DOI:10.19476/j.ysxb.1004.0609.2019.10.20

黔北务正道地区铝土矿焙烧脱硫及溶出性能的提升

周剑飞1,赵 博2,陈延信2,何 伟3,韩 丁2

(1. 西南能矿集团股份有限公司,贵阳 550004;

2. 西安建筑科技大学 材料科学与工程学院,西安 710055;

3. 遵义能矿投资股份有限公司,遵义 563000)

摘 要:提出了一种新的工艺路线—“闪烁焙烧+精矿拜耳法”,研究矿物物相变化和热分析,对焙烧脱硫过程中的重要参数(焙烧温度和焙烧时间)进行系统优化,全面提升焙烧精矿在拜耳法工艺中的溶出性能。结果表明:在活化焙烧温度为550 ℃、炉内停留时间为1.6 s的条件下,所得焙烧矿中硫化物型硫的平均质量分数约为0.05%,脱硫率达到95.2%,且后续溶出试验效果明显优于原矿的;在溶出温度270 ℃、溶出时间60 min、石灰添加量14%、苛性碱质量浓度245 g/L且配料苛性碱与氧化铝的摩尔比为1.40的条件下,焙烧矿相对溶出率可达到95%以 上,相比原矿的提高2%~3%。研究成果为加快推进高硫铝土矿的高效产业化利用提供了一种新工艺及相关基础数据。

关键词:高硫铝土矿;闪烁焙烧;精矿拜尔法;脱硫率;溶出率

文章编号:1004-0609(2019)-10-2394-09 中图分类号:TF803.1 文献标志码:A

我国铝土矿资源匮乏,可采储量约10亿t,仅占世界铝土矿资源的3%~4%,静态可采年限仅为14 a。国内已探明铝土矿资源储量中的一水硬铝石高硫型铝土矿储量占总储量的14%[1],其中约42%的中低品位高硫高硅铝土矿基本处于未开采、未利用状态[2]。我国高硫铝土矿远景储量达20亿t[3],主要分布于河南、贵州、广西、重庆与山东等省份[4],其中铝硅比为4~7的铝土矿中一半以上为高硫铝土矿[5]。据统计2017年我国氧化铝产能增至6901万t,占全球氧化铝产能56%左右,铝土矿进口量达到52%左右[2]。随着高品位铝土矿日益枯竭,高硫铝土矿占国内总储量的比例逐渐增大,全球贸易摩擦导致矿产资源国际局势多变。因此,加大铝土矿资源勘查及高硫铝土矿的开发利用成为保障我国铝工业持续发展的有效途径。在高硫铝土矿开发利用的地域中,贵州北部地区(黔北务正道地区)中低品位高硫铝土矿占有重要地位。

黔北务正道地区铝土矿资源丰富,是全国第一批47个整装勘查区之一[6]。目前,已发现铝土矿矿床24个,探明大型铝土矿矿床13个,铝土矿资源量已突破7亿t[7]。随着务正道地区铝土矿资源的深入勘查,高硫铝土矿储量逐渐“增加”,以一水硬铝石高硫型为主,其特点为中高铝、中高硅、高硫与中低铝硅比。行业内铝土矿硫含量低于0.5%才满足拜耳法工业生产要求[8],硫元素主要以黄铁矿(FeS2)的形式存在[9],生产过程中以 、

、 、

、 与

与 形态在铝酸钠溶液中分解,不仅造成Na2O的损失,还造成设备腐蚀,并使Al2O3溶出率与品位下降;另一方面,生成的硫酸盐在适宜条件下会与碳酸钠形成复盐析出,造成蒸发和分解工序结疤,降低反应器的传热系数[10-11]。

形态在铝酸钠溶液中分解,不仅造成Na2O的损失,还造成设备腐蚀,并使Al2O3溶出率与品位下降;另一方面,生成的硫酸盐在适宜条件下会与碳酸钠形成复盐析出,造成蒸发和分解工序结疤,降低反应器的传热系数[10-11]。

目前,国内外针对高硫铝土矿的脱硫研究主要有浮选脱硫、过程脱硫、生物脱硫与焙烧脱硫[12-13]等。浮选脱硫脱硫率低、成本高,浮选药剂因不同地区铝土矿的适应性不一;过程脱硫适合于硫含量≤0.5%的中硫铝土矿,但会造成生产设备腐蚀;回转窑、沸腾炉和流化床等堆积态焙烧工艺耗时长、温度高、能耗大,需在750~850 ℃焙烧10~30 min才能够满足后续生产要求[14]。近年来,新研发的闪烁焙烧工艺可使物料实现快速脱硫与活化反应,其气固相接触面积大,传热传质速率比传统堆积态反应速率提高1~3个数量级。矿石中大部分硫、有机物等有害杂质能被快速除去,一水硬铝石与高岭石中含铝物相转变成不定型氧化铝,提升了后续溶出及赤泥沉降性能,提高了Al2O3回收率。

本文作者针对黔北务正道地区高硫铝土矿,提出了一种新的工艺路线—“闪烁焙烧+精矿拜耳法”,研究矿物物相、进行热分析,对焙烧脱硫过程中的重要参数(焙烧温度和焙烧时间)进行系统优化,全面提升焙烧精矿在拜耳法工艺中的溶出性能,为加快推进高硫铝土矿的高效产业化利用提供一种新工艺及配套基础参数。

1 实验

1.1 原料

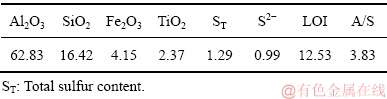

高硫铝土矿样品经破碎、粉磨至粒径<75 μm占75%±5%(质量分数)。对粉矿样品缩分取样,样品水份含量为1.90%(质量分数)、灼减量为12.53%(质量分数)。表1所列为矿样的化学元素分析结果,其中硫元素含量采用《硫酸钡重量法》测定、三氧化二铝含量采用《EDTA滴定法》测定、二氧化硅含量采用《钼蓝光度法》测定。

表1 高硫铝土矿化学组成及灼减量

Table 1 Chemical composition and burning reduction of high-sulfur bauxite (mass fraction, %)

取一定量粉料进行X射线衍射分析,所用仪器为日本理学(RIGAKU)生产的D/MAX2200型X射线衍射仪(Cu靶,扫描速率10 (°)/min,2θ角度5°~90°),结合元素化学分析方法和德国布鲁克公司S4-Pioneer型X射线荧光光谱仪的元素定量分析结果,对图谱和数据进行综合分析得知:原矿含铝矿物主要以一水铝石为主,一水硬铝石占48%(质量分数),一水软铝石占16%(质量分数);含硅矿物主要以高岭石和石英为主,两者占18%(质量分数),另铝硅酸盐矿物占14%(质量分数);含钛矿物为锐钛矿,占2%(质量分数);含硫矿物为黄铁矿,占3%,具体见表2。

表2 高硫铝土矿物相组成

Table 2 High sulphur bauxite phase composition (mass fraction, %)

1.2 试验方法

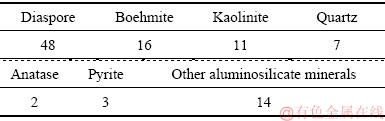

本文研究内容主要为高硫铝土矿“闪烁焙烧脱硫、精矿拜耳法溶出”两部分,重点研究物相、化学成分变化规律及最佳工艺参数等关键指标,试验流程如图1所示。

图1 “闪烁焙烧-精矿拜尔法”工艺流程图

Fig. 1 Process flow diagram of “flash roasting-concentrate Bayer process”

1.2.1 焙烧试验

闪烁焙烧工艺特点主要表现为热传递面积大、综合传递系数大与传递动力大。粉状物料以悬浮态进入炉内,物料与空气接触面积大幅度增大,气固传质边界层变薄,气固界面温差增大,从而形成巨大的传输动力,在很短的时间内快速完成脱硫与活化反应[15]。

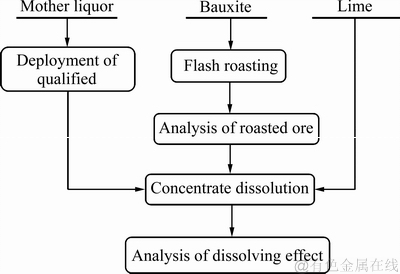

焙烧试验采用自主研发的焙烧小试系统,工作温度范围0~1100 ℃、处理能力20 kg/h。系统主要由给料机、热风炉、悬浮焙烧炉、电辅热系统、旋风分离器、袋式除尘器及电气控制系统等构成(见图2)。试验方法:将原矿粉料在500、550、600和650 ℃ 4个温度段进行焙烧,每个温度设置0.89、1.14和1.6 s 3个焙烧停留时间,共获得12个焙烧矿样,待冷却至室温后取样编号保存,分析在不同温度、时间条件下的焙烧样品的全硫和硫酸盐含量,研究焙烧过程中的复合反应特征。

图2 焙烧系统构成图

Fig. 2 Roasting system composition diagram

1.2.2 溶出试验

溶出试验采用高压溶出试验设备—钢弹式高压釜,型号ZWYYL120-06,釜体个数6个,每个釜体容积100 mL,工作压力15.75 MPa,工作温度350 ℃,转速45 r/min,加热功率18 kW。试验方法为:按照配料要求,将一定比例母液、铝土矿及石灰加入钢弹中,搅匀矿浆后加盖密封,装在可旋转运动的钢弹架中,再放入已升至预定温度的熔盐浴中并立即搅拌。当达到预定时间后,取出钢弹,立即放入水中骤冷,再采用真空抽滤进行固液分离,分析溶出液与赤泥的化学成分,计算Al2O3的溶出率。本试验模拟产业化生产状态,在溶出温度240~280 ℃、溶出时间40~80 min、CaO 掺入量8%~16%(质量分数)、Na2Ok浓度225~265 g/L的状态区间内,考察分析原矿和焙烧矿的溶出效果。

2 结果与讨论

2.1 热分析

高硫铝土矿在中低温(400~700 ℃)氧化焙烧过程中主要发生水铝石、硅铝酸盐等矿物的脱羟吸热反应和黄铁矿脱硫放热反应[16],如式(1)、(2)和(3)所示。

一水硬铝石脱水反应:

Al2O3·H2O→Al2O3+H 2O (1)

高岭石脱水反应:

Al2O3·2SiO2·nH2O→Al2O3·2SiO2+H 2O (2)

黄铁矿氧化反应:

FeS2+O2→Fe2O3+SO2 (3)

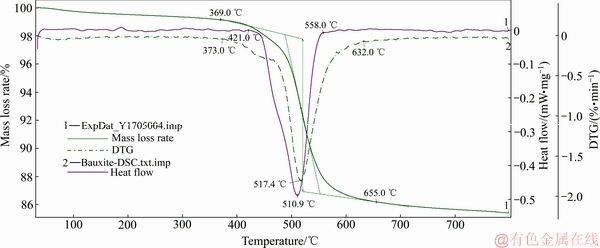

使用NETZSCH 409PC TG-DSC同步分析仪,采用多重升温速率试验方法对铝土矿样品进行热分析,分析测试铝土矿中矿物组分的脱水、脱硫和分解过程。热分析测试条件为:90% N2+10% O2(体积分数),升温速率10 ℃/min,样品量5.7 mg。测试得到的TG、DTG、DSC分析图谱如图3所示。

从图3中可以看出,样品从373.0 ℃开始发生质量损失,大约到630.0 ℃结束,反应最大的质量损失率出现在517.4 ℃。DSC曲线表明,总体反应为吸热,明显的吸热从421.0 ℃开始到558.0 ℃结束。结合高硫铝土矿中各矿物相的反应特性,从其DTG曲线和DSC曲线可以看出质量损失主要是一水铝石(和高岭石)的脱水造成的,脱水反应的起始温度在373.0 ℃左右,517.4 ℃左右达到最大脱水速率,632.0 ℃左右脱水反应完成。从DSC曲线上明显可以看出,421.0 ℃左右高硫铝土矿开始对外吸热,DSC曲线上出现明显的吸热曲线,表明有明显吸热反应开始。在510.9 ℃时,DSC曲线上出现一个对外热效应速率的最大值,这是反应初期吸热速率和脱水吸热速率相差最大的温度点,此后吸热逐渐减弱,至558.0 ℃时本阶段反应结束。

2.2 焙烧试验分析

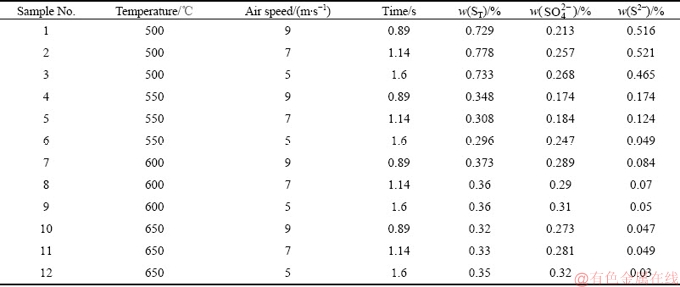

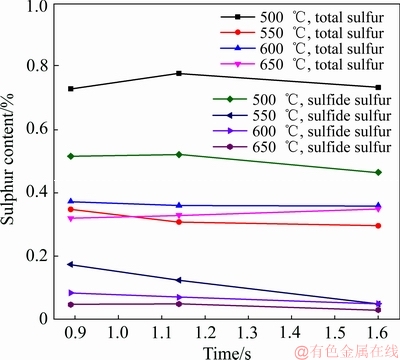

采用X射线荧光能谱仪结合X射线衍射仪对焙烧矿样进行分析和表征。具体方法为:通过XRF检测焙烧矿主要元素;通过XRD检测分析焙烧矿物相组成和微晶结构;采用硫酸钡重量法测定总硫和硫酸盐的质量分数,通过差减法求得ST、 、S2-含量,如表3所示;同时,根据试验数据得到,不同焙烧温度条件下全硫与硫化物型硫含量与焙烧时间的关系图,如图4所示。

、S2-含量,如表3所示;同时,根据试验数据得到,不同焙烧温度条件下全硫与硫化物型硫含量与焙烧时间的关系图,如图4所示。

从表3和图4可以看出,随着焙烧温度的上升与焙烧时间的延长,全硫与硫化物型硫含量逐渐降低,焙烧温度影响权重大于焙烧时间。其中,500 ℃焙烧矿含硫量随焙烧时间延长未有显著降低,全硫含量大于0.7%(质量分数)、硫化物型硫含量大于0.5%(质量分数),均达不到脱硫要求,说明500 ℃不利于铝土矿快速脱硫;550 ℃以上焙烧矿的全硫含量小于0.5%(质量分数)、硫化物型硫含量小于0.3%(质量分数),均满足氧化铝生产要求,其中550 ℃焙烧矿对焙烧时间的延长最为敏感。当焙烧时间达到1.6 s时,550、600和650 ℃焙烧矿的硫化物型硫含量均达到0.1%(质量分数)以下。焙烧后期的全硫含量逐渐趋于稳定,主要由于硫化物型硫在高温下快速氧化为SO2,随着硫化物型硫含量的减少,全硫含量在焙烧后期趋于稳定。

图3 铝土矿的TG-DTG-DSC谱

Fig. 3 TG-DTG-DSC curves of bauxite

表3 温度、时间对脱硫效果的影响

Table 3 Effect of temperature and time on desulfurization

图4中部分温度的全硫曲线呈现先升后降的趋势,随着焙烧时间延长,硫酸盐硫含量出现小幅度上升,该现象是由于铝土矿在较低焙烧温度和较短焙烧时间状态下,脱硫反应生成的SO2与原料发生吸附生成不稳定的亚硫酸盐,从而导致硫酸盐型硫含量升高,原料中的硫酸盐可分为两类[17]:一类是在600 ℃以下发生分解的硫酸盐,另一类是在650 ℃左右发生分解的硫酸盐[18]。

图4 全硫/硫化型硫含量随焙烧时间的变化趋势图

Fig. 4 Variation trend of total sulfur/sulfide type sulfur content with roasting time

硫含量是表征焙烧矿中硫元素高低的重要指标,在考察焙烧时间和焙烧温度对脱硫效果的影响规律时,用脱硫率来表征脱硫效果[19]。引入全硫脱硫率( )和硫化物型硫脱硫率(

)和硫化物型硫脱硫率( )的概念,以氧化铝为固定基来计算脱硫率。全硫脱硫率和硫化物型硫脱硫率的表达式分别如式(4)和(5)所示:

)的概念,以氧化铝为固定基来计算脱硫率。全硫脱硫率和硫化物型硫脱硫率的表达式分别如式(4)和(5)所示:

(4)

(4)

(5)

(5)

式中: 为总脱硫率,%;

为总脱硫率,%; 为硫化物型硫脱硫率,%;

为硫化物型硫脱硫率,%; 为焙烧矿中的硫质量分数,%;

为焙烧矿中的硫质量分数,%; 为原矿中的硫质量分数,%;

为原矿中的硫质量分数,%; 为焙烧矿中Al2O3质量分数,%;

为焙烧矿中Al2O3质量分数,%; 为原矿中Al2O3质量分数,%;

为原矿中Al2O3质量分数,%; 为焙烧矿中硫化物型硫质量分数;

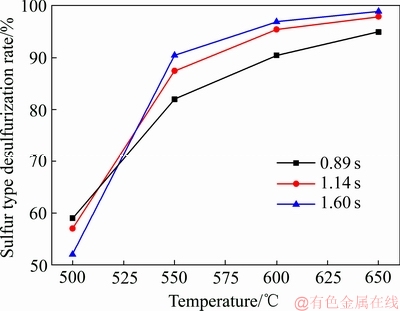

为焙烧矿中硫化物型硫质量分数; 为原矿中硫化物型硫质量分数。根据上述公式计算得到焙烧矿硫化物型硫脱硫率与焙烧温度、焙烧时间的关系图,如图5所示。

为原矿中硫化物型硫质量分数。根据上述公式计算得到焙烧矿硫化物型硫脱硫率与焙烧温度、焙烧时间的关系图,如图5所示。

图5 不同焙烧时间条件下硫化物型硫脱硫率随温度的变化趋势

Fig. 5 Change trend of sulfur desulfurization rate with temperature under different roasting times

焙烧矿硫化物型硫脱硫率随焙烧温度增加而逐渐增大,最大值为97.10%。在反应前期,脱硫率上升幅度较大,550 ℃以后幅度变缓,基本稳定在90%以上。焙烧时间较长时,硫化物型硫脱硫率在600~650 ℃范围内基本无明显变化,说明在一定焙烧时间下或者在硫化物型脱硫率达到90%以后,提高焙烧温度并不能显著提高硫化物型脱硫率。该现象主要因为黄铁矿氧化为扩散控制过程,残余硫脱除需要更长的时间。综上分析,建议按照焙烧时间1.6 s、焙烧温度550 ℃所得焙烧矿进行后续溶出试验为佳。

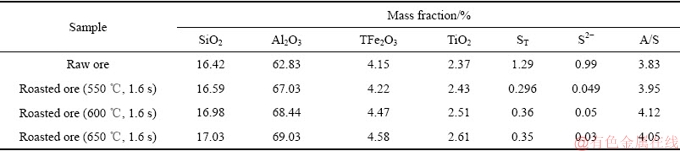

表4 原矿与焙烧矿样品化学成分

Table 4 Chemical composition of raw ore and roasted ore samples

2.3 物相与成分分析

对原矿与焙烧时间1.6 s条件下的550、600、 650 ℃焙烧矿4个样品进行化学元素分析,如表4所示,高温环境下原矿中硫、有机物及易分解组分等从矿石中排出,焙烧矿中Al2O3和SiO2含量相比原矿有所升高。550、600、650 ℃焙烧矿中S2-均达到0.1%以下,铝硅比从3.83上升到4.1左右。

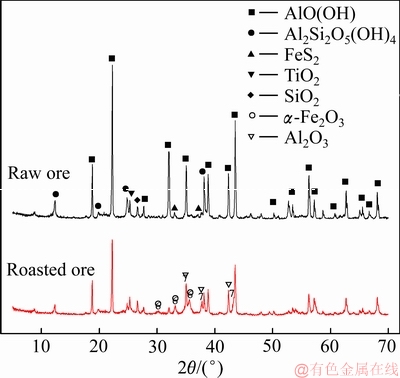

图6所示为原料与焙烧时间1.6 s条件下550 ℃焙烧矿的XRD谱。原矿在550 ℃焙烧系统中完成了黄铁矿氧化、菱铁矿氧化、部分高岭石和一水硬铝石脱水等反应。通过XRD谱不难发现:焙烧矿中高岭石的特征衍射峰基本消失,说明高岭石脱水反应基本完成;一水硬铝石特征衍射峰的峰高明显减小,说明部分一水硬铝石完成了脱水反应;黄铁矿特征衍射峰完全消失,赤铁矿特征衍射峰明显,说明黄铁矿氧化反应完成。

图6 原料与550 ℃(1.6 s)焙烧矿的XRD谱

Fig. 6 XRD patterns of raw material and 550 ℃(1.6 s) roasted ore

2.4 溶出试验分析

经焙烧脱硫处理后,矿石表面裂纹增大、疏松,有利于后续溶解,同时将矿石中的针铁矿转化为赤铁矿,改善了其沉降性能[20]。对原矿与550 ℃焙烧矿进行溶出温度、溶出时间、CaO添加量与苛碱浓度的单因素对比试验,摸索最优工艺参数组合,以达到最佳溶出性能。试验用铝酸钠溶液取自贵州某铝业公司的蒸发原液和蒸发母液,石灰取自贵州某铝业公司,其有效CaO含量大于80%(质量分数)。

溶出温度是影响氧化铝溶出率最主要的因素,首先考察溶出温度对矿石溶出效果的影响。试验固定条件:Na2Ok浓度235 g/L,CaO添加量6%(质量分数),溶出时间60 min,配料苛性碱与氧化铝的摩尔比为1.40。原矿、焙烧矿Al2O3相对溶出率与溶出温度的变化趋势如图7所示。结果显示,溶出温度对氧化铝溶出率的影响非常敏感,焙烧矿溶出效果优于原矿。溶出温度240 ℃时,原矿与焙烧矿的Al2O3相对溶出率为63.33%和72.76%;当温度升高到270 ℃时,相对溶出率分别提高到92.67%与95.88%,提高幅度为30%~45%,说明原矿与焙烧矿均需较高温度才可获得理想溶出率。溶出温度大于270 ℃,Al2O3溶出率上升幅度较小,溶出动力不足,产业化生产过程中将会增加能耗和设备负担。因此,选择溶出温度270 ℃作为下步试验条件。

图7 溶出温度对Al2O3溶出率的影响

Fig. 7 Effect of temperature on dissolution rate of Al2O3

考察溶出时间对矿石溶出效果的影响。试验固定条件:溶出温度270 ℃,Na2Ok浓度235 g/L,CaO添加量为6%,配料苛性碱与氧化铝的摩尔比为1.40。原矿、焙烧矿Al2O3相对溶出率与溶出时间的变化趋势如图8所示。结果显示,溶出时间对原矿与焙烧矿Al2O3溶出率的影响较小。溶出时间40 min时,原矿与焙烧矿Al2O3相对溶出率分别为86.32%与88.76%;从40 min延长到60 min,其相对溶出率分别提高到92.86%与95.11%,说明适当延长溶出时间,Al2O3溶出更加完善。继续延长溶出时间,Al2O3相对溶出率基本不变,甚至有下降趋势,说明原矿与焙烧矿在60 min时,Al2O3的溶出已基本完成。因此,选取溶出时间60 min作为下步试验条件。

图8 溶出时间对Al2O3溶出率的影响

Fig. 8 Effect of dissolution time on relative dissolution rate of Al2O3

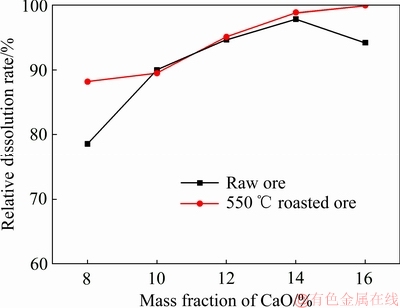

考察 CaO添加量对矿石溶出效果的影响。结合溶出温度和溶出时间试验结果,试验固定条件:溶出温度270 ℃,Na2Ok浓度235 g/L,溶出时间60 min,配料苛性碱与氧化铝的摩尔比为1.40。原矿、焙烧矿Al2O3相对溶出率与CaO添加量的变化趋势如图9所示。结果显示,CaO添加量对原矿与焙烧矿Al2O3溶出率影响较显著,焙烧矿溶出效果优于原矿。随着CaO添加量的增加,原矿与焙烧矿Al2O3相对溶出率明显提高。CaO添加量为14%(质量分数)时,原矿与焙烧矿Al2O3相对溶出率分别达到97.83%与98.86%,且原矿溶出率出现高位拐点。因此,选取CaO添加量14% (质量分数)作为下步试验条件。

图9 CaO添加量对矿石Al2O3溶出率的影响

Fig. 9 Effect of CaO content on relative dissolution rate of Al2O3

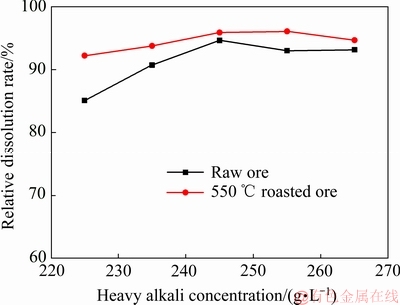

图10 苛碱浓度对矿石Al2O3溶出率的影响

Fig. 10 Effect of heavy alkali concentration on relative dissolution rate of Al2O3

考察苛碱浓度对原矿溶出效果的影响。试验固定条件:溶出温度270 ℃,CaO添加量为14%,溶出时间60 min,配料苛性碱与氧化铝的摩尔比为1.40。原矿、焙烧矿Al2O3相对溶出率与苛碱浓度的变化趋势如图10所示。结果显示,苛碱浓度对原矿与焙烧矿的Al2O3溶出率影响较显著,焙烧矿溶出效果优于原矿。随着苛碱浓度的增加,溶出率出现了先上升后下降的走势。苛碱浓度245 g/L 时,原矿相对溶出率达到94.62%峰值。焙烧矿在苛碱浓度245~255 g/L时走势上升缓慢,Al2O3相对溶出率为95.88%~96.07%。考虑到产业化生产实际,选取苛碱浓度245 g/L为宜。

3 结论

1) 高硫铝土矿Al2O3含量为62.83%、A/S为3.83,ST含量为1.29%,硫化物型硫含量为0.99%;原矿含铝矿物以一水铝石为主,一水硬铝石占48%,一水软铝石占16%;含硅矿物以高岭石和石英为主,两者占18%,其他铝硅酸盐矿物占14%;含钛矿物为锐钛矿,占2%;含硫矿物为黄铁矿,占3%。

2) 闪烁焙烧脱硫试验表明:经过高温处理,原矿中硫、有机物及易分解组分得到有效脱出,铝硅比A/S由3.83增加到4.0,在550 ℃及以上焙烧温度下,1~ 2 s内完成高硫铝土矿快速脱硫。硫化物型硫含量降到0.1%以下,黄铁矿氧化、菱铁矿氧化、部分高岭石和一水硬铝石的脱水等反应充分。

3) 精矿拜耳法溶出试验表明:相同工艺条件下,550 ℃焙烧矿溶出效果优于原矿的,相比原矿溶出率提高2%~3%,说明矿石经焙烧后,起到脱硫、脱有机质与活化含硅矿物的功效。溶出温度、溶出时间、CaO添加量、苛碱浓度与溶出率呈正比关系,但在试验条件区间后期,出现上升滞缓,甚至有下降趋势。

4) 通过反复摸索得到适宜溶出条件为:溶出温度270 ℃、CaO添加量14%、苛碱浓度245 g/L、溶出时间60 min、配料苛性碱与氧化铝的摩尔比为1.40,Al2O3相对溶出率可达到95%以上。

REFERENCES

[1] 彭 欣, 金立业. 高硫铝土矿生产氧化铝的开发与应用[J]. 轻金属, 2010(11): 14-17.

PENG Xin, JIN Li-ye. Development and application of alumina production from high-sulfur bauxite[J]. Light Metal, 2010(11): 14-17.

[2] 谢振山, 李军旗, 陈朝轶, 兰苑培. 中低品位高硫铝土矿焙烧脱硅研究[J]. 有色金属(冶炼部分), 2018(7): 13-16.

XIE Zhen-shan, LI Jun-qi, CHEN Chao-yi, LAN Yuan-pei. Research on flash roasting-alkali dissolving desilication of low grade high-sulfur bauxit[J]. Nonferrous Metals (Extractive Metallurgy), 2018(7): 13-16.

[3] 陈喜峰. 中国铝土矿资源勘查开发现状及可持续发展建议[J]. 资源与产业, 2016, 18(3): 16-22.

CHEN Xi-feng. Exploration and development situation of bauxite resources in China and suggestions for sustainable development[J]. Resources & Industries, 2016, 18(3): 16-22.

[4] 党殿原. 高硫高硅铝土矿浮选分离工艺研究[D]. 郑州: 郑州大学, 2018: 3-4.

DANG Dian-yuan. Study on flotation separation process of high sulfur and high silicon bauxite[D]. Zhengzhou: Zhengzhou University, 2018: 3-4.

[5] 任少峰, 何 伟, 刘金海, 李天霞. 高硫铝土矿脱硫脱硅扩大连续选矿试验研究[J]. 有色金属(选矿部分), 2017(2) : 13-16.

REN Shao-feng, HE Wei, LIU Jin-hai, LI Tian-xia. Research on high-sulfur bauxite for scale-up continuous test of desulfurization and desilication[J]. Nonferrous Metals (Mineral Processing), 2017(2): 13-16.

[6] 赵远由, 苏书灿. 黔北务正道地区黄龙组地质特征及其找矿指示意义[J]. 地质科技情报, 2013, 32(1): 23-26.

ZHAO Yuan-you, SU Shu-can. Geological characteristics of Huanglong formation and significance of prospecting for mineral resources in Wuzhendao County of Northern Guizhou[J]. Geological Science and Technology Information, 2013, 32(1): 23-26.

[7] 袁 睿, 鲜绍军, 金中国, 宋小军. 黔北道真向斜西翼铝土矿地质特征及成因探讨[J]. 西部探矿工程, 2014(4): 107-110.

YUAN Rui, XIAN Shao-jun, JIN Zhong-guo, SONG Xiao-jun. Discussion on geological characteristics and genesis of bauxite in west wing of Daozhen syncline in Northern Guizhou[J]. West-china Exploration Engineering, 2014(4): 107-110.

[8] 吕国志, 张廷安, 鲍 丽. 高硫铝土矿的焙烧预处理及焙烧矿的溶出性能[J]. 中国有色金属学报, 2009, 19(9): 1684-1689.

Lü Guo-zhi, ZHANG Ting-an, BAO Li. Roasting pretreatment of high-sulfur bauxite and digestion performance of roasted ore[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(9): 1684-1689.

[9] 张风林, 王克勤, 邓海霞, 王 皓, 陈 津. 高硫铝土矿脱硫研究现状与进展[J]. 山西科技, 2011, 26(1): 94-95.

ZHANG Feng-lin, WANG Ke-qin, DENG Hai-xia, WANG Hao, CHEN Jin. Research status and progress of desulphurization in high-sulfur bauxite[J]. Shanxi Science and Technology, 2011, 26(1): 94-95.

[10] ZHANG Nian-bing, LI Zhi-ying, GUO Pei-li. Desulfurization mechanism and application of high sulfur bauxite[J]. Metalurgia International, 2013, 18(3): 29-32.

[11] PIETERSE J A Z, van EIJK S, van DIJK H A J, van den BRINK R W. On the potential of absorption and reactive adsorption for desulfurization of ultra low-sulfur commercial diesel in the liquid phase in the presense of fuel additive and bio-diesel[J]. Fuel Processing Technology, 2011, 92(3): 616-623.

[12] 牛芳银, 张 覃, 张 杰. 某高硫铝土矿浮选脱硫的正交试验[J]. 矿物学报, 2007, 27(3): 393-395.

NIU Fang-yin, ZHANG Qin, ZHANG Jie. Orthogonal test of flotation desulphurization for a high-sulfur bauxite[J]. Acta Mineralogica Sinica, 2007, 27(3): 393-395.

[13] 郝跃鹏, 李花霞. 细菌浸出高硫铝土矿中杂质硫的研究[J]. 轻金属, 2014(10): 11-15.

HAO Yue-peng, LI Hua-xia. Study of bioleaching sulfur from bauxite with high sulfur using acidithiobacillus ferrooxidans bacterias[J]. Light Metal, 2014(10): 11-15.

[14] 陈延信, 赵 博, 酒少武, 吴 锋, 韩 丁. 高硫铝土矿悬浮态焙烧脱硫[J]. 中南大学学报(自然科学版), 2016, 47(8): 2577-2583.

CHEN Yan-xin, ZHAO Bo, JIU Shao-wu, WU Feng, HAN Ding. Desulfurization roasting of high sulfur bauxite in suspended state[J]. Journal of Central South University (Natural Science), 2016, 47(8): 2577-2583.

[15] 刘喜军. 低品位铝土矿悬浮态焙烧碱浸预脱硅试验研究[D]. 西安: 西安建筑科技大学, 2017: 14-16.

LIU Xi-jun. Experimental study on pre-desilication from low grade bauxite by suspension roasting-alkali leaching process[D]. Xi’an: Xi’an University of Architecture and Technology, 2017: 14-16.

[16] 董成勇. 贵州某高硫铝土矿焙烧过程能耗分析[J]. 轻金属, 2017(11): 5-8.

DONG Cheng-yong. Energy consumption analysis of high-sulfur bauxite calcination in Guizhou[J]. Light Metal, 2017(11): 5-8.

[17] 毕诗文. 氧化铝生产工艺[M]. 北京: 化学工业出版社, 2006: 96-103.

BI Shi-wen. Technology of alumia production [M]. Beijing: Chemical Industry Press, 2006: 96-103.

[18] HE Bo-quan. Discussion on the new de-sulfuration method of Chinese high sulfur bauxite[J]. Light Metals, 1996(12): 3-5.

[19] 赵 博, 陈延信, 酒少武, 韩 丁, 杨 潘. 高硫铝土矿悬浮态焙烧及焙烧矿的溶出性能[J]. 中南大学学报(自然科学版), 2016, 47(9): 2929-2935.

ZHAO Bo, CHEN Yan-xin, JIU Shao-wu, HAN Ding, YANG Pan. Suspended roasting of high sulfur bauxite and leaching performance of roasted ore[J]. Journal of Central South University(Natural Science), 2016, 47(9): 2929-2935.

[20] 任 振. 焙烧预脱硅与脱硫的简单探讨[J]. 世界有色金属, 2017(12): 226-227.

REN Zhen. Briefly analyzing baking process of pre-desilicon and desulfurization[J]. World Nonferrous Metals, 2017(12): 226-227.

Roasting desulphurization and leaching performance promotion of bauxite in Wuchuan-Zheng’an-Daozhen Area, Northern Guizhou Province

ZHOU Jian-fei1, ZHAO Bo2, CHEN Yan-xin2, HE Wei3, HAN Ding2

(1. Southwest Energy and Mineral Resources Corporation Co., Ltd., Guiyang 550004, China;

2. College of Materials Science and Engineering, Xi’an University of Architecture and Technology, Xi’an 710055, China;

3. Zunyi Energy and Mineral Investment Co., Ltd., Zunyi 563000, China)

Abstract: In China, the potential reserves of high-sulfur bauxite deposits are 2 billion tons, but they were hard to be exploited in alumina industry at present due to the bad properties of sulfur, such as corrosion to machines, deterioration of dissolution of Al2O3. In this paper, a novel process route “flash roasting+concentrate Bayer process” was proposed. The key parameters of flash roasting (roasting temperature and time), phase transformation and the thermodynamics during roasting desulfurization process were analyzed. Digestion properties of roasted bauxite in “concentrate Bayer process” were further investigated. The results show that the S content decreases to approximately 0.05%, and the desulfurization rate reaches 95.2% when being roasted at 550 ℃ for 1.6 s. In the digestion experiment, the performance of the roasted ore is significantly better than that of raw ore. The Al2O3 relative dissolution rate of roasted ore exceeds 95%, which is 2%-3% higher than that of raw ore, at the following conditions: temperature of 270 ℃, CaO dosage of 14%, Na2Ok concentration of 245 g/L, duration of 60 min, and burdening αk 1.40. The study results propose a novel desulfurization process for accelerating the efficient industrial utilization of high-sulfur bauxite.

Key words: high-sulfur bauxite; flash roasting; concentrate Bayer process; desulfurization rate; dissolution rate

Foundation item: Project(2018YFC1903504) supported by National Key Research and Development Program of China

Received date: 2018-10-29; Accepted date: 2019-06-08

Corresponding author: ZHOU Jian-fei; Tel: +86-15885549080; E-mail: jf_zhou@qq.com

(编辑 李艳红)

基金项目:国家重点研发计划资助项目(2018YFC1903504)

收稿日期:2018-10-29;修订日期:2019-06-08

通信作者:周剑飞,高级工程师;电话:15885549080;E-mail:jf_zhou@qq.com