DOI: 10.11817/j.issn.1672-7207.2020.07.020

复合固化剂加注方法对土遗址加固效果的影响

张迎敏1,谌文武1,杨光2,戴鹏飞3,李永杰1

(1. 兰州大学 土木工程与力学学院,西部灾害与环境力学教育部重点实验室,甘肃 兰州,730000;

2. 中水北方勘测设计研究有限责任公司,天津,300222;

3. 浙江省古建筑设计研究院,浙江 杭州,310014)

摘要:研究复合加固剂的加注方法对土遗址透气性及力学特征的影响。将复合加固剂分别以钻孔注浆、浸泡、毛细吸收、表面喷洒4种方式对重塑土样进行加固,通过固化剂的有效吸收量控制试样的透气性,并对加固后试样表面和整体力学特性的变化进行评价,以寻求具有良好效果的加注方法。研究结果表明:钻孔注浆对固化剂的吸收量较大,烘干后表面硬度增幅较大,但抗压强度增加较小,加固后应对注浆孔用铆钉进行补强。浸泡和毛细吸收试样的固化剂吸收量较低,土体的透气性增加,由于其由外而内渗透的加注方式表面硬度提升明显,抗压强度也较高,加固效果较好。表面喷洒试样固化剂有效吸收量较大,透气性能维持原状,同时获得了较高的表面硬度和抗压强度。因此,浸泡、毛细吸收和表面喷洒方法是处理土遗址表面风化较为有效的方法。

关键词:土遗址;复合加固剂;加注方法;透气性;力学特征

中图分类号:TU411 文献标志码:A

文章编号:1672-7207(2020)07-1946-09

Influence of treatment methods of composite consolidant on consolidation of earthen sites

ZHANG Yingmin1, CHEN Wenwu1, YANG Guang2, DAI Pengfei3, LI Yongjie1

(1. Key Laboratory of Mechanics on Disaster and Environment in Western China, Ministry of Education, School of Civil Engineering and Mechanics, Lanzhou University, Lanzhou 730000, China;

2. China Water Resources Bei Fang Investigation Design & Research Co. Ltd., Tianjin 300222, China;

3. Zhejiang Historical Architecture Design & Research Institute, Hangzhou 310014, China)

Abstract: The influences of treatment methods of composite consolidants on the ventilation and the mechanical properties of earthen sites were studied. The remolded soil samples were treated with composite consolidant by trickling infiltration, soaking, capillary absorption and spraying, respectively. Breathability was controlled by effective absorption of the consolidant, and then the changes of surface and overall mechanical properties of the specimens were evaluated after treatment to explore effective treatment methods. The results show that the amount of consolidant absorbed by trickling infiltration is large. The surface hardness after drying rises considerably, while compressive strength increases slightly, Therefore, rivets should be used to reinforce the grouting holes. The specimens treated by soaking and capillary absorption have lower absorbance and higher breathability, and surface hardness and compressive strength are improved obviously due to the way of infiltration from outside to inside, which results in good consolidation effects. The specimens treated by spraying absorb larger amount of consolidant, and the breathability maintain the original stage, so that the specimens have the higher surface hardness and compressive strength. Therefore, soaking, capillary absorption and surface spraying are effective methods to preserve the external weathered layers of earthen sites.

Key words: earthen sites; composite consolidant; treatment methods; ventilation property; mechanical characteristics

土遗址是指人类在不同历史时期生产、生活而遗留下来的以土为主要建筑材料的遗迹,在中国历史、文化以及民族精神中具有崇高的地位[1]。然而,土遗址受自然环境、人为破坏等因素影响,病害发展迅速,多数土遗址正面临着严重的威胁,因此,对土遗址进行保护加固已刻不容缓[2]。国际古迹遗址理事会,美国盖蒂文物保护所、国际罗马文物保护修复研究中心、敦煌研究院、兰州大学文物保护研究中心等土遗址保护机构对土遗址保护进行了大量的研究工作,但土遗址的表面风化问题未能很好的解决,化学加固仍然是现阶段的重要加固手段。有机材料具有良好的渗透性、黏接性和耐水性,已在很多实际工程中得以应用[3-4],如纳米二氧化硅可以有效增加黄土的抗压强度[5],但也存在滋养微生物、耐老化性差[6-7]等问题。以石灰水[8]、碱性硅酸盐[9]为代表的无机材料因具有优良的兼容性和耐久性[10],近年来已成为化学加固的探索方向,但其渗透性较差,往往会堵塞遗址表面孔隙形成局部硬壳,造成遗址表面开裂脱落。因此,无机材料目前还未能很好地取代有机材料的补强作用,将二者进行复合是相对简单有效的加固方法。曾余瑶等[11]将石灰与糯米浆、蛋清进行配比,验证了无机和有机复合加固剂良好的黏接能力、耐水性和耐老化性能。CHEN等[12]通过对比复合加固剂与单一材料加固后土体的性能发现复合加固剂可以有效改善加固效果。基于复合加固剂一系列优良的性能,本文选取微米石灰和硅酸乙酯混合的方式进行加固。常规的加注方法包括涂刷、钻孔滴注、浸泡、毛细吸收等[3]。目前关于固化剂加注方法对土体透气性和力学特征的改变的研究还没有取得显著的成果。根据文物古迹保护准则[13],加固材料不应过多改变土遗址原状。若透气性降低太大,将导致遗址内部和外界环境之间物质和能量交换受阻,水汽、易溶盐等在阻断界面聚集,遗址将受高低温交变体积胀缩而发生坍塌、裂隙和剥落等病害[14]。此外,加固后的强度问题是文物保护的另一核心问题。加固材料应有足够的强度,以缓解损伤,但加固后强度增强不宜过大,以免内外层应力差过大而产生开裂剥落等威胁遗址保存的现象[15]。因此,加固后土体的透气性和强度是文物保护的关键问题。本文作者研究固化剂加注方法对土体透气性及力学特性的影响,以寻求具有良好加固效果的加注工艺。现场工程实例表明,土遗址风化层的厚度一般为3~5 cm,由于不同加注方法的加固深度存在差异,故将复合加固剂分别以钻孔注浆、浸泡、毛细吸收和表面喷洒4种方式对永昌明长城遗址土进行加固,通过固化剂的有效吸收量控制试样的透气性,并对加固后试样表面和整体力学特性的变化进行评价。

1 加固材料的配制

复合加固剂选用的有机材料是上海德赛堡建筑材料有限公司生产的碧林@增强剂(型号为KSE OH300),为硅酸乙酯增强材料,其与建筑材料孔隙或空气中的水分发生反应,无定形的水合二氧化硅与土颗粒相连,作为黏接物沉淀下来,具有补强作用。硅酸乙酯凭借其超强的渗透性,已在潮湿地区和西北干旱地区多处土遗址及石质文物保护中推广使用[4, 16-17]。

选用的无机材料是该公司生产的碧林@微-纳米石灰(型号为NHL-010)。石灰水自20世纪初就已被文物保护工作者尝试使用,后因其常温下浓度低,渗透深度小而被弃用;随着材料科学和纳米技术的发展,经改进后的微-纳米石灰克服了传统石灰水的缺点,成为极具发展潜力的加固材料。其加固原理是石灰与空气中的水分和二氧化碳反应生成氢氧化钙,氢氧化钙在遗址孔隙内继续反应生成碳酸钙沉淀,提升颗粒间的黏接力[18-19]。微米石灰已在砖、石、土质文物古迹的修缮保护工程中得以应用,并取得了显著的加固效果。

KSE OH300外观无色透明,纯度>99%,NHL-010外观呈乳白色,质量浓度为5 g/L。工程实践及试验资料表明,采用高浓度硅酸乙酯会导致遗址表面颜色加深,不符合文物保护的原则,而使用低浓度时加固效果不理想,因此,将硅酸乙酯和无水乙醇按体积比1:3配比,然后与微-纳米石灰混合,搅拌均匀后用聚乙烯保鲜膜封存备用。

2 加固试验

2.1 试样制备

选用的遗址土属于粉质黏土(液限为27.17%,塑限为17.01%,相对密度为2.72)。将扰动土充分碾碎后过孔径2 mm筛,将筛下土放入电热鼓风恒温干燥箱内,设定温度为108 ℃,干燥12 h。将烘干土冷却至室温后加入蒸馏水,按含水率16.5%配土,拌和均匀,用聚乙烯塑料袋密封后放入保湿器内浸润24 h,使水均匀分布在土体中。用土遗址专用制样机按照干密度为1.65 g/cm3,将土压制成边长为5 cm的立方体试样。将压制成型的试样放在室内环境下自然风干。

2.2 加注方法

为了对比不同加注方法加固前后土体性质的变化,排除试样含水率的影响,将自然风干的立方体样放入68 ℃烘箱内至恒质量,取出后测量试样实际尺寸、质量和表面硬度。依据土样体积、干密度、相对密度等计算所需加固剂的量。对试样采取钻孔注浆、浸泡、毛细吸收、表面喷洒4种方法进行加固,同时设置空白对照组和钻孔对照组作为参照。加注方法和具体操作步骤见表1。

钻孔注浆和表面喷洒加注方法的加固剂用量U参考文献[22],按最大饱和度Sr=85%计算:

(1)

(1)

式中:ρd为试样干密度,ρd=1.65 g/cm3;V为试样实际体积,cm3;Gs为土的相对密度,Gs=2.72;ρw为水的密度。

表1 加注方法和操作步骤

Table 1 Consolidation methods and procedures

加固后,将所有试样放置在塑料箱内,并用保鲜膜密封,以减缓溶剂无水乙醇的蒸发。18 h后将保鲜膜打开,将试样置于室内环境下养护28 d。

3 试验结果及分析

3.1 固化剂吸收量

固化剂的有效吸收量与试样的透气性相关。采用同种方法加固时,可通过固化剂的有效吸收量来控制试样的透气性。固化剂的吸收量由加固前后试样的质量变化确定[23]:

(2)

(2)

(3)

(3)

式中: 和

和 分别为土体中固化剂的含量及其有效吸收量,mg/g;md和

分别为土体中固化剂的含量及其有效吸收量,mg/g;md和 分别为加固前和加固28 d后的各组试样的平均干质量,g;

分别为加固前和加固28 d后的各组试样的平均干质量,g; 为加固处理后室内养护28 d时各组试样的平均质量,g。

为加固处理后室内养护28 d时各组试样的平均质量,g。

将所有试样放入68 ℃烘箱内至恒质量后(由于部分材料的耐热程度约为80 ℃,温度提高会使材料的质量和性质发生变化,因此,设定烘干温度为68 ℃,烘干时间为48 h)取出,然后放置于干燥器内冷却至室温后称质量,结果如表2所示。

由表2可知:不同加注方法处理后的试样对固化剂的有效吸收量存在差异。试样采用钻孔注浆法加固时,固化剂的有效吸收量最大,因为其渗透深度大,表面挥发慢。表面喷洒法次之,其采用低浓度多次渗透的方式,也获得了较高的有效固化剂含量。相比之下,毛细吸收和浸泡法中,固化剂的有效吸收量较低。

表2 与初始烘干质量相比复合加固剂的吸收量和干质量残留量

Table 2 Amount of composite consolidant absorbed and dry matter retained compared with initial dry mass

总体而言,在这4种加注方法中,试样对复合加固剂的有效吸收量是微量的( <1%),加固后试样的透气性和力学强度需进一步进行检验。需要指出的是,钻孔注浆试样在钻孔的过程中,对试样的扰动程度不同,孔的直径和深度也存在略微差异,导致固化剂有效吸收量的标准差较大,浸泡、毛细吸收、表面喷洒方法加固试样的固化剂有效吸收量较为接近。

<1%),加固后试样的透气性和力学强度需进一步进行检验。需要指出的是,钻孔注浆试样在钻孔的过程中,对试样的扰动程度不同,孔的直径和深度也存在略微差异,导致固化剂有效吸收量的标准差较大,浸泡、毛细吸收、表面喷洒方法加固试样的固化剂有效吸收量较为接近。

3.2 透气性

透气性试验经常被用来检测固化剂是否堵塞遗址原有的孔隙,优良的加固材料应尽可能保持孔隙通道畅通,加固后的试样应具有一定的透气性,确保遗址内的水分能够以流体水或水蒸气的形式与大气交流。本文在以往对透气性检测的基础上[24],进一步改进试验方案,探究一种可行的透气性检测方法。

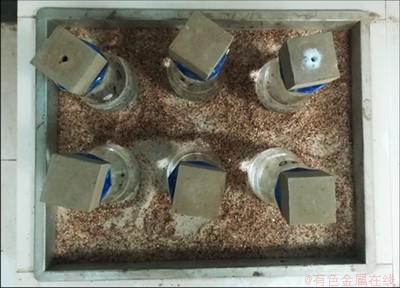

加固完养护28 d后,对各组试样进行透气性检验,试验操作步骤如下:1) 将试样烘干,在干燥器内冷却至室温后称质量;2) 将直径约为5 cm的宽口径玻璃锥形瓶洗净烘干并称质量;3) 向锥形瓶内倒入一定量的水,将土样盖在锥形瓶口上,用聚乙烯保鲜膜包裹试样与烧杯的连接处,用绝缘胶带固定,并用透明胶带封严,如图1所示;4) 将盖有土样的锥形瓶置于恒温装置内,每隔5 min对锥形瓶进行称质量,记录时间和质量。

图1 处理后的锥形瓶装置

Fig. 1 Processed conical bottle device

透气性试验原理是:锥形瓶内外存在温度差,锥形瓶内的水蒸气通过土样扩散到温度相对较低的空气中,因此,可通过分析锥形瓶装置的累计失水量随时间的变化对比不同方法加固后试样的透气性:

(4)

(4)

式中:X为累计失水率; 为某时刻锥形瓶装置总质量,g;m0为开始时刻锥形瓶装置总质量,g;mw为初始锥形瓶内加入水的质量,g。

为某时刻锥形瓶装置总质量,g;m0为开始时刻锥形瓶装置总质量,g;mw为初始锥形瓶内加入水的质量,g。

3.2.1 水浴法测透气性

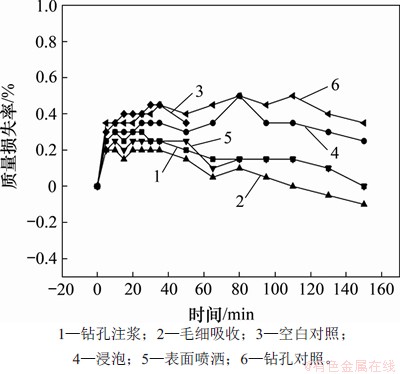

水浴法测透气性使用的是水浴恒温震荡箱,设定温度为60 ℃。在试验初期,每隔5 min对锥形瓶装置进行称质量。35 min后,每隔15 min进行称质量,并按式(4)计算质量损失率(图2)。其中,空白对照试样在50 min时被人为损坏。

图2 水浴法测累计失水率与时间关系

Fig. 2 Relationship between cumulative water loss rate and time measured by water bath method

从图2可见:试样的质量损失率在水浴恒温箱内经过3个阶段:第1阶段,试验初期,质量迅速增加,是因为锥形瓶内水蒸气温度较低,其透过试样散发到空气中的量较少,而恒温水浴箱内有大量的水蒸气,土样快速吸收;第2阶段,质量基本保持不变,在该温度和湿度环境下,锥形瓶内水蒸气排出量与土样吸收环境中的水蒸气量达到平衡;第3阶段,锥形瓶内水蒸气大量散失,质量持续下降。

水浴法中,由于恒温水浴箱内大量水蒸气的影响,质量随时间的下降规律不太明显,因此,用此装置进行试样的透气性检验存在一定的弊端。为尽量减小恒温水浴箱内大量的水蒸气对锥形瓶装置总质量的干扰,将水浴改为砂浴进行试验。

3.2.2 砂浴法测透气性

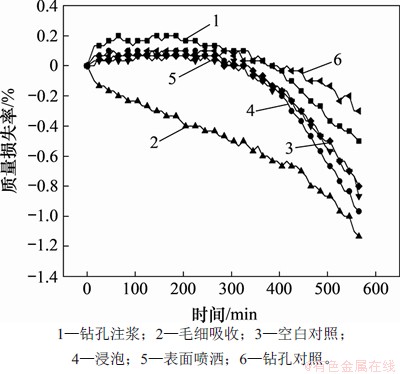

砂浴法测透气性使用的是恒温砂浴箱(图3),初期设定温度为80 ℃,预热锥形瓶装置,以免冷的锥形瓶接触砂浴箱,温差太大,而出现炸裂等情况。2 h后待锥形瓶内水温度上升至一定温度后,将砂浴温度调为120 ℃。每隔5 min对锥形瓶装置进行称质量,并按式(4)计算质量损失率(图4),根据质量损失率与时间的关系变化,判断加固后试样的透气性。

图3 砂浴法测透气性

Fig. 3 Sand bath for measuring breathability

图4 砂浴法测累计失水率与时间关系

Fig. 4 Relationship between cumulative water loss rate and time measured by sand bath method

从图4可以看出:毛细吸收加固试样在透气性试验中,随时间的增加锥形瓶内水的质量持续快速下降,且累计失水率最大,在445 min后质量下降速度更快。浸泡、表面喷洒、空白对照、钻孔注浆与钻孔对照这5组试样呈现出相似的趋势,锥形瓶内水的质量先增加后减少。在砂浴初期,锥形瓶装置内水的质量上升,是因为烘干的土样吸收了空气中的水。在325~385 min区间处于变化的节点,这5组试样吸收空气中水的质量与锥形瓶内水的散发质量平衡。毛细吸收和浸泡法加固使得土体透气性增加。表面喷洒法加固试样与空白对照试样曲线大致重叠,表明表面喷洒后,土体的透气性能维持原状。钻孔注浆加固试样较钻孔对照试样随时间的增加,质量下降速度较快,因此,注浆后土体透气性增强。但两者相对其余4组变化较慢,尤其是钻孔对照试样在试验初期质量几乎没有下降,485 min后质量才略微下降。钻孔后的试样无论加固与否,锥形瓶内水的质量下降均较慢。这是因为试样温度较高,尤其在钻孔处,与顶部周围环境形成温差,空气中冷的水蒸气遇热在试样顶部凝结。

在砂浴透气性试验中,毛细吸收和浸泡法加固后土体透气性有所增加。表面喷洒后,试样的透气性基本能维持原状。钻孔后的试样受空气中水蒸气影响显著,结果需进一步改善。从空气湿度、水浴箱内水加热产生的水蒸气对透气性装置影响以及结果的有效性等因素考虑,砂浴检测法较水浴检测法更具可行性。

4 加固方法对土体力学特性的影响

4.1 表面硬度试验

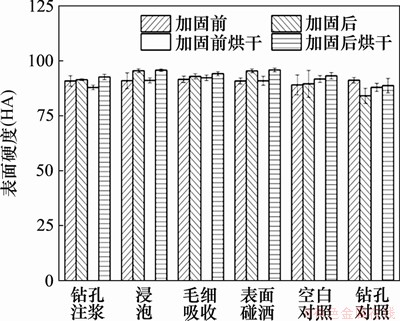

表面硬度是检测遗址表面风化程度的重要手段。不同加注方法对试样表面硬度的影响不同,因此,在试样加固前、加固前烘干后、加固后室内养护28 d、加固28 d烘干后,分别采用邵氏橡胶硬度计对各组试样的表面硬度(HA)进行测量,测量范围为0~100。按照硬度计的操作说明,在试样顶面选择5个区,每个区各取1个测点,为避免对试样造成破坏且保证测量结果的准确性,各测点的位置应至少距离试样边缘1.2 cm,将压针平稳垂直压在土样的顶面,1 s时记录读数[25],取点位置具体如图5所示,取其平均值作为试样的表面硬度,结果如图6和表3所示。

图5 测量表面硬度取点位置

Fig. 5 Location of measuring surface hardness

图6 不同加注方法对表面硬度的影响

Fig. 6 Effect of different treatment methods on surface hardness

表3 加固前后表面硬度增幅

Table 3 Surface hardness increase before and after treatment

由图6和表3可知:烘干后试样的表面硬度增大。表面喷洒和浸泡后试样的表面硬度增加较大,且两者具有较高的表面硬度。因为这2种加注方法中,试样表面直接与加固剂接触,固化剂含量较高,加固剂渗入试样,增加了土颗粒间的黏结力。钻孔注浆后试样在室内环境下硬度增幅很小,是由于钻孔操作在试样烘干后进行,对试样顶面钻孔使得表面土体变得松散,钻孔对照试样在室内环境下放置28 d后,表面硬度显著下降,也验证了上述结论。毛细吸收是利用毛细作用,自下而上吸收加固剂,而表面硬度测量的是试样顶面的表面力学特征,顶面吸收的材料相对较少,因而表面硬度增幅最小。空白对照组试样在28 d后,室内环境下表面硬度和烘干后表面硬度均十分接近,也验证了该测量结果的准确性。

可见,表面硬度是表征土体表面强度较为可靠的指标。表面喷洒和浸泡后试样的表面硬度增加较大,钻孔注浆试样烘干后硬度增加明显,毛细吸收试样的表面硬度增幅较小。

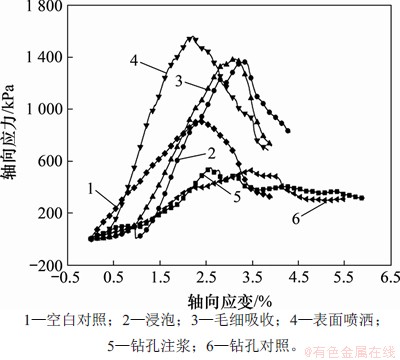

4.2 无侧限抗压强度试验

无侧限抗压强度是检测加注方法对遗址土体力学性能的影响最直接的一种测量手段。为去除含水率对试样抗压强度的影响,将加固养护28 d后的试样烘干并冷却至室温后,采用电液伺服万能试验机对6组立方体试样进行抗压试验,设定加载速率为1 mm/min。试验结果见图7和表4。

图7 试样应力应变关系

Fig. 7 Stress-strain curves of uniaxial compression test samples

表4 不同加注方法加固后试样抗压强度

Table 4 Unconfined compressive strengths of samples after treatment with different consolidation methods

表面喷洒对试样表面硬度提升较高,从表4可以看出:表面喷洒对试样的抗压强度也有大幅度的提升,因此,适量的表面喷洒可以有效地对土遗址表面风化进行加固。浸泡和毛细吸收加注方法对土体的抗压强度有明显的积极作用,且两者应力应变曲线大致相同。与空白对照试样相比,两者强度提升了约50%。钻孔注浆加固后的试样和钻孔对照试样的抗压强度最低,两者均在注浆孔处产生破坏。在钻孔和注浆的过程中,由于注浆孔周围土体疏松而隆起,万能试验机顶部夹具接触的是中间注浆孔与侧边线,因此,抗压强度不是垂直于顶底面获得,造成结果偏低。但仍然可以看出,注浆加固对试样的抗压强度略有提升。因此,钻孔注浆后的试样应对注浆孔用铆钉进行补强,使得注浆孔的强度略有提升,而不应成为土体的脆弱点。

5 结论

1) 在不同的加注方法下,相同的加固材料可能会产生不同的加固效果。不同的加注方法不仅导致固化剂有效吸收量和透气性存在差异,而且表面和整体力学特征也不同。

2) 采用钻孔注浆和表面喷洒的方式,试样获得了较高的有效固化剂含量,表面喷洒后试样的透气性能维持原状。钻孔注浆后试样的透气性受注浆孔影响显著。毛细吸收和浸泡法中,试样对固化剂的有效吸收量较低,透气性有所增加。

3) 在透气性方面,水浴法由于恒温水浴箱内大量水蒸气的影响存在明显弊端,而砂浴法测得结果更具有效性,该方法可为评估透气性提供新思路。

4) 试样烘干后的表面硬度大体呈增大趋势。表面喷洒和浸泡加注方法对试样表面硬度和抗压强度的增加较大。钻孔注浆由于注浆孔未做后续处理,室温下表面硬度增幅很小,抗压强度提升较小。由于毛细吸收是自下而上吸收加固的,该方式对试样的表面硬度增幅最小,但是抗压强度显著提升。表面硬度是表征土体表面强度较为可靠的指标。

5) 就整体加固效果而言,钻孔注浆对固化剂的吸收量较大,烘干后表面硬度增幅较大,但由于注浆孔的存在抗压强度增加较小,加固后应对注浆孔用铆钉进行补强。浸泡和毛细吸收试样的固化剂吸收量较低,土体的透气性增加,由于其由外而内渗透的加注方式表面硬度提升明显,抗压强度也较高,加固效果较好。表面喷洒试样的固化剂有效吸收量较大,透气性能维持原状,同时获得了较高的表面硬度和抗压强度。因此,浸泡、毛细吸收和表面喷洒是处理土遗址表面风化较为有效的方法。

参考文献:

[1] 孙满利. 土遗址保护研究现状与进展[J]. 文物保护与考古科学, 2007, 19(4): 64-70.

SUN Manli. Research status and development of the conservation of earthen sites[J]. Sciences of Conservation and Archaeology, 2007, 19(4): 64-70.

[2] 李最雄. 丝绸之路古遗址保护[J]. 中国文化遗产, 2004(3): 118-122.

LI Zuixiong. The protection of the Silk Road in ancient relics[J]. China Cultural Heritage, 2004(3): 118-122.

[3] KARATASIOS I, THEOULAKIS P, KALAGRI A, et al. Evaluation of consolidation treatments of marly limestones used in archaeological monuments[J]. Construction and Building Materials, 2009, 23(8): 2803-2812.

[4] MARAVELAKI-KALAITZAKI P, KALLITHRAKAS-KONTOS N, KORAKAKI D, et al. Evaluation of silicon-based strengthening agents on porous limestones[J]. Progress in Organic Coatings, 2006, 57(2): 140-148.

[5] KONG Ran, ZHANG Fanyu, WANG Gonghui, et al. Stabilization of loess using nano-SiO2[J]. Materials, 2018, 11(6): 1014.

[6] GRIFFIN P S, INDICTOR N, KOESTLER R J. The biodeterioration of stone: a review of deterioration mechanisms, conservation case histories, and treatment[J]. International Biodeterioration, 1991, 28(1/2/3/4): 187-207.

[7] BOOTH J, VILES H, FLETCHER P. An assessment of three consolidants for use on museum artefacts in comparison to organo silanes[C]// FASSINA V. 12th International Congress on the Deterioration and Conservation of Stone. New York: Columbia University, 2012:1-10.

[8] OSSOLA F, TOMASIN P, DE ZORZI C, et al. New calcium alkoxides for consolidation of carbonate rocks. Influence of precursors' characteristics on morphology, crystalline phase and consolidation effects[J]. New Journal of Chemistry, 2012, 36(12): 2618.

[9] 李黎, 陈锐, 邵明申, 等. 经PS加固土遗址水饱和强度及加固效果的环境影响研究[J]. 岩石力学与工程学报, 2009, 28(5): 1074-1080.

LI Li, CHEN Rui, SHAO Mingshen, et al. Saturation strength of earthen Ruins reinforced by potassium silicate and influence of environmental factors on reinforcement effect[J]. Chinese Journal of Rock Mechanics and Engineering, 2009, 28(5): 1074-1080.

[10] CHEN Wenwu, DAI Pengfei, YUAN Pengbo, et al. Effect of inorganic silicate consolidation on the mechanical and durability performance of sandstone used in historical sites[J]. Construction and Building Materials, 2016, 121: 445-452.

[11] 曾余瑶, 张秉坚, 梁晓林. 传统建筑泥灰类加固材料的性能研究与机理探讨[J]. 文物保护与考古科学, 2008, 20(2): 1-7, 73.

ZENG Yuyao, ZHANG Bingjian, LIANG Xiaolin. Study on characteristics and consolidation mechanism of historical mortar materials[J]. Sciences of Conservation and Archaeology, 2008, 20(2): 1-7, 73.

[12] CHEN Wenwu, ZHANG Yingmin, ZHANG Jingke, et al. Consolidation effect of composite materials on earthen sites[J]. Construction and Building Materials, 2018, 187: 730-737.

[13] 国际古迹遗址理事会中国国家委员会. 中国文物古迹保护准则[M]. 北京: 文物出版社, 2015: 14-18.

ICOMOS. China Principles for the conservation of heritage sites in China[M]. Beijing: Cultural Relics Publishing House, 2015: 14-18.

[14] DU Y, CHEN W, CUI K, et al. A model characterizing deterioration at earthen sites of the Ming Great Wall in Qinghai Province, China [J]. Soil Mechanics and Foundation Engineering, 2017, 53(6): 426-434.

[15] 张秉坚, 尹海燕, 铁景沪. 石质文物表面防护中的问题和新材料[J]. 文物保护与考古科学, 2000, 12(2): 1-4.

ZHANG Bingjian, YIN Haiyan, TIE Jinghu. The problems and new materials in conservation of historic stone structures[J]. Sciences of Conservation and Archaeology, 2000, 12(2): 1-4.

[16] 朱杰, 蔡乐刚, 郭戈. 硅酸乙酯类加固材料在潮湿环境土遗址加固保护中的应用研究[J]. 文物保护与考古科学, 2015, 27(4): 7-14.

ZHU Jie, CAI Legang, GUO Ge. Application of ethyl silicate as a strengthening agent for consolidation and conservation of earthen sites under moisture circumstances[J]. Sciences of Conservation and Archaeology, 2015, 27(4): 7-14.

[17] BARAJAS M, LIMA E, LARA V H, et al. Effect of organic and inorganic consolidation agents on Tlaltecuhtli monolith[J]. Journal of Archaeological Science, 2009, 36(10): 2244-2252.

[18] LIU Qiang, LIU Yongjun, ZENG Kunwei, et al. Advanced design of Chinese traditional materials for the conservation of historic stone buildings[J]. Journal of Archaeological Science, 2011, 38(8): 1896-1900.

[19] SMALLEY I J. “In-situ” theories of loess formation and the significance of the calcium-carbonate content of loess[J]. Earth-Science Reviews, 1971, 7(2): 67-85.

[20] PINTO A P F, RODRIGUES J D. Consolidation of carbonate stones: influence of treatment procedures on the strengthening action of consolidants[J]. Journal of Cultural Heritage, 2012, 13(2): 154-166.

[21] DAI P, CHEN W, WANG N. Research on laboratory preparation of nano calcium-based consolidant and preliminary application in earthen site reinforcement projects[C]// Ancient Underground Opening and Preservation. London: CRC Press, 2016: 9-15.

[22] 赵海英, 王旭东, 李最雄, 等. PS材料模数、浓度对干旱区土建筑遗址加固效果的影响[J]. 岩石力学与工程学报, 2006, 25(3): 557-562.

ZHAO Haiying, WANG Xudong, LI Zuixiong, et al. Impact of modulus and concentration of potassium silicate material on consolidating earthen architecture sites in arid region[J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(3): 557-562.

[23] PINTO A P F, RODRIGUES J D. Stone consolidation: the role of treatment procedures[J]. Journal of Cultural Heritage, 2008, 9(1): 38-53.

[24] 陈利君. 硅溶胶/硅丙复合土遗址加固剂的合成与应用[D]. 西安: 西安建筑科技大学化学与化工学院, 2012: 47-55.

CHEN Lijun. The synthesis and application of composite latex reinforcing agents prepared by silicon sol and silicon acrylic-acid[D]. Xi'an University of Architectural Science and Technology. School of Chemistry and Chemical Engineering, 2012: 47-55.

[25] 谌文武, 张起勇, 刘宏伟, 等. 高分子材料SH渗透加固遗址土的效果研究[J]. 工程地质学报, 2017, 25(5): 1307-1313.

CHEN Wenwu, ZHANG Qiyong, LIU Hongwei, et al. Reinforcing effect of relic soil sites penetrated with high polymer material sh[J]. Journal of Engineering Geology, 2017, 25(5): 1307-1313.

(编辑 赵俊)

收稿日期: 2019 -09 -03; 修回日期: 2019 -12 -21

基金项目(Foundation item):国家自然科学基金资助项目(51578272) (Project(51578272) supported by the National Natural Science Foundation of China)

通信作者:谌文武, 博士, 教授, 从事地质工程、岩土工程和文物保护工程研究; E-mail: sungp@lzu.edu.cn