文章编号:1004-0609(2011)11-2739-05

热碾压对AZ31镁合金焊接接头组织和性能影响

初雅杰1, 2, 李晓泉2, 吴申庆1

(1. 东南大学 材料科学与工程学院 江苏省先进金属材料高技术研究重点实验室,南京 211189;

2. 南京工程学院 材料工程学院,南京 211167)

摘 要:采用交流钨极氩弧焊和热碾压装置对AZ31变形镁合金进行焊接试验和热碾压试验;利用光学显微镜、扫描电镜(SEM)、显微硬度计、电子拉伸试验等手段对焊接接头的显微组织、元素分布、断口形貌、接头硬度和强度等进行分析。结果表明:热碾压熔焊接头的抗拉强度可达225 MPa,为母材金属的90%以上,而焊态下熔焊接头的抗拉强度仅为母材金属的60%左右;热碾压焊接试样的伸长率(9%~11%)均高于焊态试样的(6%~8%);热碾压接头断口呈现一定的准解理断裂特征,且可以观察到热碾压塑性变形流变线,而焊态断口呈现以解理断裂为主的断裂机制,同时伴随有极少量的韧窝断裂特征。

关键词:AZ31镁合金;热碾压;变形;力学性能

中图分类号:TG 146.2 文献标志码:A

Effect of hot rolling on microstructure and mechanical properties of welded joints of AZ31 magnesium alloy

CHU Ya-jie1, 2, LI Xiao-quan2, WU Shen-qing1

(1. School of Material Science and Engineering, Jiangsu Key Laboratory for Advanced Metallic Materials,

South East University, Nanjing 211189, China;

2. School of Material Engineering, Nanjing Institute of Technology, Nanjing 211167, China)

Abstract: The conventional welded joint and hot rolled tests were carried out for AZ31 magnesium alloy on TIG welding and hot rolling equipment, and the microstructure, the element distribution, the appearance of fracture, hardness and strength of the welded joint were studied by OM, SEM, micro-hardness tester, tensile testing machine. The results show that the tensile strength of the hot rolled welded joint is 225 MPa, which is over 90% of that of the base metal, and the tensile strength of the conventional welded joint is just about 60% of that of the base metal. The elongation of the hot rolled welded specimen (9%-11%) is higher than that of the conventional welded specimen (6%-8%). The hot rolled joint fracture shows some characteristics of the quasi-cleavage fracture, and the plastic deformation flow lines can be observed. The conventional welded joint shows the cleavage fracture mechanism, accompanied by a very small amount of dimple fracture.

Key words: AZ31 magnesium alloy; hot rolled; deformation; mechanical properties

镁合金被认为是汽车及轨道交通制造中最具应用前景的轻质金属结构材料,但镁合金结构的焊接加工目前还存在较大的难度。由于金属镁本质上具有滑移系相对较少的密排六方晶体结构,且热导率高、线膨胀系数大,因而熔焊形成的铸态焊缝组织粗大,加之焊缝组织中强化相析出在远离非平衡条件下很难有充足的动力学保证,这使得熔焊接头的强度及塑性均比母材金属的低[1-5]。特别是对于变形镁合金,熔焊接头与母材力学性能匹配问题尤显突出。近年来,国内外的一些学者通过搅拌摩擦焊、等离子弧焊以及真空电子束焊等方法进行研究[6-13],这些方法受焊缝凝固时间短、过程远离平衡等影响,很难使焊缝组织细化。已有研究表明[14-16],对密排六方结构的金属镁在高温条件下施加一定的塑性变形,使其发生动态回复与再结晶,在细化晶粒的同时还可开通新的滑移系,甚至诱发超塑性机制。同时,研究还表明,铸态镁合金组织遵循Hall-Petch公式σs=σ0+Kd-1/2,而K值的大小取决于滑移系的多少。这说明镁合金的屈服强度对其晶粒度具有很强的依赖性,动态再结晶所产生的晶粒细化有利于镁合金熔焊接头室温强度的提高,进而达到显著提高强度及塑性的力学改性效果。据此,本文作者针对Mg-Al-Zn系的AZ31变形镁合金,用钨极氩弧焊获得熔焊接头,然后对熔焊接头区域进行局部热碾压力学改性试验,以期探索实现镁合金熔焊接头强度及塑性可控化的有效途径。

1 实验

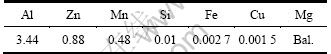

实验用AZ31镁合金材料的化学成分见表1。采用化学成分完全相同的AZ31镁合金经轧制、拉拔成d3 mm丝材作为焊接时的填充材料。用尺寸为200 mm×60 mm×4.6 mm的2块板材组成1副对接焊试板。焊接试板开60°的V型坡口,根部间隙控制在3~4 mm。将焊接区域用砂纸打磨,坡口面经刮削清除氧化膜。用交流钨极氩弧焊进行手工焊接,正面施焊2层,背面施焊1层,形成具有一定余高的双面焊缝,共施焊10副相同试板。

表1 AZ31镁合金的化学成分

Table 1 Chemical composition of AZ31 magnesium alloy (mass fraction, %)

焊态试板经X射线探伤合格后按图1所示用线切割方法截取拉伸试样。截取出的试样一部分将焊缝打磨平整后直接在CMT-5105型微机控制电子万能试验机进行拉伸试验,测试熔焊接头焊态下的强度及伸长率;另一部分试样用作热压试验,采用专门制作的陶瓷电加热装置,将试样两端插入加热箱中,中间露出焊缝区域待热压变形。试验时,通电加热至350 ℃并保温10 min,然后在高温拉伸试验机上以0.5 mm/min的加载速度反复压制焊缝表面,直至焊缝表面与母材表面平行。取出碾压试样且冷却至常温,在CMT-5105型微机控制电子万能试验机上进行常温拉伸,拉伸速度为1 mm/min,以测试经碾压后熔焊接头的强度及伸长率。用HXD-1000型显微硬度计测量硬度,自焊缝中心向母材方向分别测量焊缝区、热影响区和母材区的显微硬度值,相同深度测试3个点取平均值,测量间距为0.5 mm,加载载荷为100 g,保持载荷时间为15 s。用JSM-6360LV扫描电镜观察焊态和碾压态拉伸试样的断口形貌,配合能谱分析断口微区成分。

图1 拉伸试样尺寸

Fig.1 Dimensions of tensile specimen (mm)

2 结果与分析

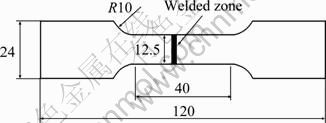

2.1 焊接接头的形貌

图2所示为焊态试样和热碾压试样形貌的对比。由图2可以看出,常规TIG焊焊接接头的表面比较粗糙,高低不平,且表面有气孔等焊接缺陷;而热碾压焊接接头表面光滑平整,无明显焊接缺陷。主要是因为镁合金焊接接头在350 ℃下进行热碾压,发生了动态再结晶。焊接接头发生了部分塑性变形,对气孔、裂纹和咬边等焊接缺陷有一定的消除作用。

图2 焊态和热碾压试样的形貌

Fig.2 Morphologies of welded (a) and hot rolled (b) joints

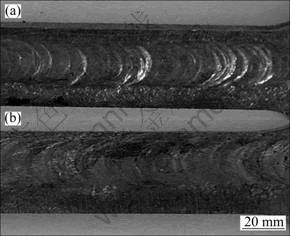

2.2 显微组织

图3(a)、(b)和(c)分别是母材、焊态试样焊缝和 热碾压焊缝的金相组织。可以看出,母材晶粒大小不一,基体组织为α-Mg固溶体和β-Mg17Al12金属间化合物;焊缝区为母材和焊丝熔化后形成的铸造重结晶组织,由于Al含量较高,有较多的共晶体出现,基体组织为α-Mg固溶体, 晶界为α-Mg+β-Mg17Al12不连续共晶体,因镁合金的导热系数较大,冷却速度快,焊缝区金属的快速凝固使其晶粒细化,焊接过程中熔池的不断搅拌作用,也促进了焊缝区细小晶粒的形成。

图3 母材、焊态试样及热碾压焊缝的显微组织

Fig.3 Microstructures of base metal (a) and conventional joint (b) and hot rolled joint (c)

由图3(b)可以看出,焊态试样焊缝区的晶粒尺寸比母材的小,在晶界处析出很多片层状和颗粒状共晶物,还有Zn、Mg和Al之间形成的金属间化合物,削弱了晶界的强度,在高温时容易使焊接接头形成焊接缺陷。另一方面,由于焊缝区Al元素的含量较高,形成中间相的数量较多,且TIG焊的焊接速度和冷却速度快,致使析出相呈弥散质点状态分布,有助于焊缝性能的提高。图3(c)所示为热碾压焊缝区晶粒的显微组织。可以看出,焊缝经热碾压后,晶粒明显得到细化,焊缝在热碾压的作用下片层状共晶物得到一定的破碎,焊缝区组织发生动态再结晶,且晶粒之间发生相互碰撞和挤压,晶粒不断碎化,生成尺寸细小的等轴晶粒。

2.3 焊接接头力学性能

AZ31镁合金TIG熔焊接头的拉伸试验表明,无论是焊态试样还是热碾压试样,拉伸试样均断裂于焊缝边缘熔合区附近,说明熔焊接头是拉伸试验的薄弱环节。

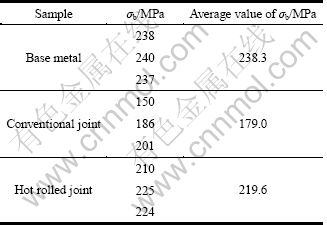

表2所列为母材、焊态试样与热碾压试样的抗拉强度。根据试验结果,经热碾压后,熔焊接头的抗拉强度可达225 MPa,AZ31镁合金母材(无焊缝)的抗拉强度实测结果为240 MPa,说明经热碾压后,熔焊接头的抗拉强度已达到母材金属的90%以上。而焊态熔焊接头的抗拉强度通常为150~200 MPa,仅为母材金属抗拉强度的60%~75%。因此,可以认为,经焊接和热碾压后,熔焊接头的强度已接近于母材金属的强度,热碾压对熔焊接头强度具有明显的改善作用。

表2 母材、焊态和热碾压试样的抗拉强度

Table 2 Tension strengths of base metal, conventional joint and hot rolled joint

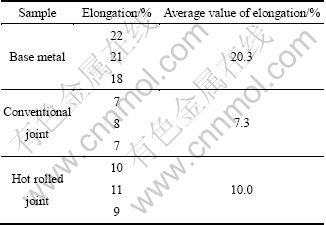

从拉伸试验的伸长率数据(见表3)来看,焊态拉伸试样的伸长率为6%~8%,而经热碾压后拉伸试样的伸长率通常为9%~11%,与母材金属的18%~22%相比尽管还有一些差距,但热碾压对熔焊接头塑性的改善作用是存在的。考虑到试验过程中焊缝余高控制得较低,因而熔焊接头动态压缩塑性变形量也相应较小,塑性改性效果还未充分表现出来。而可通过施焊时增加正、反两面的焊缝余高来增大压缩塑性变形量。

表3 母材、焊态和热碾压试样的伸长率

Table 3 Elongations of base metal, conventional joint and hot rolled joint

通过以上分析可知,热碾压镁合金焊接试样的各项力学性能指标均优于常规焊态试样的。热碾压的高温动态塑性变形能促进非平衡凝固焊接接头组织内部强化相的弥散析出及焊接接头过饱和合金元素均匀化扩散,使镁合金熔焊接头的强度和塑性优于常规焊接接头的,接近母材的性能。

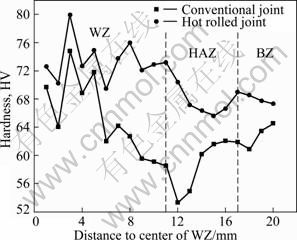

图4所示为AZ31镁合金焊态和热碾压试样的显微硬度分布。可以看出,虽然采用与母材同质的焊接材料,但是接头硬度分布仍不一致。焊缝区(WZ)的硬度最高,已超过母材硬度;热影响区(HAZ)的硬度最低,热碾压焊接接头的硬度均高于常规焊接接头的硬度,这是由于镁合金焊接接头经过热碾压塑变以后,晶粒得到进一步细化。

图4 AZ31镁合金焊态和热碾压试样的硬度分布曲线

Fig.4 Microhardness distribution curves of conventional joint and hot rolled joint of AZ31 magnesium alloy

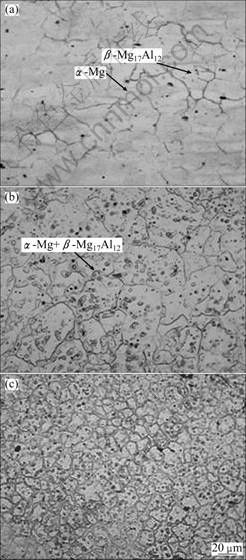

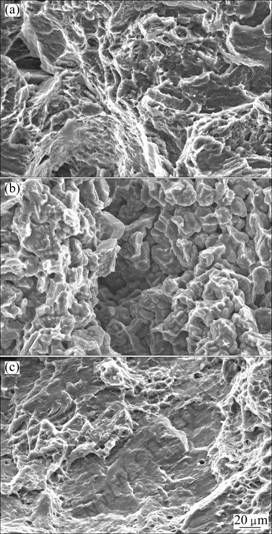

2.4 断口形貌

图5(a)、(b)和(c)分别是母材、焊态和热碾压试样拉伸断口在扫描电镜下的典型形貌。断口形貌分析显示,母材断口(见图5(a))具有一定的塑性变形和韧窝特征。由焊态断口(见图5(b))可以看出,裂纹扩展无塑性变形,具有典型的沿晶开裂特征,裂纹沿晶界脆性相β-Mg17Al12扩展;同时,Al的存在增加了焊接熔池凝固过程中晶界处析出相的偏聚,即增加了β-Mg17Al12的体积分数,且脆性相在晶界趋于网状连续分布,导致焊态接头力学性能恶化。热碾压断口(见图5(c))的解理台阶明显减少,同时可以观察到具有明显方向性的热碾压塑性变形流变线,表现出一定的准解理断裂特征。热碾压后晶粒在平行于流变线方向被显著拉长,并出现晶粒破碎现象。与焊态拉伸断口相比,铸态焊缝的柱状晶在一定程度上得以打破。

图5 母材、焊态和热碾压试样的拉伸断口形貌

Fig.5 Morphologies of tensile fracture surface of base metal (a), conventional joint (b) and hot rolled joint (c)

3 结论

1) 焊态试样焊缝区晶粒在晶界处析出很多片层状和颗粒状的共晶体,削弱了晶界的强度;热碾压焊缝区晶粒得到明显细化,片层状共晶体在热碾压作用下得到一定的破碎,焊缝区发生动态再结晶,生成细小的等轴晶粒。

2) 热碾压焊接试样的抗拉强度和伸长率分别可达225 MPa和9%~11%,比常规焊接接头的分别提高了15%和35%。

3) 焊态试样断口具有典型的沿晶开裂特征,呈现以解理断裂为主的断裂,但解理台阶较小,并产生少量韧窝;而热碾压的断口解理台阶明显减少,可以观察到具有明显方向性的热碾压塑性变形流变线,呈现一定的准解理断裂特征。

REFERENCES

[1] 余 琨, 黎文献, 王日初, 马正青. 变形镁合金的研究开发及应用[J]. 中国有色金属学报, 2003, 13(2): 277-288.

YU Kun, LI Wen-xian, WANG Ri-chu, MA Zheng-qi. Research development and application of wrought magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 277-288.

[2] MORDIKE B L, EBERT T. Magnesium properties applications potential[J]. Materials Science and Engineering A, 2001, 302: 37-45.

[3] 冯吉才, 王亚荣, 张忠典. 镁合金焊接技术的研究现状及应用[J]. 中国有色金属学报, 2005, 15(2): 165-178.

FENG Ji-cai, WANG Ya-rong, ZHANG Zhong-dian. Status and expectation of research on welding of magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(2): 165-178.

[4] 孙德新, 孙大千, 李金宝, 李明高, 殷世强. 镁合金焊接技术的研究进展及应用[J]. 材料导报, 2006, 20(8): 122-127.

SUN De-xin, SUN Da-qian, LI Jin-bao, LI Ming-gao, YIN Shi-qiang. Research progress and application of welding technology of magnesium alloys[J]. Materials Review, 2006, 20(8): 122-127.

[5] 于建民, 张治民, 张宝红. 塑性变形对AZ31镁合金晶粒细化的影响[J]. 热加工工艺, 2009, 38(15): 11-14.

YU Jian-min, ZHANG Zhi-min, ZHANG Bao-hong. Effects of plastic deformation on AZ31 magnesium alloy grain refinement[J]. Hot Working Technology, 2009, 38(15): 11-14.

[6] 谭 兵, 陈东高, 高 明, 冯杰材, 王有祁. AZ31B变形镁合金激光-MIG复合焊焊接组织和性能分析[J]. 航空材料学报, 2008, 28(6): 36-41.

TAN Bing, CHEN Dong-gao, GAO Ming, FENG Jie-cai, WANG You-qi. Microstructure and properties of welding joints for lase-MIG welding of AZ31B transformative magnesium[J]. Journal of Aeronautical Materials, 2008, 28(6): 36-41.

[7] 罗 君, 刘政军, 苏允海, 田 雨. 纵向直流磁场对AZ31镁合金TIG焊焊接接头组织及性能的影响[J]. 焊接学报, 2007, 28(7): 53-59.

LUO Jun, LIU Zheng-jun, SU Yun-hai, TIAN Yu. Influence of longitudinal direct current magnetic field on microstructure and property of AZ31 magnesium alloy TIG welded joint[J]. Transactions of the China Welding Institution, 2007, 28(7): 53-59.

[8] MUNITZ A, COTLER C. Mechanical properties and microstructure of gas tungsten arc welded magnesium AZ91D plates [J]. Material Science and Engineering A, 2001, 302: 68-73.

[9] MUNITZ A, COTLER C. Electron beam welding of magnesium AZ91D plates [J]. Welding Journal, 2000, 79(7): 202-208.

[10] GUENTHER S, ARMANDO J. Electron beam process delivers consistent welds [J]. Welding Journal, 2001, 80(6): 53-57.

[11] WEISHEIT A, GALUN R. Laser welding of various magnesium alloys[J]. Magnesium Alloy and their Applications, 1998(4): 28-30.

[12] HONGYING W, ZHIJUN L. Effect of filler wire on the joint properties of AZ31 magnesium alloys using CO2 laser welding[J]. China Welding, 2007, 16(2): 16-21.

[13] LEE W B, YEON Y M, JUNG S B. Joint properties of friction stir welded AZ31B-H24 magnesium alloy[J]. Materials Science and Technology, 2003, 19(6): 785-790.

[14] 刘楚明, 刘子娟, 朱秀荣, 周海涛. 镁及镁合金动态再结晶研究进展[J]. 中国有色金属学报, 2006, 16(1): 1-12.

LIU Chu-ming, LIU Zi-juan, ZHU Xiu-rong, ZHOU Hai-tao. Research and development progress of dynamic recrystallization in pure magnesium and its alloys[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(1): 1-12.

[15] 余 琨, 黎文献, 王日初. 镁合金塑性变形机制[J]. 中国有色金属学报, 2005, 15(7): 1081-1086.

YU Kun, LI Wen-xian, WANG Ri-chu. Plastic deformation mechanism of magnesium alloys[J]. The Chinese Journal of Nonferrous Metals, 2005, 15(7): 1081-1086.

[16] LI Shu-bo, WANG Yan-qiu, ZHENG Ming-yi, WU Kun. Dynamic recrystallization of AZ91 magnesium alloy during compression deformation at elevated temperature[J]. Transactions of Nonferrous Metals Society of China, 2004, 14(2): 306-310.

(编辑 陈卫萍)

基金项目:江苏省自然科学基金资助项目(BK2009354);南京工程学院校级科研基金资助项目(QKJA2010002)

收稿日期:2010-08-16;修订日期:2011-02-11

通信作者:李晓泉,教授,博士;电话: 025-86118278;E-mail: lixiaoquan@njit.edu.cn