文章编号:1004-0609(2015)-11-3164-07

复合纤维含量对精铸硅溶胶型壳强度及透气性的影响

芦 刚,毛 蒲,严青松,纪超众,饶文杰

(南昌航空大学 轻合金加工科学与技术国防重点学科实验室,南昌 330063)

摘 要:采用陶瓷和尼龙复合纤维增强熔模精铸硅溶胶型壳,通过测试与分析复合纤维增强硅溶胶型壳的常温及焙烧后强度和透气性,研究复合纤维含量对硅溶胶型壳强度和透气性的影响规律,确定复合纤维含量与焙烧温度和型壳强度的关系,并通过SEM对型壳试样断口形貌进行观察和分析。结果表明:复合纤维对硅溶胶型壳强度和透气性的影响显著,当复合纤维含量小于0.6%(质量分数)时,硅溶胶型壳强度和透气性同时增大;当复合纤维含量大于0.6%时,型壳常温及焙烧后强度开始减小,焙烧后基体中孔隙率增加,型壳透气性继续增大;当复合纤维含量为0.6%、焙烧温度为1050 ℃时,型壳焙烧后强度达到最大值。

关键词:熔模精铸;硅溶胶型壳;复合纤维含量;强度;透气性

中图分类号:TG249.5 文献标志码:A

Effect of composite fiber content on strength and breathability of silica sol shell for investment casting

LU Gang, MAO Pu, YAN Qing-song, JI Chao-zhong, RAO Wen-jie

(National Defence Key Discipline Laboratory of Light Alloy Processing Science and Technology,

Nanchang Aeronautical University, Nanchang 330063, China)

Abstract: Ceramic and nylon composite fibers were used to enhance silica sol shell of investment casting. The effects of composite fiber content on the strength and breathability of silica sol shell were studied by testing and analyzing the green and fired strength and breathability. Meanwhile, the relationships among composite fiber content and firing temperature and fired strength of shell were established. The fracture appearances of shell specimens were observed by scanning electron microscopy (SEM). The results indicate that the effect of composite fibers on strength and breathability of silica sol shell is obvious. When composite fiber content is less than 0.6% (mass fraction), the strength and permeability of silica sol shell both increase. When composite fiber content is more than 0.6%, the green strength and fired strength of fiber-reinforced shell decrease firstly, and the matrix porosity increases, the shell breathability continues to increase; When the composite fiber content is 0.6% and firing temperature is 1050 ℃, the fired strength reaches maximum value.

Key words: investment casting; silica sol shell; composite fiber content; strength; breathability

熔模精铸是一种先进的材料近净成形技术,具有高精度、高效率、低损耗等优点,在航空航天、汽车工业等领域有广泛的应用前景[1-4]。硅溶胶是精铸业常用的一种优质粘结剂,硅溶胶型壳高温强度较高、表面质量较好。但硅溶胶型壳残留强度偏高,导致脱壳性差、铸件难以清理;其次,硅溶胶型壳湿强度较低,不易型壳的搬运,干燥慢,且制壳周期长。然而,精铸硅溶胶型壳强度和透气性存在相互制约的关系,往往采用增加型壳厚度保证型壳强度,导致散热困难,晶粒粗大,而且透气性差、充型困难,必须提高金属液浇注温度,使得型壳与金属发生反应的程度加剧,大大影响了产品的表面质量,同时金属液的高温使得型壳变形严重,从而影响精铸件质量[5]。迄今为止,国内外学者研究以纤维作为增强体加入金属基复合材料,可有效提高复合材料基体的力学性能和组织性能[6-10]。根据纤维增强复合材料的思路,在型壳中加入陶瓷有机纤维能够阻碍型壳裂纹的扩展,当裂纹越过纤维时,要将纤维从型壳基体中拔出也需要较高的能量,可显著提高型壳的常温强度,其次使得型壳在高温下也不容易胀裂,从而提高型壳的高温强度[11-12]。在浆料中加入高分子粘接剂和尼龙有机纤维对型壳进行强化,发现对强度影响不大,但可以增加型壳单层挂浆厚度,对尖角处抗开裂有着显著效果;同时,型壳在焙烧以后,尼龙纤维被完全烧失,在型壳内留下许多微孔隙,增强了型壳透气性[13-14]。陶瓷型壳中加入米糠,型壳焙烧前后的性能明显改善,特别是米糠在型壳焙烧时被烧失,增加了陶瓷型壳的孔隙率,降低了型壳裂纹的产生,从而提高了精铸件的质量[15-16]。基于此,为了同时保证型壳具有较高常温强度、足够的高温强度和较好透气性,本文作者采用陶瓷和尼龙复合纤维增强精铸硅溶胶型壳,研究复合纤维含量对硅溶胶型壳常温及焙烧后强度和透气性的影响规律,并探讨其增强机理,为高熔点复杂结构整体精铸件的生产提供科学依据和理论支撑。

1 实验

1.1 实验材料

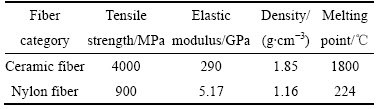

耐火材料采用郑州市海旭磨料有限公司生产的白刚玉和亿隆耐火材料厂生产的莫来石砂;粘结剂为山东济南银丰硅制品有限责任公司的碱性硅溶胶,SiO2含量为29%~31%,胶体粒径为9~20 nm;尼龙纤维,直径为d 9~13 μm,长度为2~4 mm,由北京融信通科技有限公司生产;陶瓷纤维(硅酸铝纤维),直径为d 3~4.5 μm,长度为4~6 mm,由淄博华岩耐火纤维有限公司生产。纤维的主要性能指标如表1所列。

表1 纤维的主要性能指标

Table 1 Main performance index of fiber

1.2 实验方法

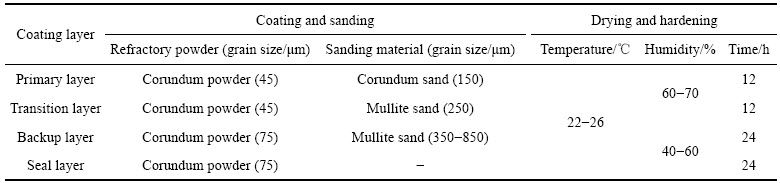

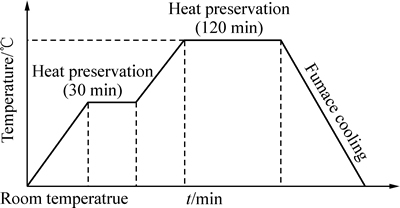

按现行工艺配制型壳面层和过度层浆料,纤维仅加入背层和封层浆料中。复合纤维含量以浆料中硅溶胶质量的0~0.75%增加,每间隔加入量为0.15%,其中复合纤维是将陶瓷纤维和尼龙纤维按质量比为1:1交织复合而成。型壳试样制备的工艺参数如表2所列。型壳试样的焙烧工艺如图1所示。

试验测试型壳强度:用尺寸为70 mm×22.36 mm×6 mm的长方块试样,采用XQY-Ⅱ型智能型砂强度仪,以三点弯曲试验测试抗弯强度的方法,测定型壳试样的常温强度及其焙烧后的强度,并在Quanta200型SEM下观察型壳试样断口形貌。

测试型壳透气性:用尺寸为d50 mm×6 mm的圆片试样,采用ZTY智能型砂型透气性测试仪,在室温下测试圆片试样的透气性。

2 结果与分析

2.1 复合纤维含量对硅溶胶型壳常温强度的影响

表2 型壳试样制备的工艺参数

Table 2 Process parameters of shell specimens preparation

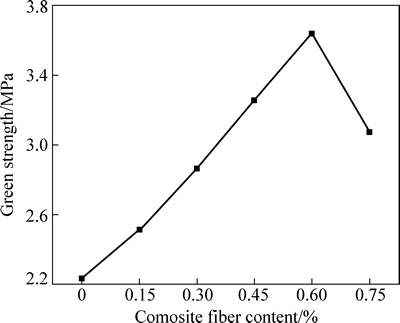

复合纤维含量对硅溶胶型壳试样常温强度的影响如图2所示。从图2可以看出,复合纤维的加入显著提高了硅溶胶型壳试样的常温强度,当复合纤维含量从0逐渐增加到0.6%时,型壳常温强度迅速增大,近似线性增长。当复合纤维含量为0.6%时,型壳常温强度达到最大值,为3.638 MPa,与传统型壳的相比提高了39%。

图1 型壳试样的焙烧工艺

Fig. 1 Sintering process of shell specimens

图2 复合纤维含量对硅溶胶型壳常温强度的影响

Fig. 2 Effect of composite fiber content on green strength of silica sol shell

纤维作为增强材料加入硅溶胶型壳,由于纤维自身具有强韧性和高张力等性能,在型壳干燥硬化的过程中,纤维与硅溶胶浆料胶凝界面形成强有力的交织网络骨架,使得耐火粉料和硅溶胶粘结剂紧密连接。在型壳试样受外加弯曲力断裂时,纤维与硅溶胶浆料基体有效结合,使其承载了一定的作用力,并可抑制型壳裂纹的产生,对型壳起了加强作用,并使其强度有所提高。当复合纤维含量低于0.6%时,纤维在硅溶胶浆料中有较好的分散性,浆料涂挂型壳较均匀,纤维在基体中呈单丝分布。随着复合纤维含量的增加,纤维与基体的有效接触面增大,形成的网状结构越结实,当施加应力时,通过型壳界面将其作用力迅速传递到纤维上,从而充分发挥了纤维对硅溶胶型壳的增强作用。当复合纤维含量高于0.6%时,纤维不能完全均匀地分散在硅溶胶浆料中,从而出现了纤维团聚现象,纤维在型壳中分布杂乱,部分纤维均匀分散,部分呈纤维束状态。纤维束的存在对型壳基体具有强大的割裂作用,严重影响纤维与基体的致密度和连续性,使纤维与型壳结合疏松,当在外力作用下,型壳试样会很快在纤维束部位发生断裂,削弱了纤维的增强作用。因此,纤维在硅溶胶浆料中分散的均匀性以及纤维与型壳基体之间的结合力大小是决定纤维对其型壳增强作用强弱的关键。

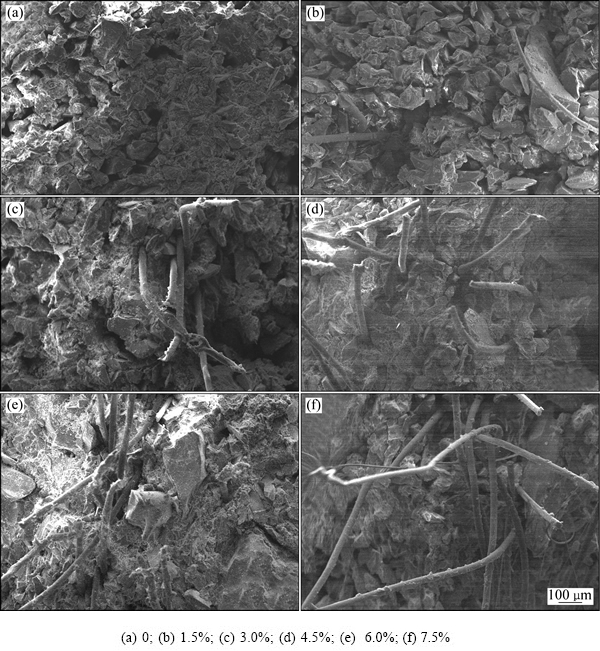

试样断口形貌的特征反映了制壳材料断裂时的特征及材料内部组织和结构,可系统地观察型壳试样的断口形貌,有助于分析纤维对型壳性能的增强机理。复合纤维增强硅溶胶型壳试样常温抗弯断裂时的断口形貌如图3所示。从图3(a)可以看出,传统型壳试样在断裂时,断口相对平整,没有特别明显的凹凸状。而从图3(b)~(f)中可以看出,相同的视场面积中,型壳基体中纤维的数目逐渐增多,型壳试样在断裂时纤维上粘附着制壳材料,使得断面呈现凹凸不平,由于陶瓷纤维和尼龙纤维纵横交叉的分布状态,纤维从型壳基体中拔出的方向不一致,使得型壳具有交叉紧实度,从而提高了型壳的常温强度。从图3(b)~(d)可知,纤维在型壳中分布的较均匀,证明纤维在硅溶胶浆料中的分散性较好,从而实现了纤维与浆料之间的良好交织,纤维硅溶胶浆料涂挂性能较好。由图3(e)可见,两种纤维均匀地分布在型壳基体中,且有部分纤维粘附着制壳材料,表明型壳试样在外力作用下,一方面,原始制壳材料承载一定的载荷后断裂;另一方面,纤维以型壳界面脱粘、整体拔出等失效方式并消耗能量,从而纤维对型壳试样的断裂起了滞后作用,因此,型壳试样的强度就有了相应的提高。由图3(f)可见,当纤维含量为0.75%时,在型壳试样中分布不均匀,部分纤维呈纤维束状且略显弯曲,这是由于纤维含量过高,在制备浆料的过程中容易出现纤维絮聚现象,纤维在硅溶胶浆料中的分散性变差,减少了纤维与浆料的接触面积,从而影响浆料的涂挂性能,在型壳基体中纤维束存在的地方变得疏松,导致型壳试样在破坏时,纤维束与型壳界面发生粘连,带动制壳材料一起脱落,形成同一方向的斜槽或孔隙,这些纤维束对型壳试样仍有增强效果,但这种增强作用大幅度降低,反而对型壳试样产生一种强烈的割裂作用,此时,纤维对型壳试样的负效应大于正效应,型壳试样的抗弯强度显著降低。

图3 复合纤维增强型壳试样在常温抗弯断裂时的断口SEM像

Fig. 3 Fracture SEM images of shell specimens with different composite fiber contents

2.2 复合纤维含量对硅溶胶型壳焙烧后强度的影响

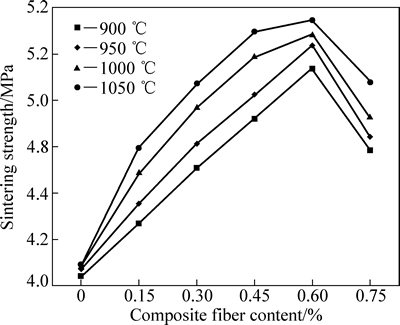

图4 复合纤维含量和焙烧温度对型壳试样抗弯强度的影响

Fig. 4 Effect of composite fiber content and firing temperature on sintering strength of shell specimens

不同复合纤维含量下焙烧温度对型壳试样抗弯强度的影响如图4所示。从图4可以看出,复合纤维增强的型壳试样经不同的焙烧温度焙烧后,型壳的抗弯强度都有不同程度的变化,在复合纤维含量为0.6%时,型壳试样的抗弯强度均达到最大值,但经1050 ℃温度焙烧后的抗弯强度最大,为5.145 MPa。而当复合纤维含量超过0.6%,型壳试样的抗弯强度开始降低。

陶瓷和尼龙复合纤维增强硅溶胶型壳焙烧后,尼龙有机纤维在型壳基体中受热熔化,冷却后凝固形成各种形态孔隙,不同形态孔隙对型壳试样焙烧后的强度各异。陶瓷无机纤维仍留在型壳内部,高温焙烧使得纤维与型壳基体紧密连接,继续增强型壳,陶瓷纤维在拔出、脱离型壳后形成纤维直径大小的圆形孔洞,表明型壳在断裂时纤维承载了部分应力。同时,随着焙烧温度的升高,型壳内物料的蒸汽压增高,扩散系数也增大,颗粒重排几率加剧,粉料与撒砂颗粒之间结合更紧密、孔隙越少,它们之间的连接层变厚,连接作用增强,颗粒与粉料之间的烧结也就越来越明显,这也可能造成型壳试样焙烧后强度增大[17]。因此,复合纤维含量在0.15%~0.6%之间,焙烧后型壳中陶瓷纤维的增强作用要比尼龙纤维的割裂作用大,与原始型壳试样相比,焙烧后抗弯强度较高。随着复合纤维含量的增加,型壳试样在不同焙烧温度下的抗弯强度呈先增加后减小,一方面,由于尼龙纤维熔失后留下的孔隙增加,对型壳试样的割裂作用加剧;另一方面,纤维含量过高,在型壳基体中分散不均而形成纤维束,纤维束的存在同样对型壳具有一定的割裂作用。

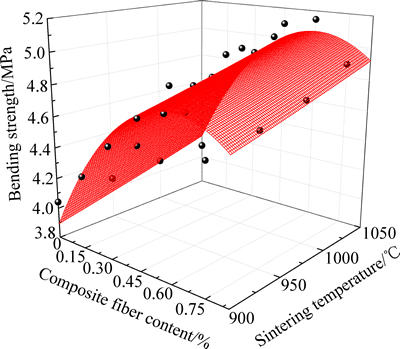

根据复合纤维增强型壳焙烧后强度的测试结果,采用曲面拟合法,拟合曲面如图5所示,可以得出型壳试样焙烧后强度p、复合纤维含量w、焙烧温度t 3者之间的关系,如式(1)所示:

(1)

(1)

图5 型壳试样焙烧后强度p、复合纤维含量w和焙烧温度t的关系拟合图

Fig. 5 Fitting relationship among sintering strength p of shell specimens and composite fiber content w and sintering temperature t for investment casting

从图5和式(1)中可以看出,型壳试样焙烧后的抗弯强度与复合纤维含量w和焙烧温度t都有一定的关系,复合纤维含量w和焙烧温度t共同影响着型壳试样焙烧后的抗弯强度p的高低,随着复合纤维含量和焙烧温度的增加,型壳试样焙烧后的抗弯强度先增大后减小。当复合纤维含量w一定时,型壳试样焙烧后的抗弯强度随着焙烧温度的升高而增大,增幅较小;当焙烧温度一定时,复合纤维含量小于0.6%时,型壳试样焙烧后的抗弯强度随着复合纤维含量的增加而增大,增幅较大,复合纤维对型壳强度起着积极的强化作用;而复合纤维含量大于0.6%时,纤维在型壳基体中极易出现纤维束现象,纤维束对型壳的增强作用相对较弱,型壳试样的抗弯强度随着复合纤维含量的增加而减小。因此,型壳焙烧后强度p、复合纤维含量w、焙烧温度t间的关系式对复合纤维增强型壳具有一定的现实理论指导意义,以选择合理的复合纤维含量和型壳焙烧温度。

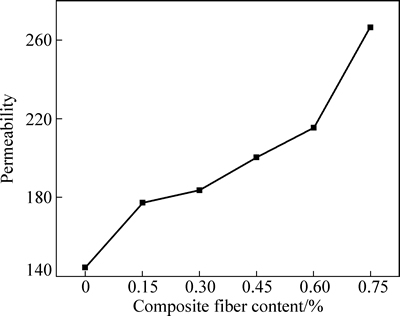

2.3 复合纤维含量对硅溶胶型壳透气性的影响

复合纤维含量对型壳试样透气率的影响如图6所示。从图6可以看出,随着复合纤维含量的增加,型壳试样的透气率逐渐增大,当纤维含量为0.75%时,型壳试样的透气率达到最大值,为266.6,与原始型壳的相比增加了46%。这是由于型壳在高温焙烧过程中,尼龙纤维被完全烧失,在型壳内部留下许多微小孔隙,增加了型壳中气体排放的通道。纤维含量过高在浆料中分散不均,容易在型壳中形成纤维束状,在高温焙烧过程中,纤维束中的尼龙纤维被烧失,陶瓷纤维仍留在其中,该纤维束存在的地方变得疏松,基体中孔隙率增加,型壳试样的透气率提高,型壳在高温金属浇注时透气性就好,但是对型壳的高温强度具有破坏作用。

图6 复合纤维含量对型壳试样透气性的影响

Fig. 6 Effect of composite fiber content on permeability of shell specimens

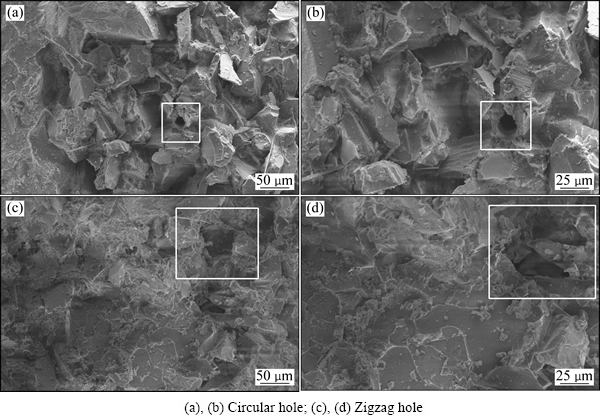

复合纤维增强硅溶胶型壳焙烧后,尼龙有机纤维被烧失在型壳内部留下的微孔隙形貌如图7所示。图7(a)和(b)是圆形孔洞(单根尼龙纤维被烧失后形成),图7(c)和(d)是锯齿形孔洞(尼龙纤维束被烧失后形成)。从图7(a)和(b)中可以看出,这个圆形孔洞的孔径接近于尼龙纤维直径,且孔的边缘没出现脱砂、变形等现象,说明这个孔洞是由于尼龙纤维在高温焙烧后留下的,而不是型壳试样在断裂时陶瓷纤维被拔出后形成。从图7(c)和(d)中可以看出,孔洞较多且不规则,近似于锯齿状,这是由于型壳基体中存在的复合纤维束,当型壳试样断裂时,陶瓷纤维从疏散的孔隙中拔出,从而形成类似锯齿状的孔洞。正是型壳经焙烧后基体中存在的圆形和锯齿状的孔洞,孔隙率随着复合纤维含量的增加而增多,型壳的透气性才得以逐渐提高。

图7 复合纤维增强型壳焙烧后在型壳内部形成的微孔隙形貌

Fig. 7 Micro pore morphologies of composite fiber enhanced shell after sintering

3 结论

1) 陶瓷和尼龙复合纤维增强精铸硅溶胶型壳,当复合纤维含量在0~0.75%时,随着纤维含量的增加,型壳常温强度先增大后减小;当复合纤维含量为0.6%时,型壳常温强度达到最大值,为3.638 MPa,与传统型壳的相比提高了39%。

2) 建立了复合纤维含量w、焙烧温度t与型壳焙烧后强度p的关系为

随着复合纤维含量和焙烧温度的增加,型壳焙烧后强度先增大后减小。当复合纤维含量为0.60%、焙烧温度为1050 ℃时,型壳试样焙烧后强度最大,为5.145 MPa。

3) 复合纤维增强型壳焙烧过程中尼龙纤维被完全烧失,在型壳内留下许多微孔隙,可有效提高型壳透气性,随着复合纤维含量的增加,型壳透气性逐渐增大。

REFERENCE

[1] 周明智, 朱春临, 陈奇海, 张 冲. 精密熔模铸造技术在雷达产品中的应用[J]. 电子机械工程, 2013(4): 46-48.

ZHOU Ming-zhi, ZHU Chun-lin, CHEN Qin-hai, ZHANG Chong. Application of investment casting to radar component manufacture[J]. Electro-Mechanical Engineering, 2013(4): 46-48.

[2] 樊振中, 徐秀利, 王玉灵, 刘建军. 熔模精密铸造技术在航空工业的应用及发展[J]. 特种铸造及有色合金, 2014(3): 285-289.

FAN Zhen-zhong, XU Xiu-li, WANG Yu-ling, LIU Jian-jun. Investment casting technology application and development in the aviation industry[J]. Special Casting & Nonferrous Alloys, 2014(3): 285-289.

[3] CHEN Yan-fei, ZHENG Shun-qi, TU Jiang-ping, XIAO Shu-long, TIAN Jing, XU Li-juan, CHEN Yu-yong. Fracture characteristics of notched investment cast TiAl alloy through in situ SEM observation[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(10): 2389-2394.

[4] DOU Yang-qing, BU Kun, DOU Yang-liu. Reversing design methodology of investment casting die profile based on ProCAST[J]. China Foundry, 2010, 7(2): 132-137.

[5] 刘朝晖, 王 强. 硅溶胶型壳脱壳性能的改良方法[J]. 热加工工艺, 2013, 42(11): 69-71.

LIU Chao-hui, WANG Qiang. Improved methods for silica sol mould shelling performance[J]. Hot Working Technology, 2013, 42(11): 69-71.

[6] ABRAHAM T N, GEORGE K E. Short nylon fiber reinforced PP: Melt rheology[J]. Polymer-Plastics Technology and Engineering, 2007, 46(3): 321-325.

[7] TRAN T K, KIM D J. High strain rate effects on direct tensile behavior of high performance fiber reinforced cementitious composites[J]. Cement and Concrete Composites, 2014, 45: 186-200.

[8] 田 君, 石子琼, 钟守炎, 廖梓龙. Al2O3 SiO2(sf)/AZ91D复合材料的蠕变微观组织和变形机理[J]. 中国有色金属学报, 2013, 23(5): 1241-1247.

TIAN Jun, SHI Zi-qiong, ZHONG Shou-yan, LIAO Zi-long. Microstructural evolution and deformation mechanism during creep of Al2O3-SiO2(sf)/AZ91D composite[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(5): 1241-1247.

[9] 刘贯军, 李文芳, 马利杰, 彭继华. 硅酸铝短纤维增强AZ91D复合材料的界面微观结构及力学性能[J]. 复合材料学报, 2008, 25(6): 156-159.

LIU Guan-jun, LI Wen-fang, MA Li-jie, PENG Ji-hua. Interface microstructure and mechanical property of (Al2O3-SiO2)sf/AZ91D composite[J]. Acta Materiae Compositae Sinica, 2008, 25(6): 156-159.

[10] 王婕丽, 林文松, 姜自旺, 段丽慧. 纤维结构钼铜复合材料的制备及组织性能[J]. 中国有色金属学报, 2014, 24(1): 174-178.

WANG Jie-li, LIN Wen-song, JIANG Zi-wang, DUAN Li-hui. Fabrication and structure properties of fiber-structured Mo-Cu composites[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(1): 174-178.

[11] MAITY P C, MAITY J. Development of high strength ceramic shell for investment casting[J]. Indian Foundry Journal, 2011, 47(7): 23-26.

[12] 吕 凯, 刘向东, 李艳芬, 冯 华, 王 浩. 纤维增强熔模铸造复合型壳的性能及断口形貌[J]. 北京航空航天大学学报, 2014, 40(10): 1361-1365.

Kai, LIU Xiang-dong, LI Yan-fen, FENG Hua, WANG Hao. Properties and fracture surface morphology of fiber-reinforced shell for investment casting[J]. Journal of Beijing University of Aeronautics and Astronautics, 2014, 40(10): 1361-1365.

Kai, LIU Xiang-dong, LI Yan-fen, FENG Hua, WANG Hao. Properties and fracture surface morphology of fiber-reinforced shell for investment casting[J]. Journal of Beijing University of Aeronautics and Astronautics, 2014, 40(10): 1361-1365.

[13] YUAN C, JONES S. Investigation of fiber modified ceramic moulds for investment casting[J]. Journal of the European Ceramic Society, 2003, 23(3): 399-407.

[14] YUAN C, JONES S, BLACKBURN S. The influence of autoclave steam on polymer and organic fiber modified ceramic shells[J]. Journal of the European Ceramic Society, 2005, 25(7): 1081-1087.

[15] HARUN Z, KAMARUDIN N H, TAIB H M. Effect of rice husk on fired ceramic shell strength[J]. Advanced Materials Research. 2013, 795: 732-737.

[16] NEUSSL E, SAHM P R. Selectively fiber-reinforced components produced by the modified investment casting process[J]. Composites: Part A, 2001, 32: 1077-1083.

[17] 肖树龙. 钛合金低成本氧化物陶瓷型壳熔模精密铸造技术研究[D]. 哈尔滨: 哈尔滨工业大学, 2007.

XIAO Shu-long. Study on technology of investment cast for titanium alloy using low cost oxide ceramic mould shell[D]. Harbin: Harbin Institute of Technology, 2007.

(编辑 王 超)

基金项目:江西省自然科学基金资助项目(20142BAB216024);华中科技大学材料成形与模具技术国家重点实验室开放基金资助项目(P201409);轻合金加工科学与技术国防重点学科实验室开放课题研究基金资助项目(gf201401004)

收稿日期:2014-04-19;修订日期:2015-07-24

通信作者:芦 刚,讲师,博士;电话:15070949571;E-mail:aimulalg@163.com