DOI:10.19476/j.ysxb.1004.0609.2018.10.01

不同冷轧路径下ZX21镁合金板材织构及力学性能调控机理

谭超兰,黄光杰,黄信德,曹玲飞,曹 宇,张成行,李 伟

(重庆大学 材料科学与工程学院,重庆 400044)

摘 要:研究轧制路径对ZX21镁合金板材织构分布和屈服各向异性的影响。结果表明:单向轧制板材形变织构为双峰基面织构,退火后呈现出垂直于冷轧方向分布的非基面双峰的织构特征。再结晶织构的分布与晶粒的定向形核和选择性长大有关,多向轧制可弱化晶粒取向分布的方向性,其晶粒尺寸相比单向轧制有所减小,退火后形成均匀分布的圈状织构,大幅降低沿轧面各个方向拉伸时基面滑移的施密特因子差异,改善板面内的力学性能各向异性,提高板材的成型性。

关键词:镁合金;轧制路径;织构;各向异性

文章编号:1004-0609(2018)-10-1949-13 中图分类号:TG146.2 文献标志码:A

镁合金作为“21世纪的绿色结构材料”,因其低密度、高比强度和比刚度的特点,在环保要求以及轻量化要求不断提高的交通运输、航空航天及能源等领域有着巨大的应用潜力[1-2]。然而,镁合金的应用仍然受限于其较低的室温塑性成形性能。这种低塑性成形性一方面源于密排六方晶体结构的镁合金室温下可开动滑移系少;另一方面,基面滑移作为临界分切应力(Critical resolved shear stress, CRSS)最小的变形机制,使得镁合金在塑性成形尤其是在压缩或者轧制变形时,容易形成强烈的基面织构,从而使板材存在明显的各向异性,导致后续成形变得困难[1, 3-4]。因此,当前对于变形镁合金的研究热点主要集中在弱化其强基面织构。

研究发现,在Mg-Zn系镁合金中加入稀土元素或者Ca元素能够有效地弱化基面织构或者推迟基面织构的形成[5-12]。LUO等[10-11]发现在Mg-2Zn合金中加入不同比例的稀土元素Gd,能够使镁合金板材在轧制过程中形成由许多细小孪晶组成的剪切带。孪晶变形带的存在使得板材中形成了峰值沿轧向分布的双峰织构,而退火时在剪切带处发生的再结晶晶粒形核和长大使得这种非基面织构得以保留,从而弱化了镁合金的强基面织构。ZENG等[13]研究发现,在Mg-0.3Zn镁合金中加入0.3%的Ca元素能够推迟基面织构的形成,这种延滞效应主要是由于Ca元素阻碍了变形时孪晶的长大而导致。较稀土元素而言,Ca元素的价格更低廉,同时又能够产生与稀土元素类似的效应,因而通过加入Ca元素来改善镁合金的成形性在工业上具有很好的应用前景。

进一步改善镁合金板材的基面织构还可从改变其加工工艺方面来考虑。近年来,异步轧制(DSR)、等通道角挤压(ECAE)、大塑性扭转挤压法(SPTS)等先进加工技术[14-16]被广泛用于变形镁合金的实验及工业应用研究中。此外,利用改变轧制路径来调控镁合金板材织构在面内的分布各向异性同样能够增强板材的二次成型能力。PAN等[17]研究发现,单一的轧制路径会导致基轴的偏转产生一定的方向性,往往形成沿板材轧向或横向分布的双峰织构,而通过交叉轧制工艺能够有效地弱化初始Mg-2Zn-2Gd合金板材中的基面织构,使晶粒的基轴偏离轧面法向(ND)而朝向四周偏转。此外,LI等[18]研究发现,交叉轧制能够在Mg-Zn-Ca合金中形成基轴偏离ND方向并在(0002)极图上呈椭圆分布的织构。由此可知,改变轧制路径能够有效地控制镁合金的织构分布,从而调控镁合金的力学性能各向异性。

本文作者以ZX21镁合金热轧退火板为研究对象,对板材进行不同路径的单向轧制和多向轧制,研究室温下轧制路径对板材织构分布的演变规律和形成机制的影响,并进一步研究了不同织构分布对成品板材力学性能面内各向异性的影响机理。

1 实验

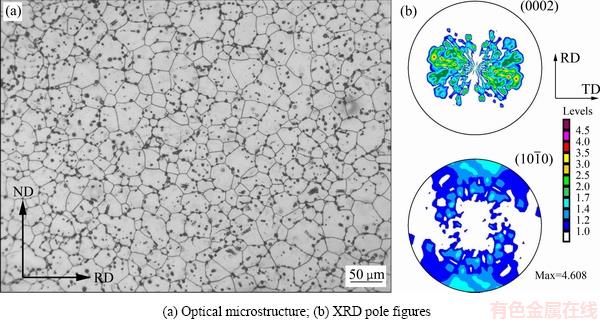

实验所用的初始板材为Mg-2%Zn-1.2%Ca(ZX21,质量分数)镁合金热轧退火板,厚度2.4 mm,其初始组织如图1(a) 所示,为完全再结晶后的等轴晶粒,平均晶粒尺寸25 μm。板材的初始织构为织构散漫度较大的非基面织构(见图1(b)),织构强度为4.608 mrd (Multiple random distribution)。

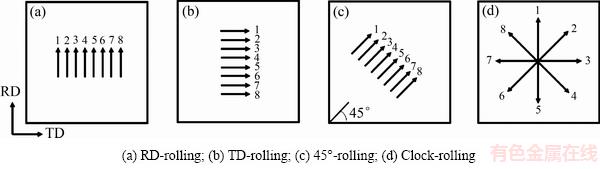

室温冷轧实验如图2所示,将ZX21镁合金板材分别按照图2中所示的4种路径进行轧制变形,道次压下量2.5%,共轧制8个道次,最终得到厚度1.92 mm的板材。为便于描述,将初始板材的热轧方向定义为RD,横向定义为TD,轧面法向定义为ND,将图2所示的4种轧制路径分别定义为RD冷轧、TD冷轧、45°冷轧和多向冷轧(Clock-rolling),其中RD冷轧、TD冷轧和45°冷轧(见图2(a)~(c))分别为沿着特定方向单向轧制,而多向冷轧(见图2(d))则在每轧制一个道次之后,轧制方向顺时针旋转45°。板材经冷轧后再进行360 ℃下不同时间的再结晶退火处理。

用于金相组织观察的试样经粗磨、细磨及电解抛光后,用苦味酸腐蚀剂(1 g苦味酸+2 mL冰醋酸+2 mL蒸馏水+16 mL无水乙醇)进行化学腐蚀,使晶界显现,然后在Carl Zeiss Axiovert 40 MAT型光学显微镜下进行金相组织观察及晶粒尺寸统计。实验使用了日本理学Rigaku D/MAX2500PC型X射线衍射仪进行宏观织构测定,测试{0002}、 、

、 、

、 4个晶面的不完全极图数据,使用LaboTex软件进行背底及散焦矫正,然后根据ODF取向分布函数计算得到4个晶面的完整极图。同时,实验采用电子背散射衍射(EBSD)技术进行微区晶体学取向测试和分析,实验样品经磨抛后去除表面应力层,再利用装配有EBSD系统的TESCAN MIRA3型扫描电镜获得电子背散射衍射花样及标定数据,最后利用CHANNEL 5.0.2软件处理数据。室温拉伸试验在Shimadzu AG-X10kN电子万能试验机上进行,拉伸速率为1×10-3 /s,采用平板拉伸试样,每组拉伸试验重复3遍,其尺寸设计参照《金属材料室温拉伸实验方法》中的国家标准(GBT 228-2002)。

4个晶面的不完全极图数据,使用LaboTex软件进行背底及散焦矫正,然后根据ODF取向分布函数计算得到4个晶面的完整极图。同时,实验采用电子背散射衍射(EBSD)技术进行微区晶体学取向测试和分析,实验样品经磨抛后去除表面应力层,再利用装配有EBSD系统的TESCAN MIRA3型扫描电镜获得电子背散射衍射花样及标定数据,最后利用CHANNEL 5.0.2软件处理数据。室温拉伸试验在Shimadzu AG-X10kN电子万能试验机上进行,拉伸速率为1×10-3 /s,采用平板拉伸试样,每组拉伸试验重复3遍,其尺寸设计参照《金属材料室温拉伸实验方法》中的国家标准(GBT 228-2002)。

图1 ZX21热轧退火初始板材的组织和织构

Fig. 1 Microstructure and texture of ZX21 sheets after hot rolling and annealing

图2 不同路径室温冷轧实验示意图

Fig. 2 Schematic diagrams showing different cold rolling paths

2 结果及分析

2.1 微观组织的演变

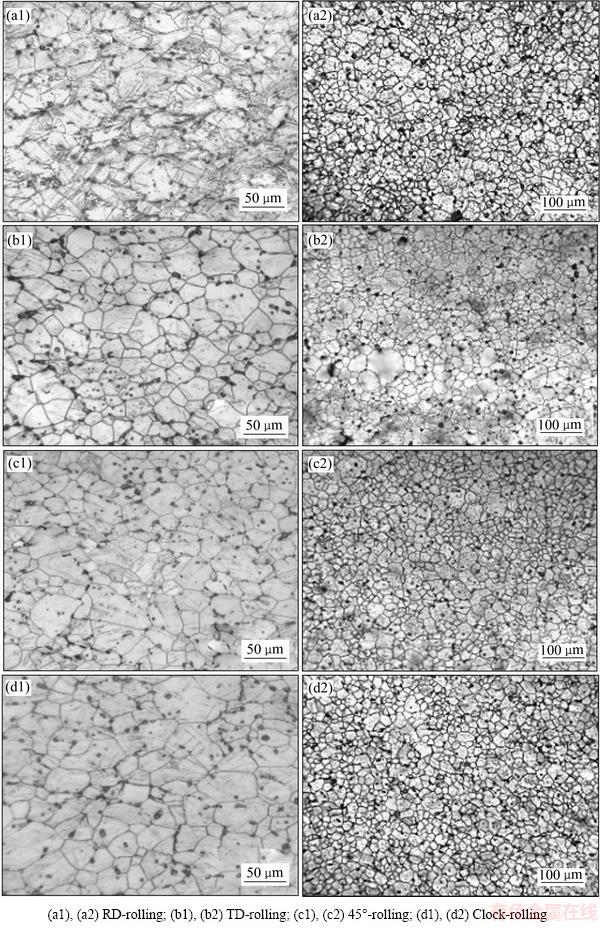

4种不同冷轧路径下ZX21镁合金板材的变形态及退火态组织如图3所示,观察面为RD-ND面。对比研究冷轧变形态组织可以看到,各板材孪晶的数量存在明显差异,其中RD冷轧板材(见图3(a))的孪晶相比其他3种冷轧路径(见图3(b)~(d))更多。变形态组织中孪晶的出现说明孪生在镁合金轧制变形中是一类重要的变形机制,而不同路径下孪晶数量的差异则主要与应变路径对各类孪生变体启动难易程度的影响有 关。室温下, 拉伸孪生是最容易启动的孪生机制,其临界分切应力相对较低[1, 19]。然而,本文选取的初始板材具有随机取向,从而使得部分晶粒处于

拉伸孪生是最容易启动的孪生机制,其临界分切应力相对较低[1, 19]。然而,本文选取的初始板材具有随机取向,从而使得部分晶粒处于 压缩孪生以及

压缩孪生以及 -

- 二次孪生的软取向。因此,拉伸孪生、压缩孪生以及二次孪生在合金轧制变形中均起到了一定的作用,这种作用将影响最终形变织构的分布特点。此外,由于冷轧变形量较小,各冷轧板材的晶粒变形并不明显。在360 ℃下退火2 h后,各板材退火晶粒尺寸相比于初始态和变形态均得到了细化,相比单向冷轧(见图3(a)~(c)),多向冷轧(见图3(d))的退火板材晶粒尺寸相对更小。4种轧制路径的板材退火后平均晶粒尺寸分别为18、19、18、16 μm。

二次孪生的软取向。因此,拉伸孪生、压缩孪生以及二次孪生在合金轧制变形中均起到了一定的作用,这种作用将影响最终形变织构的分布特点。此外,由于冷轧变形量较小,各冷轧板材的晶粒变形并不明显。在360 ℃下退火2 h后,各板材退火晶粒尺寸相比于初始态和变形态均得到了细化,相比单向冷轧(见图3(a)~(c)),多向冷轧(见图3(d))的退火板材晶粒尺寸相对更小。4种轧制路径的板材退火后平均晶粒尺寸分别为18、19、18、16 μm。

图3 360 ℃退火2 h前后的ZX21冷轧板材金相组织

Fig. 3 Optical microstructures of ZX21 cold-rolling sheets before((a1), (b1), (c1), (d1)) and after((a2), (b2), (c2), (d2)) annealing at 360 ℃ for 2 h

2.2 宏观织构的演变

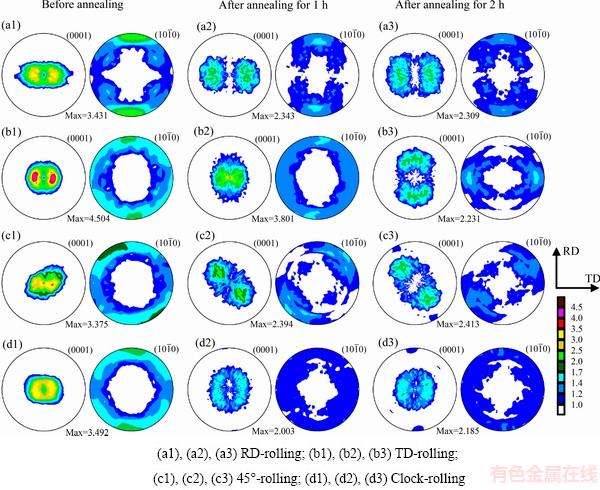

沿RD方向单向轧制及360 ℃退火1 h、2 h前后ZX21镁合金的{0001}、 XRD极图如图4(a)所示。与轧制前具有非基面织构的初始板材(见图1(b))相比,冷轧后板材的织构表现出明显的基面化趋势,绝大多数晶粒的基轴朝ND方向偏转,呈现出沿TD方向分布的双峰基面织构,峰值位置出现在偏离ND约20°的位置。但这种基面化的趋势在经过360 ℃退火1 h后减弱为非基面织构的分布特点,延长退火时间至2h后织构强度变化不大,主要织构类型的分布也并未发生明显变化。TD冷轧、45°冷轧样品在退火前后的织构演变规律与RD冷轧样品类似,但二者在退火1 h时非基面的特征并不明显,只有在退火2 h后才出现类似的非基面分布特点。由于三者均属于单向轧制,在轧制过程中轧制方向并未改变,综合3种单向轧制路径的XRD宏观织构演变规律,表明轧制路径对形变织构及随后退火形成的再结晶织构均会产生影响,使得形变织构沿着轧制方向或横向发展,再结晶织构则垂直于轧制方向分布。无论哪种轧制方向,退火后基面织构都得到了一定程度的弱化,但织构分布的面内各向异性仍然存在。因此,有必要通过改变每道次的轧制方向来调控其织构在面内分布的特点,从而减小这种各向异性。从多向冷轧样品的{0001}极图上来看(见图4(d)),通过改变冷轧过程每一道次的主应变方向,使每一次轧制过程晶粒的取向在轧面内的分布都不相同,最终形成了近似圈状分布的各向同性织构特点。上述研究结果与关于通过轧制路径调控Mg-2Zn-2Gd合金织构演变的研究结果基本一致[17]。实际上,在Mg-Zn-Ca合金中出现的这种形变织构特征主要与Ca元素影响镁合金塑性变形滑移及孪生机制启动的临界分切应力有关。YUASA等[20]研究发现,Ca元素能够降低镁合金的基面层错能,从而促进柱面滑移以及锥面滑移的启动,这些非基面滑移的启动导致形成基面织构的趋势有所减弱。此外,ZENG等[13]进行了镁合金轧制织构演变行为的准原位研究,发现微量Ca元素的加入能够使孪晶的长大受到抑制,从而推迟基面织构的形成。结合本实验研究结果,冷轧板组织中孪晶片层数量不多,因此,ZENG等[13]的结论也同样可用于解释本实验所看到的双峰织构分布特点,即Ca元素影响了变形过程中基面织构的演变。

XRD极图如图4(a)所示。与轧制前具有非基面织构的初始板材(见图1(b))相比,冷轧后板材的织构表现出明显的基面化趋势,绝大多数晶粒的基轴朝ND方向偏转,呈现出沿TD方向分布的双峰基面织构,峰值位置出现在偏离ND约20°的位置。但这种基面化的趋势在经过360 ℃退火1 h后减弱为非基面织构的分布特点,延长退火时间至2h后织构强度变化不大,主要织构类型的分布也并未发生明显变化。TD冷轧、45°冷轧样品在退火前后的织构演变规律与RD冷轧样品类似,但二者在退火1 h时非基面的特征并不明显,只有在退火2 h后才出现类似的非基面分布特点。由于三者均属于单向轧制,在轧制过程中轧制方向并未改变,综合3种单向轧制路径的XRD宏观织构演变规律,表明轧制路径对形变织构及随后退火形成的再结晶织构均会产生影响,使得形变织构沿着轧制方向或横向发展,再结晶织构则垂直于轧制方向分布。无论哪种轧制方向,退火后基面织构都得到了一定程度的弱化,但织构分布的面内各向异性仍然存在。因此,有必要通过改变每道次的轧制方向来调控其织构在面内分布的特点,从而减小这种各向异性。从多向冷轧样品的{0001}极图上来看(见图4(d)),通过改变冷轧过程每一道次的主应变方向,使每一次轧制过程晶粒的取向在轧面内的分布都不相同,最终形成了近似圈状分布的各向同性织构特点。上述研究结果与关于通过轧制路径调控Mg-2Zn-2Gd合金织构演变的研究结果基本一致[17]。实际上,在Mg-Zn-Ca合金中出现的这种形变织构特征主要与Ca元素影响镁合金塑性变形滑移及孪生机制启动的临界分切应力有关。YUASA等[20]研究发现,Ca元素能够降低镁合金的基面层错能,从而促进柱面滑移以及锥面滑移的启动,这些非基面滑移的启动导致形成基面织构的趋势有所减弱。此外,ZENG等[13]进行了镁合金轧制织构演变行为的准原位研究,发现微量Ca元素的加入能够使孪晶的长大受到抑制,从而推迟基面织构的形成。结合本实验研究结果,冷轧板组织中孪晶片层数量不多,因此,ZENG等[13]的结论也同样可用于解释本实验所看到的双峰织构分布特点,即Ca元素影响了变形过程中基面织构的演变。

图4 冷轧和退火1 h和2 h的XRD极图

Fig. 4 XRD pole figures of ZX21sheets before((a1), (b1), (c1), (d1)) and after annealing for 1 h((a2), (b2), (c2), (d2)) and 2 h((a3), (b3), (c3), (d3))

2.3 再结晶织构形成机理

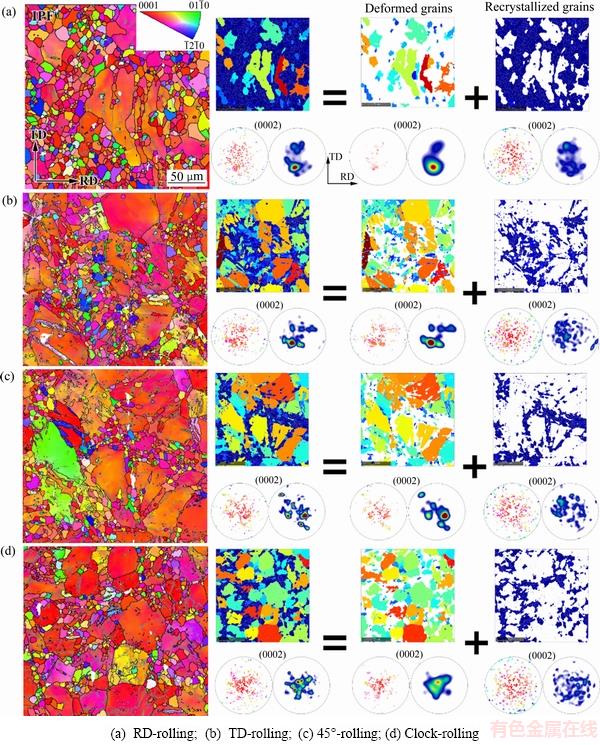

XRD宏观织构测试结果表明,对于单向轧制的板材(见图4(a)~(c)),再结晶织构的分布与轧制路径呈垂直关系,而多向轧制板材的再结晶织构在基面极图上呈圆形分布。目前为止,关于轧制路径对再结晶织构分布的影响机制尚待研究。为进一步探讨应变路径对再结晶织构的影响规律,采用EBSD技术对整个再结晶过程(包括形核和晶粒的长大)进行显微组织与晶体学取向的表征,通过比较形核过程中变形晶粒与再结晶晶粒的取向关系以及晶粒长大过程中大小晶粒之间的取向差异,揭示再结晶织构的形成机理。

图5 ZX21镁合金冷轧板在360 ℃退火2 min后的EBSD分析结果

Fig. 5 EBSD analysis results of cold rolled sample after annealing at 360 ℃ for 2 min

图5所示为4种不同轧制路径冷轧板在360 ℃条件下保温2 min后的EBSD分析结果。反极图(IPF图)显示,各冷轧板360 ℃保温2 min后形成了部分再结晶的微观组织。一般来说,在EBSD数据分析时,可以根据晶粒内取向差分布值(Grain orientation spread, GOS)来分辨再结晶晶粒和原始变形晶粒:GOS值小于1°的晶粒定义为再结晶晶粒,否则为变形晶粒[8]。按照这一标准,将部分再结晶组织中变形晶粒与再结晶晶粒分别挑选出来,分析其各自的晶体取向特点。由此可见,变形晶粒以基面取向为主,其基轴偏离ND方向的角度在20°以内,而再结晶晶粒的取向分布则较为弥散。相关研究表明[21],非基面取向的再结晶晶粒相比于基面取向的晶粒更具有生长优势,这也就解释了再结晶退火后织构分布呈现出非基面发展趋势的原因。然而,关于织构分布向板面内垂直轧制方向发展的原因则需要进一步的研究。从离散的(0002)极图中可以看到,非基面取向的晶粒主要为再结晶晶粒,且其分布基本上具有一定的方向性,单向轧制下再结晶晶核的取向主要垂直于轧向,但仍然有部分晶粒的取向较为随机。这也就说明,再结晶退火初期,有一定的定向形核机制在起作用,影响最终板材织构类型的分布。

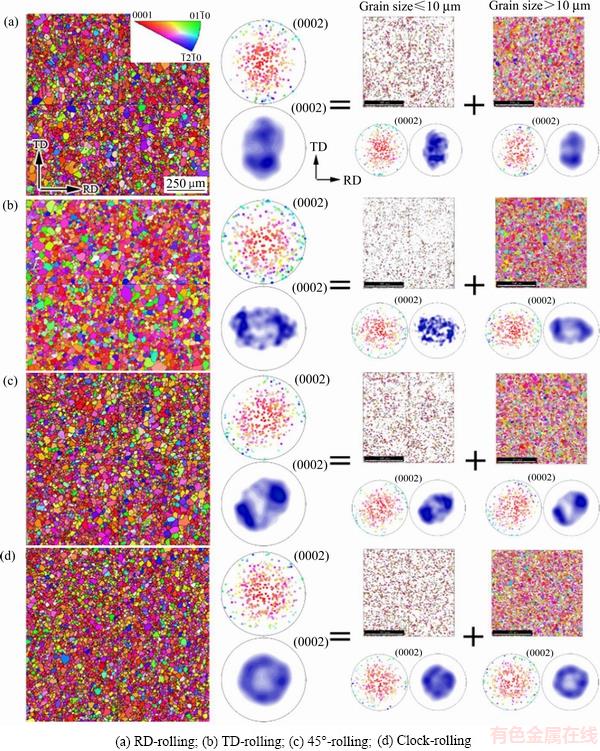

图6 ZX21镁合金冷轧板在360 ℃退火2 h后的EBSD分析结果

Fig. 6 EBSD analysis results of cold rolled sample after annealing at 360 ℃ for 2 h

除了定向形核机制的作用外,再结晶晶核在后续生长过程中是否会出现选择性长大而影响最终织构的形成也同样不可忽略。为了揭示轧制路径影响大部分再结晶晶粒朝垂直于轧向偏转的机理,对360 ℃退火2 h后的样品进行了EBSD微观组织表征,其结果如图6所示。此时的组织为完全再结晶组织,并且有一部分的晶粒发生了明显的长大行为。从总体的极图上来看,EBSD分析结果与XRD分析结果基本一致,即再结晶织构垂直于轧向发展。为了研究再结晶后期晶粒的选择性长大行为,将完全再结晶组织中的小晶粒(晶粒尺寸小于10 μm)与大晶粒(晶粒尺寸大于10 μm)分离出来,分别统计其取向信息。可以看到,大小晶粒的取向差别并不是很大,但是从离散的极图上可以发现,大晶粒的取向分布更为集中,接近于总体的分布特点。这也表明,最终退火后的织构分布与晶粒选择性长大有一定的关系,板材内织构的偏转方向是由初始再结晶晶核的取向以及再结晶晶粒的选择性长大共同决定的。不同轧制路径下,主应变方向会影响轧制变形时不同变形机制启动的难易程度,改变合金的微观组织特征。此外,由于再结晶晶粒与变形晶粒的特定取向关系,调控轧制路径必然影响最终再结晶织构的分布方向,从而改变板材性能的各向异性。

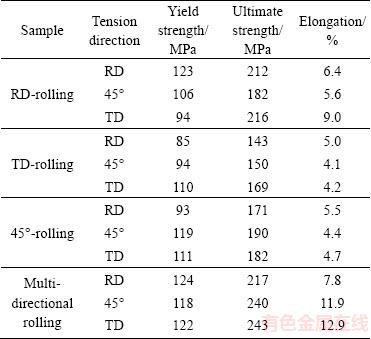

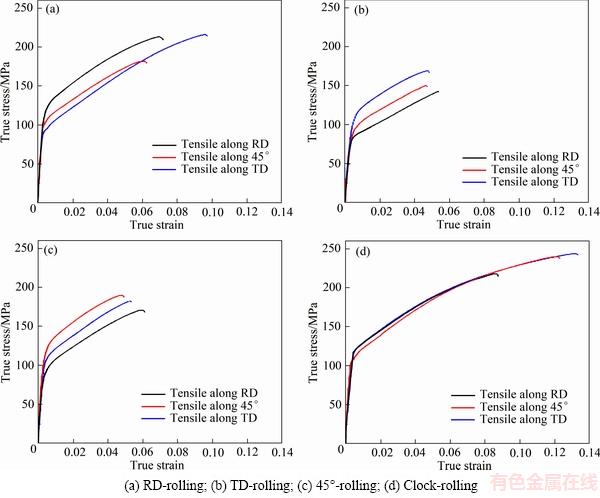

2.4 力学性能

为研究4种不同冷轧路径下镁合金板材的力学性能各向异性,将退火后的各板材分别沿着RD、TD以及与RD成45°的方向进行了室温拉伸性能力学试验,其力学性能测试结果见表1,真应力-真应变曲线见图7。由表1可见,RD冷轧退火板材沿RD方向的拉伸屈服强度比TD方向高29 MPa,而多向冷轧退火板材各方向屈服强度差异仅有6 MPa。对于单向轧制退火板材(见图7(a)~(c)),沿轧制方向的屈服强度最高,而垂直于轧制方向的屈服强度最低。这种各向异性主要是由于板材晶粒取向沿特定方向分布决定的,对于多向轧制的板材,因晶粒取向在轧面内各个方向的分布较为均匀,因此沿着3个不同方向进行拉伸时,屈服强度无明显差异。同时,多向冷轧退火板材的断后伸长率明显高于单向冷轧板材的(见表1),这可能是由于其晶粒尺寸更小,拉伸变形时位错不易塞积,能协调更多变形所产生的结果。

表1 360 ℃退火2 h后ZX21板材沿不同方向拉伸的屈服强度、抗拉强度和断后伸长率

Table 1 Yield strength, ultimate strength and elongation along different directions under tension of ZX21 sheets after annealing at 360 ℃ for 2 h

图7 360 ℃退火2 h后ZX21板材在不同方向上的真应力-真应变拉伸曲线

Fig. 7 True stress-strain tensile curves along different directions of cold-rolled ZX21 sheets after annealing at 360 ℃ for 2 h

2.5 板材性能各向异性的施密特因子分析

拉伸测试结果表明,单向轧制板材的屈服强度表现出明显的各向异性,而多向轧制则会减弱这种各向异性,形成这种差异的原因主要与织构的分布有关。为了研究织构在板面内的分布特点对板材屈服各向异性的影响,利用Matlab软件计算出完全再结晶退火板材沿板材面内不同方向(RD、TD和45°)拉伸时各类变形机制的施密特因子,探讨织构对各类拉伸变形机制启动难易程度的影响。

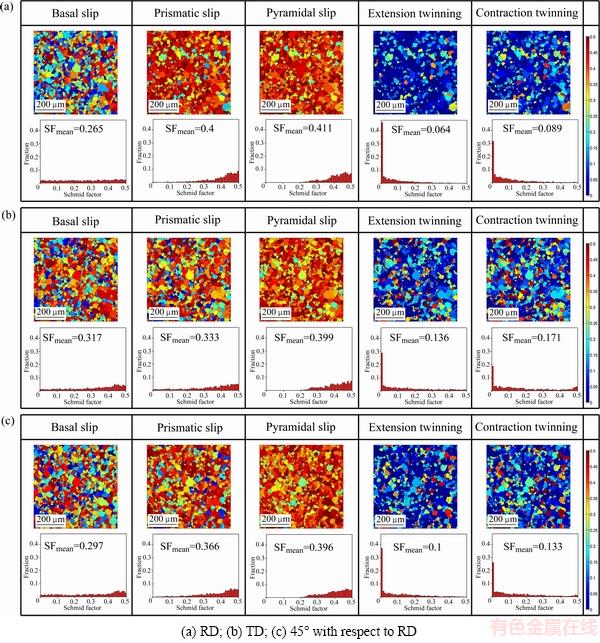

图8 RD-冷轧退火板沿不同方向拉伸时各类变形机制的施密特因子(SFmean)

Fig. 8 Schmid factor (SFmean) analysis of different deformation modes in RD-cold-rolled sheet when tension along different directions

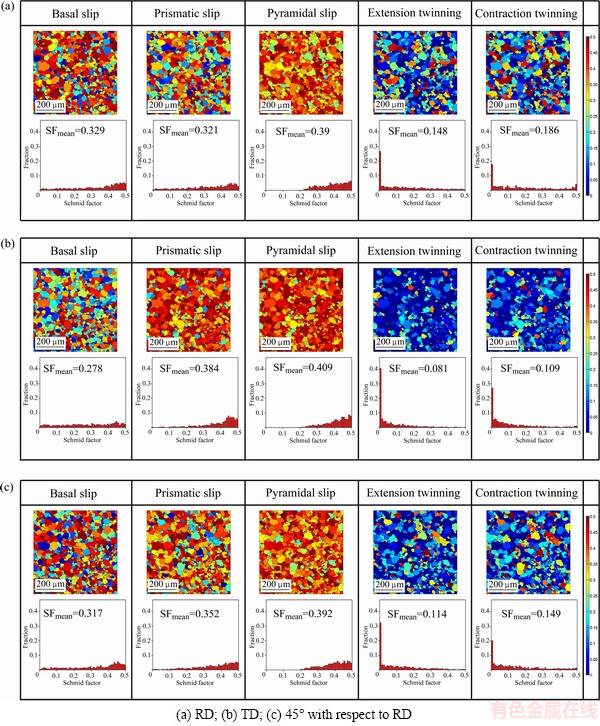

图9 TD-冷轧退火板沿不同方向拉伸时各类变形机制的施密特因子

Fig. 9 Schmid factor analysis of different deformation modes in TD-cold-rolled sheet when tension along different directions

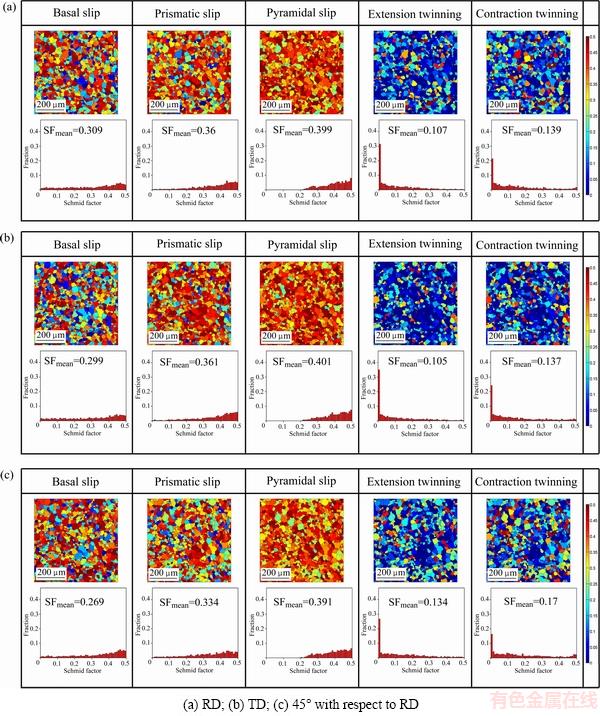

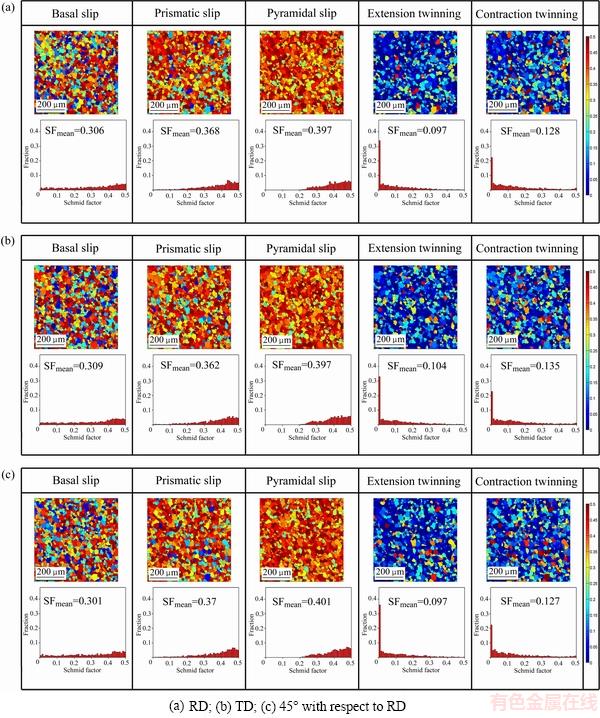

施密特因子(SFmean)分析的结果如图8~11所示。可以看出,4种不同冷轧路径轧制退火后的板材在沿不同方向拉伸时,拉伸孪生、压缩孪生的施密特因子都很小,表明在拉伸变形时,孪生机制难以启动。此时,变形主要受滑移控制,其中以锥面滑移、柱面滑移的施密特因子最大,说明绝大多数的晶粒是处于这两类滑移系的软取向。考虑到锥面滑移、柱面滑移的临界分切应力CRSS相对较高,而基面滑移时所需的CRSS较低[1-2, 22],因此主要从基面滑移的角度去分析产生屈服各向异性的原因。

对于RD冷轧退火板材,当拉伸沿着TD方向进行时,其基面滑移(Basal slip)的施密特因子最大,即该方向上的基面滑移最容易启动,从而导致该方向上的屈服强度低于RD方向和45°方向。而在RD方向上基面滑移的施密特因子最小,因而屈服强度最高(见图8)。

TD冷轧退火板以及45°冷轧退火板材基面滑移的施密特因子也同样呈现出与RD冷轧退火板相似的规律(见图9~10),沿冷轧方向拉伸的施密特因子最小,而垂直于冷轧方向则最大。这也就说明,单向轧制的板材由于轧制路径的不同,导致拉伸时基面滑移的施密特因子存在差异,从而影响基面滑移启动的难易程度,造成板材的拉伸性能存在明显的各向异性。然而,对于多向轧制的板材,沿不同方向拉伸时,基面滑移的施密特因子非常接近,因而屈服强度的差别并不明显(见图11)。

图10 45°-冷轧退火板沿不同方向拉伸时各类变形机制的施密特因子

Fig. 10 Schmid factor analysis of different deformation modes in 45°-cold-rolled sheet when tension along different directions

图11 多向冷轧退火板沿不同方向拉伸时各类变形机制的施密特因子

Fig. 11 Schmid factor analysis of different deformation modes in DX-cold-rolled sheet when tension along different directions

3 结论

1) 轧制路径影响ZX21镁合金板材织构的分布特征,单向轧制的板材形变织构的基面化趋势明显,而退火后的板材则呈现出垂直于冷轧方向分布的非基面双峰织构。

2) 再结晶织构的形成受定向形核机制以及再结晶晶粒的选择性长大行为共同控制,形核初期有一部分晶核的取向较为随机,但这部分晶粒在后续长大过程中会被取向垂直于冷轧方向分布的晶粒吞并。在晶粒长大过程中,相比基面取向的晶粒,非基面取向的晶粒更具有长大优势,从而弱化了最终的基面织构。

3) 单向轧制的板材呈现出明显的屈服各向异性,其原因主要与拉伸时基面滑移启动的施密特因子有关。多向轧制过程中由于晶粒取向在面内各个方向的分布较为均匀,退火后形成均匀分布的圈状织构,沿不同方向拉伸时基面滑移的施密特因子很接近,且由于多向轧制后晶粒尺寸有所减小,因而显著改善了板面内的力学性能和屈服强度各向异性。

REFERENCES

REFERENCES

[1] HIRSCH J, Al-SAMMAN T. Superior light metals by texture engineering: Optimized aluminum and magnesium alloys for automotive applications[J]. Acta Materialia, 2013, 61: 818-843.

[2] 陈振华, 夏伟军, 严红革, 李落星, 程永奇, 郭 强, 陈 鼎. 变形镁合金[M]. 北京: 化学工业出版社, 2005: 1-6.

CHEN Zhen-hua, XIA Wei-jun, YAN Hong-ge, LI Luo-xing, CHENG Yong-qi, GUO Qiang, CHEN Ding. Wrought magnesium[M]. Beijing: Chemical Industry Press, 2005: 1-6.

[3] 丁文江, 靳 丽, 吴文祥, 董 杰. 变形镁合金中的织构及其优化设计[J]. 中国有色金属学报, 2011, 21(10): 2371-2381.

DING Wen-jiang, JIN Li, WU Wen-xiang, DONG Jie. Texture and texture optimization of wrought Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(10): 2371-2381.

[4] CHINO Y, KIMURA K, MABUCHI M. Twinning behavior and deformation mechanisms of extruded AZ31 Mg alloy[J]. Materials Science and Engineering A, 2008, 486(1/2): 481-488.

[5] WANG Guang-gang, HUANG Guang-sheng, CHEN Xiang, DENG Qian-yuan, TANG Ai-tao, JIANG Bin, PAN Fu-sheng. Effects of Zn addition on the mechanical properties and texture of extruded Mg-Zn-Ca-Ce magnesium alloy sheets[J]. Materials Science and Engineering A, 2017, 705: 46-54.

[6] KIM Y M, MENDIS C, SASAKI T, LETZIG D, PYCZAK F, HONO K, YI S. Static recrystallization behaviour of cold rolled Mg-Zn-Y alloy and role of solute segregation in microstructure evolution[J]. Scripta Materialia, 2017, 136: 41-45.

[7] TONG L B, ZHENG M Y, KAMADO S, ZHANG D P, MENG J, CHENG L R, ZHANG H J. Reducing the tension-compression yield asymmetry of extruded Mg-Zn-Ca alloy via equal channel angular pressing[J]. Journal of Magnesium and Alloys, 2015, 3(4): 302-308.

[8] BASU I, AL-SAMMAN T. Twin recrystallization mechanisms in magnesium-rare earth alloys[J]. Acta Materialia, 2015, 96: 111-132.

[9] CHEN Tao, CHEN Zhi-yong, YI Liu, XIONG Jiang-ying, LIU Chu-ming. Effects of texture on anisotropy of mechanical properties in annealed Mg-0.6%Zr-1.0%Cd sheets by unidirectional and cross rolling[J]. Materials Science and Engineering A, 2014, 615: 324-330.

[10] LUO J, HU W W, JIN Q Q, YAN H, CHEN R S. Unusual cold rolled texture in an Mg-2.0Zn-0.8Gd sheet[J]. Scripta Materialia, 2017, 127: 146-150.

[11] LUO J, YAN H, CHEN R S, HAN E H. Effects of Gd concentration on microstructure, texture and tensile properties of Mg-Zn-Gd alloys subjected to large strain hot rolling[J]. Materials Science and Engineering A, 2014, 614: 88-95.

[12] YAN H, CHEN R S, HAN E H. Room-temperature ductility and anisotropy of two rolled Mg-Zn-Gd alloys[J]. Materials Science and Engineering A, 2010, 527(15): 3317-3322.

[13] ZENG Z R, BIAN M Z, XU S W, DAVIES C H J, BIRBILIS N, NIE J F. Texture evolution during cold rolling of dilute Mg alloys[J]. Scripta Materialia, 2015, 108: 6-10.

[14] KO Y G, HAMAD K. Structural features and mechanical properties of AZ31 Mg alloy warm-deformed by differential speed rolling[J]. Journal of Alloys and Compounds, 2018, 744: 96-103.

[15] JORGE JR A M, PROKOFIEV E, TRIQUES M R M, ROCHE V, BOTTA W J, KIMINAMI C S, RAAB G I, VALIEV R Z, LANGDON T G. Effect of cold rolling on the structure and hydrogen properties of AZ91 and AM60D magnesium alloys processed by ECAP[J]. International Journal of Hydrogen Energy, 2017, 42(34): 21822-21831.

[16] LIU T, WANG Y, WU S, PENG R L, HUANG C, JIANG C, LI S. Textures and mechanical behavior of Mg-3.3% Li alloy after ECAP[J]. Scripta Materialia, 2004, 51(11): 1057-1061.

[17] PAN Shi-wei, XIN Yun-chang, HUANG Guang-jie, LI Qi, GUO Fei-long, LIU Qing. Tailoring the texture and mechanical anisotropy of a Mg-2Zn-2Gd plate by varying the rolling path[J]. Materials Science and Engineering A, 2016, 653: 93-98.

[18] LI Q, HUANG G, HUANG X, PAN S, TAN C, LIU Q. On the texture evolution of Mg-Zn-Ca alloy with different hot rolling paths[J]. Journal of Magnesium and Alloys, 2017, 5(2): 166-172.

[19] LI B, ZHANG Q W, MATHAUDHU S N. Basal-pyramidal dislocation lock in deformed magnesium[J]. Scripta Materialia, 2017, 134: 37-41.

[20] YUASA M, HAYASHI M, MABUCHI M, CHINO Y. Improved plastic anisotropy of Mg-Zn-Ca alloys exhibiting high-stretch formability: A first-principles study[J]. Acta Materialia, 2014, 65: 207-214.

[21] BASU I, AL-SAMMAN T, GOTTSTEIN G. Shear band-related recrystallization and grain growth in two rolled magnesium-rare earth alloys[J]. Materials Science and Engineering A, 2013, 579: 50-56.

[22] CHAPUIS A, DRIVER J H. Temperature dependency of slip and twinning in plane strain compressed magnesium single crystals[J]. Acta Materialia, 2011, 59(5): 1986-1994.

Tailor mechanism of texture and mechanical properties in ZX21 alloy sheets with different cold rolling paths

TAN Chao-lan, HUANG Guang-jie, HUANG Xin-de, CAO Ling-fei, CAO Yu, ZHANG Cheng-hang, LI Wei

(College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China)

Abstract: The influence of cold rolling path on texture and mechanical anisotropy in ZX21 alloy sheets was investigated. The results show that double peaks appear in the basal texture after unidirectional rolling, which subsequently change into off-basal texture with double peaks distributing perpendicular to the cold rolling path after annealing. The distribution of recrystallization texture is associated with the preferential nucleation and growth of recrystallized grains. The multi-directional rolling can weaken the preferential orientation of grains, whilst a circle-like texture distribution is obtained with the decrease of grain size after annealing. The yielding anisotropy is optimized by decreasing the difference of Schmid factor when tensioning along various directions and hence improves the mechanical property of sheets.

Key words: Mg alloy; rolling path; texture; anisotropy

Foundation item: Project(51671040) supported by the National Natural Science Foundation of China

Received date: 2018-03-30; Accepted date: 2018-05-31

Corresponding author: HUANG Guang-jie; Tel: +86-23-65112334; E-mail: gjhuang@cqu.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51671040)

收稿日期:2018-03-30;修订日期:2018-05-31

通信作者:黄光杰,教授,博士;电话:023-65112334;E-mail: gjhuang@cqu.edu.cn