终轧工艺对AM50镁合金轧板力学性能和织构特征的影响

来源期刊:中国有色金属学报(英文版)2014年第9期

论文作者:丁汉林 张义伟 Shigeharu KAMADO

文章页码:2761 - 2766

Key words:AM50 alloy; hot rolling; mechanical anisotropy; texture

摘 要:采用不同的轧辊温度和速率制备AM50镁合金轧板,研究终轧工艺对镁板力学性能和织构特征的影响。研究表明:在轧辊温度为200 °C和轧辊速率为5 m/min条件下制备的镁板的强度(极限抗拉强度:295 MPa;屈服强度:224 MPa)和伸长率(22.9%)之间达到较优组合;在热轧过程中,轧板的屈服强度主要取决于轧制温度,而织构强度则对轧辊速率更为敏感;提高轧制温度或轧辊速率均可改善AM50镁合金板材力学性能的各性异性。

Abstract: The conventional hot rolling of AM50 alloy at different roll temperatures and speeds was performed to investigate the effects of finish-rolling conditions on the mechanical properties and texture of rolled sheet. The better combination between strength (ultimate tensile strength: 295 MPa; yield strength: 224 MPa) and ductility (22.9%) can be obtained for the AM50 sheet rolled at the roll temperature of 200 °C with the roll speed of 5 m/min. The yield stress depends strongly on roll temperature, while the texture intensity in rolled sheets is more sensitive to roll speed during hot rolling. Increasing rolling temperature or roll speed can improve the mechanical anisotropy of AM50 rolled sheets.

Trans. Nonferrous Met. Soc. China 24(2014) 2761-2766

Han-lin DING1, Yi-wei ZHANG1, Shigeharu KAMADO2

1. School of Materials Science and Engineering, Anhui University of Technology, Ma’anshan 243002, China;

2. Department of Mechanical Engineering, Nagaoka University of Technology, Kamitomioka, Nagaoka, Niigata 940-2188, Japan

Received 15 August 2013; accepted 26 October 2013

Abstract: The conventional hot rolling of AM50 alloy at different roll temperatures and speeds was performed to investigate the effects of finish-rolling conditions on the mechanical properties and texture of rolled sheet. The better combination between strength (ultimate tensile strength: 295 MPa; yield strength: 224 MPa) and ductility (22.9%) can be obtained for the AM50 sheet rolled at the roll temperature of 200 °C with the roll speed of 5 m/min. The yield stress depends strongly on roll temperature, while the texture intensity in rolled sheets is more sensitive to roll speed during hot rolling. Increasing rolling temperature or roll speed can improve the mechanical anisotropy of AM50 rolled sheets.

Key words: AM50 alloy; hot rolling; mechanical anisotropy; texture

1 Introduction

With increasing applications of wrought magnesium alloys as lightweight structural materials substituting for steel and aluminum, rolled Mg sheets are expected to produce for complex parts with thin-walled geometries or large surface areas used in automotive and electrical industries. However, a major obstacle encountered for hot-rolled Mg sheet is the mechanical anisotropy and the resulting limited press formability at ambient temperature. AGNEW and DUYGULU [1] have demonstrated that the mechanical anisotropy is primarily attributed to the strong basal texture where the c-axes favor to be perpendicular to the rolling plane. Therefore, changing the basal texture or weakening the texture intensity would be an available approach to improve the formability of the rolled sheet. Recently, some special processes such as cross-rolling [2,3] and differential speed rolling [4-6] have been developed to enhance the stretch formability of AZ31 alloy since these methods can effectively modify the rolling texture as compared with conventional symmetrical rolling. The microstructural analyses in these studies suggested that the texture modification is mainly achieved by the introduction of intense shear deformation imposed in normal direction throughout the sheet thickness. In this regard, the final thickness of the rolled sheets produced by these methods is usually limited to no more than 1 mm [2-6].

Conventional symmetrical rolling has been successful in producing the Mg sheets with a large range of thickness, but it is yet unknown how to obtain the rolled Mg sheet with weak texture intensity by this conventional method. Our previous work [7] has studied the effect of rough rolling and intermediate annealing conditions on the mechanical properties of AM50 rolled sheets and suggested that excellent mechanical properties can be obtained after conventional symmetrical rolling. In this study, a systematic finish-rolling process was performed. Effects of various roll temperatures and speeds on mechanical properties and texture of rolled sheet were investigated. Finally, an optimized rolling schedule was proposed for AM50 alloy to develop the rolled sheet with weakening texture intensity.

2 Experimental

The investigated AM50 (Mg-5.0%Al-0.3%Mn, mass fraction) alloy was received in the form of as-cast slabs. The billets with 300 mm in length, 80 mm in width and 25 mm in thickness used for rolling were cut directly from the slabs and then homogenized at 424 °C for 24 h. The mean grain size was about 311 μm for homogenized billet. The sheet rolled to 2 mm in thickness with a total cumulative rolling reduction of 92% was achieved through a 12-pass rough rolling (10% per pass) and a subsequent 4-pass finish rolling (30% per pass). Two groups of finish rolling were adopted to study the influence of roll temperature and speed on the mechanical properties and texture of rolled sheet. The finish-rolling conditions are listed in Table 1. The sheets were reversed after each pass. The graphite lubrication was used in hot rolling.

Specimens used for microstructure observations were cut from the RN (RD-ND) and TN (TD-ND) planes of finish-rolled sheets (RD: rolling direction; ND: normal direction; TD: transverse direction). Electron back- scatter diffraction (EBSD) observation was performed in a JEOL scanning electron microscope (SEM) machine operating at 25 kV. The samples for EBSD were final-polished by colloidal silica suspension following mechanical polishing. The orientation imaging microscopy was measured at a step size of 0.4 μm. The strength of (0002) pole figures was measured on the surface (RD-TD plane) of rolled sheets by X-ray texture analysis. The tensile specimens with 50 mm in length, 2 mm in thickness and 4 mm in gauge width were machined from the finish-rolled sheets with the angles of 0°, 45° and 90° between the tensile direction and the rolling direction. All the tensile tests were carried out at room temperature with an initial strain rate of 10-3 s-1. The average values of mechanical properties were calculated by  =(X0+2X45+X90)/4 based on the data of the specimens of three orientations.

=(X0+2X45+X90)/4 based on the data of the specimens of three orientations.

3 Results and discussion

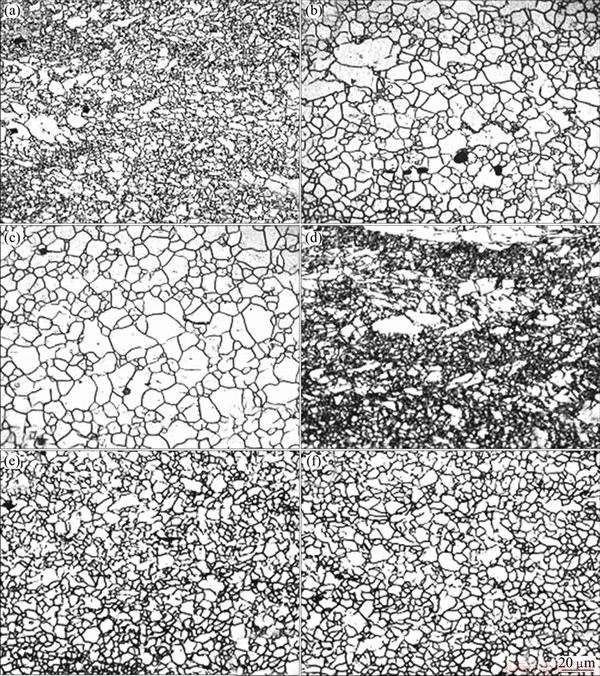

The optical images in the RD-ND planes of AM50 sheets rolled at different conditions are shown in Fig. 1. The average grain sizes are examined to be 1.4, 3.4 and 4.2 μm as roll temperature increases from 200 °C to 300 °C (Figs. 1(a)-(c)), or 1.7, 3.3 and 3.7 μm as roll speed increases from 1 m/min to 20 m/min (Figs. 1(d)-(f)), respectively. For both groups of samples, the grain refinement arisen from the occurrence of dynamic recrystallization (DRX) is evidently observed. The smaller grain size at lower roll temperature can be attributed to a larger Zener-Hollomon parameter. Furthermore, the particles precipitated at a low roll temperature of 200 °C may provide more nucleation sites for recrystallized grains during hot rolling. In particular, those precipitates lying on the grain boundaries may restrict the movement of grain boundaries, which is another beneficial factor for grain refinement.

However, for the samples rolled at different roll speeds, the grain size increasing with the increase of roll speed has been found despite the fact that the effective strain rate is larger at the high roll speed. This is because a rapid roll speed would reduce the decrease of sheet temperature resulted from the heat exchange but significantly enhance the increase of sheet temperature from the mechanical to thermal energy conversion, which leads to a higher actual deformation temperature during hot rolling [8]. For the sample rolled at 1m/min, a few elongated unrecrystallized grains and the precipitation of second phase particles can also be observed (Fig. 1(d)), whilst for the sheets rolled at 5 or 20 m/min, the DRX is fully complete.

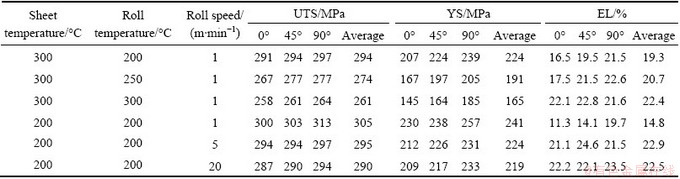

Table 1 Mechanical properties of AM50 alloy rolled at different roll temperatures and speeds

Fig. 1 Optical images of microstructure of AM50 alloy after finish rolling at different roll temperatures of 200 °C (a), 250 °C (b), 300 °C (c) at sheet temperature of 300 °C and roll speed of 1 m/min, or at different roll speeds of 1 m/min (d), 5 m/min (e), 20 m/min (f) at sheet temperature of 200 °C and roll temperature of 200 °C (Rolling direction is horizontal)

The mechanical properties for the specimens tested at different tensile directions are all listed in Table 1. It can be found that the ultimate tensile strength (UTS) and the 0.2% yield strength (YS) decrease, while the elongation to fracture (EL) increases with the increase of the roll temperatures or speeds. This reveals the strong dependence of mechanical properties on the rolling conditions. However, the influence of the roll temperature and speed on the mechanical properties exhibits different ways: as the roll temperature increases, the elongation is enhanced slightly accompanied by a notable decrease in YS, while a larger elongation is attained and a relatively higher strength can be kept with the increase of roll speed. For all these sheets studied, the better combination between strength and ductility is achieved in the sheet rolled at a roll speed of 5 m/min with a sheet temperature of 200 °C. In this case, the average UTS is 295 MPa, the average YS is 224 MPa and the average elongation is 22.9%.

Additionally, the comparison of the mechanical properties of the samples tested at different directions shows that both tensile strength and elongation increase as the tensile direction ranges from 0° to 90°. The fact that the rolled sample exhibits different elongation depending on testing direction indicates the presence of distinct anisotropy in ductility, which is commonly observed in other rolled Mg alloys [9,10].

The 0.2% YS depending on the grain size can be generally described by the well-known Hall-Petch relation. As shown in Fig. 2, the YS of the sheets in our case is also plotted against the square root of grain size, in which the YS increases with larger d-1/2 value, indicating that the grain refinement serves to the enhancement in yield stress. From the linear fitting results, it is clearly found that the YS obtained from different tensile directions may be best fitted by a similar slope for each group sheet, although the rolled sheets exhibit strong mechanical anisotropy when they are tested at different tensile directions. Note that, the Hall-Petch slopes are different for the two groups of samples. The slope for the samples rolled at different speeds (85 MPa·μm1/2 on average) is less than that for the samples rolled at different temperatures (141 MPa·μm1/2 on average), indicating a weaker grain size dependence of yield stress for the sheets rolled at different roller speeds as compared with the sheets rolled at different roller temperatures. That is, for the hot rolling of AM50 alloy, the roller temperature change has a more significant effect on the yield stress than the roller speed.

Fig. 2 0.2% proof stress plotted against grain size for sheets rolled at different roll temperatures and speeds

At least two plausible viewpoints have been presented to explain the significant variation of Hall-Petch slope with deformation conditions or microstructure characteristics. First, it is commonly accepted that the Hall-Petch slope for deformation twinning mediated plasticity is much larger than that for ordinary dislocation plasticity [11-13]. However, this is not the essential reason for our case. It is because that the formation of deformation twinning in Mg alloys depends strongly on the grain size [14], while the two groups of rolled sheets studied have similar recrystallized grain sizes (Fig. 1) and also these small grains are not favorable for the activity of deformation twinning.

Second, the texture type, especially the texture intensity, would also give rise to different Hall-Petch slopes [15]. The previous work has studied the application of equal channel angular pressing (ECAP) in Mg alloys [14,15] and demonstrated that the difference in yield stress for different samples contained not only the contribution from the difference in grain size, but also the contribution from the difference in texture. Since ECAP can extensively weaken the strong basal fiber texture, the weakening effect on yield stress from the decrease in texture intensity is stronger than the strengthening effect from the grain refinement, and consequently results in a relatively small or even an inverse Hall-Petch relation [15]. For the purpose of comparison, the YS of ECAPed AM60 alloy [16] is also shown in Fig. 2. The fitted Hall-Petch slope, 51 MPa·μm1/2, obviously, is less than either group of rolled sheets. In order to fully understand the potential effects of texture on yield stress and their distinct response to the tensile directions, the discrepancy of texture in each group of rolled sheets will be investigated in detailed as follows.

EBSD measured (0002) pole figure and Schmid factor of basal <a> slip in RD-ND and TD-ND planes, as shown in Fig. 3, are used to study the effect of tensile direction on mechanical properties. The samples are cut from the sheet rolled at a roller speed of 20 m/min. It is apparent that the texture of rolled AM50 sheet exhibits a basal fiber texture, that is, (0002) plane tends to be parallel to rolling plane. Simultaneously, the inclination of basal pole towards RD can also be found, which is attributed to the occurrence of shear deformation throughout sheet thickness. In this case, the basal slip can be activated much easier when the tensile force is loaded on the samples along RD than that when the tensile force is loaded along TD. The activation of basal slip is beneficial for enhancing the elongation of rolled sheet. In addition, the Schmid factor should be quite small when the slip planes are mostly parallel to the stress axis. Therefore, RN plane has a relatively larger Schmid factor of 0.22 than that of 0.18 in TN plane. According to Schmid’s law, a larger Schmid factor prefers to result in a remarkable decrease in YS.

Fig. 3 EBSD measured (0002) pole figure of RD-ND plane (a) TD-ND plane (b), and Schmid factor of RD-ND plane (c) and TD-ND plane of rolled sheet (d)

As a useful supplement for the analysis of basal texture in rolled sheets, the  pole figures in TN plane of sheets rolled at different speeds are shown in Fig. 4. The (0002) pole figures for these samples are all similar, as shown in Fig. 3(c). For the sheet rolled at a roll speed of 20 m/min, the

pole figures in TN plane of sheets rolled at different speeds are shown in Fig. 4. The (0002) pole figures for these samples are all similar, as shown in Fig. 3(c). For the sheet rolled at a roll speed of 20 m/min, the  plane distributes randomly and uniformly within TN plane although c axis tends to be parallel to the normal direction of the sheet.

plane distributes randomly and uniformly within TN plane although c axis tends to be parallel to the normal direction of the sheet.

However, the distribution of  plane in the sheet rolled at a lower roll speed exhibits some given orientations relative to TN plane. The anisotropy in the tensile elongation is also likely related to this difference of the special texture component.

plane in the sheet rolled at a lower roll speed exhibits some given orientations relative to TN plane. The anisotropy in the tensile elongation is also likely related to this difference of the special texture component.

Fig. 4  pole figures of sheets rolled at roll speeds of 1 m/min (a), 5 m/min (b) and 20 m/min (c) with roll temperature of 200 °C

pole figures of sheets rolled at roll speeds of 1 m/min (a), 5 m/min (b) and 20 m/min (c) with roll temperature of 200 °C

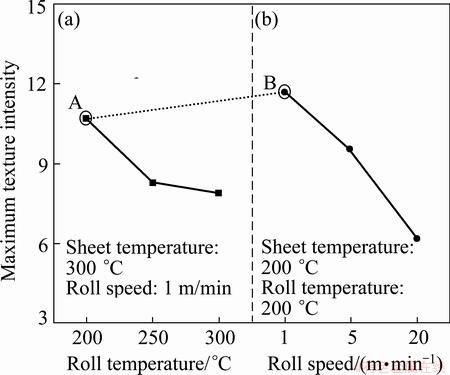

The texture intensity under different rolling conditions was investigated by means of the (0002) pole figures on the sheet surface (RD-TD plane) measured by XRD. The result is shown in Fig. 5. A trend for the texture intensity to decrease with the increase of the roller temperatures is clearly observed. It is known that non-basal slips may be activated with the increase of the deformation temperature since the critical resolved shear stress decreases sharply as the temperature increases. The activation of non-basal slips enhances the deformation capability and in turn weakens the basal texture intensity. Additionally, the comparison for the sheets A and B (Fig. 5) rolled at the same condition except for the sheet temperature shows that the texture intensity can also be weakened by increasing the sheet temperature. On the other hand, the texture intensity decreases from 11.7 to 6.2 as the roll speed increases. For the texture change with different roller speeds, apart from the influence of the discrepancy of actual deformation temperature as mentioned earlier, more severe shear deformation favored to be imposed in the sheet rolled at a high speed may also result in the inclination of c-axis towards RD and the resulting weaker texture intensity. Interestingly, the decrement of texture intensity with the increase of roller speed is larger than that in the samples rolled at different temperatures (decreasing from 10.7 to 7.9), indicating that increasing roller speed can weaken the texture intensity more effectively, and consequently enhance the weakening role of texture on yield stress. This is another reason responsible for the Hall-Petch slope of the samples rolled at different speeds less than that rolled at different temperatures (Fig. 2).

Fig. 5 Variation of maximum texture intensity in (0002) pole figures with roll temperatures (a) and speeds (b)

Generally, a favored texture for the basal <a> slip in the rolled sheets produced by means of some special rolling methods [5,17] is considered as the primary reason for a superior formability in both deep drawing and stretch forming, while the conventional rolling usually results in a strong basal texture. High temperature that contributes to the decrease of the critical resolved shear stress for prismatic and pyramidal slip systems [18] and/or high strain rate that contributes to the occurrence of twinning [19] have also been reported to significantly contribute to plastic deformation of rolled sheets, even during the conventional rolling [20]. Also, the results in this work show that increasing the roll temperature or speed during hot rolling is an effective approach to improve the mechanical anisotropy and possibly enhance the formability of AM50 rolled sheet at room temperature. Furthermore, according to Figs. 2 and 5, it can be concluded that the roll speed has a remarkable effect on the texture intensity as compared with roll temperature, while the influence of roll temperature on yield stress is relatively evident. In addition, the microstructure simulation of hot rolling of AM50 alloy shows that microstructural heterogeneity may be improved as roll temperature or roll speed increases [8]. Therefore, it is conceivable that the hot rolling conducted at a high roll temperature with a high roll speed is a feasible finish-rolling schedule for the manufacture of AM50 sheet with the weak mechanical anisotropy and excellent formability.

4 Conclusions

1) The average UTS of 295 MPa, the average YS of 224 MPa and the average elongation of 22.9% can be obtained for AM50 sheet rolled at the speed of 5m/min. The rolled sheets exhibit a mechanical anisotropy depending on the tensile direction.

2) The texture intensity of rolled sheets decreases with the increase of roll temperature or roll speed. The roll speed has a dominant effect on the texture intensity, while the yield stress depends strongly on roll temperature.

4) It is shown that the weak mechanical anisotropy and excellent formability of AM50 alloy sheet can be obtained by rolling at high roll temperature with high roll speed.

References

[1] AGNEW S R, Duygulu  . Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B [J]. Int J Plast, 2005, 21: 1161-1193.

. Plastic anisotropy and the role of non-basal slip in magnesium alloy AZ31B [J]. Int J Plast, 2005, 21: 1161-1193.

[2] Chino Y, Sassa K, Kamiya A, Mabuchi M. Enhanced formability at elevated temperature of a cross-rolled magnesium alloy sheet [J]. Mater Sci Eng A, 2006, 441: 349-356.

[3] Li X, Al-Samman T, Gottstein G. Mechanical properties and anisotropy of ME20 magnesium sheet produced by unidirectional and cross rolling [J]. Mater Des, 2011, 32: 4385-4393.

[4] Kim W J, Lee J B, Kim W Y, Jeong H T, Jeong H G. Microstructure and mechanical properties of Mg–Al–Zn alloy sheets severely deformed by asymmetrical rolling [J]. Scripta Mater, 2007, 56: 309-312.

[5] Huang X S, Suzuki K, Watazu A, Shigematsu I, Saito N. Mechanical properties of Mg–Al–Zn alloy with a tilted basal texture obtained by differential speed rolling [J]. Mater Sci Eng A, 2008, 488: 214-220.

[6] Chang L L, Kang S B, Cho J H. Influence of strain path on the microstructure evolution and mechanical properties in AM31 magnesium alloy sheets processed by differential speed rolling [J]. Mater Des, 2013, 44: 144-148.

[7] Ding H L, Hirai K, Kamado S. Microstructure characteristics during the multi-pass hot rolling and their effect on the mechanical properties of AM50 magnesium alloy sheet [J]. Mater Sci Eng A, 527: 3379-3385.

[8] Ding H L, Hirai K, Homma T, Kamado S. Numerical simulation for microstructure evolution in AM50 Mg alloy during hot rolling [J]. Comp Mater Sci, 2010, 47: 919-925.

[9] Styczynski A, Hartig C, Bohlen J, Letzig D. Cold rolling textures in AZ31 wrought magnesium alloy [J]. Scripta Mater, 2004, 50: 943-947.

[10] Bohlen J,  M R, Senn J W, Letzig D, Agnew S R. The texture and anisotropy of magnesium-zinc-rare earth alloy sheets [J]. Acta Mater, 2007, 55: 2101-2112.

M R, Senn J W, Letzig D, Agnew S R. The texture and anisotropy of magnesium-zinc-rare earth alloy sheets [J]. Acta Mater, 2007, 55: 2101-2112.

[11] Meyers M A, Vohringer O, Lubarda V A. The onset of twinning in metals: A constitutive description [J]. Acta Mater, 2001, 49: 4025-4039.

[12] Stanford N, Carlson U, Barnett M R. Deformation twinning and the Hall-Petch relation in commercial purity Ti [J]. Metall Mater Trans A, 2008, 39: 934-944.

[13] Yu Q, Shan Z W, Li J, Huang X X, Xiao L, Sun J, Ma E. Strong crystal size effect on deformation twinning [J]. Nature, 2010, 463: 335-338.

[14] Wang J T, Yin D L, Liu J Q, Tao J, Su Y L, Zhao X. Effect of grain size on mechanical property of Mg-3Al-1Zn alloy [J]. Scripta Mater, 2008, 59: 63-66.

[15] Kim W J, Hong S I, Kim Y S. Texture development and its effect on mechanical properties of an AZ61 Mg alloy fabricated by equal channel angular pressing [J]. Acta Mater, 2003, 51: 3293-3307.

[16] Kulyasova O, Islamgaliev R, Mingler B, Zehetbauer M. Microstructure and fatigue properties of the ultrafine-grained AM60 magnesium alloy processed by equal-channel angular pressing [J]. Mater Sci Eng A, 2009, 503: 176-180.

[17] Yukutake E, Kaneko J, Sugamata M. Anisotropy and non-uniformity in plastic behavior of AZ31 magnesium alloy plates [J]. Mater Trans, 2003, 44: 452-457.

[18] Barnett M R. A Taylor model based description of the proof stress of magnesium AZ31 during hot working [J]. Metall Mater Trans A, 2003, 34: 1799-1806.

[19] Ishikawa K, Watanabe H, Mukai T. High temperature compressive properties over a wide range of strain rates in an AZ31 magnesium alloy [J]. J Mater Sci, 2005, 40: 1577-1582.

[20] Hiroaki K, Tetsuo S, Hiroshi U, Satoshi M. Deformation and texture evolution during high-speed rolling of AZ31 magnesium sheets [J]. Mater Trans, 2007, 48: 2023-2027.

丁汉林 1, 张义伟 1, Shigeharu KAMADO2

1. 安徽工业大学 材料科学与工程学院,马鞍山 243002;

2. Department of Mechanical Engineering, Nagaoka University of Technology, Kamitomioka, Nagaoka, Niigata 940-2188, Japan

摘 要:采用不同的轧辊温度和速率制备AM50镁合金轧板,研究终轧工艺对镁板力学性能和织构特征的影响。研究表明:在轧辊温度为200 °C和轧辊速率为5 m/min条件下制备的镁板的强度(极限抗拉强度:295 MPa;屈服强度:224 MPa)和伸长率(22.9%)之间达到较优组合;在热轧过程中,轧板的屈服强度主要取决于轧制温度,而织构强度则对轧辊速率更为敏感;提高轧制温度或轧辊速率均可改善AM50镁合金板材力学性能的各性异性。

关键词:AM50合金;热轧;力学各向异性;织构

(Edited by Chao WANG)

Foundation item: Project (51204003) supported by the National Natural Science Foundation of China; Project (KJ2011A051) supported by the Scientific Research Foundation of Education Department of Anhui Province, China

Corresponding author: Han-lin DING; Tel/Fax: +86-555-2311570; E-mail: hanlind@ahut.edu.cn

DOI: 10.1016/S1003-6326(14)63407-5