DOI: 10.11817/j.issn.1672-7207.2015.04.010

规整填料内气相载荷对液膜流动特性的影响

李相鹏,李锋,张超

(浙江工业大学 机械工程学院,浙江 杭州,310032)

摘要:为研究逆向气相载荷对规整填料表面液膜流动特性的影响,采用流体力学计算软件FLUENT建立基于Navier-Stokes方程和VOF方法相结合的CFD分析模型,湍流结构模拟采用RNG k-ε模型。针对Mellapak 250Y型金属板波纹填料表面不同气相载荷(F因子)对液膜流体动力学特性的影响进行模拟分析。研究各工况下液膜动态运动分布、气液两相流场结构、界面速度场分布特征,及相应持液量、有效界面传质面积变化分布规律。研究结果表明:气相速度对上述参数均有不同程度影响。

关键词:气液两相流;规整填料;逆向气流;F因子

中图分类号:TQ028.4 文献标志码:A 文章编号:1672-7207(2015)04-1239-08

Influences of gas load on hydrodynamics of liquid film flow over structured packings

LI Xiangpeng, LI Feng, ZHANG Chao

(College of Mechanical Engineering, Zhejiang University of Technology, Hangzhou 310032, China)

Abstract: In order to study influences of the countercurrent gas load on the hydrodynamics of liquid film flow, a CFD model based on Navier-Stokes equations and VOF method was developed with software package FLUENT, and the turbulent structure was modeled with RNG k-ε model. The simulations were conducted to study the variations of liquid film hydrodynamics with countercurrent gas load (F factor) over Mellapak 250Y corrugated packing sheet. The analysis was mainly focused on the transient motions of liquid film, gas-liquid two-phase flow structure, velocity fields distribution feature along interface, and corresponding liquid holdup and effective interfacial area. The results show that the counter current gas flow velocity has great influence on the previously mentioned parameters.

Key words: gas-liquid two-phase flow; structured packing; countercurrent gas flow; F factor

精馏和吸收过程中气液两相流场分布和界面传质是目前业内研究的焦点[1]。基础实验测试和分析研究的不足,“效率驼峰”、液泛等机理尚不能完全掌握,这阻碍了分离效率的进一步提高。因此有必要对精馏过程中气液两相流体力学特性进行进一步地研究和探索[2]。就目前而言,对于规整填料塔内大规模流动和传质过程的模拟还是无法采用直接数值模拟的方法进行。因此,现有研究多通过模拟填料层内一些代表性的结构单元内的气液两相的流动和传质过程,来近似描述宏观填料层内的流体力学行为和传质行为[3]。针对规整填料内气液两相流的研究,Iliuta等[4]采用体积平均的方法,对规整填料塔建立了一个适用于载点以下操作范围的两相流模型,并用这个模型来计算填料层的压降和持液量。Szulczewska等[5]建立了一个关于Mellapak 250Y型板波纹规整填料的二维两相流模型,采用Fluent软件对倾斜平板/波纹板和竖直平板/波纹板上的气液两相逆流流动的过程进行了模拟。Gao 等[6]针对Mellapak 250Y型板波纹规整填料表面液膜流动进行了数值模拟分析,研究了填料表面结构、液相流量的影响,同时针对逆流气液两相流进行了模拟,发现在界面处存在向下流动的气流。刘春江等[7]采用流体体积(volume of fluid,简称为VOF)多相流模型建立了描述规整填料内部鼓泡流动现象的二维模型。Petre等[8]通过将规整填料拆分为若干填料单元的方法,研究了规整填料内的压降,可以借助这种方法研究规整填料内的液相返混。Higler等[9-10]使用CFD工具研究了规整填料内流体的返混情况,他们主要以一种填料交叉单元和片填料为研究对象,并引入“Toblerone”单相流模型的概念,其研究不是针对整塔,而其结构单元也不能全面的体现规整填料的结构。Raynal等[11-12]针对规整填料表面气液两相流进行了一系列的数值模拟分析,研究了液-壁、气-液间的相互作用、填料表面液膜流特征、持液量及气液两相间反应传质过程。Trifonov[13]针对平板和波纹板表面液膜流动及其对液泛影响进行了一系列数值模拟分析,研究了气相流量和填料表面结构对液膜流体动力学特性的影响,并对液泛形成机理进行了探索。Haroun等[14]采用直接数值模拟方法计算了平面表面和波纹板表面气液两相并流层流流动情况下气液两相流场结构、流线分布,采用VOF方法对气液两相界面波动性进行了分析,获得了界面处液膜速度,并针对反应和非反应吸收过程界面传质进行了研究。本文作者前期针对文献[15]中C型填料表面降膜流进行了模拟分析,研究了逆向气流作用下液膜流体动力学特性及持液量、有效界面传质面积变化分布规律。至今对规整填料表面降膜流研究都是针对较高液相流量的情况,即能在填料表面形成稳定连续的液膜。然而,由于偏流或进料波动,局部液相流量可能会很低,这时填料表面液膜很薄甚至不连续。液膜破裂后填料表面直接与气相接触形成干板区,导致有效界面面积减小,从而影响传质效率。所以有必要针对较低液相流量情况下液膜流体动力学特性及逆向气载的影响进行进一步研究。本文作者采用Mellapak 250Y型金属板波纹填料实际结构尺寸进行建模,基于Navier-Stokes方程和VOF多相流模拟方法建立了填料内气液两相流CFD分析模型,模拟分析了逆流流动条件下气相载荷(F因子)对小液相流量下液膜动态运动分布、气液两相流场结构、界面速度场分布及持液量、有效界面传质面积变化分布特征的影响。

1 数值模拟模型

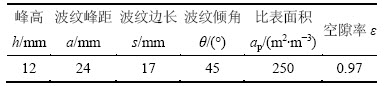

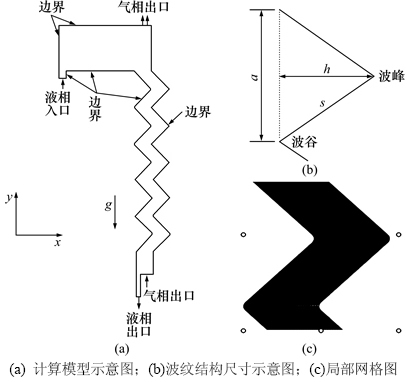

Mellapak 250Y型金属板波纹填料结构参数如表1所示。根据其结构参数建立了如图1所示的二维气液两相流分析模型,该模型被广泛应用于填料内气液两相流的模拟研究中。取5个波纹进行模拟研究,模型长度为180 mm,包括气相出口63 mm、液相入口5 mm,液相出口3 mm,气相入口9 mm,其余各面为壁面,如图1(a)所示。为跟踪复杂的界面变化,模型采用结构化网格进行划分。图1(b)所示为波纹结构尺寸示意图,图1(c)所示为局部网格图。

考虑到气液两相流过程中复杂的界面变化,在界面区域需要对网格进行加密。一般要保证液膜厚度内包含5个以上的网格,而界面上的液膜往往不足1 mm,需要对网格从气相区向液相区逐层加密,气相区网格尺寸比较大,液相区网格尺寸比较小,填料间网格如图1(c)所示,最后得到的网格总数约25万个。

取甲醇-空气体系作为气液两相流研究介质。液相和气相入口设置速度边界条件,壁面设置无滑移壁面边界条件。结合Navier-Stokes方程、RNG k-ε模型和VOF两相流模型对规整填料表面液膜流形成和发展过程进行模拟分析。

RNG k-ε模型是对瞬态的Navier-Stokes方程用重组化群(renomalization group theory)的数学方法推导出来的模型。RNG k-ε模型与标准k-ε模型很相似,其方程如下:

(1)

(1)

(2)

(2)

式中:Gk为平均速度产生的湍动能;Gb为浮力产生的湍动能;YM为湍流扩张波动对扩散率的影响;μeff为有效黏度;C1ε,C2ε和C3ε为模型常数;αk和αε分别为湍动能k和耗散率ε的湍流普朗特数的倒数。湍流黏

性系数计算公式为

(3)

(3)

其中: ;湍流常数

;湍流常数 。

。

表1 Mellapak 250Y 型金属孔板波纹填料结构特性参数[16]

Table 1 Geometric data for structured metal plate of corrugation packing of Mellapak 250Y[16]

图1 模型结构示意图

Fig. 1 Model structure diagram

相对标准k-ε模型,RNG k-ε模型适用于更广泛的流动中,并且具有更高的可信度和精度。特别适用于模拟:分层流;环流;低雷诺数流体湍流;过渡流;涡旋流;弯曲几何体内的流动;快速变形的流动;剪切层不稳定的流动和低Prandtl数流体的传热。

气液两相流及界面跟踪采用VOF模型。在VOF模型中,各相流体共享一个动量方程,每一相的体积分数在整个计算域内被追踪。适用VOF模型的多相流应用包括分层流、有自由分界面的流动、液体灌注、容器内液体震荡、液体中大气泡运动、气液界面的稳态和瞬态追踪等。

2 模型的模拟及验证

为了验证模拟所用的模型和数值方法的准确性,对文献[15]中试验工况进行建模分析,并与试验结果进行比较。采用文献[15]中的S型表面结构作为计算对象,甘油作为液相介质,其密度为1 261 kg/m3,动力黏度为0.45 Pa·s,表面张力为0.062 5 N/m。

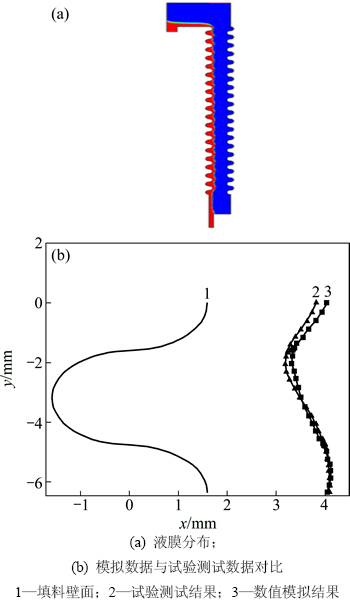

图2 液膜分布图和模拟数据与试验测试数据对比

Fig. 2 Comparison of liquid film distribution simulated data and test data

对液相流量为1.843×10-6 m3/(s·m)流动稳定时形成的液膜状况及CFD模拟与实验得到的液膜厚度进行对比。图2中,产生的最大绝对误差在Y轴为01 mm时,为0.22 mm,同时在此处产生了最大相对误差为5.77%,相对误差范围都在10%以内,平均相对误差为2.36%,证明了数值计算模型和数值方法的准确性。

3 模拟结果与讨论

3.1 气相速度对液膜流分布特征的影响

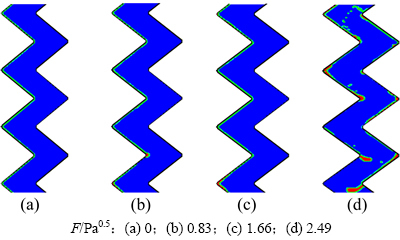

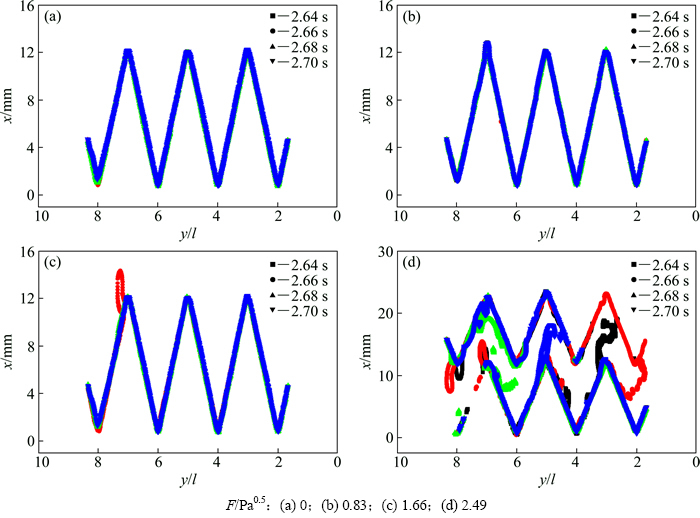

在填料塔内气液两相的传质分离过程多采用两相逆流方式,而气相载荷的变化对规整填料表面液膜流动的影响仍不是很明确。下面针对不同气相载荷(F因子,F=u·ρ0.5,其中u为气相的空塔速度,ρ为气相密度)条件下液膜瞬态分布特征进行研究。液相流量设为0.75×10-4 m3/(s·m),气相进口速度分别取0,1,2和3 m/s,相应F因子分别为0,0.83,1.66和2.49 Pa0.5。图3所示为不同气相F因子时,液膜的分布云图(取波纹板中部4个波纹表面液膜进行分析)。而图4所示为不同气相F因子在不同时刻时液膜自由界面沿填料表面的变化分布曲线(l=0.5a,a为波纹板波长)。

在小液相流量下,F=0 Pa0.5 (无入口气速)时液膜在填料壁面形成稳定的液膜流,液膜贴合在填料表面,其形状和填料表面形状相似,由于液相流量小,液膜厚度非常小,其厚度为2.839×10-4 m左右,如图3(a)和4(a)所示;当F=0.83 Pa0.5 时,由于气流作用,液膜表面逐渐出现波动,在第7节波纹板表面出现液流积聚,其液膜厚度为2.868×10-4 m左右,(见图3(b)和4(b));当F=1.66 Pa0.5 时,液膜波动加剧,在第7节波纹板表面有时出现液流积聚而形成外悬的液流,其液膜厚度在3.053×10-4 m左右,如图3(c)和4(c)所示;当F=2.49 Pa0.5 时,气流作用变大,彻底破坏了液膜流动的平衡,液膜波动急剧增大,部分液膜脱离波纹板表面形成液滴,液滴落到对侧形波纹板表面成另一股液流,部分液滴则随气流向上运动,形成液相“返混”现象,同时部分液膜处发生断裂,出现干板区。液膜厚度最大处达到3.673×10-4 m,如图3(d)和4(d)所示。

图3 填料表面液膜随气相F因子分布云图

Fig. 3 Contours of liquid film distribution on surface of structured packing with F factor

图4 不同F因子时液膜自由表面变化分布曲线

Fig. 4 Evolution of liquid free surface with time at different F factor

3.2 气相速度对液膜流速度场分布的影响

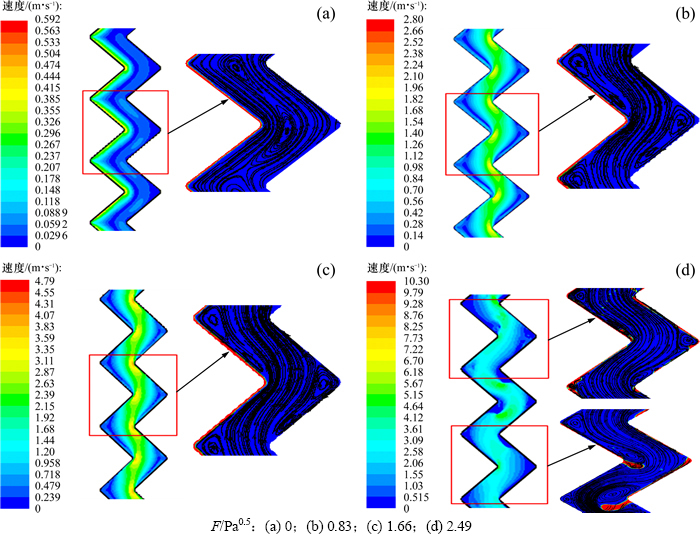

在VOF模型中,各相流体共享一组控制方程,所以可以通过云图观察同一个工况下各区域的速度变化情况。图5所示是液相流量为0.75×10-4 m3/(s·m)时不同气相F因子条件下气液两相速度分布云图及局部流线图。

当气相F=0 Pa0.5时,液膜流下降,带动液膜附近的气体下降,并与远离液膜的气体发生剪切作用,从而形成回流区,如图5(a)所示。F为0.83和1.66 Pa0.5时,气体经过通道上升,由于气流的影响,沿填料表面交错形成大小不等规则分布的气相回流区,如图5(b)和5(c)所示。当气相F因子增大到2.49 Pa0.5 时,波纹板波峰处液膜向上流动特征明显,在液相区也形成回流区,液相区和气相区回流区分布不规则,上升液滴背风面形成较大回流区,如图5(d)所示。

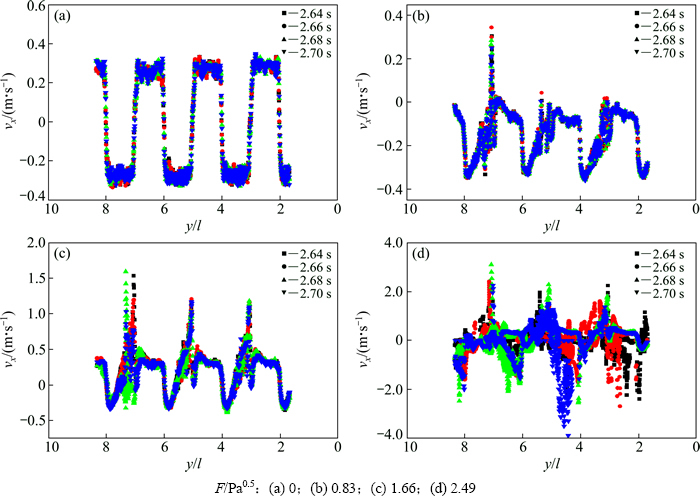

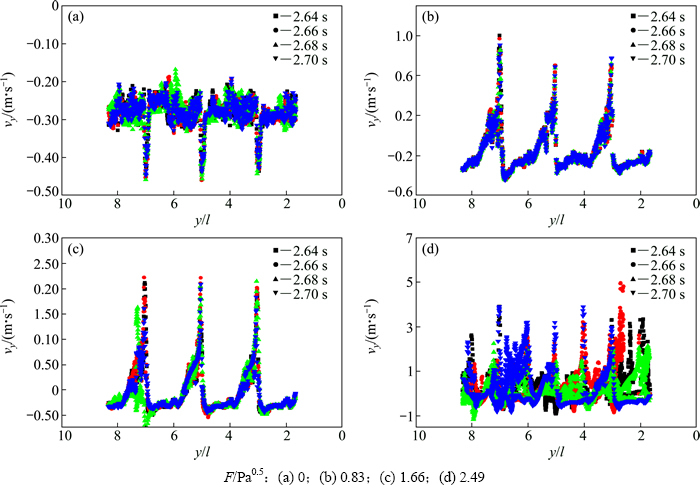

为深入了解不同F因子时液膜动力学特性的变化规律,绘制了4个连续时刻时各工况两相界面处速度分量vx和vy分布曲线图,分别如图6和图7所示。

当F=0 Pa0.5 时,如图6(a)所示,vx曲线沿波纹板表面呈周期性变化,vx的峰值和谷值绝对值基本一致,液膜在波纹板倾斜表面上的vx基本不变。F=0.83 Pa0.5时,vx明显变化,vx峰值和谷值分别出现在波纹板波峰和波谷处,在波纹板波峰处速度增大。这是因为气流直接作用在液膜表面使其速度增大,其速度变化为-0.32 m/s至1.0 m/s。F=1.66 Pa0.5 时曲线和图6(b)的曲线图大致一样。随着气相速度的增大,vx的峰值有所增大,其速度变化为-0.3 m/s至1.6 m/s,见图6(c)。气相因子F=2.49 Pa0.5 时液膜界面处速度分量vx波动剧烈,速度变化为-4 m/s至3.2 m/s,如图6(d)所示。

当F=0 Pa0.5 时,液膜表面速度分量vy沿波纹板表面呈周期性分布,且vy均为负值(速度向下),vy谷值在波纹板波峰处,为-0.57 m/s。F=0.83 Pa0.5时,在波纹板波峰处vy出现峰值,且vy>0 m/s(速度向上),说明在波纹板波峰处液膜有向上流动的特征,最大值约1 m/s,见图7(b)。当F=1.66 Pa0.5 时,vy的分布曲线与F=1 Pa0.5 时相似,见图7(c);只是液膜向上流动的特征更加明显,在波峰处vy峰值最大为2.1 m/s。当F=2.49 Pa0.5 时,液膜波动剧烈,界面vy>0 m/s的面积进一步增大,vy峰值最大达到3.9 m/s,见图7(d)。

图5 气液两相速度分布云图及局部流线图

Fig. 5 Velocity contours of gas and liquid and stream lines

图6 不同F因子时液膜界面处速度分量vx的变化曲线

Fig. 6 Distribution of velocity component vx at different F factor

图7 不同F因子时液膜界面处速度分量vy的变化曲线

Fig. 7 Distribution of velocity component vy at different F factor

3.3 气相速度对液膜持液量和有效传质面积的影响

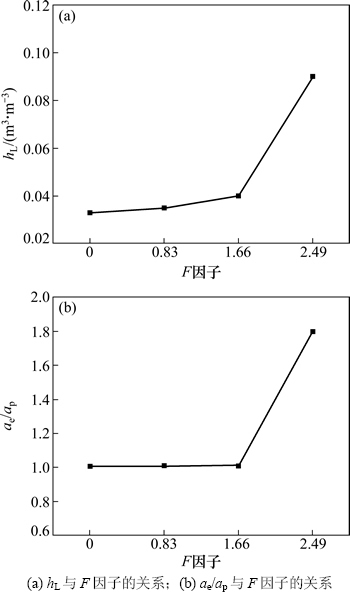

图8(a)和8(b)所示分别为持液量hL及有效界面传质面积与填料比表面积比值ae/ap随F因子的变化曲线。图8(a)所示为hL随F因子的增大而增大,且当F因子小于1.66 Pa0.5时增幅较小,气相因子大于1.66 Pa0.5时增幅较大;有效界面传质面积的变化分布也基本类似,当气相F因子小于1.66 Pa0.5时,ae/ap随F因子的增大稍有增大,当气相F因子大于1.66 Pa0.5时,液膜波动剧烈,有效传质面积增幅较大。

图8 hL和ae/ap随F因子的变化分布曲线

Fig. 8 Variation of hL and ae/ap with F factor

4 结论

1) 在小液相流量下,气相F=0 Pa0.5时液膜形成稳定的液膜流,液膜形状和填料表面形状相似;气相F为0.83和1.66 Pa0.5时,液膜表面逐渐出现波动,波纹板波峰和波谷出现液流积聚;F=2.49 Pa0.5时,液膜流发生断裂出现干板区,同时发生“返混”现象。气相F因子在0~2.49 Pa0.5范围内,随着F因子的增大液膜厚度有所增加。

2) 当气相F=0 Pa0.5时,液膜流带动附近气体下降并在液膜中部形成回流区;而F为0.83和1.66 Pa0.5时,由于气流作用,沿填料表面交错形成大小不等规则分布的气相回流区;F=2.49 Pa0.5 时,气流作用加剧,液相区和气相区回流区分布不规则,上升液滴背风面形成较大回流区。

3) 当气相F=0 Pa0.5时,vx曲线上的峰值和谷值绝对值大致相同;气相F为0.83和1.66 Pa0.5时,vx曲线的分布特征近似,vx峰值和谷值出现在填料波纹顶部和底部处,由于气流的影响,vx在波峰处增大,且随着F因子增大,vx峰值有所增大;气相因子F=2.49 Pa0.5时,vx波动加剧,vx峰值和谷值均有所增大。

4) 当气相F=0 Pa0.5时,vy均为负值(速度向下),vy在波纹板波峰处较小;气相F为0.83和1.66 Pa0.5时,vy曲线的分布特征接近,在波纹板波峰处出现vy>0(速度向上)的区域,液流出现向上流动特征,且随着F因子增大,vy峰值有所增大;气相因子F=2.49 Pa0.5时,界面vy>0的面积进一步增大。

5) 气相F因子在0~2.49 Pa0.5范围内,随着F因子的增大hL和ae/ap均有所增大;气相F因子小于1.66 Pa0.5时,气相因子F增大时hL和ae/ap增幅较小,气相F因子大于1.66 Pa0.5时,增幅较大。

参考文献:

[1] Haroun Y, Raynal L, Legendre D. Mass transfer and liquid hold-up determination in structured packing by CFD[J]. Chemical Engineering Science, 2012, 75(12): 342-348.

[2] Daniel S, Sai G, Panneerselvam R, et al. Micro-scale CFD modeling of reactive mass transfer in falling liquid films within structured packing materials[J]. International Journal of Greenhouse Gas Control, 2015, 33(1): 40-50.

[3] William G A, Irving J K. Process for the preparation of higher fatty acid monoglycerides: US, 3083216[P]. 1963-03-26.

[4] Iliuta I, Petre C F, Larachi F. Hydrodynamic continuum model for two-phase flow structured-packing-containing columns[J]. Chemical Engineering Science, 2004, 59(5): 879-888.

[5] Szulczewaka B, Zbicinski I, Gorak A. Liquid flow on structured packing: CFD simulation and experimental study[J]. Chemical Engineering Technology, 2003, 26(5): 580-584.

[6] GAO Guohua, ZHANG Luhong, LI Xingang, et al. CFD simulation of film flow and gas/liquid countercurrent flow on structured packing[J]. Tianjin University, 2011, 17(3): 194-198.

[7] 刘春江, 成洁, 袁希钢. 规整填料内鼓泡流动的二维CFD模拟[J]. 中国科技论文在线, 2008, 3(12): 933-940.

LIU Chunjiang, LI Jie, YUAN Xigang. Two dimensional CFD simulation of bubbling flow on structured packing[J]. Science Paper Online, 2008, 3(12): 933-940.

[8] Petre C F, Larachi F, Iliuta I, et al. Pressure drop through structured packing: Breakdown into the contributing mechanisms by CFD modeling[J]. Chemical Engineering Science, 2003, 58(2): 163-177.

[9] Higler A P, Krishn R, Ellenberger J, et al. Counter-current operation of a structured catalytically packed-bed reactor: Liquid phase mixing and mass transfer[J]. Chemical Engineering Science, 1999, 54(21): 5145-5152.

[10] van Baten J M, Ellenberger J, Krishna R. Radial and axial dispersion of the liquid phase within a KATAPAK- S structure: Experiments vs. CFD simulations[J]. Chemical Engineering Science, 2001, 56(3): 813-821.

[11] Raynal L, Royon-Lebeaud A. A multi-scale approach for CFD calculations of gas-liquid flow within large size column equipped with structured packing[J]. Chemical Engineering Science, 2007, 62(24): 7196-7204.

[12] Haroun Y, Legendre D, Raynal L. Direct numerical simulation of reactive absorption in gas-liquid flow on structured packing using interface capturing method[J]. Chemical Engineering Science, 2010, 65(10): 351-356.

[13] Trifonov Y Y. Counter-current gas-liquid flow between vertical corrugated plates[J]. Chemical Engineering Science, 2011, 66(20): 4851-4866.

[14] Haroun Y, Legendre D, Raynal L. Volume of method for interfacial reactive mass transfer: application to stable liquid film[J]. Chemical Engineering Science, 2010, 65(10): 2896-2909.

[15] Zhao L Q, Cerro R L. Experimental characterization of viscous film flows over complex surfaces[J]. International Journal of Multiphase Flow, 1992, 18(4): 495-516.

[16] 王树楹. 现代填料塔技术指南[M]. 北京: 中国石化出版社, 1998: 91.

WANG Shuying. The guidelines of modern packing tower technical[M]. Beijing: China Petrochemical Press, 1998: 91.

(编辑 杨幼平)

收稿日期:2014-04-19;修回日期:2014-06-08

基金项目(Foundation item):浙江省自然科学基金资助项目(Y20110169);“十二五”科技支撑计划项目(2011BAK06B02)(Project (Y20110169) supported by the Natural Science Foundation of Zhejiang Province of China; Project (2011BAK06B02) supported by the National Science and Technology Pillar Program During the 12th Five-year Plan Period)

通信作者:李相鹏,博士,副教授,从事热能工程、化工过程等数值模拟与优化研究;E-mail:rocleexp@zjut.edu.cn