DOI: 10.11817/j.issn.1672-7207.2019.09.003

低品位高硫铝土矿脱硅精矿溶出及微观结构演变

吴鸿飞1, 2,夏飞龙1, 2,李军旗1, 2,陈朝轶1, 2,徐树涛3,张仕恒1, 2

(1. 贵州大学 材料与冶金学院,贵州 贵阳,550025;

2. 贵州省冶金工程与过程节能重点实验室,贵州 贵阳,550025;

3. 贵阳铝镁设计研究院有限公司,贵州 贵阳,550025)

摘要:为有效开发与利用低品位高硫铝土矿,降低拜耳法流程中硫矿物的危害并提高氧化铝溶出率,采用高压溶出工艺考察苛碱质量浓度、时间、石灰添加量和温度对脱硅精矿溶出性能的影响。研究结果表明:最佳溶出条件为溶出条件为温度280 °C,苛碱质量浓度245 g/L,时间70 min,石灰添加质量分数8%,在此条件下的相对溶出率为95.14%,比原矿和焙烧矿相对溶出率分别提高7.50%和9.77%,脱硅精矿溶出液中硫质量浓度为0.11 g/L,硫的实际溶出率为11.2%;脱硅精矿比表面积增大为31.25 m2/g,孔容和孔径分别增至0.0784 cm3/g和14.76 nm;氧化铝晶体[113]面在碱浸过程中晶粒粒径减小;脱硅精矿晶面间距减小,Al—O键长变大并存在0.185 4和1.971 0 nm 2种键长。

关键词:高硫铝土矿;高压溶出;比表面积;晶体结构

中图分类号:TF11 文献标志码:A 开放科学(资源服务)标识码(OSID)

文章编号:1672-7207(2019)09-2074-10

Digestion performance and microstructure evolution of desilicated concentrate from low-grade high sulfur bauxite

WU Hongfei1, 2, XIA Feilong1, 2, LI Junqi1, 2, CHEN Chaoyi1, 2, XU Shutao3, ZHANG Shiheng1, 2

(1. School of Materials and Metallurgy, Guizhou University, Guiyang 550025, China;

2. Guizhou Province Key Laboratory of Metallurgical Engineering and Process Energy Saving,Guiyang 550025, China;

3. Guiyang Aluminum Magnesium Design & Research Institute Co. Ltd., Guiyang 550025, China)

Abstract: To effectively develope and utilize the low grade high sulfur bauxite, and reduce the hazards of sulfur minerals in the Bayer process and improve the digestion properties of alumina, the effects of caustic alkali mass concentration, time, lime addition amount and temperature on the digestion performance of desilicated concentrate were systematically investigated after roasting desulfurization and alkali leaching desilication. The results show that the best digestion conditions are as follows: the digestion temperature is 280 ℃; the caustic mass concentration is 245 g/L; the digestion time is 70 min ; the lime mass fraction is 8%. The relative digestion ratio is 95.14%, which is 7.50% higher than that of the raw ore and 9.77% higher than that of the calcined ore, respectively. The mass concentration of sulfur in the digestion solution of desilicated concentrate is 0.11 g/L, and the actual digestion ratio of sulfur is 11.2%. The specific surface area of desilicated concentrate increases to 31.25 m2/g, pore volume and pore diameter increase to 0.078 43 cm3/g and 14.76 nm, respectively. The reaction of [113] surface of alumina crystal during alkali leaching process leads to the decrease of grain size. The interplanar spacing of desilicated concentrate decreases and the length Al—O increases, with two bond lengths of 0.185 4 nm and 1.971 0 nm, respectively.

Key words: high sulfur bauxite; high pressure digestion; specific surface area; crystal structure

随着我国铝工业持续快速发展,优质铝土矿资源不断消耗。据统计2018全年国内氧化铝产量为3.648 5亿t,较同期增长1.6%,对铝土矿需求量也不断增加[1]。资源短缺已成为制约我国氧化铝工业发展的瓶颈,针对复杂难处理的铝土矿开发与利用迫在眉睫。在我国难处理的铝土矿大量分布于贵州和山东,为高硫铝土矿,由于与煤矿共生或矿层较深、矿物中硫质量分数较高(>0.7%),无法应用于氧化铝工业生产[2]。对低品位高硫铝土矿的开发,其关键在于解决高硫铝土矿中硫在溶出过程中的危害以及氧化铝相对溶出率低的问题。高硫铝土矿中硫在溶出过程中以S2-, 和

和 和

和 等形态存在,对溶出工艺造成很大影响并腐蚀设备等[3-5]。由于矿石中铝硅比小于5,结构复杂,溶出性能差,未达到工业拜耳法生产要求,需要提高矿石铝硅比。通过氧化焙烧能有效除去矿石中的硫化物和硫酸盐,使溶出过程中硫质量浓度低于0.18 g/L,达到工业生产要求[6]。焙烧矿中的SiO2大多以非晶态形式存在,在碱浸过程中SiO2易于脱除,提高矿石中铝硅比[7-8]。目前人们对高硫矿的研究主要集中在脱硫研究与高铝硅比溶出,对于低铝硅比矿石溶出性能以及微观结构演变的研究较少[9-11]。为此,本文作者以高硫铝土矿为原料,对其脱硫脱硅后,根据单因素实验探讨溶出温度、时间、CaO添加质量分数和苛碱质量浓度对脱硅精矿溶出性能的影响,采用XRD,SEM-EDS,BET和Materials Studio等手段系统研究溶出过程中矿相变化以及微观结构演变规律。

等形态存在,对溶出工艺造成很大影响并腐蚀设备等[3-5]。由于矿石中铝硅比小于5,结构复杂,溶出性能差,未达到工业拜耳法生产要求,需要提高矿石铝硅比。通过氧化焙烧能有效除去矿石中的硫化物和硫酸盐,使溶出过程中硫质量浓度低于0.18 g/L,达到工业生产要求[6]。焙烧矿中的SiO2大多以非晶态形式存在,在碱浸过程中SiO2易于脱除,提高矿石中铝硅比[7-8]。目前人们对高硫矿的研究主要集中在脱硫研究与高铝硅比溶出,对于低铝硅比矿石溶出性能以及微观结构演变的研究较少[9-11]。为此,本文作者以高硫铝土矿为原料,对其脱硫脱硅后,根据单因素实验探讨溶出温度、时间、CaO添加质量分数和苛碱质量浓度对脱硅精矿溶出性能的影响,采用XRD,SEM-EDS,BET和Materials Studio等手段系统研究溶出过程中矿相变化以及微观结构演变规律。

1 实验

1.1 实验原料

溶出实验所用矿石为焙烧与脱硅后得到的脱硅精矿,其化学成分如表1所示。溶出实验所采用的铝酸钠溶液取自贵州某氧化铝工厂,其成分如表2所示。实验分析用水为去离子水,化学分析试剂为国药集团分析纯试剂。

表1 脱硅精矿化学组成(质量分数)

Table 1 Main chemical constituents mass fraction of desilicated concentrate %

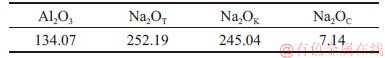

表2 溶出液化学组成及分析结果(质量分数)

Table 2 Main chemical constituents of digestion solution g/L

1.2 实验方法

溶出实验时向钢弹中加入80 mL铝酸钠溶液,再加入矿石及石灰,混匀密封后放入山东正威机械高压釜。溶出实验结束后取出钢弹,采用自来水冷却3 min,用100 °C去离子水洗涤矿浆至容量为500 mL的烧杯中。稀释后的矿浆采用真空泵过滤,同时用100 °C去离子水洗涤赤泥5~7次。过滤后得到赤泥,并将其放置于干燥箱中,于110 °C干燥12 h。将烘干的赤泥研磨,称取一定质量赤泥(15~20 mg)与氢氧化钠放置于银坩埚,马弗炉750 °C焙烧30 min。取出银坩埚放置于烧杯中,加入一定量温度为50 °C的去离子水与50 mL分析纯盐酸溶解,将溶液洗涤至500 mL容量瓶,定容、摇匀、静置至室温滴定分析。

1.3 溶出实验参数设置

溶出实验考察了温度、时间、石灰添加质量分数和苛碱质量浓度对脱硅精矿溶出性能的影响。基于现行工业生产参数及矿石特点,采取温度为260~285 °C;时间为45~75 min;石灰添加量为6%~12%;苛碱质量浓度为235~255 g/L进行研究。

2 结果与讨论

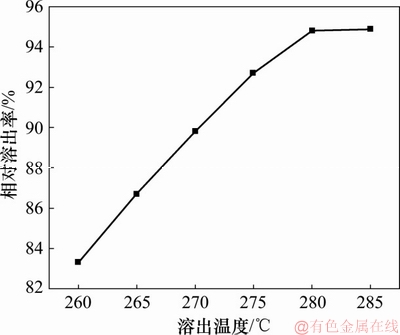

2.1 温度对氧化铝相对溶出率影响

氧化铝在溶出过程中,温度对溶出性能影响显著。在溶出时间为70 min,石灰添加质量分数为8%,苛碱质量浓度为245 g/L,Rp(配料比)为1.15条件下,研究温度对氧化铝溶出性能的影响,结果如图1所示。

图1 温度对Al2O3相对溶出率影响

Fig. 1 Effect of temperature on relative digestion ratio of Al2O3

从图1可以看出:当溶出温度为260 °C时,氧化铝相对溶出率为83.34%;当温度增加到270 °C时,氧化铝相对溶出率提高到89.81%;当温度增加到280 °C时,氧化铝相对溶出率达到最高值94.81%。这说明温度与氧化铝溶出率呈线性正相关。由式(1)及式(2)可知化学反应速率常数及扩散速率常数与温度密切相关。提高溶出温度,铝土矿颗粒表面的化学反应速度加快,液相反应物穿过液膜层立即与固相反应物发生反应。因此,从动力学上分析,提高溶出温度能够促进氧化铝的溶出。另一方面,在溶出过程中,矿球表面会有钛酸盐及铝硅酸盐薄膜,阻滞反应物及产物扩散。提高溶出温度,导致薄膜再结晶破裂,为化学反应及扩散提供有利场所[12-13]。

(1)

(1)

式中:E为化学反应活化能;R气体常数;K为化学反应速率常数;T为热力学温度;C为常数。

(2)

(2)

式中:D为扩散速率常数;μ为溶液黏度;δ为扩散层厚度;N为常数。

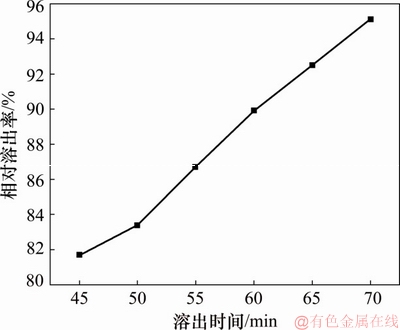

2.2 时间对氧化铝相对溶出率影响

理论上只要溶出时间足够长,矿石中的氧化铝能够完全溶出。在温度为280 °C,石灰添加量为8%,苛碱质量浓度为245 g/L,Rp为1.15条件下,研究时间对氧化铝相对溶出率的影响,结果如图2所示。

图2 时间对Al2O3相对溶出率影响

Fig. 2 Effect of time on relative digestion ratio of Al2O3

从图2可见:当溶出时间为45 min时,氧化铝相对溶出率为81.72%,说明矿石中大部分氧化铝已经溶出;随着溶出时间延长,氧化铝的相对溶出率缓慢增加,在70 min达到最高值95.15%;矿石反应过程中传质过程比较缓慢,随着时间的延长,反应界面面积逐渐减小,有利于CaO变成Ca(OH)2,提高溶出效果。

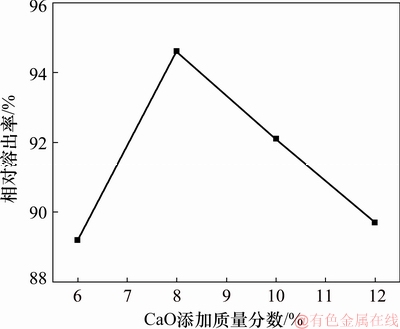

2.3 石灰添加质量分数对氧化铝相对溶出率的影响

在拜耳法溶出工艺中,添加适量的石灰有利于氧化铝的溶出,并减少赤泥中苛碱的质量浓度[14]。因此,在温度为280 °C,溶出时间为70 min,苛碱质量浓度为245 g/L, Rp为1.15条件下,研究不同石灰添加质量分数对氧化铝溶出性能影响,结果如图3所示。

图3 石灰添加质量分数对Al2O3相对溶出率影响

Fig. 3 Effect of lime addition on mass fraction relative digestion ratio of Al2O3

由图3可知:当石灰添加质量分数为6%~12%时,氧化铝的相对溶出率呈现先上升后下降的趋势。当添加质量分数为8%时,氧化铝的相对溶出率最高,达到94.63%;当石灰添加质量分数为12%时,氧化铝相对溶出率较低,其溶出率为89.73%。在拜耳法溶出过程中,添加石灰能够有效提高氧化铝相对溶出率及溶出速度。在溶出过程中,钛矿物会与碱反应形成钛酸钠吸附在颗粒表面形成薄膜,阻滞反应进行扩散,添加适量的石灰,在溶出过程中破坏钛酸钙或羟基钛酸钙薄膜,促进反应扩散。石灰添加质量分数过高,在溶出反应过程中生成铝硅酸钙进入赤泥,造成铝损失[15]。

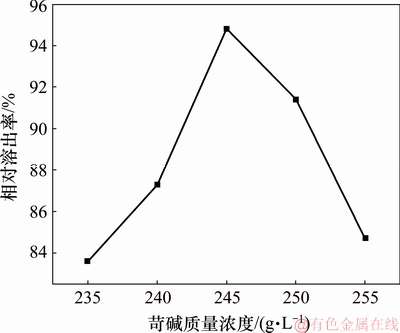

2.4 苛碱质量浓度对氧化铝相对溶出率的影响

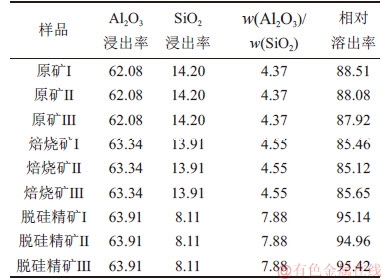

表3 Al2O3相对溶出率对比表

Table 3 Digestion ratio contrast about Al2O3 %

在其他条件一定的情况下,溶出液碱质量浓度越高,溶液未饱和程度越大,矿石中氧化铝溶出速度越快。溶出液碱质量浓度越高,导致其溶液的黏度增加,其扩散过程受到限制,氧化铝溶出性能受到影响,因此,需要选择适宜的苛碱质量浓度。在温度为280 °C,溶出时间为70 min,石灰添加质量分数为8%,Rp为1.15条件下,研究不同苛碱质量浓度对氧化铝溶出性能影响,结果如图4所示。

图4 苛碱质量浓度对Al2O3相对溶出率影响

Fig. 4 Effect of caustic acid mass concentration on relative digestion ratio of Al2O3

从图4可知:当苛碱质量浓度为235 g/L时,矿石氧化铝相对溶出率为83.64%;增加苛碱质量浓度为245 g/L时,氧化铝相对溶出率最高,达到94.85%;当苛碱质量浓度继续增加为255 g/L时,氧化铝的相对溶出率为84.79%。在一定条件下,溶出母液中较高或较低苛碱质量浓度导致矿石中氧化铝溶出性能较差。究其原因,苛碱质量浓度较低,溶液中氧化铝趋于饱和,在反应过程中,溶解矿石中的氧化铝有限。在高质量浓度苛碱条件下,苛碱及Al2O3 质量浓度增加导致溶液黏度过大,溶出过程中扩散速率降低。

2.5 溶出对比试验

为确定脱硅精矿的溶出性能,对比相同工艺条件下原矿、焙烧矿和脱硅精矿的溶出性能,在溶出温度为280 °C,苛碱质量浓度为245 g/L,时间为70 min,石灰添加质量分数为8%条件下进行实验。实验分析得到的溶出结果如表2所示。其中w(Al2O3)/w(SiO2)为氧化铝与二氧化硅质量分数比。从表2可见:脱硅精矿氧化铝相对溶出率最高达到95.14%,相比原矿提高了7.5%,相比焙烧矿提高了9.77%;脱硅精矿溶出液中硫质量浓度低于0.18 g/L,硫的实际溶出率为11.2%,表明低品位高硫铝土矿通过焙烧-碱浸脱硅溶出工艺,能够达到工业生产的要求。

2.6 表征分析

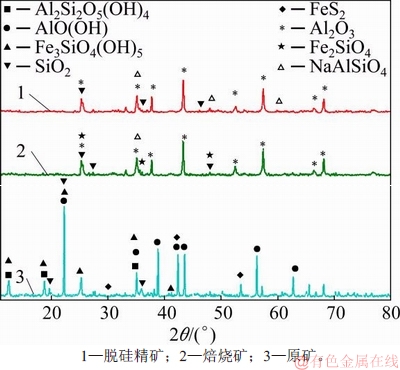

2.6.1 物相分析

图5所示为原矿、焙烧矿和脱硅精矿XRD图谱。由图5可知:原矿主要是由一水铝石、高岭石、二氧化硅、黄铁矿、绿锥石等物质组成;焙烧矿主要为氧化铝、二氧化硅、硅酸铁;精矿主要为氧化铝、铝硅酸钠、二氧化硅;焙烧矿中一水铝石、高岭石、绿锥石衍射峰消失,发生物相转变,如式(3)~(6)所示,一水铝石脱水生成氧化铝,高岭石分解得到铝尖晶石,部分黄铁矿氧化得到三氧化二铁,同时产生二氧化硫进入空气,绿锥石脱水生成硅酸铁[16-18]。对于式(4),高岭石分解得到铝尖晶石,但焙烧矿无此物相,表明该物相以非晶态形式存在。通过分析焙烧矿,其存在一定质量分数的硫矿物,说明黄铁矿并未完全氧化,发生式(5)反应。

(3)

(3)

(4)

(4)

(5)

(5)

(6)

(6)

图5 原矿、焙烧矿和脱硅精矿XRD衍射图谱

Fig. 5 XRD patterns of ore, roasted ore and desilication concentrate

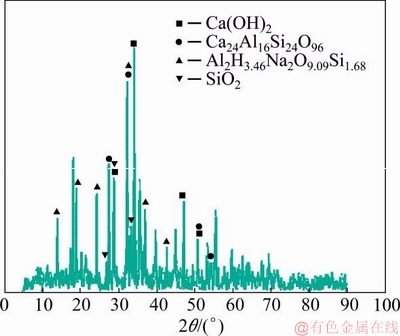

图6 脱硅精矿溶出赤泥XRD衍射图谱

Fig. 6 XRD patterns of digestion of red mud from desilicated concentrate

图6所示为脱硅精矿溶出赤泥的XRD衍射图谱,由图6可见:脱硅精矿溶出后赤泥主要是Ca(OH)2,CaO·Al2O3·SiO2和Na2O·Al2O3·xSiO2等物质组成;没有发现氧化铝的衍射峰,脱硅精矿能够有效溶出;赤泥中出现Ca(OH)2物相,说明石灰活性较差,部分CaO向Ca(OH)2转变时间较长,直接进入赤泥中[19];赤泥中存在着CaO·Al2O3·SiO2物相,说明部分石灰在拜耳法溶出过程中参与反应。在溶出过程中,含硅矿物及氧化铝与碱反应如式(7)和式(8)所示。由于溶出过程中添加了氧化钙,因此,在溶出过程中钙会将铝硅酸钠中的铝部分置换生成石榴石,其化学反应如式(9)所示。

(7)

(7)

(8)

(8)

(9)

(9)

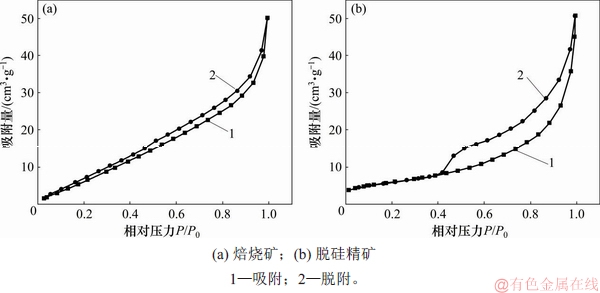

2.6.2 矿物吸附性能及形貌分析

图7所示为焙烧矿及脱硅精矿等温吸附曲线。由图7可知:根据IUPAC分类准则,焙烧矿与脱硅精矿为Ⅳ型吸附,在低于常压条件下分子冷凝填充了介孔孔道。首先在孔壁上环状吸附膜液面上产生毛细凝结吸附,而脱附是从孔口的球形弯月液面开始,因此,吸脱附等温线不相重合形成滞后环。曲线出现下凹是由于吸附质与吸附剂分子间的相互作用比较弱,在较低的吸附质浓度下,吸附平衡量比较小,在较高吸附质浓度下出现冷凝,可使吸附量大增,发生毛细冷凝导致曲线出现陡增[20]。焙烧矿滞后环中相对压力P/P0在0.2~1.0之间,因此,在低压条件下无吸附限制。脱硅精矿的滞后环P/P0在0.4~1.0之间,低压条件下吸附受到限制。

图7 N2等温吸附与脱附曲线

Fig. 7 Isothermal adsorption and desorption curves of N2

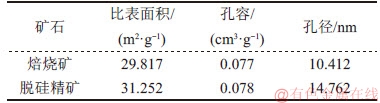

表4 矿石比表面积参数

Table 4 Specific surface area parameters of ore

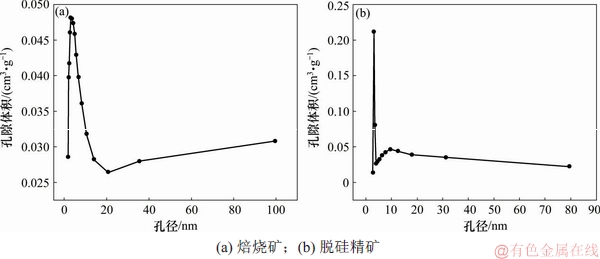

图8 氧化铝孔径分布

Fig. 8 Pore diameter distribution of Al2O3

图8所示为焙烧矿和脱硅精矿氧化铝孔径分布。由图8可知:焙烧矿孔径主要集中在2.7~9.5 nm之间,在3.4 nm时有1个明显峰,说明焙烧矿孔径3.4 nm分布居多。脱硅精矿中孔径主要集中在11.27~15.00 nm之间,在3.11 nm之间有明显的峰,说明脱硅精矿孔径3.11 nm分布居多,而且说明焙烧矿与脱硅精矿孔径以中孔为主。表4所示为通过氮气吸附采用不同方法计算得到的比表面积。由表4可知:焙烧矿的BET表面积为29.817 m2/g,累积孔容为0.077 cm3/g,平均孔径为10.412 6 nm;脱硅精矿的BET表面积为21.252 m2/g,累积孔容为0.078 cm3/g,平均孔径为14.762 nm。脱硅精矿的累积孔容与平均孔径大于焙烧矿,是由于在碱浸脱硅过程中,苛碱溶液与矿石发生反应,生成硅酸钠溶液及其他物质。

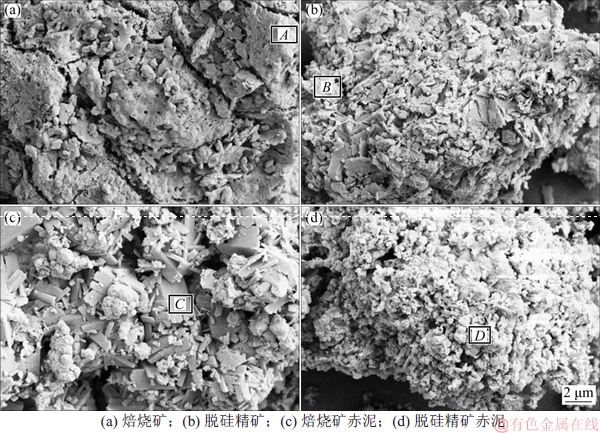

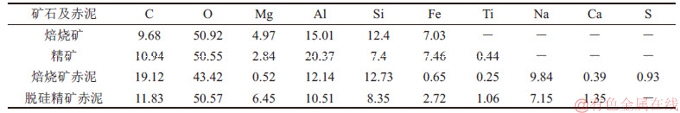

矿石和赤泥形貌如图9所示,图9中标注点处元素特征如表5所示。从图9可以看出:焙烧矿结构致密,部分区域有孔洞及裂纹,这是由于焙烧过程中脱水及脱硫矿石颗粒热应力过大。经过碱浸脱硅,矿石中部分氧化铝进入溶液,因此,脱硅精矿呈现厚度小于2 μm层状疏松结构,其比表面积增大。焙烧矿溶出呈现赤泥絮状及块状,但精矿溶出赤泥呈现褶皱状。

图9 矿石及赤泥SEM照片

Fig. 9 SEM images of ore and red mud

表5 矿石及赤泥元素组成(质量分数)

Table 5 EDS composition mass fraction of ores and red mud %

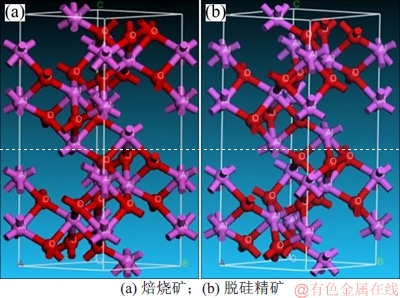

图10 氧化铝晶体结构模型

Fig. 10 Crystal structure models of Al2O3

2.6.3 电子结构

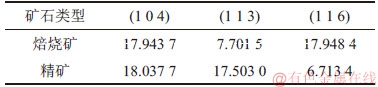

图10所示为氧化铝晶体结构模型。通过图5中XRD图谱分析氧化铝物相,精修得到表6与表7数据。表6所示为焙烧矿及脱硅精矿Al2O3晶体精修数据,由表6可知:精修指数与精修系数均小于要求特定值(15与1.5),说明精修数据合理。表7所示为Al2O3晶体参数,由表7可知:焙烧矿结晶度大于脱硅精矿。氧化铝三强锋对应的晶面分别为(1 0 4),(1 1 3)和(1 1 6),其中脱硅精矿(1 0 4)与 (1 1 6) 2个面晶粒粒径略大于焙烧矿,但(1 1 3)面对应的晶粒粒径相对焙烧矿减小。这是由于碱浸脱硅过程中,(1 1 3)面有极强吸附能,吸附溶液中NaOH反应生成铝酸钠,造成晶体粒径减小。

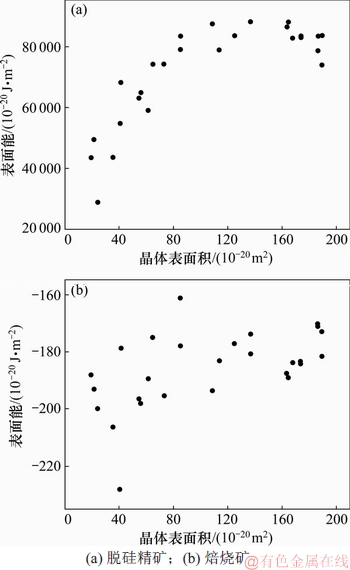

通过Materials Studio计算3个面与NaOH结合能、晶体表面积以及表面能,其结果如表8所示。从表8可知:(1 1 3)面与NaOH结合能为 7.701 5 kJ,相对低于(1 0 4)和(1 1 6)晶面与NaOH的结合能。因此,在脱硅反应过程中NaOH先与 (1 1 3)面Al2O3结合反应,使部分Al2O3进入溶液,其晶面尺寸减小。通过Materials Studio计算焙烧矿氧化铝晶体的表面积为55.20×10-20 m2,脱硅精矿氧化铝晶体的表面积为56.12×10-20 m2,经过脱硅后精矿氧化铝晶体膨胀。通过建立的2种模型计算晶体表面积与表面能的关系,结果如图11所示。图11(a)中脱硅精矿Al2O3晶体表面积由0×10-20 m2增加到120 ×10-20 m2时,其表面能逐渐增加,当超过120 ×10-20 m2时,表面能缓慢上升然后下降。从图11(b)可知:焙烧矿Al2O3晶体表面积增加其表面能变化不大。对比2个模型的计算结果,脱硅精矿氧化铝晶体表面能大于焙烧矿氧化铝晶体表面能。反应过程中表面能大,具有较强吸附能力,并通过吸附溶液中的离子降低表面能达到稳定状态。在碱浸过程中,NaOH与SiO2反应,同时会诱导部分Al2O3进行反应进入溶液中,未反应的Al2O3在脱硅过程中化学键发生变化。因此,基于密度泛函理论的第一性原理方法,计算模型的布局分布及电子结构。采用 Materials Studio8.1 计算软件包 CASTEP (cambridge serial total energy package)程序完成。Al2O3晶体中各原子轨道上电荷的分布如表9所示。

表6 焙烧矿及脱硅精矿Al2O3晶体精修数据

Table 6 Refining data of Al2O3 crystal from roasted ore and desilicated concentrate

图11 晶体表面积与表面能

Fig. 11 Crystal surface area and surface energy

表7 Al2O3晶体数据

Table 7 Crystal data of Al2O3

表8 Al2O3晶体不同晶面与苛碱结合能

Table 8 Binding energy between Al2O3 crystal plane and caustic surfacekJ/mol

从表9可知:Al2O3是典型的离子晶体,Al原子带正电荷,为+1.62,氧原子带负电荷为-1.08。这是由于费米能级附近的Al 原子和O原子轨道上的电子形成2 pσ和2 pπ成键轨道,电子之间有较强的相互关联作用,Al原子将丢失的外层电子转移到O原子的周围,因此,Al原子的大部分电子被O原子定域,Al和O之间形成较强的Al—O 离子键[21-22]。

表9 Al2O3晶体电子分布

Table 9 Electron distribution of Al2O3

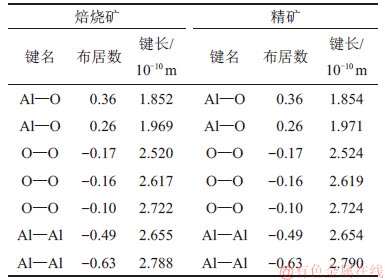

通过Materials Studio计算2种晶体模型,得到晶体的键长及键布居数如表10所示。由表10可知焙烧矿及脱硅精矿Al2O3晶体中均含有2种不同的Al—O键,这是由于在刚玉型结构中,[AlO6]八面体存在一定的畸变,这种变形结构会降低晶体的对称性,原子键长及原子的电荷量发生变化。O—O键之间的布居数为负值,这表明O—O键存在较大排斥力,O离子有向八面体外移动的趋势[23]。表10中精矿Al—O键长大于焙烧矿Al—O键长,因此,在反应过程中,精矿中Al—O极易被破坏重组参与反应。

表10 Al2O3晶体布居分布

Table 10 Population distribution of Al2O3 crystal

3 结论

1) 高硫铝土矿通过焙烧脱硫,碱浸脱硅后得到脱硅精矿,其溶出最佳条件如下:温度为280 °C,苛碱质量浓度为245 g/L,时间为70 min,石灰添加质量分数为8%。在此条件下,氧化铝相对溶出率达到95.14%。脱硅精矿溶出液中硫质量浓度低于0.18 g/L,硫的实际溶出率为11.2%。

2) 焙烧矿经过脱硅后,脱硅精矿其颗粒表面疏松多孔,比表面积增大为31.252 m2/g,孔容与孔径分别增至0.078 cm3/g和14.762 nm。

3) 焙烧矿Al2O3晶体结构中[113]面与NaOH结合能最低,极易反应,晶粒粒径减小为867.883 nm,晶体变大,间距减小。A—O键长相对于焙烧矿变大,在反应中极易被破坏。

参考文献:

[1] Word Aluminium. Primary aluminium production [EB/OL]. [2019-04-25]. http://www.world-aluminium.org/statistics/

[2] 吕国志. 利用高硫铝土矿生产氧化铝的基础研究[D]. 沈阳: 东北大学材料与冶金学院, 2010: 7-8.

LU Guozhi . Basic research on alumina production by using high-sulfur bauxite[D]. Shenyang: Institute of Materials and Metallurgy, Northeast University, 2010: 7-8.

[3] LI Xiaobin, LI Chongyang, PENG Zhihong, et al. Interaction of sulfur with iron compounds in sodium aluminate solutions[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(2): 608-614.

[4] LI Xiaobin, NIU Fei, LIU Guihua, et al. Effects of iron-containing phases on transformation of sulfur-bearing ions in sodium aluminate solution[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(4): 908-916.

[5] CHAI Qinqin, YANG Chunhua,Kok L T, et al. Optimal control of an industrial-scale evaporation process: sodium aluminate solution[J]. Control Engineering Practice, 2012, 20(6): 618-628.

[6] HU Xiaolian, CHEN Wenmi, XIE Qiaoling. Sulfur phase and sulfur removal in high sulfur-containing bauxite[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(7): 1641-1647.

[7] KONG Xiangfeng, JIANG Xingxing, XUE Shengguo, et al. Migration and distribution of saline ions in bauxite residue during water leaching[J]. Transactions of Nonferrous Metals Society of China, 2018, 28(3): 534-541.

[8] PAN Xiaolin, YU Haiyan, TU Ganfeng, et al. Effects of precipitation activity of desilication products (DSPs) on stability of sodium aluminate solution[J]. Hydrometallurgy, 2016, 165: 261-269.

[9] 赵博, 陈延信, 酒少武, 等. 高硫铝土矿悬浮态焙烧及焙烧矿的溶出性能[J]. 中南大学学报(自然科学版), 2016, 47(9): 2929-2935.

ZHAO Bo, CHEN Yanxin, JIU Shaowu, et al. Suspended roasting of high sulfur bauxite and leaching performance of roasted ore[J]. Journal of Central South University (Science and Technology), 2016, 47(9): 2929-2935.

[10] LIU Zhanwei, LI Dunyong, MA Wenhui, et al. Sulfur removal by adding aluminum in the bayer process of high-sulfur bauxite[J]. Minerals Engineering, 2018, 119: 76-81.

[11] CHAI Wencui, HUANG Yanfang, PENG Weijun, et al. Enhanced separation of pyrite from high-sulfur bauxite using 2-mercaptobenzimidazole as chelate collector: Flotation optimization and interaction mechanisms[J]. Minerals Engineering, 2018, 129: 93-101.

[12] 李小斌, 余顺文, 董文波, 等. 锐钛矿对氧化铝溶出性能的影响及其机理[J]. 中国有色金属学报, 2014, 24(11): 2864-2871.

LI Xiaobin, YU Shunwen, DONG Wenbo, et al. Effect and mechanism of anatase on digestion performance of alumina[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(11): 2864-2871.

[13] DUDEK K, JONES F, RADOMIROVIC T, et al. The effect of anatase, rutile and sodium titanate on the dissolution of boehmite and gibbsite at 90 °C[J]. International Journal of Mineral Processing, 2009, 93(2): 135-140.

[14] PAN Xiaolin, YU Haiyan, DONG Kaiwei, et al. Pre-desilication and digestion of gibbsitic bauxite with lime in sodium aluminate liquor[J]. International Journal of Minerals, Metallurgy and Materials, 2012, 19(11): 973-977.

[15] 潘晓林, 于海燕, 涂赣峰, 等. 石灰对三水铝石型铝土矿低温溶出行为的影响[J]. 东北大学学报(自然科学版), 2013, 34(4): 551-555.

PAN Xiaolin, YU Haiyan, TU Ganfeng, et al. Effect of lime on digestion of gibbsitic bauxites at low temperature[J]. Journal of Northeastern University (Natural Science), 2013, 34(4): 551-555.

[16] 魏存弟, 马鸿文, 杨殿范, 等. 煅烧煤系高岭石的相转变[J]. 硅酸盐学报, 2005, 33(1): 77-81.

WEI Cundi, MA Hongwen, YANG Dianfan, et al. Phase transformation for calcined coal measures kaolinite[J]. Journal of the Chinese Ceramic Society, 2005, 33(1): 77-81.

[17] 胡小莲, 陈文汨, 谢巧玲. 高硫铝土矿氧化焙烧脱硫研究[J]. 中南大学学报(自然科学版), 2010, 41(3): 852-858.

HU Xiaolian, CHEN Wenmi, XIE Qiaoling. Desulfuration of high sulfur bauxite by oxidation roasting[J]. Journal of Central South University (Science and Technology), 2010, 41(3): 852-858.

[18] CHEN Yanxin, LIU Peiyu, ZHAO Bo, et al. Experiment on alkali leaching desilication of high silicon bauxite suspension roasted ore [J]. Light Metal, 2017(11): 19-24.

[19] 毕诗文. 氧化铝生产工艺[M]. 北京: 化学工业出版社, 2006: 92-93.

BI Shiwen, YU Haiyan. Alumina production process [M]. Version 1. Beijing: chemical Industry Press, 2006: 92-93.

[20] HE Yusheng, LI Zhong, XI Hongxia, et al. Research progress of gas-solid adsorption isotherms [J]. Ion Ex-change and Adsorption, 2004, 20(4): 376-384.

[21] 谭训彦, 王昕, 尹衍升, 等. α-Al2O3的晶体结构与价电子结构[J]. 中国有色金属学报, 2002, 12(S1): 18-23.

TAN Xunyan, WANG Xin, YIN Yansheng, et al. Crystal structure and valence electron structure of α-Al2O3[J]. The Chinese Journal of Nonferrous Metals, 2002, 12(S1): 18-23.

[22] 常秋香, 刘廷禹, 马昌敏. 第一性原理和热力学计算预测α-Al2O3中缺陷的稳定性[J]. 中国科学: 化学, 2016, 46(4): 394-400.

CHANG Qiuxiang, LIU Tingyu, MA Changmin. Prediction of the stability of point defects in a-Al2O3 from first-principles and thermodynamic calculations[J]. Scientia Sinica (Chemica), 2016, 46(4): 394-400.

[23] 汝强, 邱秀丽. 第一性原理计算α-Al2O3电子结构及力学性能[J]. 材料研究与应用, 2009, 3(3): 162-167.

RU Qiang, QIU Xiuli. The electronic structure and mechanical property of α-Al2O3 by first principles calculation[J]. Materials Research and Application, 2009, 3(3): 162-167.

(编辑 秦明阳)

收稿日期: 2019 -01 -17; 修回日期: 2019 -04 -20

基金项目(Foundation item):国家自然科学基金资助项目(U1812402, 51774102, 51574095, 51564003);贵州省科技平台及人才团队建设计划项目([2015] 4005,黔教合KY字[2015]334号) (Projects (U1812402, 51774102, 51574095, 51564003) supported by the National Natural Science Foundation of China; Projects(Talent Team Giant [2015] 4005, KY[2015]334) supported by Talents of Guizhou Science and Technology Cooperation Platform)

通信作者:李军旗,博士,教授,从事氧化铝研究;E-mail:jqli@gzu.edu.cn