烧结余热回收竖罐内固定床层的阻力特性

冯军胜,董辉,李明明,蔡九菊

(东北大学 国家环境保护生态工业重点实验室,辽宁 沈阳,110819)

摘要:利用自制的固定床气固流动实验装置,研究气流通过余热回收罐体内料层的阻力特性,得到影响料层阻力特性的主要因素及其影响规律。研究结果表明,影响罐体内料层阻力特性的主要因素有颗粒表观流速、床层填充特性参数(颗粒直径及其分布、罐体的直径等)、床层温度等。其中,单位料层高压力损失随颗粒表观流速的增加呈二次方关系增加,随颗粒直径的增加呈指数关系衰减;临界雷诺数与床层几何因子呈线性关系,并随颗粒直径的增加呈线性关系增加;颗粒表观流速为1.0~2.5 m/s时,烧结矿单位料层高压力损失为0.33~1.72 kPa。

关键词:烧结;余热;固定床;填充床;阻力特性

中图分类号:TK115 文献标志码:A 文章编号:1672-7207(2014)08-2566-06

Resistance characteristics of fixed bed layer in vertical tank for recovering sinter waste heat

FENG Junsheng, DONG Hui, LI Mingming, CAI Jiuju

(State Environment Protection Key Laboratory on Eco-industry,

Northeastern University, Shenyang 110819, China)

Abstract: The resistance characteristics of air flow through the sinter bed layer in waste heat recovery tank were investigated using the homemade fixed bed experimental device of gas-solid flow. The main factors and influence rules influencing the resistance characteristics of sinter bed layer were obtained. The results show that the main factors that influence the resistance characteristics of bed layer in vertical tank include apparent particle velocity, bed filling characteristic parameters (the particle size and its distribution, the diameter of the tank,and so on), bed layer temperature, and so on. Among them, the unit pressure drop of sinter bed layer increases as a quadratic relationship with the increase of apparent particle velocity and reduces as exponential relationship with the increase of particle size; critical Reynolds number shows a linear relationship with bed layer geometrical factor, and increases as a linear relationship with the increase of particle size; apparent particle velocity is 1.0-2.5 m/s, and the unit pressure drop of sinter layer is 0.33-1.72 kPa.

Key words: sinter; waste heat; fixed bed; packed bed; resistance characteristics

烧结过程余热资源高效回收与利用是降低烧结工序能耗的主要途径之一[1-2],其主要方式是在环形或带式冷却台车内分段气固热交换实现余热回收,从根本上存在着系统漏风率高、回收余热品位和效率低等难以克服的弊端[3]。竖罐式余热回收是针对于传统烧结余热回收系统的弊端,借鉴干熄焦中干熄炉的结构和工艺提出的一种烧结余热高效回收方式,其具有余热回收率高、余热载体即携带烧结矿显热的热空气能级较高等优点,为后续生产高品质蒸汽进而提高吨烧结矿发电量提供了保证[4-5]。同时,余热回收竖罐的预存段对烧结矿具有保温作用,促使烧结矿温度的均匀化和残存挥发分析出,从而进一步提高烧结矿成熟度和品质。竖罐式余热回收的可行性主要取决于3方面,即罐体内料层阻力特性、料层内气固传热特性以及冷却速度对烧结矿冶金性能的影响;其中,料层阻力特性直接影响着鼓风机的全压与配套电动机功率,进而影响着竖罐式回收的经济性与可行性。从本质上而言,烧结余热回收罐体是一种气固逆流式移动床,罐体内烧结矿下移速度为1~2 mm/s[4],因此,余热回收罐体可近似为颗粒固定床。可借鉴化工、农业等领域颗粒固定床层内气流阻力损失等相关理论来研究罐体料层内气流阻力特性。与化工领域中的颗粒固定床相比,烧结余热回收罐体内床层的主要特点是:它属于随机填充有限填充床范畴,烧结矿颗粒直径范围较广,颗粒形状因子较小,空隙率分布不均,且床层处于疏床与密床之间,罐体上部趋向于疏床,罐体下部趋向于密床;床层的当量直径与颗粒的当量直径之比即床层几何因子较大(100~150)。其中,烧结矿颗粒直径、颗粒形状因子、空隙率和床层几何因子是影响料层阻力特性的主要因素[6]。表征颗粒床层阻力特性的公式主要是Ergun公式及其系列修正式。其中,Eisfeld 和 Schnitzlein[7]提出了一个Ergun经验修正式,研究了气流分布不均和边缘效应对阻力特性的影响;Ozahi等[8]考虑了颗粒雷诺数、颗粒摩擦因数等因素,对Ergun系数加以修正,使Ergun公式的偏差减小4%;Damjan等[9]提出了MRD(Mean Relative Deviation)概念,并将其运用于Ergun公式中,以适用于任意形状颗粒;Robert等[10]用实验方法推出了床径比较小时固定床阻力损失的实验关联式;此外,还有学者从其他角度对Ergun公式中的参数因子进行了修正[11-12]。本文作者拟通过实验,研究影响烧结余热回收竖罐内烧结矿料层阻力特性的主要因素及其影响规律,在此基础上,拟合出描述罐体内料层阻力特性的Ergun修正关联式,进而为烧结余热竖罐式回收技术的研发奠定坚实的理论基础。

1 实验原理及设备

在设计实验设备时,考虑到烧结矿在竖罐内移动缓慢,为了简化实验装置以固定床替代移动床。实验过程中,边缘效应会对结果产生一定的影响[13-15],为了尽量减小这种影响,设计罐体的长×宽×高为0.9 m×0.9 m×3.4 m。

实验采用标准皮托管对实验过程中不同位置压力进行检测,同时通过对鼓风机的调节来控制风量及风速,采用孔板流量计来检测冷却风流量。实验装置示意图如图1所示。

影响烧结矿单位料层高压力损失的因素可分为2方面:一方面是床层因素,另一方面是流动介质因素。床层因素包含烧结矿形状因子Ф,床层温度t(即烧结矿温度),料层孔隙率ε(通过颗粒平均直径d来反映);流动介质因素包含颗粒表观流速u以及流体(动力)黏度μ。本文综合考虑颗粒直径、颗粒表观流速流速以及床层温度对单位料层高压力损失的影响。实验过程分为2步:第1步为冷态实验,即测试颗粒直径和颗粒表观流速对冷态床层(烧结矿温度为常温)料层高压力损失的影响;第2步为热态实验,先将烧结矿加热到一定温度再缓慢空冷,检测不同床层温度下颗粒直径和颗粒表观流速对料层高压力损失的影响,进而得出床层温度、颗粒直径以及颗粒表观流速对料层高压力损失的共同影响效果。

图1 实验装置示意图

Fig. 1 Schematic of experimental equipment

2 实验结果及分析

2.1 临界雷诺数的测定

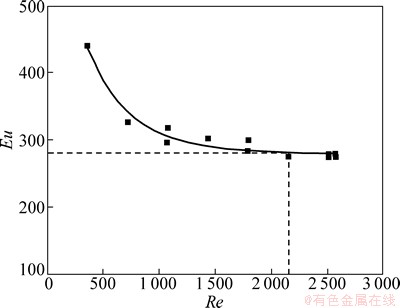

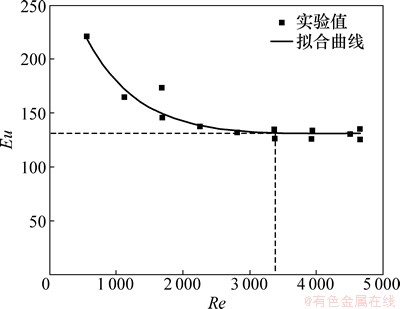

实验过程中自小到大调节风机出口流量,测定料层典型位置的静压力差,然后计算Eu和Re,不同颗粒直径烧结矿Eu-Re关系曲线如图2~5所示。

图2 颗粒直径为10~18 mm烧结矿Eu-Re关系曲线

Fig. 2 Eu-Re curve of sinter with 10-18 mm particle size

图3 颗粒直径18~30 mm烧结矿Eu-Re曲线

Fig. 3 Eu-Re curve of sinter with 18-30 mm particle size

图4 颗粒直径为30~40 mm烧结矿Eu-Re曲线

Fig. 4 Eu-Re curve of sinter with 30-40 mm particle size

图5 未经筛分烧结矿Eu-Re关系曲线

Fig. 5 Eu-Re curve of sinter with mixed particle size

实验过程中颗粒直径10~18 mm的烧结矿的临界Re*为2 174;颗粒直径18~30 mm的临界雷诺Re*为3 375;颗粒直径30~40 mm的临界Re*为4 029;未经筛分烧结矿临界Re*为2 900,介于颗粒直径10~18 mm与18~30 mm烧结矿的临界Re*之间。

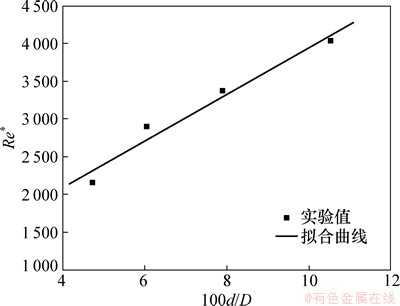

颗粒平均直径d与罐体当量直径D之比为无因次量,临界雷诺数Re*与d/D关系曲线如图6所示,拟合公式为:

(1)

(1)

由此可见,二者呈近似线性关系。

图6 临界Re*与100d/D关系曲线

Fig. 6 Relationship between Re* and 100d/D

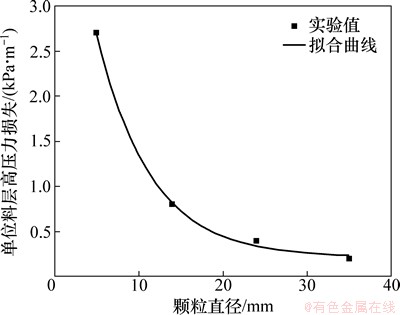

2.2 颗粒直径对单位料层高压力损失的影响

参照干熄焦技术设置颗粒表观流速u=1.5 m/s,床层温度为室温,颗粒直径在0~10 mm范围内取平均直径为5 mm,在10~18 mm范围内取平均直径为14 mm,在18~30 mm范围内取平均直径为24 mm,在30~40 mm范围内取平均直径为35 mm,得出单位料层高压力损失与颗粒直径的关系,如图7所示。

图7 单位料层高压力损失与颗粒直径关系

Fig. 7 Relationship between particle size and per height pressure drop

经拟合得出:

(2)

(2)

式中:△p为料层高压差;L为料层高度。

由式(2)可知:单位料层高压力损失随着颗粒平均直径与罐体当量直径比值的增大而呈指数关系衰减,即当罐体直径一定时,单位料层高压力损失随着颗粒平均直径的增大而成指数关系衰减。这是由于,随着颗粒直径的增加,料层的空隙率增加,导致气流流经料层的压力损失减小。

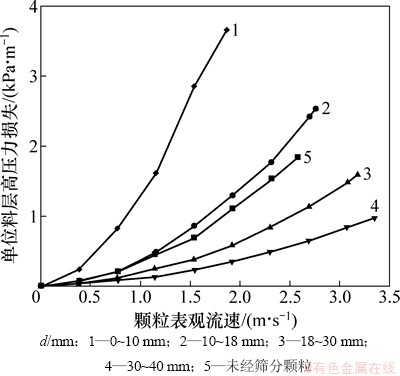

2.3 颗粒表观流速对单位料层高压力损失的影响

不同颗粒直径下颗粒表观流速对单位料层高压力损失的影响如图8所示。以未筛分颗粒为研究对象,其他因素恒定,考虑颗粒表观流速对料层高压力损失的影响;对实验数据拟合可得

(3)

(3)

由此可见,单位料层高压力损失与颗粒表观流速近似呈二次方关系。在颗粒表观流速为1.0~2.5 m/s范围内,单位料层高压力损失为0.33~1.72 kPa。

图8 不同颗粒直径单位料层高压力损失与流速关系

Fig. 8 Relationship between velocity and per height pressure drop of different particle sizes

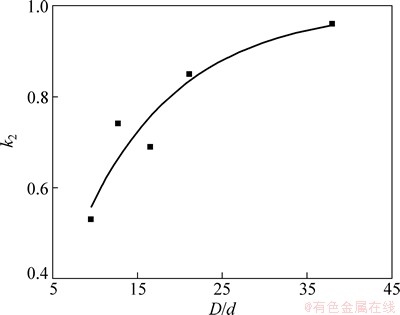

2.4 Ergun方程阻力系数的修正

根据实验数据对Ergun公式的2个阻力系数进行修正,得出冷态和热态时Ergun修正式。

2.4.1 冷态实验

通过分析冷态实验中不同颗粒直径和不同流体流速与单位料层高压力损失之间的关系,得出拟合常数k1,k2与无量纲数D/d之间关系,结果如图9~10所示。

图9 k1与D/d关系拟合曲线

Fig. 9 Fitting curve of k1 and D/d

图10 k2与D/d关系拟合曲线

Fig. 10 Fitting curve of k2 and D/d

k1拟合曲线方程:

(4)

(4)

k2拟合曲线方程:

(5)

(5)

综上所述,烧结矿冷态单位料层高压力Ergun公式可表述为:

(6)

(6)

式中:ε为床层孔隙率;μ为气流动力黏度,kg/(m·s);ρf为气流密度,kg/m3;Ф为颗粒形状因子;u0为颗粒表观流速,m/s;dp为颗粒当量直径,m。

2.4.2 热态实验

热态时,针对Ergun公式引入气体状态方程,将式中各参数转换成常温常压下的值,首先,无论以何种状态作为基准,流过床层的质量流量保持不变,所以

(7)

(7)

式中:ρ为工况气体密度,kg/m;u为工况颗粒表观流速,m/s;ρ0为常温气体密度,kg/m;u0为常温下颗粒表观流速,m/s。

根据气体状态方程,床层内操作状态下与常温常压下气体状态参数之间关系为

(8)

(8)

式中:p0为常温条件下测量高度的平均压力,Pa;p为工况条件下测量压力,Pa;T0为常温,K;T为工况热力学温度,K。

将式(8)代入Ergun方程一般式可得

(9)

(9)

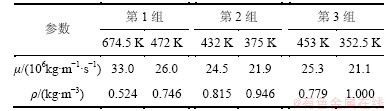

采用实验数据对式(9)进行验证,相关参数见表1,式(9)可以转换为

(10)

(10)

令

(11)

(11)

(12)

(12)

式中:C和E为常数。

式(10)变换为

(13)

(13)

2种工况单位料层高压力损失差为

(14)

(14)

将第1组和第2组代入式(14),C为12 108 359.56,E为1 014.83。第3组代入式(13)求得单位料层高压力损失为225.3 Pa/m,实验工况单位料层高压力损失为231.6 Pa/m,相对误差为2.72%,基本符合实验工况。因此,根据式(9)分析温度对单位料层高压力损失的影响是正确的。综上烧结矿热态单位料层高压力损失为:

(15)

(15)

表1 实验数据相关参数

Table 1 Related parameters of experimental data

3 结论

(1) 影响烧结矿料层阻力特性的主要因素有颗粒表观流速、烧结矿颗粒直径、床层温度等。其中,烧结矿单位料层高压力损失随颗粒表观流速的增加而呈二次方关系增加,随烧结矿颗粒直径的增加而呈指数关系衰减。在颗粒表观流速1.0~2.5 m/s范围内,单位料层高压力损失为0.33~1.72 kPa。

(2) 临界雷诺数随着烧结矿颗粒直径的增加而增加,并与颗粒平均直径d与料层当量直径D之比(d/D)呈线性关系变化为 。

。

(3) 对冷态烧结矿不同颗粒直径单位料层高压力损失及相关系数进行曲线拟合,得到冷态烧结矿单位料层高压力损失的拟合方程:

(4) 当烧结矿颗粒有温度变化过程时,可引入气体状态方程对Ergun方程进行修正,得到热态烧结矿单位料层高压力损失的拟合方程:

参考文献:

[1] 蔡九菊, 王建军, 陈春霞, 等. 钢铁工业余热资源的回收与利用[J]. 钢铁, 2007, 42(6): 1-7.

CAI Jiuju, WANG Jianjun, CHEN Chunxia, et al. Waste heat recovery and utilization in iron and steel industry[J]. Iron and Steel, 2007, 42 (6): 1-7.

[2] 董辉, 郭宁, 杨柳青, 等. 烧结混合料干燥过程的实验研究[J]. 东北大学学报(自然科学版), 2010, 29(4): 546-549.

DONG Hui, GUO Ning, YANG Liuqing, et al. Experimental study on sinter mixture’s drying process[J]. Journal of Northeastern University (Natural Science), 2010, 29(4): 546-549.

[3] 董辉, 赵勇, 蔡九菊, 等. 烧结-冷却系统漏风问题研究[J]. 钢铁, 2012, 47(1): 95-99.

DONG Hui, ZHAO Yong, CAI Jiuju, et al. On the air leakage problem in sintering cooling system[J]. Iron and Steel, 2012, 47(1): 95-99.

[4] 蔡九菊, 董辉. 烧结过程余热资源的竖罐式回收与利用方法及其装置: 中国, 200910187381.8[P]. 2009-09-15.

CAI Jiuju, DONG Hui. The method and device of sintering waste heat recovery and utilization with vertical tank: China, 200910187381.8[P]. 2009-09-15.

[5] Marcelo R E, Luiz F M. Thermodynamic analysis of a coke dry quenching unit[J]. Energy Conversion & Management, 2000, 41(2): 109-127.

[6] Mayerhofer M, Govaerts J, Parmentier N, et al. Experimental investigation of pressure drop in packed beds of irregular shaped wood particles[J]. Powder Technology, 2011, 205(1/2/3): 30-35.

[7] Eisfeld B, Schnitzlein K. The influence of confining walls on the pressure drop in packed beds[J]. Chemical Engineering Science, 2001, 56(14): 4321-4329.

[8] Ozahi E, Gundogdu M Y, Carpinlioglu M  . A modification on Ergun’s correlation for use in cylindrica packed beds with non-spherical particles[J]. Advanced Powder Technology, 2008, 19(4): 369-381.

. A modification on Ergun’s correlation for use in cylindrica packed beds with non-spherical particles[J]. Advanced Powder Technology, 2008, 19(4): 369-381.

[9] Damjan N, Janez L. Flow through packed bed reactors: 1.Single-phase flow[J]. Chemical Engineering Science, 2005, 60(24): 6947-6957.

[10] Robert K N. Physical insight into the Ergun and Wen & Yu equations for fluid flow in packed and fluidized beds[J]. Chemical Engineering Science, 2002, 57(3): 527-534.

[11] 吕友军, 韩强, 赵亮, 等. 超临界水流化床流动阻力特性的实验研究[J]. 工程热物理学报, 2011, 32(10): 1685-1687.

L Youjun, HAN Qiang, ZHAO Liang, et al. Experimental study on pressure drop characteristics of supercritical water fluidized bed[J]. Journal of Engineering Thermophysics, 2011, 32(10): 1685-1687.

Youjun, HAN Qiang, ZHAO Liang, et al. Experimental study on pressure drop characteristics of supercritical water fluidized bed[J]. Journal of Engineering Thermophysics, 2011, 32(10): 1685-1687.

[12] Yoksenakul W,Jugjai S. Design and development of a SPMB (self-aspirating, porous medium burner) with a submerged flame[J]. Energy, 2011, 36 (5): 3092-3100.

[13] CHENG Niansheng. Wall effect on pressure drop in packed beds[J]. Powder Technology, 2011, 210(3): 261-266.

[14] Rupesh K R, Jyeshtharaj B J. CFD modeling of pressure drop and drag coefficient in fixed beds: Wall effects[J]. Particuology, 2010, 8(1): 37-43.

[15] Theodoros A, Eugeny Y K. CFD-based analysis of the wall effect on the pressure drop in packed beds with moderate tube/particle diameter ratios in the laminar flow regime[J]. Chemical Engineering Journal, 2009, 155(1/2): 404-410.

(编辑 赵俊)

收稿日期:2013-08-30;修回日期:2013-11-06

基金项目:国家自然科学基金资助项目(51274065);沈阳市科技计划项目(F11-264-1-05)

通信作者:董辉(1969-),男,辽宁黑山人,教授,从事冶金过程余热余能高效回收利用研究;电话:13998859180;E-mail:Dongh@smm.neu.edu.cn