文章编号: 1004-0609(2005)03-0386-05

反应热压法制备Al2O3/NiCrAl复合材料及

功能梯度材料

李均钦1, 谷坤明1, 汤皎宁1, 谢盛辉1, 庄应烘2

(1. 深圳大学 材料科学与工程系 深圳市特种功能材料重点实验室, 深圳 518060;

2. 广西大学 材料研究所, 南宁 530004)

摘 要: 采用NiO、 Al和Cr粉末反应热压制备了Al2O3/NiCrAl复合材料, NiCrAl合金由NiO还原出来的Ni与添加的Cr和Al反应形成。 制备了不同Al2O3含量的Al2O3/NiCrAl复合材料, 并以Al2O3体积分数分别为25%、 52.2%和75%的Al2O3/NiCrAl复合材料为过渡层制备了Y稳定氧化锆(YSZ)到NiCrAl合金的功能梯度材料。 X射线衍射分析、 金相观察、 硬度测量和热循环冲击实验结果表明: 用该方法制备的复合材料由Al2O3陶瓷相和(Ni, Cr, Al)固溶体组成, 而Al2O3颗粒由NiO与Al原位反应形成, 尺寸细小, 呈弥散分布。 该功能梯度材料经从室温到1000℃空气中10次热循环后未发现有裂纹, 表明该方法制备的材料陶瓷相与合金相有良好的相容性、 较高的结合强度、 良好的耐高温抗氧化及热循环冲击性能。

关键词: 反应热压法; Al2O3/NiCrAl复合材料; 功能梯度材料

中图分类号: TG323 文献标识码: A

Al2O3/NiCrAl composites and functional gradient materials fabricated by reactive hot pressing

LI Jun-qin1, GU Kun-ming1, TANG Jiao-ning1, XIE Sheng-hui1, ZHUANG Ying-hong2

(1. Shenzhen Key Laboratory of Special Functional Materials, Department of

Materials Science and Engineering, Shenzhen University, Shenzhen 518060, China;

2. Institute of Materials Science, Guangxi University, Nanning 530004, China)

Abstract: The Al2O3/NiCrAl composites were fabricated by NiO, Al and Cr powders using reactive hot pressing method. The NiCrAl alloy with good high-temperature properties was formed by the reaction of extra Al, Cr and the Ni reduced from NiO. The Al2O3/NiCrAl composites with various Al2O3 fraction were successfully fabricated by the proper addition of Ni, Cr, Al or Al2O3 powders. A 5-layer functional gradient material of YSZ-NiCrAl was fabricated using the composites as interlayers. The results from XRD analysis, optical microscope observation, hardness measurement and thermal cycling test show that the composites fabricated by this method consist of Al2O3 phase and (Ni, Cr, Al) solid solution. The Al2O3 grains formed by the in-situ reaction between NiO and Ni are fine and dispersive. No cracking is found in the functional gradient materials after 10 thermal cycles up to 1000℃. The composites and functional gradient material have strong strength, good resistance to wear and thermal shock.

Key words: reactive hot pressing; Al2O3/NiCrAl composite; functional gradient material

陶瓷/金属功能梯度材料(FGM)是针对高温、 热循环、 大温度落差、 磨损及腐蚀环境而开发的一类新型功能材料[1, 2], 它综合利用了陶瓷的耐高温、 耐磨及抗腐蚀等性能和金属合金良好的力学性能。 功能梯度材料的引入是为了减小或消除由于陶瓷和金属热膨胀系数的差异在制备或服役过程中引起的应力。 根据不同应用要求, 研究和开发了Nb5Si3-Nb[3]、 SiC-Al2124[4]、 3YTZP-Sus304[5]、 ZrO2-NiAl[6]、 PSZ-Mo[7]和YSZ-NiCr[8]等陶瓷/金属功能梯度材料。 这些陶瓷/金属功能梯度材料通常是采用外加陶瓷粉末颗粒法工艺制备, 例如熔体搅拌铸造法、 半固态铸造法、 熔体压力浸渗(挤压铸造)和无压浸渗工艺、 粉末冶金法等。 由于外加陶瓷相与基体间的润湿性差, 难以制备出界面结合良好的复合材料, 导致陶瓷相和金属相的结合强度低, 使工件在制备及使用过程中存在残余应力而导致其开裂而失效[9]。

近年来, 研究与开发了许多原位生成陶瓷颗粒增强复合材料及陶瓷/金属功能梯度材料的方法, 包括放热弥散法(XD)[10]、 反应热压法(RHP)[11]、 自蔓燃反应法(SHS)[12]等。 在这些方法中, 反应热压法由于材料组织容易控制及操作简单而倍受重视, 在真空或气氛保护热压条件下, 各组元直接反应, 原位合成了超细的陶瓷颗粒, 其与基体间相容性好、 界面结合强度高、 热力学性能稳定, 从而大大提高了陶瓷/金属复合材料及功能梯度材料的强度。

Al2O3、 Ni及其合金(NiAl、 NiCr或NiCrAl合金)具有高温强度高、 韧性好、 抗氧化和耐腐蚀等优点[13], 而被广泛用于高温结构材料, 如汽轮机及飞机发动机的叶片等, Y稳定氧化锆(YSZ)具有良好的韧性、 高的热膨胀系数及良好的热障性能而广泛用于热障涂层。 反应热压烧结制备Al2O3-Ni[14]、 Al2O3-NiAl [15] 复合材料或功能梯度材料已有报道, 而NiCrAl具有更优越的耐高温抗氧化性能, 但Al2O3/NiCrAl功能梯度材料的研究未见报道。 本文作者采用反应热压法制备Al2O3/NiCrAl复合材料, 以不同Al2O3陶瓷相的复合材料作为过渡层制备了YSZ/NiCrAl功能梯度材料, 并研究了这些材料的显微组织和热循环冲击性能。

1 实验

实验所用原材料为商用NiO 粉 (粒度45μm, 99.9 %), Cr粉 (粒度35μm, 99.9 %), Al粉 (粒度45μm, 99.9 %), 纳米α-Al2O3粉末 (粒度35nm, 99.9 %), YSZ粉末 (粒度0.5μm, 99.9 %)和超细镍粉 (粒度〈2.0μm, 99.9 %)。 将Ni、 Cr、 Al、 NiO等粉末按所需比例称量, 在QM-SB型行星式球磨机上在高纯氩气保护下球磨24h, 使粉末进一步细化及充分混合均匀。 Al2O3/NiCrAl复合材料及功能梯度材料的反应热压在高纯氩气保护的高温热压炉中进行, 模具内壁衬托石墨纸, 便于脱模, 为避免在热压烧结过程中样品跟石墨发生反应, 在石墨纸内壁上喷涂一层BN。 反应热压温度为900至1250℃, 压力为22MPa, 保温时间为30min, 升温速度为20℃/min, 以20℃/min的降温速度从反应热压温度降至600℃后炉冷至室温。

用Netzsch STA PG/PC 热重/差热分析仪对混合粉末冷压块进行热分析以测定反应温度区间, 反应热压得到的复合材料的物相分析在Philips PW1140 X射线衍射仪上进行, 采用CuKα辐射, 管压35kV, 管流25mA。 所得的复合材料及功能梯度材料样品的横截面经磨光及抛光后用Olympus金相显微镜观察其显微组织。

功能梯度材料样品的热冲击循环实验在空气中进行, 以20℃/min的升温速度从室温升至1000℃, 保温1.5h后随炉冷却至室温, 反复进行多次循环后, 进行金相观察其横截面显微组织。

2 结果与讨论

2.1 材料的制备工艺

本研究的目的是利用热压反应把Al/NiO/Cr坯体反应生成致密的Al2O3/NiCrAl复合材料或功能梯度材料。 Zhu等[15]对反应热压制备Al2O3/NiAl复合材料的研究表明: NiO/Al混合粉末在热压条件下, Al2O3是首先形成的(约600℃), 而Ni-Al化合物或合金(如NiAl3, NiAl)在更高的温度下(约900℃)才由被置换出来的Ni与剩余的Al反应形成。 过程中的反应可以表示为如下的方程式:

2Al+3NiO→Al2O3+3Ni(1)

Ni+0.301Cr+0.145Al→NiCr0.301Al0.145(2)

合金NiCr0.301Al0.145(摩尔分数, %)是由反应式(1)置换出来的Ni与额外添加的Cr和Al反应生成的。 因此, 获得Al2O3/NiCrAl复合材料的反应方程为:

2.435Al+3NiO+0.903Cr→Al2O3+

3NiCr0.301Al0.145(3)

根据Al2O3的密度(3.98g/cm3)和NiCrAl的密度(8.2g/cm3), 可计算出由反应式(3)获得的复合材料Al2O3和NiCrAl的体积分数分别为52.2%和47.8%。 差热分析及X射线衍射分析表明本方法制备具有良好高温性能的Al2O3/NiCrAl复合材料是可行的。

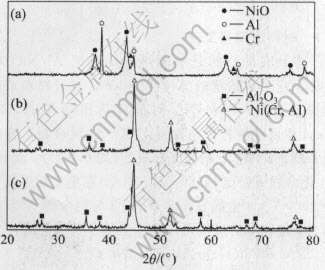

图1给出了按反应式(3)配比的混合粉末, 以及在900和1250℃反应热压烧结后样品的X射线衍射谱。 实验发现按反应式(3)配比的混合粉末经过24h球磨后, 其物相仍为NiO及Al和少量的Cr(图1(a)), NiO峰出现宽化, 表明NiO颗粒细小。 根据谢乐公式由37.1°处NiO峰的半峰宽估算得到NiO颗粒粒径为16nm。 该混合粉末经900℃热压烧结后, 反应生成α-Al2O3陶瓷相和(Ni, Cr, Al)固溶体, 未发现有未反应的Cr或NiO存在(图3(b)), 样品为Al2O3/NiCrAl复合材料。 当反应热压烧结温度升高时(如1250℃), 生成的物相不再改变, 仍是α-Al2O3陶瓷相和(Ni, Cr, Al)固溶体(图3(c)), 只是得到的复合材料的密度有进一步的提高。 计算可知获得的复合材料中α-Al2O3陶瓷相的含量为52.2%(体积分数), 但其XRD峰较弱并出现宽化。 可以认为这是因为在热压条件下由纳米级NiO与Al反应形成细小α-Al2O3晶粒所致, 由58.4°处α-Al2O3峰的半峰宽估算得到α-Al2O3颗粒粒径为20nm。 这有利于提高金属和陶瓷相的结合强度及复合材料强度。

图1 反应前的混合粉末(a)、 900℃(b)和1250℃(c)反应热压烧结样品的X射线衍射谱

Fig.1 XRD patterns of powder mixture (a), and samples fabricated by reactive hot pressing at 900℃ (b) and 1250℃ (c)

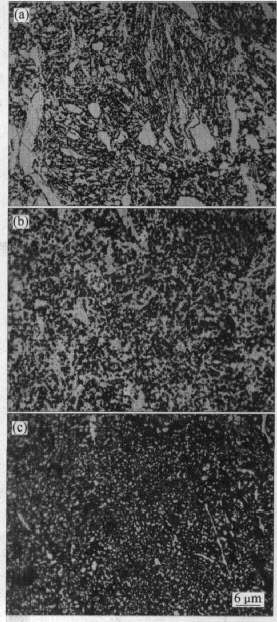

因为Al/NiO/Cr混合粉末在热压条件下首先生成Al2O3, 因此添加额外的Cr, Al和Ni不会影响其置换反应, 但能够调整复合材料中Cr、 Al、 Ni和NiCrAl的含量。 本工作在反应式(3)配比的基础上, 通过添加额外的Cr, Al和Ni金属粉末或纳米Al2O3 (35nm)陶瓷粉末制备了不同Al2O3含量的Al2O3/NiCrAl复合材料。 图2给出了1250℃反应热压烧结获得的致密的Al2O3陶瓷体积含量分别为25%、 52.2%和75%的Al2O3/NiCrAl复合材料的金相显微组织。 能谱分析结果表明图中的白亮相为(Ni, Cr, Al)固溶体而灰相为Al2O3相。 由图2可以看出该复合材料组织致密, α-Al2O3陶瓷相和(Ni, Cr, Al)固溶体分布均匀, 互构成网络结构, α-Al2O3陶瓷相颗粒细小, 而(Ni, Cr, Al)固溶体颗粒较粗, 随着α-Al2O3陶瓷相含量的增加, 其从弥散相(图2(a))转变为基体相(图2(c))。

图2 1250℃反应热压烧结获得的Al2O3/NiCrAl复合材料的金相显微组织

Fig.2 Microstructures of Al2O3/NiCrAl composites with 25%(a), 52.2%(b) and 75%(c) Al2O3 by hot pressing at 1250℃

2.2 功能梯度材料制备及热循环冲击分析

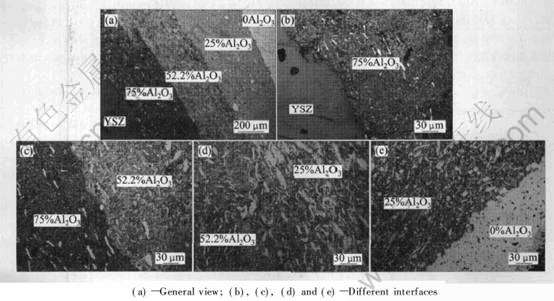

在1250℃反应热压制备了陶瓷-金属功能梯度材料, 图3(a)所示为所得的功能梯度材料横截面的金相照片。 该功能梯度材料设计成5层, 每层的厚度约为220μm, α-Al2O3陶瓷体积分数分别为25%, 52.2%及75%的Al2O3/NiCrAl复合材料作为过渡层, 两端分别为YSZ陶瓷和NiCrAl合金, 从而构成了从纯陶瓷到金属的功能梯度材料。 根据Al2O3和NiCrAl的热膨胀系数[16], 分别为8.0×10-6K-1和16.0×10-6K-1, 由最简单的复合材料热膨胀系数计算公式αc=αmVm+αmVm可得含α-Al2O3 75%的Al2O3/NiCrAl复合材料的热膨胀系数为10.0×10-6K-1, 接近YSZ的热膨胀系数10.5×10-6K-1, 意味着纯陶瓷层与高α-Al2O3陶瓷含量的Al2O3/NiCrAl复合材料层的热膨胀系数相差很小, Al2O3-NiCrAl复合材料过渡层已经完成了功能梯度材料热膨胀系数的过渡, 纯陶瓷层与高α-Al2O3陶瓷含量的Al2O3/NiCrAl复合材料层的热应力应接近零。 图3(b)~(e)所示为该功能梯度材料不同陶瓷含量层界面处的显微组织。 可以看出, 除了YSZ/75% Al2O3-NiCrAl的界面较为清析外(见图3(b)), 其它界面都较模糊。 我们认为这是由于该功能梯度材料在制备过程中, 在界面处存在成分梯度而出现的扩散形成的; 因而形成了连续过渡层, 改善了界面处的成分突变, 从而有利于减少界面处的残余应力。

为了测试该功能梯度材料的热稳定性、 抗高温氧化性能及热循环冲击性能, 进行了该功能梯度材料热循环冲击实验。 先将样品在空气中以20℃/min的升温速度从室温升至1000℃, 保温1.5h后随炉冷却至室温, 反复进行多次循环后, 进行横截面显微组织观察。 图4给出了10次热循环冲击实验后的样品横截面金相照片, 可见样品没有出现层间削离现象, 样品内部无明显变化, 且未发现裂纹, 表明该功能梯度材料具有良好的热稳定性、 抗高温氧化性能及热循环冲击性能。 这是因为该功能梯度材料中的金属相为NiCrAl合金, 高温下其表面很快形成一层致密的Al2O3薄层而防止其进一步氧化, 另外功能梯度材料中的α-Al2O3有效地阻止O2在复合材料中的扩散, 因此, Al2O3/NiCrAl复合材料比Al2O3/Ni、 Al2O3/NiAl和YSZ/NiCr复合材料具有更优越的高温性能。 由于反应热压法制备的复合材料或功能梯度材料中的陶瓷相是原位反应生成的, 与基体相容性好, 界面结合强度高, 从而大大提高了陶瓷/金属复合材料及功能梯度材料的强度, 高于由于梯度层间膨胀系数的差异引起的残余应力, 才使该功能梯度材料在热循环冲击过程中不出现裂纹的形成及长大。

图3 反应热压法制备的YSZ-NiCrAl功能梯度材料横截面的形貌

Fig.3 Microstructures of cross-section for YSZ-NiCrAl functional graded materials using Al2O3-NiCrAl composites with 25%, 52.2% and 75% Al2O3 as interlayers by hot pressing at 1250℃

图4 反应热压法制备的YSZ-NiCrAl功能梯度材料经10次热循环后横截面的形貌

Fig.4 General view of cross-section for YSZ-NiCrAl functional graded materials after 10 thermal cycles up to 1000℃

3 结论

采用适量的NiO、 Al和Cr粉末反应热压制备了不同Al2O3陶瓷含量的Al2O3/NiCrAl复合材料。 并以含Al2O3陶瓷体积分数分别为25%、 52.2%和75%的Al2O3/NiCrAl复合材料为过渡层制备了YSZ-NiCrAl功能梯度材料。 用该方法制备的复合材料由α-Al2O3陶瓷相和Ni(Cr, Al)固溶体组成, Al2O3颗粒由NiO与Al原位反应形成, 尺寸细小, 弥散分布, 与合金相有良好的相容性, 具有较高的结合强度。 该功能梯度材料经从室温到1000℃空气中10次热循环冲击实验后, 样品没有出现层间削离现象, 样品内部无明显变化, 未发现裂纹, 表明该功能梯度材料具有良好的热稳定性、 抗高温氧化性能及热循环冲击性能。

REFERENCES

[1]Neubrand A, Roedel J. Gradient materials: An overview of a novel concept[J]. Zeitschrift fur Metallkunde, 1997, 88(5): 358-371.

[2]Hirai T, Chen L. Recent and prospective development of functionally graded materials in Japan[J]. Materials Science Forum, 1998-1999, 308-311: 509-514.

[3]Heian E M, Gibeling J C, Munir Z. Synthesis and characterization of Nb5Si3/Nb functionally graded materials[J]. Mater Sci Eng A, 2004, A368: 168-174.

[4]Lin C Y, Bathias C, McShane H B, et al. Production of silicon carbide Al 2124 alloy functionally graded ma-terials by mechanical powder metallurgy technique[J]. Powder Metallurgy, 1999, 42(1): 29-33.

[5]Jung Y G, Choi S C. Fabrication of 3Y-TZP/SUS304 functionally graded materials by slip casting, application of porous alumina molds[J]. Materials Science Letters, 1998, 37(6): 312-319.

[6]He Y R, Subramanian V, Lannutti J J. Phase instability in ZrO2-NiAl functionally graded materials[J]. J Materials Research, 1997, 12(10): 2589-2593.

[7]李云凯, 王勇, 李树奎, 等. PSZ/Mo功能梯度材料[J]. 复合材料学报, 2003, 20: 42-46.

LI Yun-kai, WANG Yong, LI Shu-kui, et al. PSZ/Mo functionally gradient materials[J]. Acta Mater Comp Sin, 2003, 20: 42-46.

[8]LI J Q, ZENG X R, TANG J N, et al. Fabrication and thermal properties of YSZ - NiCr joint with YSZ-NiCr functionally graded materials interlayer[J]. Journal of the European Ceramic Society, 2003, 23: 1847-1853.

[9]Qin C D, Derby B. Diffusion bonding of a nickel (chromium) alloy to zirconia-mechanical-properties and interface microstructures[J]. Journal Materials Science Letters, 1993, 28: 4366-4374.

[10]Kuruvilla A K, Prased K S, Mahajan Y R. Microstructure-property correlation in Al/TiB2 composites[J]. Scripta Metall Mater, 1990, 24(5): 873-878.

[11]MA Z Y, BI J, LU Y X. In-situ ceramic particle-reinforced aluminum matrix composite fabricated by reaction pressing in the TiO2(Ti)-Al-B(B2O3) system[J]. Metallurgical Transactions A, 1997, 28A(7): 1931-1942.

[12]Ranganath S, Vijayakumar M, Subrahamanyam J. Combustion-assisted synthesis of Ti-TiB-TiC composite via the casting route[J]. Mater Sci Eng A, 1992, A149(1-2): 253-257.

[13]Sun X, Yoemans J. The optimization of a ductile-particle-toughened ceramic[J]. Journal of American Ceramic Society, 1996, 79: 2705-2717.

[14]Fahrenholtz W G. Reactive hot pressing of Al2O3-Ni composite[J]. Journal of Materials Science, 2003, 38: 3073-3080.

[15]Zhu H X, Abbaschian R. In-situ processing of NiAl-alumina composites by thermite reaction[J]. Mater Sci Eng A, 2000, A282: 1-7.

[16]Ilavsky J, Berndt C C. Thermal expansion properties of metallic and cermet coatings[J]. Surface and Coatings Technology, 1998, 102: 19-24.

(编辑袁赛前)

基金项目: 深圳市科技三项费用资助项目(200322) 收稿日期: 2004-08-10; 修订日期: 2005-01-18

作者简介: 李均钦(1961-), 男, 教授, 博士.

通讯作者: 李均钦, 教授; 电话: 0755-26538537; E-mail:junqinli@szu.edu.cn