DOI: 10.11817/j.issn.1672-7207.2021.04.025

基于火用效率目标的烧结余热竖罐操作参数优化

张晟1,赵亮1,冯军胜2,董辉1

(1. 东北大学 冶金学院,辽宁 沈阳,110819;

2. 安徽建筑大学 环境与能源工程学院,安徽 合肥,230601)

摘要:以年产260万t的烧结余热回收竖罐为研究对象,基于多孔介质和局部非热力学平衡理论,借助软件二次开发功能,将烧结矿颗粒的下移过程以对流项的形式定义到能量方程中,建立竖罐三维稳态数值计算模型;然后提出竖罐火用效率分析模型,研究并分析影响竖罐余热回收的主要因素及其影响规律。研究结果表明:出口冷却气体的火用和竖罐火用效率随烧结矿颗粒直径增大而逐渐减少,随冷却气体进口温度升高而逐渐增加;在研究范围内,随着冷却气体质量流量增加,出口冷却气体的火用和火用效率呈现出先增大后减少的趋势,存在峰值拐点;在不同的颗粒直径情形下,对应的峰值拐点也有所不同,结合实际生产床层内粒径分布不均的情形,适宜的冷却气体质量流量应设置为89.1~91.2 kg/s。

关键词:烧结竖罐;传热;火用效率;数值模拟;移动床

中图分类号:TK11+5 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2021)04-1287-10

Optimization of operating parameters of sinter waste heat vertical tank based on exergy efficiency

ZHANG Sheng1, ZHAO Liang1, FENG Junsheng2, DONG Hui1

(1. School of Metallurgy, Northeastern University, Shenyang 110819, China;

2. School of Environment and Energy Engineering, Anhui Jianzhu University, Hefei 230601, China)

Abstract: Sinter waste heat recovery vertical tanks with an annual output of 2.6 million tons was taken as research objects. Based on the porous medium and local non-thermodynamic equilibrium theory, with the help of the secondary development function of the software, the downward movement process of the sinter particles was defined in the form of convection terms in the energy equation. Thus, a 3D steady-state heat transfer model of the vertical tank was established. An exergy efficiency analysis model for sinter vertical tanks was proposed to study and analyze the main factors influencing the recovery of waste heat and their influencing laws. The results show that as the sinter particle diameter increases, the exergy of the outlet cooling gas and the efficiency of the vertical tank gradually decrease. However, on the contrary, as the cooling gas inlet temperature increases, both gradually increase. Within the scope of the study, with the increase of cooling gas mass flow rate, the exergy and efficiency show a trend of first increasing and then decreasing, and there is a peak inflection point. In the case of different particle diameters, the corresponding peak inflection points are also different. Considering the uneven particle size distribution in actual production, the appropriate cooling gas mass flow should be 89.1-91.2 kg/s.

Key words: sinter vertical cooler; heat transfer; exergy efficiency; numerical simulation; moving bed

烧结矿生产过程中产生大量的余热资源,据统计,每生产1 t烧结矿产生的产品显热量为1.02 GJ,烧结矿余热占我国钢铁余热资源总量的8%[1-3]。目前我国烧结矿余热回收主要有两大类技术:一类技术是基于环冷机模式的余热回收技术,另一类是借鉴CDQ干熄焦炉提出的烧结余热竖罐式余热回收工艺,其吨矿发电量有望翻倍。该技术被列入中国《钢铁工业调整升级规划(2016—2020)》中,在“十二五”期间,中国有2台竖罐式余热回收工程得以实施;“十三五”期间陆续又有几个工程开始实施建设。然而从已生产或在调试的工程来看,目前国内竖罐式烧结余热回收系统运行效果并不理想。烧结余热竖罐作为整个工艺的关键设备,其内部气固流动及传热过程有待进一步了解。

针对环冷机内气固传热过程已有大量研究[4-7],烧结余热竖罐内的颗粒在重力作用下由罐体顶部向下缓慢移动,是一种典型的大颗粒散料床层,床层内发生气固逆流式换热过程。冯军胜等[8-10]针对烧结矿颗粒床层的特殊性,对其内部空隙率分布、气体流动及气固传热过程开展了理论研究;高建业等[11-12]采用解析方法建立竖罐解析计算模型,研究了单一参数对竖罐气固换热过程的影响,进而确定竖罐热工参数的取值范围;FENG等[13]通过嵌入内热源形式,建立了竖罐三维稳态模型,初步探索了年冷却390万t烧结矿竖罐的热工参数组合;PAN等[14]提出了一种研究竖罐内传热和流动过程的解析方法,分析了冷却风量、冷却时间、装置高度和压降之间的关系;ZHANG等[15]提出将量纲一的火用耗作为竖罐余热回收效果的评判标准,分析了各影响因素对其影响。

本文作者以多孔介质模型和局部非热力学平衡理论为基础,采用多物理场仿真软件COMSOL对竖罐内的气固传热过程进行数值计算,借助软件二次开发功能将料层阻力系数与气固换热系数编入模型当中,并将烧结矿颗粒的下移过程以对流项的形式定义到能量方程中,建立适用于烧结余热回收竖罐的三维稳态气固逆流传热模型。基于火用分析方法,研究并分析影响竖罐内气固传热及火用效率的主要影响因素及其影响规律。该研究将对烧结余热竖罐及其类似颗粒填充移动床层的研究及设计具有指导性意义。

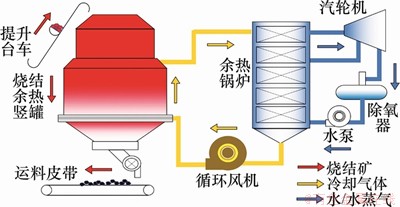

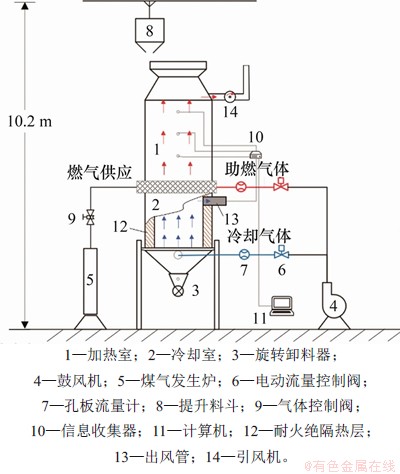

图1 烧结余热竖式余热回收系统

Fig. 1 Sintering waste heat vertical recovery system

1 系统热力学优化判据

1.1 烧结余热竖式回收工艺流程

烧结余热竖式回收系统是目前新兴的烧结余热回收工艺,相比于传统的环冷机可以更大限度的回收烧结矿显热,并且减少漏风。烧结余热竖式余热回收系统如图1所示。由图1可见:高温烧结矿由提升料斗运输至余热竖罐顶部入口,在重力作用下首先经过预存段,在冷却段中高温烧结矿与来自底部的冷却气体进行热量交换,经过一段时间后颗粒温度降低至120 ℃以下,达到冷却工艺要求,最后由竖罐底部的旋转卸料阀排出。冷却气体与烧结矿进行热交换后温度上升至550 ℃左右,由竖罐预存段与冷却段之间的环形风道排出,到达余热锅炉生产蒸汽,进而推动汽轮机发电,余热锅炉底部排出的中低温烟气由循环风机加压后,再次送至烧结余热竖罐用于冷却烧结矿。

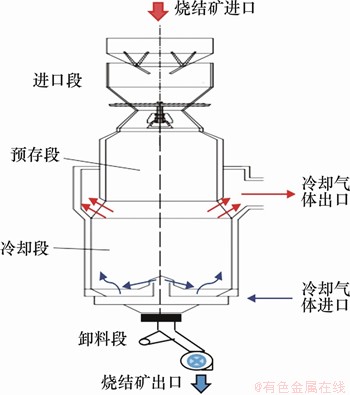

烧结余热竖罐式是烧结余热竖式回收工艺的关键设备,其结构形式如图2所示。竖罐出口处的冷却气体温度及流量会直接影响后续系统的发电量。在烧结机产量及工况,即竖罐进口烧结矿流量及温度一定的情况下,罐体的结构尺寸及操作参数都会对罐体内颗粒、气体流动以及两者之间的传热过程产生影响,进而影响出口冷却气体的温度及流量,因此,存在适宜的运行参数使热量回收系统效率达到较高水平。

图2 烧结余热竖罐结构示意图

Fig. 2 Schematic diagram of sinter waste heat vertical tank

1.2 火用分析方法

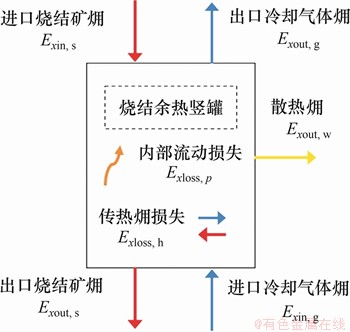

传统的热力学第一定律分析法只考虑能量总量,这与能量的实际效用不符合。火用分析方法建立在热力学第一定律与第二定律基础上,可以在偏离环境状态的情况下,更好地分析解释工质的做功能力,揭示系统内部损失的实质,对于整个系统的热力学完善具有指导意义[16]。火用包括物理火用、化学火用、机械能火用和潜能火用,由于烧结余热竖罐内只涉及气固间传热与气体流动,因此,在计算时主要考虑物理火用。烧结余热竖罐内火用流如图3所示。

图3 烧结余热竖罐的火用流

Fig. 3 Exergy flow of waste heat recovery of sinter vertical tank

当进出口工质i温度为Ti时,所具有火用的表达式为

(1)

(1)

式中:ExT,i为进出口工质i所具有火用,J/s,qm为进出系统工质质量流量,kg/s,cp为工质比热容,J/(kg·K);T0与Ti分别为环境温度和工质温度,K,本研究中环境温度取293 K。

其中冷却气体比热容为

(2)

(2)

烧结矿的比热容为[17]

(3)

(3)

式中:Tg与Ts分别为气体温度和烧结矿温度,K。

冷却气体经过烧结矿床层时,受到颗粒对气体流动阻碍的影响,势必会产生压力损失,使用压力火用进行定量描述,其表达式为

(4)

(4)

式中:Exloss, p为工质所损失的压力火用,J/s;R为气体常数,R=8.314 J/(mol·K);M为气体摩尔质量,kg/mol;P和P0分别为工质压力与环境压力,Pa。

烧结余热竖罐内冷却气体与烧结矿之间存在温差,由此引发气固间热量传递,在热量传递过程中亦会产生能量品质的损失,即传热火用损失。然而由于罐体内不同位置处气固间温差有所差异,且传热量不尽相同,很难具体计算各个位置处传热火用损失。考虑到火用分析方法是建立火用平衡方程基础上,火用平衡方程与能量守恒方程是一致的,即对于给定系统,进入系统的火用等于系统出口的火用加上系统内部火用损失,本研究将罐体壁面视为绝热边界,忽略散热能量损失。由此可得传热火用损失的表达式为

(5)

(5)

式中:Exloss, h为传热火用损失,J/s。

火用效率是评价系统能量回收效果的重要指标,指输出能量被进一步利用的占总体输入的比例,火用效率越高,代表系统的能量回收效率越高。火用效率 的表达式如下:

的表达式如下:

(6)

(6)

式中:Exout, useful为出口且投入使用的火用,J/s,在本研究中即为出口冷却气体火用。

2 烧结余热竖罐模型的建立及验证

2.1 物理模型

整个烧结余热竖罐罐体可分为进口段、预存段、冷却段及卸料段。由于罐体内气固传热过程主要发生在冷却段中,为了降低仿真模拟的耗费时间,本研究取烧结余热竖罐的冷却段及预存段部分区域进行仿真分析研究。

烧结矿经烧结机烧结,破碎机破碎之后,形成粒径不同,形状不规则的块状颗粒。在保证其求解精度的前提下,简化处理烧结矿床层。目前通常采用的方法是统计平均法[18-19],经过此方法处理之后,烧结矿床层可被看作是多孔介质[20]。由此对余热竖罐的物理模型进行以下简化处理:

1) 烧结余热竖罐运行状况稳定且所有相关设备运行参数恒定;

2) 在稳定状况下,罐体底部入口各个位置的风速与分布压力相同;

3) 烧结矿的体积随温度变化热胀冷缩很小,忽略不计,且颗粒内外温度一致,没有温度梯度,床层内颗粒运动速度只随竖罐横截面积变化。

2.2 数学模型

2.2.1 多孔介质模型

烧结余热竖罐内气体的流动以三维湍流为主,利用湍流k-ε方程对冷却气体流经烧结矿床层过程中的质量守恒及动量守恒进行控制,其中动量描述方程如下:

(7)

(7)

式中:ρ为流体密度,kg/m3;u为流体速度矢量,m/s;p为压力,包括静压力与流体黏性压力,Pa;I为单位方向矢量;μ为冷却空气的动力黏度,Pa·s;μT为湍流黏性系数,主要受湍流流动过程中的湍动能和湍动能耗散率的影响;F为冷却空气受到的体积力矢量,N/m3;Si为动量损失源项,N/m3。

为描述流体在多孔介质内的流动,需要在动量方程中增加一个源项,Si[21]。该源项由黏性损失项与惯性损失项2部分组成,分别为式(8)右边第1项与第2项。

(8)

(8)

式中:1/α为黏性阻力系数;C2为惯性阻力系数。

为了确定该源项,本文采用以烧结矿床层为研究对象得到的修正Ergun公式来确定黏性阻力系数和惯性阻力系数[8],分别为:

(9)

(9)

(10)

(10)

式中:ε为空隙率;φ为颗粒形状因子;dp为颗粒直径,m。

2.2.2 局部非热力学平衡双能量方程

烧结余热竖罐内,由于气固两相热导率及热容差别较大,相同位置处两相温度差别较明显,因此,采用局部非热力学平衡双能量方程来求解多孔介质内的传热过程。

固相能量方程为

(11)

(11)

气相能量方程为

(12)

(12)

式中:ρs和ρf分别为烧结矿和气体密度,kg/m3;cs和cf分别为烧结矿和气体比热容,J/(kg·K);us和uf分别为烧结颗粒平移速度和气体表观流速,m/s;ts和tf分别为固体和气体温度,℃;λs和λf分别为烧结矿和气体导热系数,W/(m·K);hv为气固之间体积对流换热系数,W/(m3·K),可由Achenbach 准则关系式确定:

(13)

(13)

此处h是气固之间换热系数,包含对流、辐射及导热,FENG等[22]通过自制试验装置,得到了烧结矿床层内综合传热努赛尔数( )。

)。

(14)

(14)

(15)

(15)

式中:hconv,hcond和hradi分别为对流换热系数、导热系数和辐射换热系数,W/(m·K);Re为颗粒雷诺数:Pr为气体普朗特数。

2.3 基于小试试验装置的模型结果验证

为验证模型的准确性,搭建了烧结矿冷却竖罐小试试验装置。小试试验装置烧结矿处理能力为5 t/h,有效冷却横截面积1 m2。整个装置外廓尺寸如下:高度为10 m,长宽均为4.5 m。主体试验罐体分为2部分:上部为加热段(有效高度为3.78 m),下部为冷却段(有效高度为1.80 m)。设置加热段是为保证冷却段上部有连续的高温物料不断进入,真实模拟烧结余热竖罐生产过程。罐体内横截面为圆形,内径为1.12 m,外部保温层厚度为0.4 m,在罐体最外侧为钢结构,确保小试试验竖罐运行的稳定性和安全性。

试验流程分为3个阶段:准备阶段、测试阶段及后处理阶段。

1) 准备阶段时,通过提升料斗将烧结矿颗粒填充至罐体当中;待罐体填充满后,加热罐体加热段内的烧结矿颗粒,加热热源为发生炉煤气燃烧所产生的热量;在加热阶段时,助燃气体管路处于开启状态,冷却气体管路处于关闭状态。加热段设置有温度探测装置,待加热段内烧结矿加热至所需温度时,关闭煤气发生炉与助燃气体管路。

2) 测试阶段时,开启罐体底部旋转下料阀及冷却气体管路,开始阶段下料阀排出的是冷却段内尚未加热的烧结矿颗粒,趁此阶段调整冷却气体流量至设计值;待高温烧结矿排出时,开始读取并记录数据,包括烧结矿排料温度及出风管处气体温度。

3) 后处理阶段主要包括试验物料的处理及测试设备的回收。

图4 小试试验装置简图

Fig. 4 Sketch map of small test device

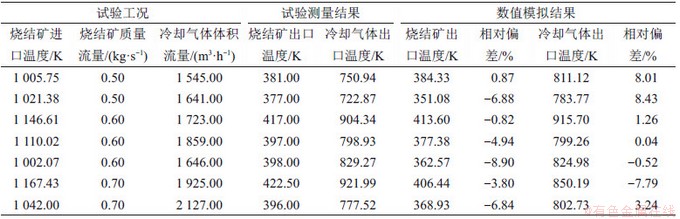

建立与小试试验装置冷却段一致的数值计算模型,保证相同的几何与边界条件,将数值计算结果与试验结果进行比较,结果如表1所示。

表1 试验测量结果与数值模拟结果对比

Table 1 Comparison of experimental measurement results and numerical simulation results

由表1可知数值计算模型模拟结果与试验测试值基本一致,但存在一定偏差,烧结矿及冷却气体出口温度平均偏差分别为4.47%和1.81%。存在偏差的主要原因是:

1) 在试验准备阶段对烧结矿进行加热时,很难将整个料层加热至统一温度,导致冷却段入口烧结矿温度有波动,与模拟计算情形有差异;

2) 测试阶段时,存在仪器误差和操作误差;

3) 数值计算模型进行了部分简化,例如忽略罐体壁面向外界的散热。

由表1可知最大相对偏差在10%以内,满足工程精度要求,能够准确描述烧结余热竖罐内传热及流动过程,因此,本文所建立的模型以及计算结果是可靠的。

3 烧结余热竖罐工艺参数对余热回收效果的影响

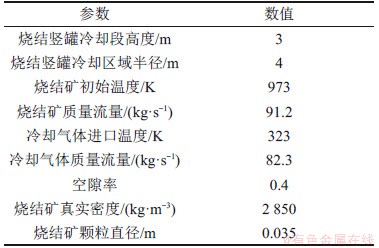

模拟计算以某钢厂年产量260万t烧结机的配套烧结余热竖罐作为基准工况,设计的具体数值如表2所示。

表2 烧结余热竖罐标况参数

Table 2 Parameters of sintering waste heat vertical cooler at standard condition

根据表2中烧结余热竖罐结构与运行参数,建立烧结余热竖罐冷却段与预存段部分区域物理模型,借助仿真软件COMSOL内置功能完成网格划分[23],并设置对应的边界条件。建立的几何模型及网格划分结果如图5所示。

图5 数值计算模型及网格划分

Fig. 5 Numerical calculation model and grid division

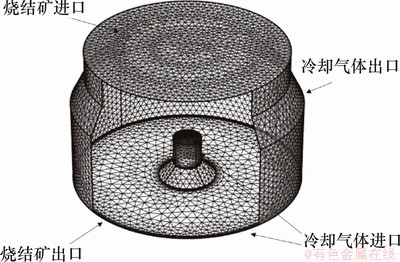

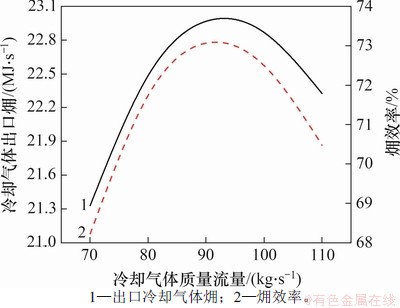

3.1 冷却气体质量流量的影响

冷却气体质量流量可通过调节风机进行控制,图6所示为冷却气体、烧结矿出口温度及料层内压降随冷却气体质量流量变化曲线。图6中曲线上的“*”表示在表2所示工况,即标准工况下,出口温度及料层内压降情况。从图6可以看出:冷却气体质量流量在70~110 kg/s范围内,每增加10 kg/s,冷却气体及烧结矿出口温度分别下降13.2 K和14.1 K,料层内压降增加202.5 Pa。从图6还可以看出:烧结矿出口温度的下降趋势有所减缓,这是由于随着冷却气体质量流量增加,罐体内烧结矿温度整体逐渐降低,气体与其进行热交换的难度提升,因此,烧结矿的冷却效果受到抑制。

图6 冷却气体、烧结矿出口温度及料层内压降随冷却气体质量流量变化曲线

Fig. 6 Cooling gas, sinter ore outlet temperature and pressure drop in vertical cooler variation with cooling gas mass flow

冷却气体质量流量对冷却气体出口火用及火用效率影响如图7所示。由图7可知:随着冷却气体质量流量增加,出口气体的火用出现先增大,在到达峰值点后又开始回落的趋势,峰值点对应的冷却气体质量流量为93.6 kg/s,此时出口气体的火用为23.03 MJ/s。从式(1)可以看出:火用可拆分为热量与能级2个因素,随着冷却气体流量增加,气体与烧结矿之间换热更加充分,出口气体携带的热量不断增加,但与此同时出口气体的温度不断降低,对应能级下降。在出口气体火用达到顶峰前,热量的增加占主导地位,火用表现为上升的态势。但由于出口气体的温度不断降低,导致回收热量的能级逐渐下降,并对出口气体的火用产生较大影响,表现为火用逐渐下降。

图7 冷却气体质量流量对冷却气体出口火用及火用效率影响

Fig. 7 Effect of cooling gas mass flow rate on cooling gas outlet exergy and exergy efficiency

由图7还可知:随着冷却气体质量流量增加,火用效率出现与出口气体火用相同的变化趋势(先增后降),峰值点对应的冷却气体质量流量为91.2 kg/s,与火用拐点位置相比略有提前。这是由于冷却气体质量流量会对竖罐的投入总火用产生影响,进而对火用效率产生影响。综上适宜的冷却气体质量流量应设置为91.2~93.6 kg/s。

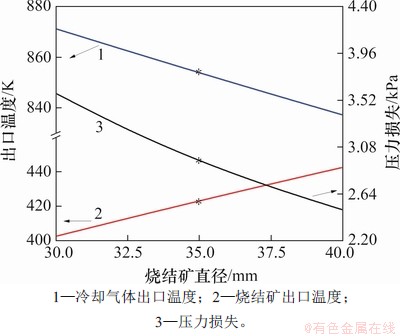

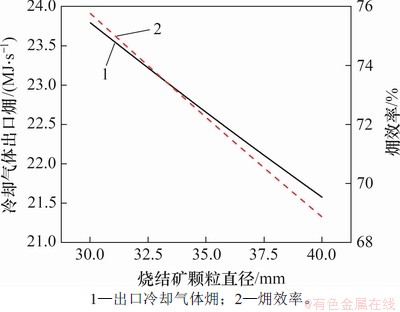

3.2 烧结矿颗粒直径的影响

图8所示为冷却气体、烧结矿出口温度及料层内压降随烧结矿颗粒直径变化曲线。从图8可以看出:颗粒直径在0.03~0.04 m范围内,每增加0.002 5 m,冷却气体出口温度下降8.51 K,烧结矿出口温度上升10.0 K。这是由于随着颗粒直径增加,烧结矿颗粒的比表面积减少,即颗粒单位体积所对应的表面积减小,由此导致相同床层体积内,颗粒与气体的换热面积缩减,导致传热效率降低。因此,增加烧结矿颗粒直径会导致余热竖罐冷却效率及余热回收效率降低。随颗粒直径增加,颗粒之间相互堆积形成的间隙不断扩大,气体流过间隙受到的阻碍随之减小,由此使得料层内压降不断降低。

图8 冷却气体、烧结矿出口温度及料层内压降随烧结矿颗粒直径变化曲线

Fig. 8 Cooling gas, sinter ore outlet temperature and pressure drop in vertical cooler vary with sinter particle diameter

图9所示为烧结矿颗粒直径对冷却气体出口火用及火用效率影响。从图9可以看出:颗粒直径在0.03~0.04 m范围内,每增加0.002 5 m,冷却气体出口火用下降0.55 MJ/s,火用效率下降1.72%。颗粒直径增加会导致罐体内气固传热效率降低,进而会对余热竖罐冷却效率及余热回收效率产生不利影响。

图9 烧结矿颗粒直径对冷却气体出口火用及火用效率影响

Fig. 9 Effect of sinter particle diameter on cooling gas outlet exergy and exergy efficiency

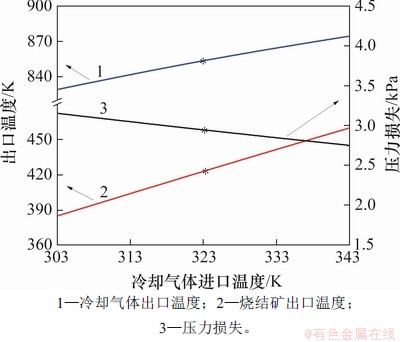

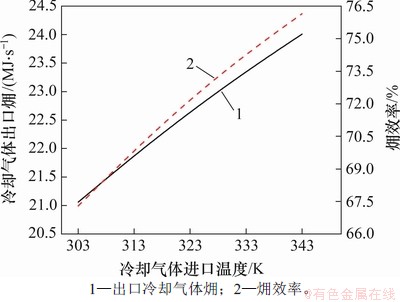

3.3 进口冷却气体温度的影响

进入余热竖罐底部的冷却气体来自余热锅炉,气体温度一方面影响竖罐的冷却效果,另一方面会对锅炉蒸汽的生产有所影响。图10所示为冷却气体、烧结矿出口温度及料层内压降随冷却气体进口温度变化曲线。从图10可以看出:冷却气体进口温度在303~343 K范围内,每增加10 K,冷却气体及烧结矿出口温度分别升高4.54 K和7.49 K,烧结矿的出口温度增长速度比冷却气体的大。这是由于随着冷却气体进口温度增加,气固间温差减小,使得两者间传热效率降低,竖罐的冷却效率降低,出口烧结矿温度上升。因为气体与烧结矿比热容有所差异,因此在能量守恒的前提下,两者出口温度变化有所差异。

图10 冷却气体、烧结矿出口温度及料层内压降随冷却气体进口温度变化曲线

Fig. 10 Cooling gas, sinter ore outlet temperature and pressure drop in vertical cooler vary with cooling gas inlet temperature

冷却气体进口温度对冷却气体出口火用及火用效率影响如图11所示。由图11可知:随着冷却气体进口温度增加,出口气体的火用及火用效率不断增加,每增加10 K,出口气体的火用增加0.29 MJ/s,火用效率增加0.89%。因此提高冷却气体进口温度将会对竖罐余热回收效果产生正效益,然而追求余热回收的前提是满足烧结矿冷却,根据先前的分析可知,冷却气体进口温度增加会提高烧结矿出口温度,冷却气体进口温度不宜设置过高。按照工艺要求,烧结矿需冷却至150 ℃以下,因此,冷却气体进口温度不宜超过323 K。

图11 冷却气体进口温度对冷却气体出口火用及火用效率影响

Fig. 11 Effect of cooling gas inlet temperature on cooling gas outlet exergy and exergy efficiency

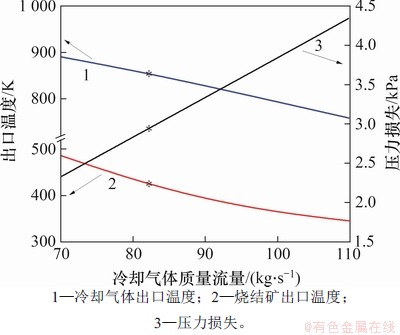

4 操作参数设计优化

根据先前的单因素分析对冷却气体质量流量、烧结矿颗粒直径和冷却气体进口温度3个参数进行优化分析。根据之前的研究可知:

1) 存在最佳的冷却气体质量流量,使得冷却气体出口火用及火用效率到达峰值;

2) 缩小颗粒直径会强化罐体内气固传热过程,进而提高竖罐的余热回收效果;

3) 冷却气体进口温度越高,冷却气体出口火用及火用效率随之增加,但受限于冷却工艺要求,进口温度不宜设置超过323 K。

在实际生产过程中,烧结矿颗粒尺寸受破碎及筛分过程影响,具有较大随机性,而冷却气体质量流量可通过风机变频及阀门进行控制,可操作性强。基于此,在保证冷却气体进口温度尽可能高的情况下(323 K),探究不同颗粒直径情况下,冷却气体质量流量对竖罐火用效率的影响,其结果如图12所示。

图12 不同烧结矿颗粒直径条件下,冷却气体进口温度对火用效率影响

Fig. 12 Effect of cooling gas inlet temperature on exergy efficiency with different sinter particle diameters

由图12可知:不同的烧结矿颗粒直径有各自对应的最佳冷却气体质量流量,随着颗粒直径增加,其对应的最佳冷却气体质量流量越大,而峰值点逐渐降低,这表明缩小烧结矿颗粒直径可达到更好的余热回收效果。当烧结矿颗粒直径从0.027 5 m增加至0.035 0 m时,对应的最佳冷却气体质量流量由89.1 kg/s增加至91.2 kg/s,变化幅度为2.3%,质量流量变化并不明显。而就实际工况而言,烧结矿床层是由不同粒径的颗粒堆积而成的,因此,适宜的冷却气体质量流量可设置为89.1~91.2 kg/s。

5 结论

1) 基于多孔介质模型及局部热力学非平衡方程,通过UDF将床层下移运动以对流项的形式编译至能量方程当中,建立了描述烧结余热竖罐内气固传热过程的三维稳态模型,并借助小试试验验证了模型的可靠性。

2) 针对既定产量与烧结矿矿温度的生产条件下,基于生产实际的可调性,冷却气体质量流量在70~110 kg/s范围内,随着流量不断增加,出口冷却气体所携带的火用呈现先增大后减小的趋势,在流量为93.6 kg/s时达到峰值,此时出口气体的火用为23.03 MJ/s,火用效率的拐点有所提前。烧结矿颗粒直径增加对竖罐余热回收效果产生负效应,在0.03~0.04 m范围内,颗粒直径每增加0.002 5 m,冷却气体出口火用下降0.55 MJ/s,火用效率下降1.72%。冷却气体进口温度在303~343 K范围内,随着温度增加,冷却气体出口火用及火用效率都随之增加,然而考虑到竖罐的冷却效果,冷却气体进口温度不宜设置过高。

3) 综合考虑冷却气体质量流量以及烧结矿颗粒直径2个因素对竖罐余热回收的影响,发现不同的烧结矿颗粒直径工况下,有对应不同的最佳冷却气体质量流量,且随着颗粒直径增加,其对应的最佳冷却气体质量流量越大,但是峰值点逐渐降低。考虑到实际生产过程中,床层内颗粒直径各不相同,因此,适宜的冷却气体质量流量应设置为89.1~91.2 kg/s。

参考文献:

[1] 蔡九菊, 王建军, 陈春霞, 等. 钢铁企业余热资源的回收与利用[J]. 钢铁, 2007, 42(6): 1-7.

CAI Jiuju, WANG Jianjun, CHEN Chunxia, et al. Recovery of residual-heat integrated steelworks[J]. Iron & Steel, 2007, 42(6): 1-7.

[2] 董辉, 林贺勇, 张浩浩, 等. 烧结热工测试与分析[J]. 钢铁, 2011, 46(11): 93-98.

DONG Hui, LIN Heyong, ZHANG Haohao, et al. Thermal test and analysis of sintering cooling system[J]. Iron & Steel, 2011, 46(11): 93-98.

[3] 蔡九菊, 董辉, 杜涛, 等. 烧结过程余热资源分级回收与梯级利用研究[J]. 钢铁, 2011, 46(4): 88-92.

CAI Jiuju, DONG Hui, DU Tao, et al. Study on grade recovery and cascade utilization of waste heat from sintering-cooling process[J]. Iron & Steel, 2011, 46(4): 88-92.

[4] JANG J Y, CHIU Y W. 3-D Transient conjugated heat transfer and fluid flow analysis for the cooling process of sintered bed[J]. Applied Thermal Engineering, 2009, 29 (14/15): 2895-2903.

[5] ZHANG Xiaohui, CHEN Zhuo, ZHANG Jiayuan, et al. Simulation and optimization of waste heat recovery in sinter cooling process[J]. Applied Thermal Engineering, 2013, 54(1): 7-15.

[6] LIU Yan, YANG Jian, WANG Jin, et al. Energy and exergy analysis for waste heat cascade utilization in sinter cooling bed[J]. Energy, 2014, 67(4): 370-380.

[7] 张晟, 高建业, 冯军胜, 等. 基于热载体焓火用的环冷机余热回收段仿真优化[J]. 中南大学学报(自然科学版), 2018, 49(8): 2083-2090.

ZHANG Sheng, GAO Jianye, FENG Junshenget al. Simulation and optimization of heat recovery section of annular cooler based on enthalpy exergy of heat carrier[J]. Journal of Central South University(Science and Technology), 2018, 49(8): 2083-2090.

[8] 冯军胜, 董辉, 李明明, 等. 烧结余热回收竖罐内固定床层的阻力特性[J]. 中南大学学报(自然科学版), 2014, 45(8): 2566-2571.

FENG Junsheng, DONG Hui, LI Mingming, et al. Resistance characteristics of fixed bed layer in vertical tank for recovering sinter waste heat[J]. Journal of Central South University(Science and Technology), 2014, 45(8): 2566-2571.

[9] 冯军胜, 董辉, 高建业, 等. 烧结矿余热回收竖罐内气固传热过程数值分析[J]. 中南大学学报(自然科学版), 2017, 48(11): 3100-3107.

FENG Junsheng, DONG Hui, GAO Jianye, et al. Numerical analysis of gas-solid heat transfer process in vertical tank for sinter waste heat recovery[J]. Journal of Central South University(Science and Technology), 2017, 48(11): 3100-3107.

[10] 冯军胜, 董辉, 李含竹, 等. 烧结矿余热回收竖罐内流动阻力特性[J]. 中南大学学报(自然科学版), 2017, 48(4): 867-872.

FENG Junsheng, DONG Hui, LI Hanzhu, et al. Flow resistance characteristics in vertical tank for sinter waste heat recovery[J]. Journal of Central South University(Science and Technology), 2017, 48(4): 867-872.

[11] 高建业, 刘一伟, 冯军胜, 等. 烧结矿余热回收中试竖罐结构和操作参数解析[J]. 钢铁研究学报, 2017, 29(1): 13-18.

GAO Jianye, LIU Yiwei, FENG Junsheng, et al. Structural and operating parameters of pilot scale vertical tank for sinter waste heat recovery[J]. Journal of Iron and Steel Research, 2017, 29(1): 13-18.

[12] 徐天骄, 张晟, 高建业, 等. 烧结矿余热回收竖罐热工参数确定方法及其应用[J]. 钢铁, 2018, 53(11): 107-112.

XU Tianjiao, ZHANG Sheng, GAO Jianye, et al. Determination method of thermal parameters of vertical tank for sinter waste heat recovery and its application[J]. Iron & Steel, 2018, 53(11): 107-112.

[13] FENG Junsheng, DONG Hui, GAO Jianye, et al. Numerical investigation of gas-solid heat transfer process in vertical tank for sinter waste heat recovery[J]. Applied Thermal Engineering, 2016, 107(25):135-143.

[14] PAN Lisheng, WEI Xiaolin, PENG Yan, et al. Theoretical study on the cooling procedure for vertical flow sinters[J]. Applied Thermal Engineering, 2017, 127(25): 592-601.

[15] ZHANG Sheng, ZHAO Liang, FENG Junsheng, et al. Thermal analysis of sinter vertical cooler based on waste heat recovery[J]. Applied Thermal Engineering, 2019, 157(5): 113708.

[16] 傅秦生. 能量系统的热力学分析方法[M]. 西安: 西安交通大学出版社, 2005: 98-107.

FU Qinsheng. Thermodynamic analysis method of energy system[M]. Xi'an: Xi'an Jiaotong University Press, 2005: 98-107.

[17] 包淑芳, 侯万升, 佟杰超. 本钢烧结矿冷却及其余热回收的试验研究[J]. 冶金能源, 1993, 12(6): 20-23.

BAO Shufang, HOU Wangsheng, TONG Jiechao. An experimental study on sinter cooling and its waste heat recovery in Benxi iron & steel co[J]. Energy for Metallurgical Industry, 1993, 12(6): 20-23.

[18] PELAGAGGE P M, CAPUTO A C, CARDARELLI G. Optimization criteria of heat recovery from solid beds[J]. Applied Thermal Engineering, 1997, 17(1): 57-64.

[19] PELAGAGGE P M, CAPUTO A C, CARDARELLI G. Comparing heat recovery schemes in solid bed cooling[J]. Applied Thermal Engineering, 1997, 17(11): 1045-1054.

[20] HINKLEY J, WATERS A G, LITSTER J D. An investigation of pre-ignition air flow in ferrous sintering[J]. International Journal of Mineral Processing, 1994, 42(1/2): 37-52.

[21] 刘伟, 范爱武, 黄晓明. 多孔介质传热传质理论与应用[M]. 北京: 科学出版社, 2006: 28-32.

LIU Wei, FAN Aiwu, HUANG Xiaoming. Porous media theory and application of heat and mass transfer[M]. Beijing: Science Press, 2006: 28-32.

[22] FENG Junsheng, DONG Hui, GAO Jianye, et al. Experimental study of gas-solid overall heat transfer coefficient in vertical tank for sinter waste heat recovery[J]. Applied Thermal Engineering, 2016, 95(25): 136-142.

[23] 苏石川, 孔为, 陈代芬. 热能工程与先进能源技术仿真与设计[M]. 北京: 化学工业出版社, 2015: 63-66, 98-129.

SU Shichuan, KONG Wei, CHEN Daifen. Thermal energy engineering and advanced energy technology simulation and design[M]. Beijing: Chemical Industry Press, 2015: 63-66, 98-129.

(编辑 杨幼平)

收稿日期: 2020 -04 -23; 修回日期: 2020 -06 -28

基金项目(Foundation item):国家自然科学基金资助项目(51974087,51904074);辽宁兴辽人才计划(XLYC1802122);辽宁省重点研发计划(2019JH2/10100007) (Projects(51974087, 51904074) supported by the National Natural Science Foundation of China; Project(XLYC1802122) supported by Liaoning Revitalization Talents Program; Project(2019JH2/10100007) supported by the Key Research & Development Plan of Liaoning Province)

通信作者:董辉,博士,教授,从事烧结余热回收及竖炉研究;E-mail:dongh@mail.neu.edu.cn

引用格式: 张晟, 赵亮, 冯军胜, 等. 基于火用效率目标的烧结余热竖罐操作参数优化[J]. 中南大学学报(自然科学版), 2021, 52(4): 1287-1296.

Citation: ZHANG Sheng, ZHAO Liang, FENG Junsheng, et al. Optimization of operating parameters of sinter waste heat vertical tank based on exergy efficiency[J]. Journal of Central South University(Science and Technology), 2021, 52(4): 1287-1296.