分析

2.1 床层平均空隙率随床层几何因子的变化

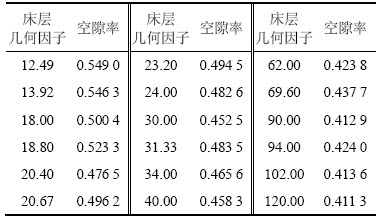

实验设定的床层几何因子D/dp范围为12~120,表1所示为床层平均空隙率与床层几何因子间的变化关系。

表1 不同床层几何因子下的床层平均空隙率

Table 1 Average voidage fraction of different bed geometric factors

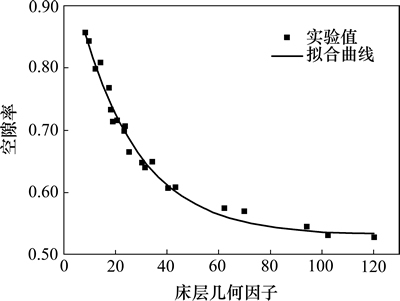

根据表1中数据绘制床层平均空隙率随床层几何因子变化的拟合曲线,如图3所示。

图3 床层空隙率随床层几何因子变化曲线

Fig. 3 Change curve of bed layer voidage with bed geometric factor

从图3可知:床层空隙率随床层几何因子的增大而减小,并最终趋于定值。这是由于随着床层几何因子的增大,边缘效应对床层空隙率的影响也逐渐减弱,同时由于布料方式对床层空隙率的影响也会逐渐减小。在相同颗粒粒径条件下,随着管径的不断增大,与管壁接触的颗粒数目也会不断增加,由于烧结矿颗粒的不均匀性,烧结矿与管壁进行面接触的比率会越来越大,从而造成管壁边缘处的空隙率不断减小,边缘空隙率随床层几何因子的变化如图4所示。当床层几何因子大于某一数值后,边缘处的空隙率几乎不会发生变化,由于床层空隙率受边缘效应的影响很大,因此,床层空隙率也会随着床层几何因子的不断增大而最终趋于定值。

图4 边缘空隙率随床层几何因子变化曲线

Fig. 4 Change curve of edge void fraction with bed geometric factor

根据图3中实验数据拟合函数如下:

(1)

(1)

式中:ε为床层平均空隙率;D为床层直径,mm;dp为颗粒平均粒径,mm;D/dp为床层几何因子。

拟合所得的函数的预测值与实验值之间的平均相对误差为1.96%,所得预测函数基本符合实验数据的总体规律。由于函数表达式中D/dp的最小值为12,因此,床层几何因子小于12的情况不能通过本实验的数据分析得出。但基于本实验所围绕的烧结余热竖罐的结构特点,较小床层几何因子可不考虑。

2.2 床层断面径向空隙率分布

2.2.1 床层径向空隙率分布规律

本部分实验目的是对所得照片进一步处理,利用若干同心圆对原始断面裁图后,分析每个环形区域内的空隙率,进而得到空隙率在半径方向上的变化规律。以环形区域边缘到管子中心的距离与圆管半径之比为横坐标,以该环形区域的空隙率为纵坐标,分别得到不同颗粒粒径条件下不同管径的空隙率分布情况,绘制全部结果如图5所示。

该部分实验对3组粒径范围和未筛分料进行分析,管径范围为310~600 mm。从图5可知:烧结床层径向空隙率变化规律基本符合HAMEL等[15]对木屑床层空隙率径向分布的测量结果。床层空隙率在管壁附近存在峰值,并向床层中心衰减,到床层中心处达到最小值。在床层边缘处存在空隙率的明显波动。

由于图5(b)和图5(c)中所使用的烧结矿颗粒在筛分时较为均匀,并没有混杂颗粒较小的烧结矿,因此,空隙率在床层中心处波动较小,并且在床层中心到管壁的一段距离内空隙率成线性增长趋势,到管壁处由于边缘效应的存在而达到最大值。图5(a)和图5(d)所示的床层径向空隙率分布规律较相似,在床层中心处存在较大的波动,并且在床层中心到管壁的一段距离内空隙率波动很小,到管壁处由于边缘效应的存在而达到最大值,这与实际生产竖罐床层内径向空隙率分布较规律较相似。因为在实际生产中,由于布料方式的影响,在布料时,颗粒大的烧结矿一般会集中在罐体内壁处,而较小的烧结矿包括粉矿会集中在罐体中心处。同时,烧结矿在罐体内下移的过程中,由于竖罐是中心处排料,这就造成中心处烧结矿的下移速度会大于内壁处烧结矿的下移速度,这也为在下移过程中由于摩擦、碰撞等因素产生的粉矿向床层中心处偏移创造了条件。这2种情况造成中心处的空隙率要远小于床层的平均空隙率,从而造成竖罐内气流的严重偏析,在实际生产中要避免这种情况的发生。

通过本实验数据可确定,在非均匀颗粒作为物料的填充床中同样有边缘效应的存在,其影响规律与使用均匀颗粒时基本相同。但使用均匀颗粒时,靠近壁面的颗粒与壁面大多为点接触,此处空隙率为1或很接近1[16]。由于本实验所研究的烧结矿颗粒为形状极不规则的颗粒,与均匀球体作为填料时的情况会有所不同。

2.2.2 床层径向空隙率分布函数

由于未筛分料更符合实际生产条件,因此,研究未筛分床层径向空隙率分布规律具有重要的意义。图5(a)中所使用的烧结矿粒径范围为0~10 mm,相比于10~20 mm和20~30 mm的粒径范围,其中混杂着很多粒径较小的颗粒,与实验中所使用的未筛分料没区别,图5(a)和图5(d)所示的床层径向空隙率分布规律已经说明了这一点,因此,可以将粒径范围为0~10 mm的烧结矿当作未筛分料处理。由图3可知:在较大的床层几何因子条件下,床层空隙率趋于定值,因此,可以用图5(a)中D为470,510和600 mm条件下的床层径向空隙率分布规律替代在实际生产中较大床层几何因子条件的床层径向空隙率分布规律,结果如图6所示。

图5 床层径向空隙率分布曲线

Fig. 5 Variation curves of bed layer radial voidage

图6 未筛分料径向空隙率分布曲线

Fig. 6 Variation curve of nature size radial voidage

根据实验数据拟合函数如下:

(2)

(2)

式中:εr为床层径向空隙率;R为竖罐半径,mm;r为竖罐内环形床层区域距罐体中心的距离,mm;r/R的范围为0~1。

将式(2)沿径向积分得床层平均空隙率为0.403 1,与实际值相比,相对误差仅为1.92%。因此,可将式(2)作为在较大床层几何因子条件下未筛分床层的径向空隙率分布函数。

3 结论

1) 与称质量法测量床层平均空隙率相比,断层图像分析法不仅能得到床层平均空隙率,而且可以获得床层径向空隙率的变化规律。

2) 床层平均空隙率随床层几何因子的增大而减小,并最终趋于定值。通过实验数据拟合得出了床层平均空隙率与床层几何因子之间的函数关系。

3) 由于烧结矿填充床内存在边缘效应,床层空隙率在壁面的附近有较大波动。床层空隙率在管壁附近存在峰值,并向床层中心衰减,到床层中心处达到最小值。通过实验分析得出了在较大床层几何因子条件下(D/dp>100)未筛分料径向空隙率分布函数关系式。

参考文献:

[1] 蔡九菊, 王建军, 陈春霞, 等. 钢铁企业余热资源的回收与利用[J]. 钢铁, 2007, 42(6): 1-7.

CAI Jiuju, WANG Jianjun, CHEN Chunxia, et al. Waste heat recovery and utilization in iron and steel industry[J]. Iron and Steel, 2007, 42(6): 1-7.

[2] 董辉, 郭宁, 杨柳青, 等. 烧结余热利用中烧结混合料干燥过程的实验研究[J].东北大学学报(自然科学版), 2010, 31(4): 546-549.

DONG Hui, GUO Ning, YANG Liuqing, et al. Experimental study on drying process of mixture being sintered utilizing waste heat[J]. Journal of Northeastern University (Natural Science), 2010, 29(4): 546-549.

[3] 董辉, 赵勇, 蔡九菊, 等. 烧结-冷却系统的漏风问题[J]. 钢铁, 2012, 47(1): 95-99.

DONG Hui, ZHAO Yong, CAI Jiuju, et al. On the air leakage problem in sintering cooling system[J]. Iron and Steel, 2012, 47(1): 95-99.

[4] 蔡九菊, 董辉. 烧结过程余热资源的竖罐式回收与利用方法及其装置: 200910187381.8[P]. 2009-09-15.

CAI Jiuju, DONG Hui. The method and device of sintering waste heat recovery and utilization with vertical tank: 200910187381.8[P]. 2009-09-15.

[5] DONG Hui, JIA Fengrui, ZHAO Yong, et al. Experimental investigation on the drying process of the sinter mixture[J]. Powder Technology, 2012, 218(2): 1-4.

[6] GOVINDARAO V M H, FROMENT G F. Voidage profiles in packed beds of spheres[J]. Chemical Engineering Science, 1986, 41(3): 533-539.

[7] MUELLER G E. Prediction of radial porosity distributions in randomly packed fixed beds of uniformly sized spheres in cylindrical containers[J]. Chemical Engineering Science, 1991, 46(2): 706-708.

[8] MUELLER G E. Radial void distributions in randomly packed fixed beds of uniformly sized spheres in cylindrical containers[J]. Powder Technology, 1992, 72(3): 269-275.

[9] NGUYEN N L, BUREN V, REIMERT R, et al. Determination of porosity and flow distribution in packed beds by magnetic resonance imaging[J]. Magnetic Resonance Imaging, 2005, 23(2): 395-396.

[10] KUBIE J. Influence of containing walls on the distribution of voidage in packed beds of uniform spheres[J]. Chemical Engineering Science, 1988, 43(6): 1403-1405.

[11]  , JOHNSSON F, et al. Voidage distributionaround bubbles in a fluidized bed: Influence on throughflow[J]. Powder Technology, 2010, 197(1/2): 73-82.

, JOHNSSON F, et al. Voidage distributionaround bubbles in a fluidized bed: Influence on throughflow[J]. Powder Technology, 2010, 197(1/2): 73-82.

[12] HAMEL S, KRUMM W. Radial voidage variation in fixed beds of fuel wood pellets[J]. Biomass and Bioenergy, 2012, 46: 203-209.

[13] ZOBEL N, EPPINGER T, BEHRENDT F, et al. Influence of the wall structure on the void fraction distribution in packed beds[J]. Chemical Engineering Science,2012, 71(26): 212-219.

[14] DAS M, BANDYOPADHYAY A, MEIKAP B C, et al. Axialvoidageprofiles and identification of flow regimes in the riser of a circulating fluidizedbed[J]. Chemical Engineering Journal, 2008, 145(2): 249-258.

[15] HAMEL S, KRUMM W. Near-wall porosity characteristics offixed beds packedwithwood chips[J]. Powder Technology, 2008, 188(1): 55-63.

[16] BENENATI R F, BROSILOW C B. Void fraction distribution in beds of spheres[J]. Aiche Journal, 1962, 8(3): 359-361.

(编辑 罗金花)

收稿日期:2015-01-27;修回日期:2015-03-27

基金项目(Foundation item):国家自然科学基金资助项目(51274065);辽宁省科技计划项目(2015307001) (Project(51274065) supported by the National Natural Science Foundation of China; Project(2015307001) supported the Science and Technology Planning Project of Liaoning Province)

通信作者:董辉,博士,教授,从事冶金过程余热余能高效回收利用研究;E-mail: Dongh@smm.neu.edu.cn