文章编号:1004-0609(2009)11-2029-09

掺杂对WCu电触头材料电弧特性的影响

陈文革1, 2,陈勉之2,邢力谦1,李金山1,洪 峰2

(1. 西北工业大学 材料科学与工程学院,西安 710072;

2. 西安理工大学 材料科学与工程学院,西安 710048)

摘 要:利用粉末冶金技术制备出分别掺杂0.3%B、2.0%Nb和1.5%Ce (质量分数)的WCu电触头材料,采用高速摄影技术和抗电弧烧蚀实验探讨不同掺杂元素对钨铜电触头材料电弧特性的影响。结果表明:真空击穿时,WCu电触头材料的电弧演化过程可以分为起弧、稳定燃烧和灭弧3个阶段;掺杂0.3%B、2.0%Nb和1.5%Ce的WCu电触头材料的电弧寿命比未掺杂的长,截流值小;等离子云体积大,颜色浅,在样品表面燃烧区域大,电弧分散,燃弧能量分散;电弧燃烧稳定,无放射状光芒。含有掺杂元素的WCu电触头材料的抗电弧烧蚀性能均得到明显改善;其中最明显的为WCu-B电触头材料,其抗烧蚀性能提高了近30%。

关键词:WCu电触头材料;掺杂;电弧特性

中图分类号:TG 146.4 文献标识码:A

Effect of doping on electrical arc characteristic of

WCu electrical contact materials

CHEN Wen-ge1, 2, CHEN Mian-zhi2, XING Li-qian1, LI Jin-shan1, HONG Feng2

(1. School of Materials Science and Engineering, Northwestern Polytechnical University, Xi’an 710072, China;

2. School of Materials Science and Engineering, Xi’an University of Technology, Xi’an 710048, China)

Abstract: The WCu electrical contact materials containing 0.3%B, 2.0%Nb and 1.5%Ce (mass fraction) were produced through powder metallurgy technology. The electrical arc characteristic of different doping elements on the electrical arc characteristics of WCu electrical contact materials and commercial WCu electrical contact alloys were researched by high-speed camera and arc erosion experiment. The results show that the evolution of arc discharge can be divided into arc forming, steady burning of arc and attenuation. Compared with the WCu alloys without doping elements, the WCu alloys with doping elements have the characters, such as longer time for arc formation, shorter time for arc stable burning and larger volume and lighter color of plasmas plumes. The arc is dispersed and stable, and the burning area on the sample surface is bigger. The anti-welding ability of the WCu alloys with doping elements is greatly improved. The best one is WCu-B alloys with anti-welding ability increased by about 30%.

Key words: WCu contact materials; doping; electric arc characteristic

电触头亦称触点或接点,是高、低压电器中的关键元件,担负着接通与分断电流的任务,它直接影响开关、电器运行的可靠性及使用寿命,所以人们将触头称为电器的“心脏”[1-3]。WCu电触头材料是由W和Cu所组成的两相均匀分布的既不固熔又不形成化合物的一类复合材料,兼有W的高熔点、高密度、高的高温强度和抗电蚀性、抗熔焊性以及Cu的高导电性、导热率、塑性及易加工性,且Cu在电弧高温下蒸发时可吸收大量的电弧能量,降低电弧温度,改善使用条件和降低电蚀作用[4-7]。为适应电网市场发展的要求,高压开关设备向着高电压、大容量、小型化的方向发展。新的断路器的容量将不断增大,而灭弧室空间逐渐缩小,从而使得弧触头单位面积上承担的负荷增大,对WCu电触头材料的性能要求更高[8-12]。

本文作者对采用熔渗法制备的掺杂不同组元WCuX触头材料进行电弧特性的研究,利用高速摄影来捕捉不同WCuX触头材料在高电压、大电流作用下的引弧、燃弧和灭弧过程,计算各个阶段所耗用的时间。并进行抗电弧烧蚀实验,采用SEM观察烧蚀后样品的表面形貌,从而探讨添加元素对WCu触头材料电弧特性的影响。

1 实验

表1所列为掺杂不同组元采用熔渗法制备的WCuX触头材料及相关性能参数。同时与商用的W80Cu20触头材料进行对比。利用高速摄影来捕捉不同WCuX触头材料在高电压、大电流作用下的引弧、燃弧和灭弧过程,并计算各个阶段所耗用的时间。同时利用示波器记录放电时的截留值。

表1 含有不同掺杂元素WCu合金的性能

Table 1 Properties of WCu with different doping elements

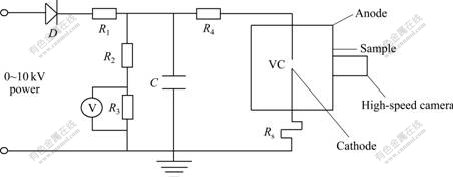

将制备的电触头材料加工成d14 mm×10 mm的形状后,磨制成金相样,然后在丙酮、酒精和去离子水中用超声波震荡仪分别清洗10 min,以去除材料表面的污染物。将上述加工好的WCu合金装入如图1所示的装置中进行高速摄影电弧试验,采用阳极在上,阴极在下的电极安排方式,阳极为d3.2 mm的纯W针状电极。真空室的真空度小于1.5×10-3 Pa。电击穿试验的电流为10 A,放电电容为12 mF,放电电压为10 kV。通过控制阴极以0.2 mm/min的速度缓慢上升,当电极之间距离小于一定距离时,真空间隙被击穿,引发真空电弧。

图1 高速摄影实验电路示意图

Fig.1 Experimental circuit diagram of high speed photography (R1 is 100 kΩ, charging resistor; R2 is 38 MΩ, measuring resistor; R3 is 2 MΩ, measuring resistor; R4 is discharging resistor; C is a capacitor; D is a diode; VC represents vacuum chamber)

用PhantomV9 型高速数字摄像机拍摄电击穿电弧形成、放电和灭弧过程。拍摄参数:拍摄速度24 000 p/s,放电电容为12 μF,放电电阻600 Ω,放电电压10 kV。

电弧烧蚀实验按ISO6848—1984E惰性气体保护氩弧焊和等离子切割、焊接用钨电极棒进行。本实验选取同样工作电压和电流,每隔一定时间称取电极烧蚀后的质量损失。其中弧长固定为3 mm;样品伸出长度为20 mm。起弧电压127 V;起弧电流140 A;氩气流量5 L/min;烧蚀时间10 min。电弧烧蚀试验结束后,使用JSM-6700E型扫描电子显微镜对烧蚀后表面形貌进行观察。

2 结果与分析

2.1 高速摄影实验

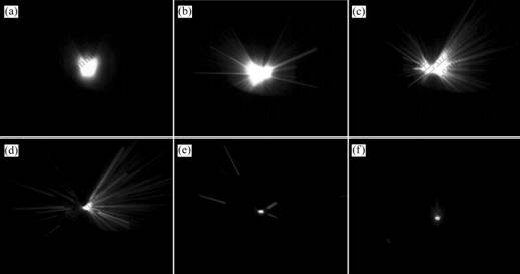

图2所示为商用WCu电触头材料电击穿过程中不同阶段的电弧形貌。图中弧光上部为阳极钨针尖,下部为电触头材料。随着阴极缓慢上升,达到电触头材料真空条件下的击穿场强,产生击穿电流,随后阳极金属蒸发形成电离云向阴极发展,阴极斑点也开始熔融蒸发,形成阴阳极金属蒸汽等离子云,这是电弧的形成阶段。由图2可看出,对于商用WCu电触头材料,起弧时间约0.252 ms;随后电弧进入稳定燃弧阶段。随电流和电压的降低,约8.904 ms后,电弧弧光颜色开始变浅,标志电弧进入衰减阶段;随时间的延长,电弧等离子云开始明显缩小,14.994 ms后离子云出现不连续,19.026 ms后看不到阴极表面电弧弧根亮点。

图2 商用WCu合金电弧演化过程

Fig.2 Arc evolution process of commercial WCu alloy: (a) 0.252 ms; (b) 4.536 ms; (c) 8.904 ms; (d) 9.618 ms; (e) 14.994 ms; (f) 19.026 ms

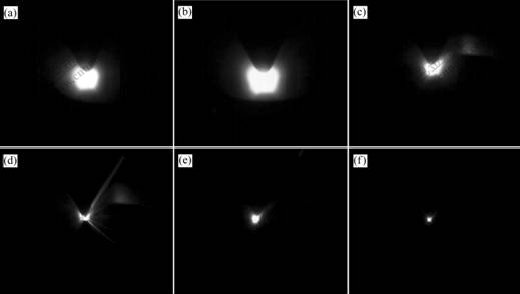

图3所示为掺杂0.3%的B的WCu合金电击穿过程中不同阶段的电弧形貌。由图3可看出,样品经过0.336 ms形成稳定电弧,稳定至3.696 ms后,等离子云中心颜色开始变浅,体积继续增大。从电弧的形态可以看出,在稳定燃烧阶段,掺杂B后的试样电弧弧根部分面积较大且平整均匀。说明电弧均匀地分布在试样表面很大一片区域,而不是集中在某一处。随着时间的延长和电流的减小,稳定燃弧与衰减没有明显的界限,很难区分,因此,以等离子云减小1/3为稳定燃弧结束,17.136 ms后看不见连续的等离子云,此时试样表面还有阴极斑点在运动;至20.118 ms看不见弧根亮点。图4所示为掺杂2.0%的Nb的WCu合金电击穿过程中不同阶段的电弧形貌。由图4可以看出,样品经过0.378 ms形成稳定电弧;稳定至3.444 ms后,等离子云中心颜色开始变浅,体积增大。与商用样品相比较,掺杂Nb后试样的稳定燃烧阶段的电弧体积较大,颜色较浅,这说明电弧能量较为分散,弧根宽度大概也是商用试样的2倍,这说明电弧没有在试样的局部产生集中。然后等离子云开始明显缩小(1/3),也没有发现明显的电弧颜色变化,16.884 ms后看不见连续的等离子云,此时阴极表面还有亮点在运动;至19.886 ms看不见弧根亮点。

图3 掺杂0.3%B WCu合金的电弧演化过程

Fig.3 Arc evolution process of WCu alloy doping 0.3%B: (a) 0.336 ms; (b) 3.696 ms; (c) 8.652 ms; (d) 10.962 ms; (e) 17.136 ms; (f) 20.118 ms

图4 掺杂2.0%Nb的WCu合金电弧演化过程

Fig.4 Arc evolution process of WCu alloy doping 2.0%Nb: (a) 0.378 ms; (b) 3.444 ms; (c) 8.316 ms; (d) 10.290 ms; (e) 16.884 ms; (f) 19.886 ms

图5所示为掺杂1.5%Ce的WCu合金电击穿过程中不同阶段的电弧形貌。由图5可以看出,试样经过0.294 ms形成稳定电弧;稳定至4.158 ms后,等离子云中心颜色开始变浅,体积增大。与商用样品相比较,掺杂Ce后试样的稳定燃烧阶段的电弧体积较大,弧根在试样表面分布均匀。随后,等离子云开始明显缩小(1/3),也没有发现明显的电弧颜色变化,18.102 ms后看不见连续的等离子云,此时电弧弧根还在快速跳动;至20.580 ms看不见弧根亮点。

图5 掺杂1.5%Ce的WCu合金电弧演化过程

Fig.5 Arc evolution process of WCu alloy doping 1.5%Ce: (a) 0.294 ms; (b) 4.158 ms; (c) 8.820 ms; (d) 11.256 ms; (e) 18.102 ms; (f) 20.580 ms

表2所列为商用电触头材料及含有不同掺杂元素的WCu合金电弧演化过程主要参数。从表2可以看出,商用WCu电触头材料的起弧时间最短,约需0.252 ms,而掺杂B和Nb的合金起弧时间约是它的1.5倍,相比起来延长了起弧时间。掺杂Ce 的试样起弧时间略微高于商用样品的。

表2 含有不同掺杂元素的WCu合金电弧演化过程主要参数

Table 2 Main parameters of WCu alloy with different doping elements during arc evolution process

电弧稳定燃烧时,在弧根有明显的颈缩,颈缩对应着电弧斑点。电弧斑点在燃弧过程中不停地运动,带动弧根运动。从图2中稳定燃弧阶段的弧根变化可以发现,商用WCu电触头材料稳定燃烧时,弧根宽度较小、等离子云体积最小、颜色最深,说明商用WCu电触头材料电弧等离子云电子密度大,使电离层温度升高。而含有掺杂元素的电触头材料的弧根宽度较大,这说明对应的电弧斑点数量多,斑点跳动迅速,铺散开的面积大,运动区域大,说明掺杂元素可以起到分散电弧的作用。这样就使每个电弧斑点通过的电流密度大大减小,在表面电阻相差不大的情况下,电弧斑点的温度降低,电弧烧蚀减轻。且对触头材料的烧蚀主要在稳定燃弧阶段,商用WCu电触头材料稳定燃弧时间最长,而含有掺杂元素的电触头材料的稳定燃烧时间相比较短,因此,含有掺杂元素的合金抗烧蚀性优于商用电触头材料的。

由于材料中各相界面处的结合力相对较弱,电子发射能力较强,所以在富铜区域的边界以及Cu和掺杂元素的相界面首先发生击穿。由于掺杂元素后,合金中铜相分布细小而且分散,所以在材料表面输入电弧热量一定的条件下,击穿不会集中发生在铜相偏聚的区域,因此,产生大面积铜相熔化和飞溅的几率减小,而输入的能量绝大多数被弥散分布铜的蒸发过程所消耗,从而为阴极区域提供了足够的金属蒸汽以维持电弧的稳定燃烧,使得截流值降低,电弧燃烧时间延长。与商用WCu合金相比,弧光没有呈现丰富的放射状光芒,这说明燃弧过程中电流稳定,没有出现大范围波动。

从以上分析可知:含有掺杂元素的WCu合金形弧时间长,电弧稳定燃烧时间短,电弧寿命长,截流值小;等离子云体积大,颜色浅,在阴极表面燃烧区域大,电弧分散,燃弧能量分散。

2.2 抗烧蚀实验

图6所示为商用WCu电触头材料和掺杂不同组元的WCu合金烧蚀10 min的累计质量损失曲线。由图6可以发现,商用WCu电触头材料在相同实验条件下的烧损量最大,而通过在WCu电触头材料中掺杂一定比例的不同组元,烧损量都有明显减小的趋势。其中以掺杂B后的合金最为明显,由烧蚀损失量来看,抗烧蚀性能提高近30%。这表明通过掺杂相关组元可以提高WCu电触头材料的耐电弧烧蚀性能。

图6 含有不同掺杂元素的WCu合金烧蚀累计质量损失曲线

Fig.6 Mass loss curves of WCu alloys with different doping elements

图7所示为商用电触头材料和含有掺杂元素的WCu合金烧蚀后的宏观形貌。在烧蚀后试样端部可看到一种特殊的现象,即在表面出现环状伞行瘤状物(结疤)。这被称之为瑞木现象[13]。由图7可以看出,商用试样经过烧蚀后,电极尖端的锥面已经完全熔化,并且在被烧蚀端的中部出现了一个凹坑(如图7(a)箭头所示);而含有掺杂元素的试样烧蚀端形状相对较为完整,其中掺杂B后的试样尖端形状保持最为完好,表面物质损失量最少。

图7 含有不同掺杂元素WCu合金烧蚀后的宏观形貌

Fig.7 Macro morphologies of WCu alloys with different doping elements: (a) Commercial WCu alloy; (b) WCu-B; (c) WCu-Nb; (d) WCu-Ce

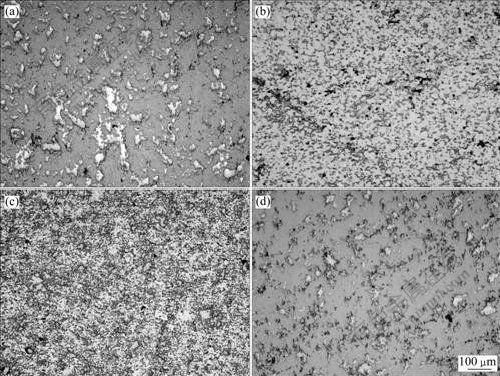

图8所示为商用电触头材料和含有掺杂元素WCu合金烧蚀后的微观形貌。由图8可以看出,商用WCu电触头材料的烧损比较严重,烧蚀后表面比较粗大疏松,烧蚀集中在一些区域,形成了若干处烧蚀深坑(如图8(a)箭头所示)。含有掺杂元素的试样烧蚀后可清晰地看见表面因Cu相飞溅形成W骨架,以及低熔点组元在热效应作用下的熔化逸出以及留下的孔洞。相对于商用样品来说,烧蚀更为均匀,孔洞直径很小,分布十分均匀,说明电弧分散,没有出现因为电弧集中而产生的深坑。其中掺杂B的试样组织最为细小均匀,掺杂Nb的试样组织中孔洞最少。与WCu-B和WCu-Nb相比,掺杂Ce的试样电弧烧蚀后W相有团聚长大的现象(见图8(d)箭头所示)。

图8 含有不同掺杂元素WCu合金烧蚀后的微观形貌

Fig.8 Micro morphologies of WCu alloys with different doping elements: (a) Commercial WCu alloy; (b) WCu-B; (c) WCu-Nb; (d) WCu-Ce

2.3 抗电弧烧蚀性能

掺杂元素B改善WCu合金的抗电弧烧蚀性能的主要原因有以下3种。1) 对于WCu合金,电击穿往往发生在富铜区域,电弧在富铜区域聚集,会在此发生严重的局部熔化,引起铜液的剧烈飞溅。在WCu合金中掺杂一定量的B元素后,改善了铜相的分布,使得铜相分布细小均匀(见图9)。燃弧过程中,电弧不会在富铜区域集中,而是均匀地分布在材料表面很大一片区域里,这样就避免电弧能量集中在富铜区域,对合金局部产生严重烧蚀,进而导致整个触头失效。2) 材料表面的微观凸起会引起局部电场的增加,很容易成为电击穿的场致发射点[14],从而会降低合金表面的击穿强度。而对于在高温电弧作用下WCu-B合 金,液相熔池内弥散分布着具有高熔点、较强的抗高温氧化性能和化学惰性的WB2,这些颗粒能起到异质形核的作用,使得液相凝固时间大幅度减少,从而使触头表面较大微粒形成的几率降低,触头表面较为光滑,细化了表面熔层的显微组织结构,使材料表面的各组元分布趋于一致,因此微粒诱发击穿的概率减小,有利于提高和稳定材料的真空击穿性能。3) 在高温电弧作用下,由于铜相的熔化和挥发,材料强度则主要取决于钨骨架的高温强度。钨虽具有较高的强度和良好的热稳定性,但其强度随温度的上升而显著下降。而高硬度、高熔点以及化学稳定性好的金属硼化物,弥散分布在钨骨架之中,起到弥散强化的作用,显著提高骨架的高温强度。由图7可以看出,商用WCu合金经过长时间的电弧烧蚀,在电极中间因为电弧能量的集中和钨骨架强度的下降而发生塌陷的现象,而掺杂B后的合金烧蚀极为轻微,表面无残缺。

掺杂元素Nb对WCu合金的抗电弧烧蚀性的影 响,主要有以下两个方面。1) 由于材料中各界面处的结合力相对较弱,电子发射能力较强,所以击穿通常发生在铜相的边界及晶界处。在WCu合金中掺杂一定量的Nb元素后,改善了铜相的分布(见图9),使得铜相分布细小均匀,另外,Nb可以细化铜的晶粒。因此,Nb的加入显着增加了铜相与钨相的边界和铜的晶界,这使得电击穿分布在各个界面处,起到了分散电弧的作用。在电弧能量一定的条件下,单位区域所承受的电弧能量较小,减小了局部铜相熔化和飞溅的几率,使得电弧对材料的侵蚀方式发生变化,由以喷溅侵蚀方式转化为以蒸发汽化为主的侵蚀方式。因此,WCu-Nb合金在电弧烧蚀后表面因为铜液飞溅而留下的孔洞最少。2) 铌与钨能形成连续固溶体,起到固溶强化的作用,提高了钨的高温强度。另外,WNb合金在所有钨基合金中具有最好的强度和塑性配合,而且具有比纯钨更高的抗氧化性能。

图9 含有不同掺杂元素WCu合金的显微组织

Fig.9 Microstructures of WCu alloys with different doping elements: (a) Commercial WCu alloy; (b) WCu-B; (c) WCu-Nb; (d) WCu-Ce

掺杂元素Ce改善WCu合金的抗电弧烧蚀性能的主要原因有以下两种。1) 是稀土元素的净化作用,合金中常有O、S、Pb、Bi等杂质元素,这些元素常常沿晶界呈网状分布,增加合金的热脆性。而稀土元素的加入改变这些夹杂物的形态,使夹杂物球化,从而排除或降低夹杂物的有害作用,提高钨骨架的高温强度,进而提高材料的抗烧蚀性。2) 开关在分断电路时,随着电流的减少,触头产生的金属蒸气量持续降低,电弧的稳定性也随之降低。当电流降低到不能维持电弧燃烧时,电弧突然熄灭使放电电流突然下降到零。这种截流现象导致在开关所控制的感性负载上产生很高的过电压[15],对系统和感性负载的绝缘性造成严重威胁。在掺杂Ce的钨铜合金中,部分Ce与O结合生成CeO2,CeO2可以降低材料的电子逸出功[16],提高合金的电子发射能力,使两极间的电弧更为稳定。微量的CeO2延长电弧寿命,降低截流值和过电压,减小电弧熄灭时的过电压对合金表面的冲击,从而提高抗电弧烧蚀能力。

3 结论

1) 钨铜电触头材料的电击穿过程分为起弧阶段、电弧稳定燃烧阶段和灭弧阶段。只是掺杂不同元素的合金3个阶段的持续时间和等离子云的体积、温度不同。

2) 掺杂后的钨铜电触头材料较商用的钨铜合金电弧形弧时间长,对触点表面烧蚀起主要作用的稳定燃烧时间短。电弧寿命长,截流值小;等离子云体积大,颜色浅,在样品表面燃烧区域大,电弧分散,燃弧能量分散;电弧燃烧稳定,无放射状光芒。

3) 含有掺杂元素的WCu电触头材料较商用的WCu合金,其抗电弧烧蚀性能均有明显改善,其中最明显的为WCu-B,其抗烧蚀性能提高了近30%。

REFERENCES

[1] 范景莲, 严德剑, 黄伯云, 刘 军, 汪澄龙.国内外钨铜复合材料的研究现状[J]. 粉末冶金工业, 2003, 13(2): 9-14.

FAN Jing-lian, YAN De-jian, HUANG Bai-yun, LIU Jun, WANG Cheng-long. Current status of R&D of W-Cu composite materials in China and abroad[J]. Powder Metallurgy Industry, 2003, 13(2): 9-14.

[2] ZHAO Nai-qin, LI Jia-jun, YANG Xia-jin. Influence of the P/M process on the microstructure and properties of WC reinforced copper matrix composite[J]. Journal of Materials Science, 2004, 39(15): 4829-4834.

[3] 陈文革, 丁秉均. 钨铜基复合材料的研究及进展[J]. 粉末冶金工业, 2001, 11(3): 45-50.

CHEN Wen-ge, DING Bing-jun. The progress and research of W-Cu matrix composites[J]. Powder Metallurgy Industry, 2001, 11(3): 45-50.

[4] 邵文柱, 崔玉胜, 杨德庄. 电接触材料的发展与现状[J]. 电工合金, 1999(1): 11-35.

SHAO Wen-zhu, CUI Yu-sheng, YANG De-zhuang. The development and present situation of electrical contact materials[J]. Electrical Engineering Alloy, 1999(1): 11-35.

[5] 陶应启, 王祖平, 方宁象, 吴仲春. 钨铜复合材料的制造工艺[J]. 粉末冶金技术, 2002, 20(1): 49-51.

TAO Ying-qi, WANG Zu-ping, FANG Ning-xiang, WU Zhong-chun. Manufacture methods of tungsten-copper composites[J]. Powder Metallurgy Technology, 2002, 20(1): 49-51.

[6] JOHNSON J L, GERMAN R M. Theoretical modeling of densification during activated solid-state sintering[J]. Metal Mater Trans A, 1996, 27(2): 441-446.

[7] 陈文革, 丁秉钧. 纳米晶W-La2O3电极材料的电弧特性[J]. 中国有色金属学报, 2003, 13(5): 1103-1106.

CHEN Wen-ge, DING Bing-jun. Arc characteristic of nanocrystalline W-La2O3 electrode materials[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(5): 1103-1106.

[8] KANG B, GERMAN R M. Power injection molding and infiltration sintering of superfine grain W-Cu[J]. The International Journal of Powder Metallurgy, 1997, 33(4): 55-63.

[9] KIM J C, RYU S S, LEE H, MOON I H. Metal injection molding nanostructured W-Cu composite power[J]. The International Journal of Powder Metallurgy, 1999, 35(4): 47-55.

[10] KIM D G, OH S T, JEON H, LEE C H, KIM Y D. Hydrogen-reduction behavior and microstructural characteristics of WO3-CuO powder mixtures with various milling time[J]. Journal of Alloys and Compounds, 2003, 354(1/2): 239-242.

[11] 王章启, 何俊佳, 邹积岩, 尹小根. 电力开关技术[M]. 武汉: 华中科技大学出版社, 2003: 197-198.

WANG Zhang-qi, HE Jun-jia, ZOU Ji-yan, YIN Xiao-gen. Technology of electric power switch[M]. Wuhan: Huazhong University of Science Technology Press, 2003: 197-198.

[12] RAGHU T, SUNDARESAN R, RAMAKRISHNAN P, RAMAMOHAN T R. Synthesis of nanocrystalline copper tungsten alloys by mechanical alloying[J]. Mater Sci Eng A, 2001, 304/306: 438-441.

[13] HERBERLEIN J V R. Plasma and synthesis of materials[C]// IEEE International Conference on Plasma Science. New York: IEEE, 1984: 101-110.

[14] 王亚平, 张丽娜, 丁秉钧, 周敬恩. 选择性相强化对CuCr触头材料在真空小间隙中耐电压强度的影响[J]. 中国电机工程学报, 1999, 19(3): 46-49.

WANG Ya-ping, ZHANG Li-na, DING Bing-jun, ZHOU Jing-en. Effect of selective strengthening of CuCr contact materials on the dielectric strength in a short vacuum gap[J]. Journal of Proceedings of the Csee, 1999, 19(3): 46-49.

[15] 荣命哲. 电接触理论[M]. 北京: 机械工业出版社, 2004: 181-182.

RONG Ming-zhe. The theory of electrical contact[M]. Beijing: China Machine Press, 2004: 181-182.

[16] 张文禄. 钨电极材料对电弧性能的影响[J]. 稀有金属与硬质合金, 1997, 128(1): 60-62.

ZHANG Wen-lu. The influence of tungsten electrode material on electric arc property[J]. Rare Metals and Cemented Carbides, 1997, 128(1): 60-62.

基金项目:中国博士后基金资助项目(20060401006)

收稿日期:2009-03-02;修订日期:2009-06-11

通信作者:陈文革,教授,博士;电话:029-82312383;E-mail: Wgchen001@263.net

(编辑 李艳红)