文章编号:1004-0609(2009)06-1061-07

退火温度对镦粗纯钼棒组织和横向塑性的影响

陈 畅,汪明朴,金 鹏,张 娟,郭明星,谭 望

(中南大学 材料科学与工程学院,长沙 410083)

摘 要:利用锻造镦粗工艺制备高横向塑性纯钼棒,检测其在退火过程中横向弯曲性能和组织结构,并利用SEM对其断口形貌进行分析。结果表明:镦态纯钼棒中形成沿纵向伸长的纤维组织,且晶粒间相互穿插,横向弯曲伸长率达到5%;在退火过程中,纯钼棒横向塑性逐渐增大,经980 ℃退火时,其横向弯曲伸长率达到最大值10%,此时开始发生再结晶。在此过程中,镦态纯钼棒中形成的位错胞亚结构逐渐合并形成许多细小亚晶;纯钼棒经锻造镦粗变形后断口以穿晶断裂为主,具有明显的河流状花样和解理台阶,解理面上出现大量塑性变形的撕裂岭,且形成鱼网状的韧窝。

关键词:纯钼棒;镦粗;横向塑性;穿晶断裂

中图分类号:TG 146.4 文献标识码: A

Effect of annealing temperature on microstructure and transverse ductility of upset pure Mo bars

CHEN Chang, WANG Ming-pu, JIN Peng, ZHANG Juan, GUO Ming-xing, TAN Wang

(School of Materials Science and Engineering, Central South University, Changsha 410083, China)

Abstract: Pure molybdenum bars with good transverse ductility were prepared by modified forge and upset technique. The transverse elongation and structure of the bars were investigated by bending measurement, optical microscopy (OM), scanning electron microscopy (SEM) and transmitting electron microscopy (TEM) during the annealing treatment. The results show that the transverse elongation of the bars produced by the modified forge and upset technique reaches 5% because of the interpenetrate grains and the fiber structures. During the annealing process, the transverse ductility of the pure molybdenum bar is improved and reaches a maximum value 10% at 980 ℃ when recrystallization begins. Over 1 250 ℃, further recrystallization continues and results in the decrease of transverse ductility. The fracture type of the pure molybdenum bar with good transverse ductility is mainly a transgranular fracture type and net-type, which is characterized by a large amount of cleavage planes and river patterns. Tearing ridge and net-type dimples can also be seen on the fracture.

Key words: pure molybdenum bar; upset; transverse ductility; transgranular fracture

钼及钼合金具有优良的导热、导电以及耐腐蚀性能,且热膨胀系数低、硬度高、耐高温性能好,被广泛应用于电子、航空航天能源核反应堆等众多高新技术领域[1?3]。但随着现代工业的发展,对钼及钼合金性能的要求也愈来愈苛刻,特别是钼的低温脆转性增大了其加工难度,因此,国内外在降低其塑?脆性转变温度(DBTT)、提高其再结晶温度以及改善其室温加工性能等方面做了大量研究工作[4?5]。

在钼中添加一定量的其他合金元素,如C、B、K、Si、Al、Ti、Zr、Re和稀土元素等,都是改善钼合金塑性的有效方法[6?8]。例如利用碳与氧之间强的结合能能抑制氧向晶界的偏聚,从而进一步降低杂质元素氧对钼合金塑性的影响。当碳与氧摩尔比在2?1 以上时,高纯钼合金都能表现出较好的塑性[4]。另外,钼铼合金具有非常优异的结合性能,当向钼中添加铼时,可大幅度降低钼合金的塑脆转变温度,且随着铼含量的增加,其塑脆转变温度逐渐降低,大大提高了钼合金的加工性能,但是铜铼合金价格昂贵,影响了其应用[8]。另一方面,也可以利用微观结构组织的改变来提高钼合金的塑性[9?10]。这种方法就需要利用不同的加工方式和热处理制度来获得改善钼塑性的组织。以前对钼及钼合金的研究大部分都是致力于纵向塑性的研究,钼合金的纵向塑性已经得到很大改善,但钼合金在横向上总是表现出较差的塑性[9],且其横向伸长率几乎为零。钼合金横向极差的塑性已经成为钼合金应用于航空上组成部件的限制因素,如轴瓦、垫圈、轮缘、螺母、套筒轴和活塞等[11?13]。到目前为止, 国内外有关改善钼及钼合金横向塑性的研究并不多 见[14?16]。

本文作者采用镦粗工艺制备了高横向塑性的钼棒,研究其在退火过程中的性能和组织变化,以期了解该工艺对纯钼棒横向塑性的影响,从而为稳定生产高横向塑性的纯钼棒提供理论和实验指导。

1 实验

该纯钼棒的制备工艺如下:等静压、1 900 ℃高温烧结→d45纯钼棒坯→1 100 ℃镦粗50%→ 1 100 ℃模锻至d45→1 100 ℃镦粗50%→1 100 ℃模锻至原来的d45→1 100 ℃镦粗50%→1 100 ℃模锻至原来的d45→然后经1 100 ℃模锻成不同变形量的纯钼棒(d35、d26、d18)→d18经1 100 ℃镦粗85%。

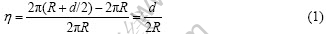

通过自制的一套弯曲模具对纯钼棒的横向塑性进行测试,弯曲性能测量原理示意图如图1所示。在10块规格为50 mm×40 mm×20 mm的不锈钢块上,用线切割切出半径分别为1 000、400、200、133.33、100、66.67、50、33.33、25、20、13.3和10 mm的圆弧。将待测的试样沿棒的横截面切割成15 mm×4 mm× 2 mm的钼条,放入半径R=1 000 mm的钢模中缓慢加压使钼条弯曲,然后再依次放入半径(R)较小的钢模中弯曲,直到钼条断裂为止,测得断裂时的R值。由于样品弯曲时上部最大,所以合金塑性可以通过计算最大伸长率来评估,具体计算公式为如下

图1 弯曲性能测量原理示意图

Fig.1 Schematic diagram of measuring bending properties

金相显微组织采用德国产LeicaEC3金相显微镜进行观察。弯曲断口分析在Serion-200场发射扫描电镜上进行。透射电镜显微组织观察在H-800分析电镜上进行,操作电压200 kV。电镜样品减薄在MTP-1双喷减薄仪上进行,电解液为硝酸和甲醇的混合液(体积比为3?7),电流为60 mA。

2 结果及分析

2.1 钼棒的横向弯曲性能研究

将镦粗纯钼棒分别在800、900、980、1 050、1 150 和1 250 ℃下进行1 h的退火处理,然后随炉空冷至室温,在样品的横截面上截取尺寸为2 mm×4 mm×15 mm钼条,对其进行弯曲实验,直到钼条断裂为止,测得断裂时的R值,将R值转换为伸长率(η),结果如表1所列。

表1 不同温度下纯钼棒的横向弯曲实验结果

Table 1 Bending properties of molybdenum bars annealed at different temperatures

从表1可以看出,纯钼棒镦粗变形经不同温度退火后,横向弯曲性能进一步提高,且随着退火温度的升高,室温塑性不断增加,980 ℃左右达到最大值,此时伸长率达到10%;继续升高退火温度,横向弯曲性能降低;当退火温度进一步升高到1 150 ℃以上时,室温弯曲性能进一步降低,此时伸长率仅为2%,通常再结晶的钼棒断口呈现出“Bamboo”形貌[9],钼棒会表现出再结晶脆性,这说明当退火温度高于1 150 ℃时,钼棒可能已经发生再结晶。

2.2 钼棒的金相显微组织

为了了解钼棒弯曲性能变化的原因,对不同退火状态下的钼棒进行了系统的金相组织观察。图2所示为镦粗变形85%的钼棒在镦态、800、980、1 050和1 250 ℃退火后的金相组织。由图2(a)和(b)可以看出,镦粗变形的钼棒形成了明显沿纵向伸长的纤维组织。晶粒间相互穿插经800 ℃退火后,与镦态相比较,其横向(见图2(c))组织变化不大;纵向(见图2(d))晶粒相互穿插,纤维组织仍然很明显;经980 ℃退火后(见图2(e)和(f)),在纤维组织中可以观测到一些细小的亚晶粒,横向组织呈不规则形状或为较宽且扭曲程度较大的晶粒,晶粒边界变得不很明晰,相互之间严重穿插,这种晶粒形态的演化可能是由于<110>纤维织构发展而来[9]。这种组织使原来结合力较低的晶界结合强度增强,裂纹更加不容易扩展,由原来的沿晶断裂转变为穿晶断裂,这可能是导致该工艺制备的纯钼棒横向塑性较好的主要原因。由表1还可以看出,此时钼棒的横向弯曲性能最好。经1 050 ℃退火后(见图2(g)),纯钼发生再结晶,基体内分布大量细小的再结晶晶粒;而经1 250 ℃退火后,纵向时纤维组织已完全消除,钼棒已经完全再结晶,基本形成了等轴晶结构(见图2(h))。再结晶态的纯钼棒晶粒之间的结合力会减弱,又因其本征脆性,因此,表现出比较差的横向弯曲性能。

图2 镦粗变形85%的钼棒经不同温度退火后的金相组织

Fig.2 Metallographs of pure molybdenum bars forged and upset by 85% after annealed at different temperatures for 1 h: (a) As-deformed, transverse; (b) As-deformed, longitudinal; (c) 800 ℃, transverse; (d) 800 ℃, longitudinal; (e) 980 ℃, transverse; (f) 980 ℃, longitudinal; (g) 1 050 ℃, longitudinal; (h) 1 250 ℃, transverse

2.3 钼棒的TEM显微组织

图3所示为钼棒镦粗变形85%镦态TEM显微组织和相应的电子衍射花样。由图3(a)可以看出,基体中分布了大量的亚晶界和胞状组织。这是由于在热锻过程中,变形量大,产生大量位错,这些位错构成亚晶界和胞状组织。由图3(a)还可以看出,位错胞壁较厚,位错密度很高。由图3(c)中可以看出,大量位错杂乱分布于晶面上,形成位错网络对胞状组织。进行选区电子衍射,发现低倍下大区域的选区电子衍射具有不连续环状特征,表明变形胞组织之间存在一定的位向差,整个区域内大量位错胞间取向差的连续变化形成了多晶衍射效应。若将衍射区进一步缩小至单个位错胞的范围(见图3(d)),发现衍射斑点变得较圆但仍然出现一定程度的拉长现象,说明单个位错胞内仍存在晶格畸变。

图3 钼棒镦粗变形85%后的TEM像及其相应的SAD衍射谱

Fig.3 TEM images and corresponding SAD patterns of molybdenum bars forged and upset by 85%: (a) As-deformed; (b) SAD pattern of (a); (c) Magnified field of (a); (d) SAD pattern of (c)

图4(a)所示为钼棒镦粗变形85%后经800 ℃退火 1 h的TEM像。由图4(a)可以看出,与镦态相比,缠结的位错数量有所减少,位错线被吸引向胞壁并与胞壁中的异号位错相互抵消,降低了位错密度。胞壁位错也已经开始松开,位错胞内孤立干净的区域增多。图4(b)所示为纯钼棒镦粗变形85%后经980 ℃退火1 h的TEM像。从图4(b)可以看出,组织发生比较明显的变化,合金中出现大量细小的亚晶粒,亚晶粒内部只能观察到少量的位错线,塞积在亚晶界上的位错有明显减少,亚晶界变窄、变薄,有的甚至消失,只留下一些细小的位错列。一些亚晶粒开始合并,晶粒的边界清晰可见。可以推断这时试样开始发生再结晶。图4(c)所示为纯钼棒镦粗变形85%后1 250 ℃退火1 h的TEM像。从图4(c)可以看到明晰的晶界。对图4(c)进行选区衍射(见图4(d))发现,此时环状衍射效应消失,衍射斑点变得较圆,这说明此时合金基本形成了等轴的再结晶组织。

图4 钼棒镦粗变形85%后退火样品的TEM像及相应的SAD衍射谱

Fig.4 TEM images and corresponding SAD pattern of annealed molybdenum bars forged and upset by 85% under different conditions: (a) 800 ℃ for 1 h, (b) 980 ℃ for 1 h, (c) 1 250 ℃for 1 h; (d) SAD pattern of (c)

2.4 钼棒的断口形貌

图5所示为纯钼棒镦粗变形85%经980 ℃退火1 h后的横向弯曲断口形貌。从图5可以看出,断口以穿晶断裂为主,断口上有大量的解理面,具有明显的河流状花样和解理台阶。这种解理台阶主要是由于裂纹在扩展过程中与螺位错的交截而形成的,此外,除了有穿晶解理台阶之外,解理面上又有大量塑性变形的撕裂岭(见图5(b)),可见金属在断裂前经过大量的塑性变形,而不是直接发生脆断。图5(c)所示为解理裂纹穿晶时的情况,由于在晶界两侧晶粒互相仅差一个小角度,因此,裂纹可以连续地穿过,即河流状花样穿过晶界继续延伸到相邻晶粒。对图5(a)所示的局部放大像的分析可以看出,断口出现大小比较均匀的韧窝(见图5(d)),韧窝小且不深,密集型的韧窝连接成鱼网状,这种韧窝的形成可能是由于合金中细小亚晶粒之间的断开。可见该状态具有很多塑性断裂方式,这也可以说明纯钼棒镦粗变形85%再经过980 ℃退火1 h后,纯钼棒的塑性提高较大。

图5 纯钼棒镦粗变形85%经980 ℃退火1 h后横向弯曲断口形貌

Fig.5 Transverse bending fractures of molybdenum bars forged and upset by 85% and annealed at 980 ℃for 1 h: (a) Cleavage plane and river-like pattern; (b) Tearing ridge; (c) Transcrystalline river-type pattern; (d) Net-type dimple

3 结论

1) 纯钼棒经锻造镦粗变形85%后横向具有较好的塑性,伸长率达到5%,这是因为纯钼棒中形成沿纵向伸长的纤维组织,且晶粒间相互穿插,这种组织大大强化了晶粒界面之间的结合力。

2) 镦粗纯钼棒在退火过程中横向塑性逐渐升高,在经980 ℃退火1 h时,伸长率达到最大值10%,此时开始发生再结晶;经1 250 ℃退火1 h后,基本形成等轴的再结晶组织,横向塑性逐渐降低。

3) 镦态纯钼棒中形成大量的位错胞亚结构,胞内有大量的位错缠结在一起,随着退火温度的升高,胞壁逐渐变薄,胞内位错逐渐减少,位错胞逐渐合并形成细小亚晶。

4) 纯钼棒经锻造镦粗变形后,断口以穿晶断裂为主,断口上出现大量的解理面,具有明显的河流状花样和解理台阶;且解理面上出现大量塑性变形的撕裂岭,且形成鱼网状的韧窝。

REFERENCES

[1] MARIO S, KATSUYA I, HITOSHI S, TADAYUKI F, TADASHI I, OKAMOTO K I. Solar thermal thruster made of single crystal molybdenum [J]. Acta Astronautica,1997, 41(1): 23?28.

[2] 张久兴, 刘燕琴, 刘丹敏, 周美玲, 左铁镛. 微量La2O3对钼的韧化作用[J]. 中国有色金属学报, 2004, 14 (1): 13?17.

ZHANG Jiu-xing, LIU Yan-qin, LIU Dan-min, ZHOU Mei-ling, ZUO Tie-yong. Toughness of La2O3 -doped Mo alloy[J]. The Chinese Journal of Nonferrous Metals, 2004, 14 (1): 13?17.

[3] MASAHIRO N, TETSUO Y, JUN T, YUTAKA H. Improvement in recrystallization temperature and mechanical properties of a commercial TZM alloy through microstructure control by multi-step internal nitriding[J]. Materials Transactions JIM, 2005, 46(10): 2129?2134.

[4] KUMAR A, EYRE B L. Grain boundary segregation and intergranular fracture in molybdenum[J]. Proc R Soc Lond, 1980, A370: 431?458.

[5] MASAHIRO N, YOSHITO T, TETSUO Y, JUN T, YUTAKA H. Preparation of structurally controlled dilute molybdenum- titanium alloys through a novel multi-step internal nitriding technique and their mechanical properties[J]. Mater Sci Eng A, 2005, 406(1/2): 50?56.

[6] HIROAKI K, YUJI K, YUTAKA H, TAMAKI S, HIDEO K. Development of molybdenum alloy with high toughness at low temperatures[J]. Materials Transactions JIM, 1996, 37(1): 89?97.

[7] INOUE T, HIRAOKA Y, SUKEDAI E. Hardening behavior of dilute Mo-Ti alloys by two-step heat-treatment[J]. International Journal of Refractory Metals and Hard Materials, 2007, 25: 138?143.

[8] AGNEW S R, LEONHARDT T. The low-temperature mechanical behavior of molybdenum-rhenium[J]. JOM, 2003, 55(10): 25?29.

[9] WADSWORTH J, PACKER C M, CHEWEY P M, COONS W J. A microstructure investigation of the origin of brittle behavior in the transverse direction in Mo-based alloy bars[J]. Metallurgical Transactions A, 1984, 15(9): 1741?1752.

[10] HIRAOKA Y, HIROAKI I, TAKESHI I. Application of fractography to the study of carbon diffusion in molybdenum[J]. Journal of Alloys and Compounds, 2004, 377: 127?132.

[11] HIRAOKA Y, KURISHITA H, NARUI M, KAYANO H. Fracture and ductile-to-brittle transition characteristics of molybdenum by impact and static bend tests[J]. Materials Transactions JIM, 1995, 36(4): 504?510.

[12] HIROAKI K, AKIRA O, HARUYOSHI K. Grain boundary fracture in Molybdenum bicrystals with various <110> symmetric tilt boundaries[J]. Materials Transactions JIM, 1985, 26(5): 341?345.

[13] HIROAKI K, KITSUNAI Y, HIRAOKA Y. Development of molybdenum alloy with high toughness at low temperatures[J]. Materials Transactions JIM, 1996, 37(1): 89?97.

[14] KOBAYASHI S, TSUREKAWA S, WATANABE T. Roles of structure-dependent hardening at grain boundaries and triple junctions in deformation and fracture of molybdenum polycrystals[J]. Mater Sci Eng A, 2008, 483/484: 712?715.

[15] HOSHIKA T, HIRAOKA Y. Effect of carbon addition on the strength and ductility of doped molybdenum[J]. Journal of the Japan Society of Powder and Powder Metallurgy, 1999, 46(5): 472?477.

[16] OERTEL C G, HUENSCHE I, SKROTZKI W, KNABL W, LORICH A, RESCH J. Plastic anisotropy of straight and cross rolled molybdenum sheets[J]. Mater Sci Eng A, 2008, 483/484: 79?83.

基金项目:国家高新技术研究发展计划资助项目(2006AA03Z517);湖南省自然科学基金资助项目(05JJ30095)

收稿日期:2008-08-27;修订日期:2008-11-06

通讯作者:汪明朴,教授,博士;电话:0731-8830264;E-mail: chench011-33@163.com

(编辑 龙怀中)