DOI: 10.11817/j.issn.1672-7207.2016.08.006

高硫铝土矿悬浮态焙烧脱硫

陈延信,赵博,酒少武,吴锋,韩丁

(西安建筑科技大学 材料与矿资学院,陕西 西安,710055)

摘要:采用自主开发的高固气比悬浮焙烧-快速冷却装置对贵州地区硫质量分数为1.35%的高硫铝土矿进行850 kg/h规模的焙烧脱硫实验。探讨悬浮态焙烧对脱硫过程和焙烧矿的影响规律。对硫物相和XRD谱进行分析。研究结果表明:悬浮态低温焙烧可实现高硫铝土矿的快速脱硫,升高焙烧温度有利于提高脱硫率;硫化物型硫的残留量降至0.08%(质量分数)之后,脱硫过程趋于完成;FeS2脱硫反应伴随着金属氧化物吸收SO2的反应,细颗粒对SO2具有更强的吸收能力;高硫铝土矿粉料在悬浮炉内的有效停留时间约2 s,焙烧炉内温度控制在610~640 ℃,焙烧矿中硫化物型硫质量分数可以降低到0.16%以下。低温闪速焙烧-冷却使得偏高领土呈高度无序的非晶相结构,相对于原料中的一水硬铝石,焙烧矿中的α-Al2O3晶体得到细化,有利于Al2O3的溶出。

关键词:高硫铝土矿;悬浮态焙烧;脱硫率;硫物相

中图分类号:TF803.1 文献标志码:A 文章编号:1672-7207(2016)08-2577-07

Desulfurization roasting of high sulfur bauxite in suspended state

CHEN Yanxin, ZHAO Bo, JIU Shaowu, WU Feng, HAN Ding

(School of Materials and Mineral Resources, Xi′an University of Architecture and Technology, Xi’an 710055, China)

Abstract: Desulfurization roasting of high sulfur bauxite (S mass fraction of 1.35%) from Guizhou province was employed by high solid-gas roasting-cooling device, with feeding capacity of 850kg/h. The influence of desulfurization process and roasted ore in suspended state roasting was investigated. Sulfur phase analysis and X-ray diffraction analysis were carried out. The results show that the sulfur content in high sulfur bauxite is rapidly decreased through low- temperature suspended state roasting, and the desulfurization efficiency is improved with higher temperature. The desulfurization reaction tends to be complete after sulfide sulfur mass fraction decreases to 0.08%. The reaction of metal-oxide absorbing SO2 is accompanied with the desulfurization of FeS2, and fine particles have better absorbing capacity of SO2. The best roasting temperature of high sulfur bauxite in suspended state is between 610 ℃ to 640 ℃ and the effective residence time in the flash calciner is about 2 s. The sulfide sulfur mass fraction decreases to less than 0.16%. The metakaolin forms a highly disordered amorphous structure during the flash roasting-cooling process. Relative to diaspora in raw ore, the crystal of α-Al2O3 is refined by roasting to the benefit of the leaching of Al2O3.

Key words: high-sulfur bauxite; suspended roasting; desulfurization rate; sulfur phase

我国铝土矿储量中高硫型铝土矿约占资源储量的11%,约5.6亿t[1]。高硫铝土矿是指硫质量分数大于0.7%的铝土矿,其中硫主要以黄铁矿(FeS2)形式存在。黄铁矿在铝酸钠溶液中会转化成为SO32-,S2O32-和S22-等形态,不仅造成Na2O的损失,而且溶液中的S22-质量分数提高后会使钢材受到腐蚀,增加溶液中铁的质量分数,使得Al2O3溶出率和品位因为铁的污染而下降,降低氧化铝的产能和产品质量;生成的硫酸盐在适宜条件下与碳酸钠形成复盐析出,造成蒸发和分解工序的结疤,降低了反应器的传热系数[2-5]。因此,在拜耳法生产氧化铝工艺中,对矿石中的硫质量分数要求低于0.7%。目前国内外针对高硫铝土矿的脱硫研究主要有湿法和火法2类,湿法研究主要是浮选除硫,每吨氧化铝脱硫成本为160~180元。火法脱硫研究主要是通过对高硫铝土矿的焙烧脱硫和添加剂焙烧展开的,焙烧还可以提高铝土矿的溶出活性;国内学者对回转炉焙烧、沸腾炉焙烧和流化床焙烧等密相焙烧方法在实验室中进行了较多的研究,但需在750~850 ℃焙烧10~30 min,所得焙烧矿才能够满足后续工段对硫质量分数的要求[6-10]。相对于密相床,在稀相悬浮态气-固系统中,气固两相接触面积大,传热、传质和反应速率高。本文作者在实验室焙烧实验和中试探索性实验的基础上,开展高硫铝土矿的悬浮态焙烧脱硫中试研究,以期得到优化的焙烧条件,在较短的焙烧时间和最低焙烧能耗下实现良好的脱硫效果,为高硫铝土矿悬浮态焙烧连续性扩大实验提供主要的工艺操作参数。

1 实验

1.1 原料与燃料

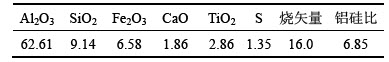

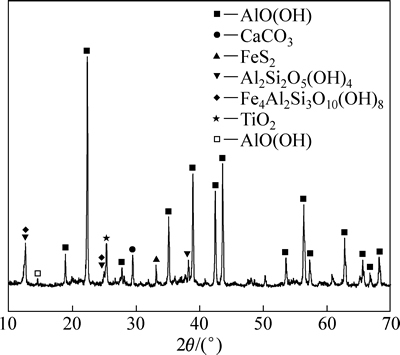

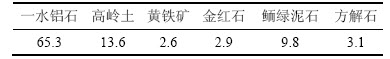

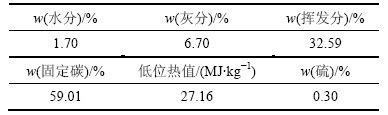

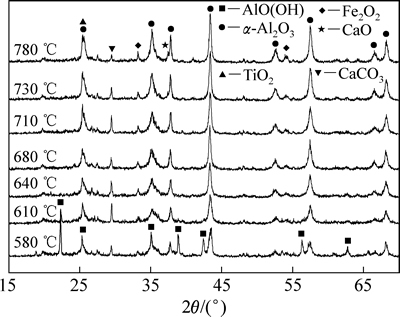

高硫铝土矿取自贵州某地,矿石经破碎粉磨后,水分质量分数为2.6%,筛分结果显示粒径75 μm筛下量占45.2%,125 μm筛上量占20.5%。表1所示为原料的化学元素分析结果,所用仪器为德国布鲁克公司S4-Pioneer型X线荧光光谱仪,S质量分数采用硫酸钡重量法测定。物相分析所用仪器为日本理学(RIGAKU)生产的D/MAX2200型X线衍射仪(Cu靶,扫描速率为10 (°)/min,2θ为5°~70°),图1所示为该高硫铝土矿的XRD谱,结合化学元素分析结果对原料进行矿物相定量分析,各矿物相质量分数如表2所示。实验所用燃料为神府煤田粉煤,表3所示为煤粉的工业分析结果。

表1 贵州高硫铝土矿化学组成及烧减量分析结果(质量分数)

Table 1 Chemical composition and ignition loss of Guizhou high sulfur bauxite %

图1 贵州高硫铝土矿XRD图谱

Fig. 1 XRD pattern of Guizhou high sulfur bauxite

表2 贵州高硫铝土矿矿物组成(质量分数)

Table 2 Mineral composition of Guizhou high sulfur bauxite %

表3 煤粉的工业分析结果(空气干燥基)

Table 3 Technical analysis of coal powder (ad)

1.2 实验装置

自制的高硫铝土矿高固气比悬浮态焙烧实验装置由喂料系统、悬浮预热系统、外循环式悬浮焙烧炉、旋风冷却系统、收尘器、引风机、喂煤喂料系统和燃煤热风炉等组成,引风机为系统提供运行动力,整个系统在负压状态下运行。悬浮焙烧炉直径×长度为0.4 m×9 m,喂料和喂煤装置均为自制的回转式变频微粉给料机,喂料机的喂料量为0~2 m3/h,喂煤机的喂煤量为0~0.5 m3/h。粉煤经气力输送装置进入燃煤热风炉,热风炉产生的高温烟气经沉降除尘后进入悬浮炉。在悬浮焙烧炉进出口配以TestoXL360便携式烟气分析仪、在各预热器出口和悬浮煅烧炉关键工艺控制点安装ABB压力变送器与一体化温度变送器,通过LabVIEW数据采集系统实时监测整个系统的工况。悬浮炉内风速测定仪器为S型标准皮托管和KIMO手持式微差压计。

实验装置的料流路线:喂料装置将高硫铝土矿粉料送至高固气比悬浮预热系统中预热器C1的换热管,粉料与上升热气流在换热管中迅速完成换热,在C1筒体中气固分离后沿C1下料管进入预热器C2A的换热管。粉料依次通过各级预热器进行预热,顺序为C1→C2A→C2B→ C3A→ C3B,多个预热器形成料路交叉、气路并联的系统,使100%的物料与50%的气流交换热量,旋风预热器内的固气比可以提高到1倍左右,从而提高了系统的换热效率;粉料通过C3B的下料管进入悬浮焙烧炉底部,在热风炉高温烟气的携带下于炉中进行脱水和脱硫反应,悬浮炉采用选择性的体外循环方式,让部分粗重颗粒在旋流分离器的作用下进入悬浮焙烧炉中循环反应,提高了悬浮炉的热稳定性、出炉物料的反应率和单位容积产量;高温焙烧矿最后进入分离器C4完成气固分离,再通过C4下料管进入旋风冷却系统,经过两级旋风冷却,C4→CC1→CC2,焙烧矿进入产品料槽。

实验装置的气流路线:在炉尾引风机的作用下,热风炉产生的高温烟气进入悬浮焙烧炉中完成高硫铝土矿的焙烧,出炉烟气在C4中完成气固分离后分两路平行进入预热器系统,其路径分别为:C4→C3A→C2A→C1A和C4→C3B→C2B→C1B,两股烟气在C1出口汇合,进入总风管→袋收尘器→引风机;冷空气经旋风冷却系统的CC2和CC1进入悬浮焙烧炉的底部,与热风炉产生的高温烟气汇合。

1.3 实验方法

实验时,首先对系统进行升温蓄热,待炉内达到一定温度后开始投料,初始投料量300 kg/h,通过调整喂煤量、系统总风量、冷却系统风量和投料量,使炉内温度达到预期设定值范围内。系统稳定运行时,投料量为(850±10) kg/h,共进行7个温度下的焙烧实验,分别是580,610,640,680,710,730和780 ℃,以上温度点是指悬浮焙烧炉中部温度,能够代表反应器中的平均温度,每个温度点下的稳定运行5 h左右。系统工况稳定时,间隔10 min对焙烧产品进行取样,冷却后密封作分析之用。

1.4 分析方法

采用X线荧光能谱仪结合X线衍射仪分析对高硫铝土矿的焙烧效果进行分析和表征。具体方法为:通过XRF检测焙烧矿的主要元素,通过XRD检测分析焙烧矿的物相组成和微晶结构;采用硫酸钡重量法测定总硫和硫酸盐的质量分数,硫化物型硫的质量分数采用差减法求得。

2 结果与讨论

一水硬铝石型高硫铝土矿在氧化焙烧过程中主要发生一水铝石、高岭石等含结晶水矿物的脱水吸热和黄铁矿氧化脱硫放热反应。采用多重升温速率实验方法对铝土矿样品进行热分析及红外光谱仪联用分析,测试分析铝土矿中矿物组分的脱水和脱硫过程。热分析采用耐驰409PC-TG-DSC同步分析仪,红外分析采用布鲁克FTIR-7600型红外光谱仪。热分析测试的条件为:样品量为5.5~5.8 mg,温度范围50~850 ℃,气氛为N2+8%O2(体积分数)混合气氛,气体流量为85 mL/min。表4所示为升温速率为10 ℃/min时高硫铝土矿各反应主要温度拐点。由表4可以看出:2种反应的起始温度相近,最大反应速率的拐点温度相差约16 ℃,这说明一水硬铝石型高硫铝土矿在升温过程中脱水反应的温度区间和脱硫反应的温度区间存在相当大的重合区域,脱水吸热和脱硫放热过程基本同步进行。

表4 升温速率为10 ℃/min时高硫铝土矿脱硫和脱水反应的拐点温度

Table 4 Turning point temperature of dehydration reaction and desulphurization reaction with 10 ℃/min

不同升温速率下的热分析表明:随着升温速率的提高,脱水和脱硫反应温度区间向高温区偏移,相应的拐点温度差距基本保持不变。相对于密相床,在稀相悬浮态焙烧系统中,气体与颗粒之间接触良好,反应界面大,热质边界层传递动力大,其传热、传质系数往往超过密相床2个数量级[11-12]。粉料进入悬浮炉后能够与气相快速完成换热。理论计算表明,在固体颗粒充分分散的过程中,固相颗粒仅在加速段的起始区即完成了99.5%的换热量[13]。因此在悬浮态下,高硫铝土矿脱硫脱水反应最大速率所对应的温度会比热分析中对应的温度高。

焙烧矿中全硫的质量分数并不能准确表达焙烧脱硫的效果,所以在考察焙烧效果时,引入总脱硫率(η)和硫化物型硫的脱硫率(η′)的概念,以氧化铝为固定基(忽略煤灰带入产品中的氧化铝和氧化硅杂质)来计算脱硫率。总脱硫率和硫化物型硫脱硫率的表达式如下:

(1)

(1)

(2)

(2)

式中:η为总脱硫率,%;η′为硫化物型硫脱硫率,%; 为焙烧矿中的硫质量分数,%;

为焙烧矿中的硫质量分数,%; 为原料中的硫质量分数,%;w(AOR)为焙烧矿中氧化铝质量分数,%;w(AOO)为原料中氧化铝质量分数,%;

为原料中的硫质量分数,%;w(AOR)为焙烧矿中氧化铝质量分数,%;w(AOO)为原料中氧化铝质量分数,%; 为焙烧矿中硫化物型硫质量分数;

为焙烧矿中硫化物型硫质量分数; 为原料中硫化物型硫质量分数。

为原料中硫化物型硫质量分数。

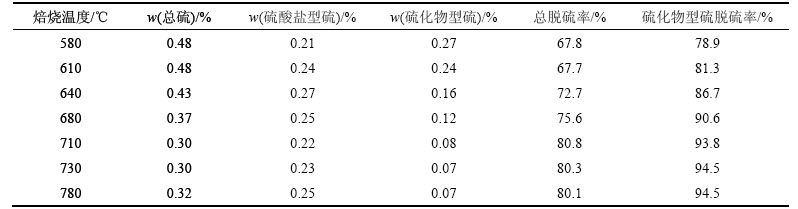

表5 不同焙烧温度下焙烧矿中硫的分析结果

Table 5 Sulfur analysis results of roasted ore under different temperatures

将每个焙烧温度下的数个焙烧矿样品各取一定量进行缩分混匀,分别进行主要元素分析、XRD分析和硫物相分析。表5所示为不同焙烧温度下中试焙烧矿硫物相的分析结果。

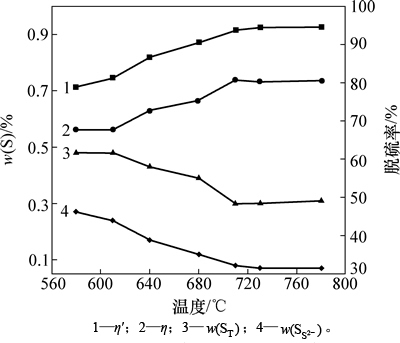

2.1 悬浮态焙烧温度对脱硫的影响

根据焙烧矿中硫的分析结果绘制的硫质量分数和脱硫率随焙烧温度升高的趋势如图2所示。在焙烧实验控制的从580~780 ℃这7个温度段内,高硫铝土矿粉料在悬浮炉内停留2 s左右都可以完成高硫铝土矿的快速脱硫,达到良好的脱硫效果。总脱硫率η和硫化物型硫脱硫率η′随着焙烧温度的升高而提高,从580 ℃到710 ℃,η和η′快速提高,分别从67.8%和78.9%提高到80.8%和93.8%;焙烧温度达到710 ℃之后,焙烧矿中总硫质量分数 降低至0.30%,硫化物型硫质量分数

降低至0.30%,硫化物型硫质量分数 小于0.08%,η和η′分别达到80.8%和94.5%左右,温度继续升高对η′影响较小,反倒会增加焙烧矿中硫酸盐质量分数。

小于0.08%,η和η′分别达到80.8%和94.5%左右,温度继续升高对η′影响较小,反倒会增加焙烧矿中硫酸盐质量分数。

图2 焙烧矿中硫质量分数和脱硫率随焙烧温度升高的趋势图

Fig. 2 Trend figure of sulfur mass fraction and desulfurization in roasted ore with temperature variation

η和η′之所以呈现上述趋势,从硫物相分析结果可以看出:随着焙烧温度的提高,焙烧矿中硫化物型硫质量分数是随之降低的,而硫酸盐型硫质量分数是先增加后减少再增加,拐点分别出现在640 ℃左右和710 ℃左右。原料中硫酸盐型硫质量分数仅为0.07%,在原料烧减完全、无外界硫侵入的情况下,焙烧矿中硫酸盐型硫质量分数最高只能达到0.083%,但是在7个焙烧温度下得到的焙烧矿中的硫酸盐型硫质量分数为0.21%,说明有外界硫进入焙烧矿中转化成硫酸盐。在高硫铝土矿焙烧过程中,FeS2与O2反应会产生SO2,燃煤烟气中也携带SO2,焙烧过程产生的Fe2O3和高温焙烧产生的CaO都具有与SO2发生化合反应的活性。

吴菊贤等[14]研究氧化铁吸收SO2的反应机理时发现:氧化铁在380~580 ℃温度区间具有良好的吸收固硫效果,α-Fe2O3的固硫效果最好,产物为Fe2(SO4)3,硫酸铁从600 ℃开始发生分解,生成Fe2O3,SO3和SO2。稀相悬浮态焙烧时,气固两相处在一个高度发展的剧烈扰动接触状态,热、质边界层窄,反应界面大,传热传质速率高,反应产物活性高,FeS2脱硫生成的高活性Fe2O3与SO2化合生成的硫酸铁也会相对稳定,Fe2O3,SO2和硫酸铁三相平衡共存温度,也就是硫酸铁表观分解温度会相对较高,导致640 ℃左右成为硫酸铁的分解拐点。

高硫铝土矿的热分析(10 ℃/min)及红外光谱仪联用分析结果显示,700 ℃左右CaCO3开始分解,不同焙烧温度下焙烧矿的XRD图谱如图3所示。由图3可以看出:焙烧温度为710,730和780 ℃的焙烧矿中出现了CaO的衍射峰,焙烧温度越高CaO的衍射峰强越明显。CaO易与SO2化合生成CaSO4,是一种良好的固硫剂。在硫酸铁开始明显分解后,CaO参与到固硫作用中,导致硫化物型硫质量分数随着焙烧温度升高呈现先提高—后降低—再提高的现象。由于焙烧矿中硫酸铁和硫酸钙的质量分数较少,且二者显峰能力较弱,使其XRD峰不能明显观察到。

图3 不同焙烧温度下焙烧矿的XRD图谱

Fig. 3 XRD patterns of roasted ore at different temperatures

2.2 不同粒级物料的脱硫特性

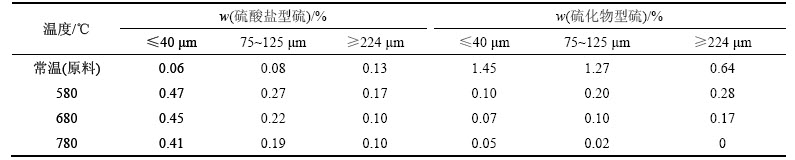

分别对3个温度下的焙烧矿进行筛分,对不同粒级的物料进行了硫物相分析,结果如表6所示。

从表6可以看出:相对于原料中粗颗粒,原料中细颗粒(特别是粒度≤40 μm的细粉)中硫化物型硫质量分数高,硫酸盐型硫质量分数相对较低。随着焙烧温度的提高,粒度≤40 μm的细粉能够快速接近脱硫终点,580 ℃时硫化物型硫已经实现95%的脱硫率。细物料比表面积大,硫质量分数高,在悬浮态焙烧时反应速率较高,可以实现快速脱硫和脱水反应,反应生成高孔隙率的细粒和相对大量的活性Fe2O3,与SO2能够快速进行化合反应,致使细粉快速接近吸收固硫的终点;随着焙烧温度的升高,CaCO3逐渐分解生成活性CaO参与到固硫作用中。粒度≥224 μm的粗物料中硫化物型硫质量分数低,颗粒尺寸大,气固两相传热传质阻力大,呈现出较弱的反应活性,脱硫速率相对缓慢,其吸收固硫作用也较弱。

2.3 焙烧脱硫对铝土矿的影响

高硫铝土矿在稀相悬浮态下快速完成了脱硫和脱水反应。一水铝石和高岭石是主要的含铝矿物,脱水后分别转变为α-Al2O3和Al2O3·2SiO2,这2种反应产物的化学活性直接影响Al2O3的溶出性能和产品质量。对图1和图3进行对比可以发现:焙烧矿中α-Al2O3的衍射峰(2θ为35.3°,43.4°,57.4°和68.2°) 宽阔而弥散,锯齿波增加,说明结晶较好的一水硬铝石脱水形成了晶粒细小或者有晶体缺陷的α-Al2O3;Al2O3·2SiO2在焙烧矿衍射图谱中没有明显的衍射峰或者“非晶包”(2θ介于15°~30°之间),非晶相的物质难以有晶格振动峰,说明偏高岭石以非晶化程度极高的无序结构存在于焙烧矿中。造成这种结果的原因是,在稀相悬浮态下,矿石脱水和焙烧矿冷却过程在数秒内连续完成,闪速焙烧和冷却使得α-Al2O3和偏高岭石处于温度急剧变化的生长环境中,温度在空间和时间方向的梯度很大,α-Al2O3难以形成具有稳定结构的规则晶体;高岭石原有的铝氧八面体结构被严重破坏,非晶化程度急剧增加,高岭石晶体转化成高度无序的非晶相偏高岭土。

通过XRD检测对一水硬铝石和氧化铝的微晶结构进行分析,利用谢乐(Scherrer)公式计算出微晶结构参数Dhkl,其表达式为

(3)

(3)

式中:Dhkl为微晶在垂直于晶面(hkl)方向上的尺寸; K为参数,取0.89;λ为辐射的波长,按Kα1的波长计算,对于铜靶,其值为0.154 056 nm;θ为半衍射角;β为衍射峰的加宽, ,B为样品的衍射峰宽(FWHM),b为仪器物理宽度。

,B为样品的衍射峰宽(FWHM),b为仪器物理宽度。

表6 焙烧矿中各粒级硫物相分析结果

Table 6 Sulfur phase analysis result in different size fraction of roasted ore

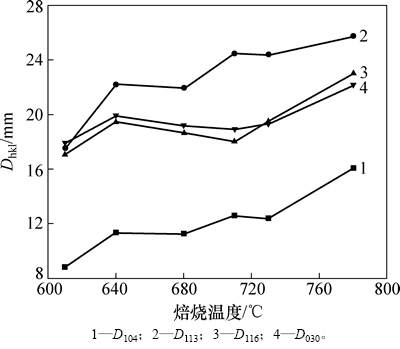

原矿中一水硬铝石的各向微晶尺寸都大于100 nm。图4所示为α-Al2O3微晶尺寸随焙烧温度T变化的趋势图。

图4 焙烧矿中α-Al2O3微晶尺寸随焙烧温度变化的趋势图

Fig. 4 Trend figure of microcrystallites size in roasted ore with temperature variation

闪速焙烧脱水使得一水硬铝石晶体细化,焙烧矿中α-Al2O3微晶在垂直于晶面104,113,116和030面的尺寸处于纳米级。随着焙烧温度的提高,微晶平均尺寸由610 ℃的15 nm增加到780 ℃的21 nm,且各向微晶尺寸呈近乎线性的增加趋势,说明相对低温的闪速焙烧和冷却有利于α-Al2O3晶体的细化。高硫铝土矿稀相悬浮态低温闪速焙烧得到的偏高岭石是高度无序的非晶相结构,α-Al2O3晶体细化,反应活性大大提高;在加碱溶出时,反应界面增大。在两者的共同作用下,有利于提高Al2O3溶出率。

在选择高硫铝土矿的焙烧温度时,应兼顾脱硫率和焙烧矿的反应活性,避免高温下焙烧,在焙烧矿中硫化物型硫达到质量要求的前提下,选择合适的较低焙烧温度,保证焙烧矿中含铝矿物的反应活性,不仅有利于提高Al2O3溶出率,也有利于降低焙烧能耗。工业实践表明:高硫铝土矿中硫化物型硫质量分数小于0.2%时,硫化物对后续溶出工序的影响基本可以消除[15]。从实验分析结果来看:对于实验中采用的中试装置,高硫铝土矿的焙烧温度宜选取在610~640 ℃之间。

2.4 悬浮态焙烧时间

悬浮态焙烧实验结果表明:相对于回转炉焙烧、沸腾炉焙烧和流化床焙烧,悬浮态焙烧能够在数秒内实现高硫铝土矿的快速脱硫,实验中粉体物料在悬浮炉内的有效停留时间约为2 s。对于高固气比悬浮态焙烧-快速冷却装置而言,粉体物料在悬浮炉内的有效停留时间在一定范围内是可以灵活设置的。悬浮炉尺寸一定的情况下,针对特定粉体物料,通过改变粗分离器的结构尺寸调整粉体物料的入炉循环量实现有效停留时间的调整,物料入炉循环量的调整范围为10%~40%。本次实验中设置粗分离器循环量为25%±2%,在后续实验工作中可以适当增加粉料的循环量,延长粗颗粒物料在悬浮炉内的有效停留时间,这样可以设置更低的焙烧温度,在降低焙烧能耗的同时以期增强焙烧矿的溶出活性。

3 结论

1) 采用高固气比悬浮态焙烧-快速冷却实验装置对贵州地区硫质量分数为1.35%的高硫铝土矿进行焙烧脱硫实验,粉料在炉内的有效停留时间2 s左右,悬浮炉内温度高于580 ℃,可以实现该高硫铝土矿的快速高效脱硫,高硫铝土矿的最优焙烧温度宜选取在610~640 ℃之间,焙烧矿中硫化物型硫质量分数可以降低到0.16%以下。

2) 对于该高硫铝土矿,随着焙烧温度的升高,总脱硫率和硫化物型硫脱硫率总体呈现提高的趋势,焙烧矿中硫化物型硫质量分数降至0.08%后,提高焙烧温度基本不会对脱硫率的增加有所影响;新生Fe2O3和CaO能够吸收SO2形成硫酸铁和硫酸钙,低温下生成的硫酸盐是硫酸铁,高温下硫酸铁分解,CaO成为主要的固硫物;相对于粗颗粒,高硫铝土矿粒度≤40 μm的细粉对SO2具有较高的固硫活性。

3) 高硫铝土矿稀相悬浮态闪速焙烧得到的偏高岭石是高度无序的非晶相结构,一水铝石晶体转化成微米级的α-Al2O3微晶,难以形成具有稳定结构的α-Al2O3完整晶体,低温焙烧比高温焙烧更有利于细化α-Al2O3晶体,加碱溶出时,反应界面增大,有利于提高Al2O3溶出率。

参考文献:

[1] 彭欣, 金立业. 高硫铝土矿生产氧化铝的开发与应用[J]. 轻金属, 2010(11): 14-17.

PENG Xin, JIN Liye. Development and application of bauxite containing high sulfur[J]. Light Metals, 2010(11): 14-17.

[2] ZHANG Nianbing, LI Zhiying, GUO Peili. Desulfurization mechanism and application of high sulfur bauxite[J]. Metalurgia International, 2013, 18(3): 29-32.

[3] 谢巧玲, 陈文汨, 杨权平. 4种钢在含硫拜耳液中的腐蚀性为[J]. 中南大学学报(自然科学版), 2014, 45(8): 2560-2565.

XIE Qiaoling, CHEN Wenmi, YANG Quanping. Corrosion behavior of four kinds of steels in sulfide-containing Bayer liquor[J]. Journal of Central South University (Science and Technology), 2014, 45(8): 2560-2565.

[4] PIETERSE J A Z, VAN EIJK S, VAN DIJK H A J, et al. On the potential of absorption and reactive adsorption for desulfurization of ultra low-sulfur commercial diesel in the liquid phase in the presense of fuel additive and bio-diesel[J]. Fuel Processing Technology, 2011, 92(3): 616-623.

[5] ZHOU Qiusheng, LI Xiaobin, PENG Zhihong. Temperate dependence of crystal structure and digestibility of roasted diaspore[J]. Transactions of Nonferrous Metals Society of China, 2004, 14(1): 180-183.

[6] HU Xiaolian, CHEN Wenmi, XIE Qiaoling. Sulfur phase and sulfur removal in high sulfur-containing bauxite[J]. Transaction of Nonferrous Metals Society of China, 2011, 21(7): 1641-1647.

[7] 胡小莲, 陈文汩, 谢巧玲. 高硫铝土矿氧化焙烧脱硫研究[J]. 中南大学学报(自然科学版), 2010, 41(3): 852-857.

HU Xiaolian, CHEN Wenmi, XIE Qiaoling. Desulfuration of high sulfur bauxite by oxidation roasting[J]. Journal of Central South University (Science and Technology), 2010, 41(3): 852-857.

[8] 吕志国, 张庭安, 鲍丽. 高硫铝土矿的焙烧预处理及焙烧矿的溶出性能[J]. 中国有色金属学报, 2009, 19(9): 1685-1689.

L Guozhi, ZHANG Tingan, BAO Li. Roasting pretreatment of high-sulfur bauxite and digestion performance of roasted ore[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(9): 1685-1689.

Guozhi, ZHANG Tingan, BAO Li. Roasting pretreatment of high-sulfur bauxite and digestion performance of roasted ore[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(9): 1685-1689.

[9] 王一雍, 张庭安, 鲍丽. 一水硬铝石矿活化焙烧工艺研究[J]. 东北大学学报(自然科学版), 2009, 30(8): 1166-1169.

WANG Yiyong, ZHANG Tingan, BAO Li. Study on roasting process of diasporic bauxite[J]. Journal of Northeastern University (Natural Science), 2009, 30(8): 1166-1169.

[10] XU Bingan, SMITH P, DE SILVA L. The Bayer digestion behaviour of transition aluminas formed from roasted gibbsite[J]. International Journal of Mineral Processing, 2013, 122: 22-28.

[11] 郭慕孙, 李洪钟. 流态化手册[M]. 北京: 化学工业出版社, 2008: 228.

KWAUK Mooson, LI Jinghai. Manual of fluidization[M]. Beijing: Chemical Industry Press, 2008: 228.

[12] LI Jinghai, KWAUK Mooson. Particle-fluid two-phase flow[M]. Beijing: Metallurgical Industry Press, 1994: 60-66.

[13] 陈延信. 粉体高固气比换热与反应系统的研究与开发[D]. 西安: 西安建筑科技大学材料与矿资学院, 2011: 165-179.

CHEN Yanxin. Research and development on high solid-gas ratio heat transfer and reaction system of powder[D]. Xi’an: Xi’an University of Architecture and Technology. School of Materials sand Mineral Resources, 2011: 165-179.

[14] 吴菊贤, 刘世斌, 韩镇海. 氧化铁吸收SO2的反应机理[J]. 硫酸工业, 1990(5): 18-23.

WU Juxian, LIU Shibin, HAN Zhenhai. Reaction mechanism of iron absorbing SO2[J]. Sulphuric Acid Industry, 1990(5): 18-23.

[15] 杨权平, 吕鲜翠. 高硫铝土矿生产冶金级氧化铝的工业实践[J]. 轻金属, 2012(7): 10-12.

YANG Quanping, L Xiancui. The industrial practice of producing metallurgical grade alumina from high sulfur bauxite[J]. Light Metals, 2012(7): 10-12.

Xiancui. The industrial practice of producing metallurgical grade alumina from high sulfur bauxite[J]. Light Metals, 2012(7): 10-12.

(编辑 杨幼平)

收稿日期:2015-08-09;修回日期:2015-12-25

基金项目(Foundation item):“十二五”国家科技支撑计划项目(2012BAA08B00)(Project (2012BAA08B00) supported by the National Science and Technology Pillar Program during the 12th “Five-Year” Plan Period)

通信作者:陈延信,副教授,从事气固两相换热与反应工程研究;E-mail:lilolmln@163.com