Trans. Nonferrous Met. Soc. China 23(2013) 2260-2264

Effect of B2O3 on microstructures and mechanical properties of cast Mg-Al-Ti-B alloys

Le-ping BU, Yang GAO, Guo-liang LI, Wei-dong ZHANG, Xue-hong DE

School of Mechanical and Electrical Engineering, Inner Mongolia Agricultural University, Hohhot 010018, China

Received 8 April 2013; accepted 5 July 2013

Abstract: The Mg-Al-Ti-B alloy prepared by mechanical alloying is poor in microstructural uniformity and compactness. In order to improve the microstructural uniformity and compactness of Mg-Al-Ti-B alloy and thus to improve the mechanical properties, effect of B2O3 on microstructure and mechanical properties of cast Mg-9Al-6Ti alloy was studied by optical microscopy, scanning electron microscopy, X-ray diffraction and mechanical property testing. The results show that due to the addition of B2O3, the average grain size of Mg-Al-Ti-B alloys is refined to 12 μm, dispersed Ti phases completely disappear, the amount of precipitation phase Mg17Al12 is reduced and TiAl3 is increased, and new phases MgB6 and Ti3B4 are precipitated. The average hardness, average tensile strength, yield strength and elongation of the alloy are HV 77.1, 171.2 MPa, 113.5 MPa and 5.2%, respectively.

Key words: magnesium alloy; boron trioxide; microstructure; mechanical properties

1 Introduction

Magnesium and magnesium alloys are the lightest structural materials in engineering so far [1]. Magnesium alloys with high strength, good thermal conductivity, damping capacity, and electromagnetic shielding, easy mechanical processing and recoverability are known as green engineering metals in the 21st century [2,3]. More and more magnesium alloys, such as AM50, AZ31 and AZ91, have been increasingly applied to automotive industry [4].

Four series of magnesium alloys have been developed: Mg-Al-Zn-Mn (AZ series), Mg-Al-Mn (AM series), Mg-Al-Si (AS series), Mg-Al-RE (AE series), but they still cannot satisfy the requirements of some important high-strength structural components. Generally, the strength and heat resistance of magnesium alloys are significantly improved [5,6] through adding rare earth elements. Magnesium alloys are strengthened by the dispersion strengthening of rare earth compounds and their effect on grain boundary sliding [7]. Mechanical alloying has been applied to Mg-Al-Ti-B alloys, and their structure and performance have been analyzed and studied [8], but their microstructure and mechanical properties are not ideal yet.

For Mg-Al-Ti-B alloy by mechanical alloying, its microstructure uniformity is poor, and the compactness is not good. In order to improve the microstructure uniformity and compactness of Mg-Al-Ti-B alloy, thus to improve the mechanical properties, in this work, Mg-9Al-6Ti alloys were fabricated by casting, and the effects of B2O3 on microstructure and mechanical properties of Mg-9Al-6Ti alloy were studied.

2 Experimental

The chemical compositions of raw materials are listed in Tables 1-4. In order to fabricate Mg-Al-Ti-B alloys, pre-alloys Mg-9Al-6Ti were prepared by stirring casting processing. Magnesium and aluminum metals were firstly melted in an electric heating crucible furnace at 720 °C, and then titanium powders were added. The mixture was stirred for 10 min with stirring speed of 500 r/min. After that, the melt was heated to 800 °C and cast in a metal mold. The melting was under the protection of argon.

B2O3 was used as the precursor of B to prepare Mg-Al-Ti-B alloys. The pre-alloys Mg-9Al-6Ti were melted at 720 °C, and then 3% or 6% B2O3 in mass fraction was added. The mixture was stirred for 5 min with stirring speed of 500 r/min. After holding the mixture for 10 min, the melts without molten slags were cast into the metal mold (d30 mm×150 mm).

The microstructures and phase composition of Mg-Al-Ti-B alloys were studied by optical microscopy (Nikon LWD200-4xC), scanning electron microscopy (JEOL JSM-6510), X-ray diffraction (Lab XRD-6000). Their hardness was measured (075020 SHANGHAI HX-1000TM), and the tensile properties were evaluated with a tensile instrument (AUTDGRAPH IS-2000).

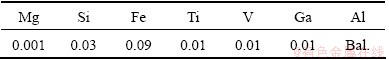

Table 1 Chemical composition of magnesium (mass fraction, %)

Table 2 Chemical composition of aluminum (mass fraction, %)

Table 3 Chemical composition of titanium powder (mass fraction, %)

Table 4 Chemical composition of B2O3 (mass fraction, %)

3 Results and discussion

3.1 Micro-hardness

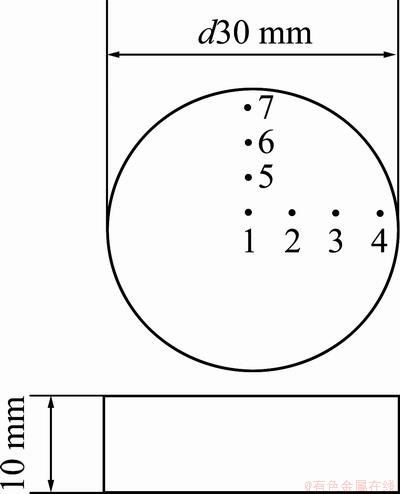

Figures 1 and 2 show the schematic diagram of point distribution for hardness testing and hardness values of alloys, respectively. The hardness values of Mg-9Al-6Ti alloy are dispersed (Fig. 2(a)), those of Mg-9Al-6Ti-3B2O3 are more concentrated (Fig. 2(b)), and those of Mg-9Al-6Ti-6B2O3 are middle (Fig. 2(c)). There are three reasons for the dispersion and centralization of the hardness. Firstly, in the crystallization process from the pouring to the solidification, due to different degrees of undercooling, the hardness value of point 1 is lower than that of point 4 or 7. Secondly, the degrees of uniformity of the microstructure of the alloys are different. Finally, the degree of densification of the alloys after the crystallization is also an important influencing factor. The later two are the main reasons of the dispersion and concentration of hardness values.

Fig. 1 Seven-point distribution of hardness test location

Fig. 2 Hardness of alloy at different points

Figure 3 shows the average hardness values of these alloys. The average hardness value of Mg-9Al-6Ti is higher than that of Mg-9Al-6Ti-3B2O3, and the value of Mg-9Al-6Ti-6B2O3 is lower than that of Mg-9Al-6Ti-3B2O3. By comprehensive considering numerical dispersion in Fig. 2, it suggests that the average hardness value of Mg-9Al-6Ti is HV 81.1, which is relatively high, but the difference of the hardness values for 7 points is large. The reason is that the relative density of the material is low and the uniformity is bad due to the existing pore in this alloy. The average hardness of Mg-9Al-6Ti-3B2O3 is HV 77.1, but the difference of hardness values for 7 points is small due to the densification and uniformity of the material. The average hardness value of Mg-9Al-6Ti- 6B2O3 is HV 75.5, which is relatively low, but the hardness value is very discrete. It is probably because the oxide impurity exacerbates the microstructures of the alloy.

Fig. 3 Average value of three alloys

3.2 Microstructure

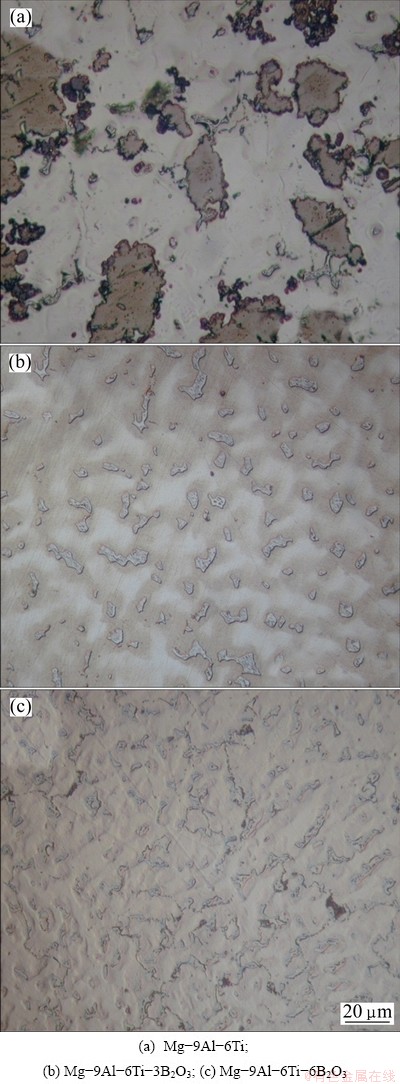

Figure 4 shows the optical microstructures of the three alloys. The densification and uniformity of the alloys have been improved by adding 3%-6% B2O3 into Mg-9Al-6Ti alloy. Specially, the microstructure of Mg-9Al-6Ti-3B2O3 is more homogeneous and denser than that of Mg-Al-Ti-B alloy prepared by mechanical alloying.

According to the phase diagrams of binary alloys Mg-Al, Mg-Ti and Al-Ti [9], the calculated mixing free energy suggests that magnesium is rarely combined with titanium, and the binding force between titanium and aluminum is strong. Therefore, α-Mg, β-Mg17Al12, TiAl and TiAl3 might be found in the alloys. However, Fig. 4(a) shows that the titanium powders of 10-30 μm in diameter are not dissolved. Figures 4(b) and (c) also show that the titanium powders in the two alloys disappear after adding B2O3. B2O3 can remove the TiO2 film on the surface of the titanium powders, and the aluminum, titanium and boron in magnesium alloy cause atomic state contact. Due to the strong binding force between titanium and boron, the titanium and boron preferentially bind and generate TiB or Ti3B4. Besides, TiAl or TiAl3 is generated.

Fig. 4 Optical microstructures of alloys

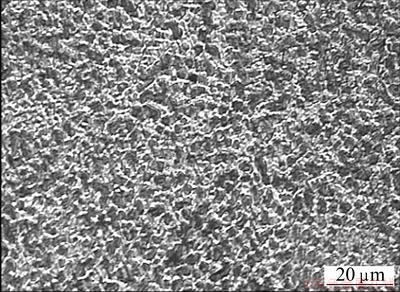

The grains of the Mg-9Al-6Ti alloys are obviously refined through adding B2O3. 3% is the threshold value of B2O3 for grain refinement of the Mg-9Al-6Ti alloy, which makes the average grain size reduced from 54.8 to 12 μm. When the added amount of B2O3 deviates from this value, the grain size of alloy is coarse. SEM image of Mg-9Al-6Ti-3B2O3 alloy is shown in Fig. 5.

Fig. 5 SEM image of Mg-9Al-6Ti-3B2O3 alloy

SEM photograph and EDS spectrum of Mg-9Al-6Ti-3B2O3 are shown in Fig. 6. The white phase at this position is composed of Al, Ti, Mg, B and O. Real-time multi-element surface scanning and line scanning distribution measurements are shown in Fig. 7. The results show that the magnesium is matrix, the distribution of aluminum is more concentrated and it is gradually outward dispersed around the concentration, but the Ti, O and B are dispersed.

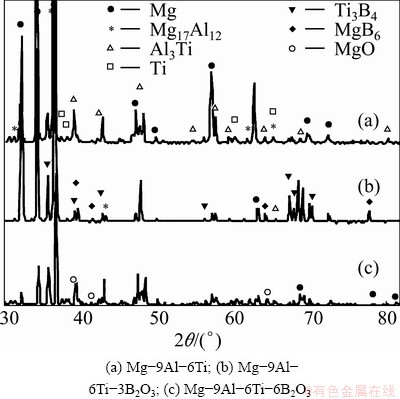

XRD patterns of alloys are shown in Fig. 8, which further confirms the phase composition. The Mg-9Al-6Ti alloy is composed of α-Mg, β-Mg17Al12, TiAl3 and α-Ti. However, due to the reaction of B2O3 with Mg and Ti, in the alloy with 3% B2O3 (Fig. 8(b)), Ti phase disappears completely, new phases MgB6 and Ti3B4 appear, precipitate Mg17Al12 phases reduce, and TiAl3 phases increase. In the alloy with 6% B2O3 (Fig. 8(c)), MgO appears due to the reaction of excess B2O3 with Mg.

3.3 Tensile properties

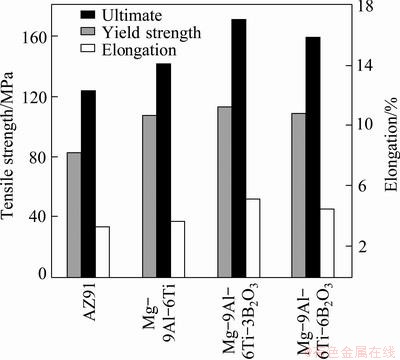

Cast AZ91 magnesium alloy has been used in the automotive and industrial applications [10-12]. The comparison of the tensile properties between the AZ91 alloy and the three alloys is shown in Fig. 9. The average tensile strength, yield strength and elongation of cast AZ91 are 123.5 MPa, 82.4 MPa and 3.4%, which are lower than those of Mg-9Al-6Ti-3B2O3 alloy, 171.2 MPa, 113.5 MPa and 5.2%, respectively.

Fig. 6 SEM image (a) and EDS spectrum (b) of Mg-9Al-6Ti-3B2O3 alloy

Fig. 7 Elemental surface distribution of Mg-9Al-6Ti-3B2O3 alloy

Fig. 8 XRD patterns of alloys

Fig. 9 Tensile properties of cast alloys at ambient temperature

4 Conclusions

1) During the casting processing of Mg-9Al-6Ti alloy, titanium powder is completely melted due to the addition of B2O3. The hardness of the alloy reduces, and its densification and uniformity can be improved.

2) Adding 3% B2O3 (mass fraction) makes the average grain size of Mg-9Al-6Ti alloy reduce from 54.8 to 12 μm.

3) The amount of precipitation phase Mg17Al12 is reduced and TiAl3 is increased, and new phases MgB6 and Ti3B4 are precipitated due to the addition of B2O3.

4) The average hardness, average tensile strength, yield strength and elongation rate of Mg-9Al-6Ti- 3B2O3 alloy are HV 77.1, 171.2 MPa, 113.5 MPa and 5.2%, respectively.

References

[1] DECKER R F. The renaissance in magnesium [J]. Advanced Mater & Proc, 1998, 9: 31-35.

[2] YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qing. Research, development and application of wrought magnesium alloy [J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288. (in Chinese)

[3] CHEN Zhen-hua. Magnesium alloy [M]. Beijing: Chemical Industry Press, 2004: 2-4. (in Chinese)

[4] LUO A. Recent magnesium alloy development for automotive power train applications [J]. Materials Science Forum, 2003, 419-422: 57-66.

[5] MORDIKE B L. Creep-resistant magnesium alloys [J]. Mater Sci Eng A, 2002, 324: 103-112.

[6] MARUYAMA K, SUZUKI M, SATO H. Creep strength of magnesium-based alloys [J]. Metal Mater Trans A, 2002, 33(3): 875-882.

[7] LI Qing-bo, ZHOU Hai-tao, ZHAO Zhong-kai, ZHONG Jian-wei, WANG Jing-tao. Microstructure and mechanical properties of Mg-Y-Zn-Zr alloy [J]. Journal of Central South University: Science and Technology, 2006, 40(3): 650-657. (in Chinese)

[8] LU L, LAI M O, TOH Y H, FROYEN L. Structure and properties of Mg-Al-Ti-B alloys synthesized via mechanical alloying [J]. Materials Science and Engineering A, 2002, 334(122): 163-172.

[9] NAGASAK S, HIRABAYASI M. Binary alloy phase atlas [M]. Tokyo, Japan: Agne Tehnology Center, Inc, 2004. (in Japanese)

[10] LIU Zheng, ZHANG Kui, ZENG Xiao-qin. Theory foundations and application of lightweight alloys based magnesium [M]. Beijing: China Machine Press, 2002: 9. (in Chinese)

[11] ZHANG Jin, ZHANG Zong-he. Magnesium alloy and application [M]. Beijing: Chemical Industry Press, 2004: 11. (in Chinese)

[12] MAO Guo-bing, LIU Qi. Influence of Sr addition on microstructure and mechanical properties of AZ91 magnesium alloy [J]. Foundry, 2010, 59(6): 614-617. (in Chinese).

B2O3对铸态Mg-Al-Ti-B合金的显微组织与力学性能的影响

卜乐平,高 阳,李国梁,张卫东,德雪红

内蒙古农业大学 机电工程学院,呼和浩特 010018

摘 要:采用机械合金化制备的Mg-Al-Ti-B合金,其微观组织的均匀性较差,而且致密性也不好。为了提高Mg-Al-Ti-B合金微观组织的均匀性和致密性,使其力学性能得到改善,制备了铸态Mg-9Al-6Ti合金。采用金相显微镜、扫描电镜、X射线衍射与力学性能测试等手段,研究B2O3对Mg-9Al-6Ti (质量分数,%)合金的显微组织与力学性能的影响。结果表明:添加3%的B2O3使Mg-Al-Ti-B合金的晶粒尺寸减小到12 μm,Ti颗粒完全消失,沉淀相Mg17Al12减少,而TiAl3相增多。由于新沉淀相MgB6和Ti3B4的析出,Mg-9Al-6Ti-3B2O3合金的结构变得均匀,平均硬度为HV77.1,平均抗拉强度、屈服强度和伸长率分别是171.2 MPa、113.5 MPa和5.2%。

关键词:镁合金;三氧化二硼;显微组织;力学性能

(Edited by Hua YANG)

Foundation item: Project (2009MS0802) supported by the Inner Mongolian Natural Science Foundation of China; Project supported by Inner Mongolia Autonomous Region Talent Development fund of China

Corresponding author: Le-ping BU; Tel: +86-471-4309215; Cell phone: +86-15848905689; E-mail: buleping1958@126.com

DOI: 10.1016/S1003-6326(13)62726-0