文章编号:1004-0609(2015)-05-1244-06

AgCuO电触头材料的电接触性能

陶麒鹦1,周晓龙1,2,周允红1,张 浩1

(1. 昆明理工大学 材料科学与工程学院,昆明 650093;

2. 昆明理工大学 稀贵及有色金属先进材料教育部重点实验室

云南省新材料制备与加工重点实验室,昆明650093)

摘 要:采用原位反应合成法制备CuO含量分别为10%、12%、15%的AgCuO电触头材料,在不同电流条件下对这3种触头材料的燃弧时间、燃弧能量、熔焊力、接触电阻等电接触性能进行了测试分析。结果表明:AgCuO电触头材料的分断燃弧时间随CuO含量的增加而增大;CuO含量为10%的样品(AgCuO(10))分断燃弧时间最为稳定;随电流的增大,AgCuO电触头材料的熔焊力不同程度地增加;电流小于20A时,CuO含量为12%的AgCuO(12)抗熔焊性较好;电流大于20A后,CuO含量为10%的AgCuO(10)抗熔焊性较好。原位反应合成法制备的AgCuO电触头材料的接触电阻随电流增大呈现出下降的趋势。

关键词:AgCuO;燃弧时间;燃弧能量;熔焊力;接触电阻

中图分类号:TG146.4 文献标志码:A

Electrical contact properties of AgCuO electrical contact materials

TAO Qi-ying1, ZHOU Xiao-long1, 2, ZHOU Yun-hong1, ZHANG Hao1

(1. Faculty of Materials Science and Engineering, Kunming University of Science and Technology, Kunming 650093, China;

2. Key Laboratory of Advanced Materials of Yunnan Province, Key Laboratory of Rare-Precious and Nonferrous Metal

Advanced Materials, Ministry of Education, Kunming University of Science and Technology, Kunming 650093, China)

Abstract: AgCuO electrical contact material was prepared by in-situ reaction synthesis method, in which CuO content were 10%, 12%, 15%. Under different current conditions, the three kinds of contact materials properties of arc duration, arc energy, welding force, contact resistance were investigated. The results show that, with the increase of CuO content, the breaking arc duration of AgCuO electrical contact material increases. AgCuO (10) is more stable than the other samples of breaking arc duration. With the increase of current, the welding force of AgCuO electrical contact materials increases in different degrees. When the current is less than 20A, AgCuO (12) in the fusion welding performance is better than others. When the current is greater than 20A, AgCuO (10) in the fusion welding performance is more excellent. The contact resistance of in-situ reaction synthesis of AgCuO electrical contact material decreases with the increase of current.

Key words: AgCuO; arc duration; arc energy; welding force; contact resistance

电触头材料是一种重要的功能与结构材料,被广泛运用于各种电接触系统中[1]。电触头材料在电路中起着接通、负载及断开电流的作用,其性能好坏直接影响着相关设备的使用寿命和安全性。最初的电触头材料采用纯金、纯银、纯铂制备,而后逐渐使用Ag-Cu、Au-Ag、Pt-Ir、Pt-Ag等合金,如今除了银合金系列外, 更多采用的是银金属氧化物(AgMeO)。

最早应用的AgMeO触头材料是AgCdO。长期研究发现,AgCdO电触头材料具有优良的耐电弧侵蚀性、抗熔焊性以及较低的接触电阻[2]。然而该材料存在一个致命的弱点,即含有对人体和环境有害的Cd。为此学者进行了大量的研究后认为,AgSnO2是最有希望替代AgCdO的电触头材料。但AgSnO2电触头材料的不足限制了该材料的发展,集中表现如下:1) AgSnO2接触电阻较大,严重影响低压电器使用性能;2) SnO2硬度较高,导致AgSnO2材料的塑、韧性下降,使其加工成型异常困难[3]。因此,对电触头材料结构、组织性能以及新型电触头材料的研发一直是研究的热点。陈敬超等[4-5]采用合金内氧化法成功制备了AgCuO新型电触头材料,此时AgCuO电触头材料开始受到关注。

目前,国内对AgCuO复合材料的研究主要集中在制备工艺的改进方面。例如周晓龙等[4]对原位反应合成(RS)制备的AgCuO电触头材料电寿命研究后发现,用RS法获得的AgCuO电触头材料电接触寿命高达11.1万次,与同质量分数的AgSnO2电触头材料的相当(电接触寿命为11.0万次),且RS法制备的AgCuO电触头材料电寿命是粉末冶金法(PM)的2倍[5],显示出较为优越的电性能。CHEN等[6]对RS法和PM法制备的AgCuO电触头材料组织性能进行了比较,发现RS法制备的AgCuO材料的塑性优于PM法制备的AgCuO材料的,说明RS法对加工设备的要求低,便于生产。但国内对于AgCuO电触头材料的电接触性能研究报道还较为少见,因此,本文作者采用原位反应合成法制备了不同CuO含量的AgCuO电触头材料,对其在不同电流条件下的燃弧时间、抗熔焊性、接触电阻等特性进行研究。

1 实验

1.1 样品制备

AgCuO电触头材料采用原位反应合成法制备。具体制备方法是:以银粉(纯度≥99.5%)、铜粉(纯度≥99.9%)和氧化剂为原料,按AgCuO中CuO含量分别为10%、12%、15%的比例(分别记为(AgCuO(10),AgCuO(12),AgCuO(15)),将原料用行星式球磨机(型号QM-ISP2)充分混合后装入d 30 mm的钢模中,在冷等静压机(型号QYL100)中以400 MPa的压力保压2 min,脱模后成形为素坯。用真空反应合成烧结炉(型号YSI-65-l350)对素坯进行原位反应合成烧结,烧结温度为850°、时间为3h,炉冷后得到AgCuO复合材料锭坯,再将锭坯挤压、拉拔成d 3 mm×5 mm的线材,最后经冷墩复合触点机(型号YFC≥16)制备得到铆钉状AgCuO电触头样品。

1.2 实验方法

本实验中对上述3种不同CuO含量AgCuO电触头进行研究,其外形尺寸(GB/T 5587-2003)为3 mm×1.3 mm(0.77 mm+1.5 mm×1.6SR0.8 mm,3 mm×1.1(0.5) mm+1.5 mm×1.5 mm下;采用接触电阻参数测试仪(JF-04B,昆明贵金属研究所生产),在电压为18 V、闭合力为0.8 N、开断频率为1 Hz(接通、断开时间均为1 s)、触点间距为1.3 mm的实验环境下,对3种AgCuO电触头分别进行5000次分断闭合实验。对每对复合触点在电流条件分别为10、15、20和25 A的低压直流负载电路下的燃弧时间、燃弧能量、熔焊力及接触电阻进行测试,每种电流条件下各做2次试验,取平均值。

2 结果与讨论

2.1 物相分析

原位反应合成法所制备的AgCuO电接触材料的XRD谱如图1所示。由图1可知,经过原位反应合成后材料中只有Ag和CuO两种物相,说明通过原位反应合成法制备的AgCuO材料中未含其他杂质。

图1 原位反应合成AgCuO电接触材料XRD谱

Fig. 1 XRD patterns of reactive synthesis AgCuO composites

2.2 燃弧时间及燃弧能量

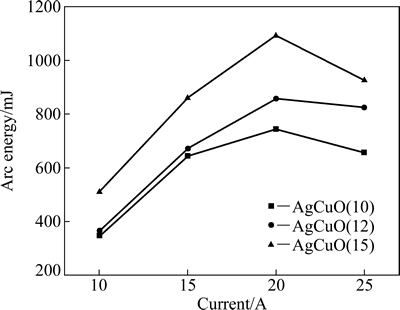

不同电流条件下,5000次电接触试验后3种AgCuO电触头材料的分断燃弧时间、分断燃弧能量与实验电流的关系分别如图2和3所示。

从整体上看,AgCuO电触头材料的分段燃弧时间随CuO含量的增大而增加。其中AgCuO(15)材料的分断燃弧时间明显高于AgCuO(10)材料的与AgCuO(12)材料的,说明随着AgCuO材料中CuO含量的增加,电流对分断燃弧时间的影响开始显现。与AgCuO(10)、AgCuO(12)材料相比,AgCuO(15)材料分断燃弧时间对电流的变化更加敏感。

图2 5000次实验后AgCuO分断燃弧时间-电流曲线

Fig. 2 Breaking arc duration-current curves of AgCuO contact materials after 5000 tests

图3 5000次实验后AgCuO分断燃弧能量-电流曲线

Fig. 3 Breaking arc energy-current curves of AgCuO contact materials after 5000 tests

由图2可知,分断燃弧时间随实验电流的增大先增加而后减小。其中AgCuO(10)材料与AgCuO(12)材料的燃弧时间相差不大。实验电流为10A时,AgCuO(10)材料与AgCuO(12)材料的分断燃弧时间近似一致(约为18.7 ms)。结合图3可知,燃弧能量的变化与燃弧时间的变化成正比。实验电流10~15 A条件下,AgCuO(10)材料与AgCuO(12)材料的燃弧能量区别不大,这可能是它们燃弧时间近似一致的原因;当实验电流增大到15A时,3种材料的分断燃弧时间均急剧增大,AgCuO(15)材料曲线斜率最大,说明AgCuO(15)材料分断燃弧时间随电流的增大而增大的速度最快。其次是AgCuO(12)材料,AgCuO(10)材料的曲线斜率最小;当实验电流超过15 A后,3种材料的分断燃弧时间增长率有不同程度的下降。

研究认为[7-8],触头在分断过程中会形成金属融桥,当进一步分离触头时,金属熔桥断裂造成金属蒸汽粒子化,引燃金属相电弧。当实验电流增加、电弧变长时,金属相电弧逐渐转变为气相电弧。燃弧时间在小电流阶段随电流的增长而快速增加,到中等电流阶段增长率减小,这种现象可以归结为电弧形态与等离子体构成的改变。如图1所示,当实验电流小于15A时,燃弧时间主要是金属相燃弧时间,且由于Cu元素易失去电子,使阴极触头成为热场电子发射的热源,这些电子在电场加速的过程中发生非弹性碰撞,造成更多电子的产生,形成电子雪崩,导致燃弧能量增大,进而对燃弧时间产生影响。而实验电流大于15 A时,燃弧时间主要是气相燃弧时间。也有研究认为[9-11],燃弧时间与触头表面凹凸状况、电源电压、触头分离速度等因素相关。

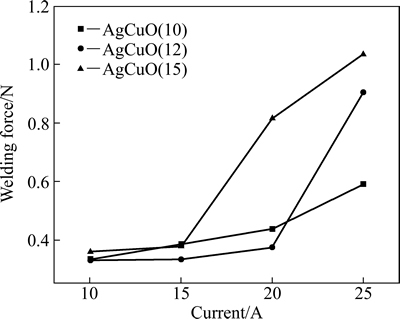

2.3 熔焊力

不同电流条件下,5000次分断实验后3种AgCuO电触头材料的熔焊力与实验电流的关系如图4所示。

总体来看,3种AgCuO电触头材料熔焊力均随电流的增大而增加。当电流小于20A时,AgCuO(12)样品熔焊力随电流的变化最为稳定,且熔焊力低于其他两种样品的。而当电流超过20A后,AgCuO(10)样品表现出更佳的抗熔焊性能。

图4 5000次实验后AgCuO熔焊力与电流的关系曲线

Fig. 4 Curves of AgCuO contact material welding force with current after 5000 tests

对比3种AgCuO电触头材料在不同电流下的熔焊力可知,当实验电流小于15A时,AgCuO(10)样品和AgCuO(15)样品的熔焊力曲线近似重合,而AgCuO(12)样品的熔焊力明显低于其他两种试样的;当实验电流不断增大至20A时,AgCuO(15)样品熔焊力急剧增大,表现出较差的抗熔焊性能,此时,AgCuO(10)样品与AgCuO(12)样品相比初始阶段并无明显差别;当实验电流超过20 A后,AgCuO(12)样品的熔焊力由0.35 N(20 A)迅速上升至0.89 N(25 A)。可以看出,3种电触头材料的熔焊力随着电流的增大均出现不同程度的升高,但并无明显规律。

整个实验过程中,AgCuO(15)样品的熔焊力波动性很大,而AgCuO(10)样品的熔焊力最为稳定,出现这种现象的原因是由于CuO含量的增加,材料强、硬度相应增大,根据KAPLAN等[12]提出的抗熔焊性判据方程(见式1)可知:

(1)

(1)

式中:Kwt为抗熔焊性判据;H为材料硬度;γ为密度;ρ表示电阻率。可见,当材料的硬度增大时,Kwt减小,即材料的抗熔焊性越差,表现为熔焊力升高,波动较大。

实际上,电接触材料的强度与其电接触性能密切相关,在电接触理论的中,有学者研究了熔焊力与材料强度、熔池接触面积的关系[13-14]。荣命哲[14]提出,熔焊力主要取决于熔焊面和触头材料的抗拉程度。假定AgCuO触头端面熔焊处的抗拉强度与触头材料的抗拉强度相等,则熔焊力与熔焊截面面积以及触头的抗拉强度的关系可用式(2)表示:

(2)

(2)

式中:F为熔焊力;σ为抗拉强度;S为载流接触面。在AgCuO电接触材料中,CuO含量的增加致使材料中第二相强化作用越显著,在第二相强化的作用下,材料的抗拉强度增大,即σ增加,材料的熔焊力F相应增大,与本实验结果基本吻合。

从文献[15-16]可看出,触头材料的抗熔焊性能与第二相金属氧化物在电触头表面的行为有关。刘向军[15]认为,在电弧作用下,AgSnO2触头表面形成金属熔池,但由于SnO2的热稳定性较高,一般无法达到SnO2的分解温度,同时SnO2与基体Ag的润湿性较差,造成大量SnO2颗粒悬浮在金属熔池表面,导致熔焊面的脆性,进而使熔焊面在分断力的作用下断裂,提高抗熔焊性能。张逸成等[17]指出,当电弧功率较大时,尤其是弧根作用的区域表面温度远高于SnO2分解温度时,通断操作中原有的第二相金属 氧化物SnO2将不存在,此时,AgSnO2的抗熔焊性实际表现为AgSn复合触头材料的抗熔焊特性。

2.4 接触电阻

不同电流条件下,5000次分断实验后3种AgCuO电触头材料的接触电阻与实验电流的关系如图5所示。

对比同等级电流条件下的AgSnO2电触头材料[18]可以明显看出,采用粉末冶金法制备的AgSnO2电触头材料接触电阻随着电流的增加而增大;而采用原位反应合成法制备的3种AgCuO电触头材料的接触电阻均随电流的增加而不同程度的呈现出逐渐下降的趋势(见图5),这进一步说明了AgCuO电触头材料具有独特的电接触性能。

图5 5000次试验后AgCuO接触电阻与电流的关系曲线

Fig. 5 Curves of AgCuO contact material contact resistance with current after 5000 tests

从图5中可以看出,当实验电流不大于15A时,AgCuO(10)样品和AgCuO(15)样品的接触电阻随电流的增大而急剧下降。当电流条件为10A时,AgCuO(10)样品的接触电阻约为118 mΩ;当电流增大到15A时,接触电阻迅速下降至77 mΩ左右,而AgCuO(12)样品的接触电阻下降的速度远低于AgCuO(10)样品和AgCuO(15)样品的,接触电阻由小到大的顺序依次为AgCuO(12)、AgCuO(10)、AgCuO(15);当电流由15A增大至20A时,AgCuO(10)样品和AgCuO(12)样品的接触电阻随电流的增加变化不大,两曲线近似重合,说明该阶段AgCuO(10)样品与AgCuO(12)样品的接触电阻相差不大;当实验电流大于20A后,AgCuO(10)样品接触电阻出现明显下降趋势,此时接触电阻由小到大的顺序依次为AgCuO(10)、AgCuO(12)、AgCuO(15)。

分析认为,电触头材料接触电阻的大小与触点表面的膜电阻的大小以及收缩电阻的大小密切相关。如前所述,AgCuO(10)硬度较其AgCuO(12)、AgCuO(15)的硬度低,抗变形能力较差,电接触实验的过程中,在冲击载荷的作用下,AgCuO(10)样品的接触端面易变形,触头间实际接触的导电斑点将增多,导致收缩电阻减少,表现出较低的接触电阻。

AgCuO电触头材料接触电阻随电流的增加而下降,其主要原因之一是由于随着实验电流的增加,电弧的燃弧能量增大(见图3),导致电弧侵蚀速度增大,电触头表面熔池中的CuO分解速度加快,同时产生Cu2O。由于Cu2O与Ag的润湿角较小(Cu2O的润湿角约为22°,CuO的约为54°),导致富集在熔池表面的Cu2O与CuO氧化膜较少,进而减小了膜电阻,使AgCuO电触头材料的接触电阻降低。另外,由于电流增加导致燃弧能量增大,使触头表面局部区域的温度升高,对于熔池表面存在氧化膜的电触头材料,温度升高会导致材料的变形抗力下降,使得电触头表面实际接触面积增大,同时电触头表面受热膨胀,加剧了触头表面膜的破坏,在触头表面形成更多的导电斑点,进而使接触电阻下降。

3 结论

1) AgCuO电触头材料的分段燃弧时间随CuO含量的增加而增大。随电流增大,分断燃弧时间缩短,较为稳定的是AgCuO(10)触头材料。

2) 随电流的增大,AgCuO电触头材料的熔焊力呈不同程度的增加。当电流小于20A时,AgCuO(12)样品的熔焊力最小且最为稳定,表现出较好的抗熔焊性能;当电流大于20A后,AgCuO(10)触头材料抗熔焊性能较好。

3) 原位反应合成法制备的AgCuO电触头材料的接触电阻呈现出随电流增大而不断下降的趋势。其中,AgCuO(10)触头材料接触电阻下降最为显著,而AgCuO(12)触头材料接触电阻最为稳定。

4) 当电流小于20A时,AgCuO(12)触头材料无论是燃弧时间、抗熔焊性能、接触电阻等方面均表现较好,说明AgCuO(12)适合在电流较小的低压电器中使用。

REFERENCES

[1] SLADE, PAUL G. Electrical contacts: principles and applications[M]. Florida: The Chemical Rubber Company Press, 2013: 233-234.

[2] PONS F, CHERKAOUI M, ILALI I, et al. Evolution of the AgCdO contact material surface microstructure with the number of arcs[J]. Journal of Electronic Materials, 2010, 39(4): 456-463.

[3] 许灿辉, 易丹青, 曹适意, 刘会群, 吴春萍, 孙顺平, 刘润勇. Ag-SnO2复合材料的热压缩变形行为[J]. 中国有色金属学报, 2011, 21(9): 2091-2098.

XU Can-hui, YI Dan-qing, CAO Shi-yi, LIU Hui-qun, WU Chun-ping, SUN Shun-ping, LIU Run-yong. Hot compression behavior of Ag-SnO2 composite material[J]. The Chinese Journal of Nonferrous Metals, 2011, 21(9): 2091-2098.

[4] 周晓龙, 陈敬超, 曹建春, 杜 焰, 张昆华, 甘国友, 孙加林, 闫杏丽. 反应合成制备Ag/CuO电触头材料及其组织性能[J]. 机械工程材料, 2006, 29(11): 49-51.

ZHOU Xiao-long, CHEN Jing-chao, CAO Jian-chun, DU Yan, ZHANG Kun-hua, GAN Guo-you, SUN Jia-lin, YAN Xin-li. Microstructure and properties of Ag/CuO electrical contact materials fabricated by reactive synthesis[J]. Materials For Mechanical Engineering, 2006, 29(11): 49-51.

[5] 周晓龙, 曹建春, 陈敬超. 制备工艺对AgCuO电接触材料组织和电寿命的影响[J]. 贵金属, 2005, 26(3): 25-29.

ZHOU Xiao-long, CAO Jian-chun, CHEN Jing-chao. Effects of preparation method on microstructure and electrical contact performance for AgCuO composites[J]. Precious Metals, 2005, 26(3): 25-29.

[6] CHEN J, SUN J, DU Y. Investigation of electrical conductivity of silver tin oxide electrical contact materials fabricated by reactive synthesis[J]. Rare Metal Materials and Engineering, 2003, 32(12): 1053-1056.

[7] CHEN Z, WITTER G. Dynamic welding of silver contacts under different mechanical bounce conditions[C]//Proceedings of the Forty-Fifth IEEE Holm Conference on Electrical Contacts, 1999. Waukegan: IEEE Conference Publications, 1999: 1-8.

[8] CHEN Z K, SAWA K. Particle sputtering and deposition mechanism for material transfer in breaking arcs[J]. Journal of applied physics, 1994, 76(6): 3326-3331.

[9] 徐金玲. 继电器触头燃弧时间分析及其试验[D]. 武汉: 华中科技大学, 2007: 48-54.

XU Jin-ling. Arcing time analysis and test of electric relay contact material[D]. Wuhan: Huazhong University of Science and Technology, 2007: 48-54.

[10] 刘明泽, 王 珂, 李震彪, 李 晨. 汽车起动器触点通断过程燃弧时间试验研究[J]. 电工材料, 2012(1): 11-14.

LIU Ming-ze, WANG Ke, LI Zhen-biao, LI Chen. Experimental study on arcing duration of automotive starter[J]. Electrical Engineering Materials, 2012(1): 11-14.

[11] 宋晓亮, 李震彪, 狄美华, 吴细秀. 汽车继电器燃弧时间分析[J]. 低压电器, 2005(8): 6-10.

SONG Xiao-liang, LI Zhen-biao, DI Mei-hua, WU Xi-xiu. Arc duration of automobile relay electrical contacts[J]. Low Voltage Apparatus, 2005(8): 6-10.

[12] KAPLAN M, TSLAF A. Criteria for the weldability of contact materials in adiabatic transient conditions[J]. Components Hybrids and Manufacturing Technology IEEE Transactions, 1984, 7(1): 33-38.

[13] 徐 坚, 熊惟皓, 傅江华, 李震彪. 第二相氧化物对银基触头材料熔池影响的模拟分析[J]. 中国有色金属学报, 2008, 18(7): 1326-1327.

XU Jian, XIONG Wei-hao, FU Jiang-hua, LI Zhen-biao. Simulation analysis of effect of second metal-oxide phase on molten pool in Ag-based electrical contact[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(7): 1326-1327.

[14] 荣命哲. 电接触理论[M]. 北京: 机械工业出版社, 2004: 105-107.

RONG Ming-zhe. Electric contact theory[M]. Beijing: China Machine Press, 2004: 105-107.

[15] 刘向军. 开关电器触头熔焊机理分析[J]. 低压电器, 2006(9): 11-14.

LIU Xiang-jun. Analysis of welding mechanism on electrical contact of switches[J]. Low Voltage Apparatus, 2006(9): 11-14.

[16] 刘 辉, 王逸虚, 覃向忠, 蒙建洲. 浅析不同添加剂对AgSnO2(12)触头材料电性能的影响[J]. 电工材料, 2013(1): 3-9.

LIU Hui, WANG Yi-xu, QIN Xiang-zhong, MENG Jian-zhou. Effects of different additives on electrical performance of AgSnO2(12) contact materials[J]. Electrical Engineering Materials, 2013(1): 3-9.

[17] 张逸成, 李震彪, 程礼椿, 张学康. 银金属氧化物触头材料的表面劣化及抗熔焊性能分析[J]. 中国电机工程学报, 1999, 19(4): 54-58.

ZHANG Yi-cheng, LI Zhen-biao, CHENG Li-chun, ZHANG Xue-kang. Contact surface deterioration and welding resistance of AgMeO contact materials[J]. Proceedings of the CSEE, 1999, 19(4): 54-58.

[18] 蒙建洲, 王立忠, 王逸虚, 侯月宾, 刘 辉, 李耀林. 不同电流等级下添加剂对AgSnO2触头材料电性能特性的影响[J]. 电工材料, 2013(4): 7-9.

MENG Jian-zhou, WANG Li-zhong, WANG Yi-xu, HOU Yue-bin, LIU Hui, LI Yao-lin. Effects of additives on electrical behavior of AgSnO2 contact materials at different current[J]. Electrical Engineering Materials, 2013(4): 7-9.

(编辑 龙怀中)

基金项目:国家自然科学基金资助项目(51361016);稀贵及有色金属先进材料教育部重点实验室开放基金资助项目(ZDS2010014B);昆明理工大学校人才培养基金资助项目

收稿日期:2014-08-20;修订日期:2015-01-06

通信作者:周晓龙,教授,博士;电话:15087063410;E-mail:kmzxlong@163.com