DOI:10.19476/j.ysxb.1004.0609.2019.06.13

真空热压烧结-内氧化法制备Al2O3-Cu/(W, Cr)触头材料的电接触性能

张晓辉1, 2,田保红1, 2,刘 勇1, 2,张 毅1, 2,宋克兴1, 2,李全安1, 2

(1. 河南科技大学 材料科学与工程学院,洛阳 471023;

2. 有色金属共性技术河南省协同创新中心,洛阳 471023)

摘 要:采用真空热压烧结-内氧化法制备Al2O3-Cu/(25)W(5)Cr和Al2O3-Cu/(35)W(5)Cr电触头材料,分别测试其致密度、导电率和布氏硬度;利用场发射扫描电镜分析触头材料的微观组织;利用JF04C电接触触点测试系统研究两种触头材料的电接触性能。结果表明:纳米Al2O3颗粒钉扎位错引起位错缠结;在电弧侵蚀过程中,Al2O3-Cu/(25)W(5)Cr触头在30 A时有少部分材料从阳极转移至阴极,但两种触头材料最终的质量转移方向都是从阴极转移到阳极;电弧侵蚀过程中随着Cu的熔化、蒸发和喷溅,W颗粒逐渐聚集并形成针状的骨架,阳极形成了凸起,阴极留下灼坑;当弥散铜基体中W 的含量从25%增加至35%(质量分数)时,触头的熔焊力下降,抗熔焊性能提高。

关键词:真空热压烧结;电接触;电弧侵蚀;材料转移;熔焊力

文章编号:1004-0609(2019)-06-1242-08 中图分类号:TG146.1+1 文献标志码:A

真空开关是采用真空作为绝缘和灭弧介质从而对电路实现闭合和分断的设备,广泛应用于电力电气、石油化工和冶金等各个领域。随着一大批国家大型工程的发展和电力系统的升级改造,对安全可靠长寿命智能化真空开关的需求越来越大。触头是真空开关中的核心部件,主要起着接通电路、载流和分断电路的作用,触头材料的好坏决定着真空开关的使用寿命。电接触的产生、维持和消除过程会伴随有接触原件局部高温、熔焊、磨损以及电弧放电等多种物理和化学作用[1-2]。根据其在不同场合发挥的作用,对真空开关触头材料的基本要求是真空开关具有良好的耐磨损和抗电弧侵蚀性能、良好的抗熔焊性能、高导电导热性和低的接触电阻[3-4]。采用内氧化法制备的纳米Al2O3增强弥散铜不仅具有高强度和高传导性,而且再结晶温度高,热稳定性能良好[5]。W的熔点高、密度和硬度大、强度高、热膨胀系数低,Cu和W组成的复合材料兼具高传导性和良好的耐电弧侵蚀等优点,被广泛应用于电触头材料[6];万成等[7]的研究表明W-25Cu电触头材料电弧侵蚀后主要由Cu、W、WO3三相组成,抗电弧侵蚀性能良好。彭清艳[8]的研究表明:采用烧结熔渗法制备的CrW/Cu复合材料比CuCr合金具有更高的耐压强度和更低的截流值。铬具有较高的熔点和硬脆特性,截流值小,分断能力强,对氧具有很大的亲和性保证了真空开关触头良好的吸气能力;另外,Cr和Cu相近的蒸汽压保证了电弧侵蚀后触头的成分稳定,这些特点决定了铜铬合金在真空开关触头材料领域的广泛应用[9]。

本文采用真空热压烧结-内氧化法制备了Al2O3- Cu/(25)W(5)Cr和Al2O3-Cu/(35)W(5)Cr(质量分数,%)触头材料,测试了其致密度、导电率和硬度,利用JF04C电接触触点测试系统进行电接触实验后分析了两种触头材料在不同电流下阴阳极材料转移量的变化,并对电弧侵蚀形貌和熔焊力变化进行了分析。

1 实验

实验所用原材料为粒径2~5 μm的Cu-0.4%Al合金粉(质量分数),平均粒径44 μm的Cr粉和平均粒径为5 μm的W粉,采用粒径2~5 μm的Cu2O粉作为氧源。复合材料成分配比如表1所列,经充分混合后在ZMY-50-15型真空钼丝热压烧结炉中进行烧结,工艺参数为:真空度3~4 Pa,升温速率10 ℃/min,升温至650 ℃时加压15 MPa,保压1 h后卸压;继续升温至950 ℃后开始保温,1h后随炉冷却,温度降至100 ℃时取出试样。

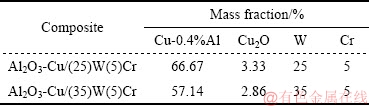

表1 Al2O3-Cu/(W, Cr)复合材料成分配比

Table 1 Composition ratio of Al2O3-Cu/(W, Cr) composites

对烧结后的试样使用Sigma2008B1数字电导率仪测试导电率;使用流体静力天平利用阿基米德排水法测量并计算其致密度;采用HB-3000B布氏硬度计,按照GB/T231.1-2009的标准进行布氏硬度测试;利用JSM-7800F场发射扫描电子显微镜分析烧结态试样的微观组织。

将烧结态复合材料线切割成尺寸为d 3.8 mm×8 mm的圆柱形试样作为阴阳极触头,触头端面经过打磨抛光处理后使用精度0.1 mg、型号为FA2004B的电子天平称取质量,触头材料的转移和损耗用实验前后的触头质量变化△m来表示。然后在JF04C电接触触点测试系统上进行10000次的触头闭合断开实验,每个试样重复两次。试验参数设置如下:上部触头为动触头,作为阳极;下部触头为静触头,作为阴极;直流电压30 V,试验在恒流模式下进行,电流分别设置为10 A、20 A、25 A和30 A;触头间接触压力0.40~0.60 N,触头通断频次为60次/min,试验后再次称量质量。最后使用JMS-5610LV扫描电镜观察并分析动静触头的电弧侵蚀形貌。

2 结果与讨论

2.1 Al2O3-Cu/(W,Cr)复合材料的性能和显微组织

表2所列为两种触头材料的综合性能,采用真空热压烧结-内氧化法制备的Al2O3-Cu/(25)W(5)Cr和Al2O3-Cu/(35)W(5)Cr两种触头材料的致密度均在97%以上,当W含量增加时,烧结态试样的导电率从67.28%IACS下降至62.20%IACS,而布氏硬度从102.31HBW上涨至126.78HBW。影响触头材料导电率的因素:电阻率高于弥散铜的W颗粒无规律地分布在基体上,且和基体互不相溶,增加了基体的不完整性,从而造成电阻增加;另外,烧结过程中材料中残存的微气孔和添加相颗粒与基体间产生的内应力都会造成对电子的散射作用加强[10-11]。W 颗粒硬度高,较为均匀地分布在基体上,阻碍位错运动且因周围塞积的位错环对位错源的反作用力,从而使复合材料硬度升高。

表2 Al2O3-Cu/(W, Cr)复合材料的综合性能

Table 2 Comprehensive properties of Al2O3-Cu/(W, Cr) composites

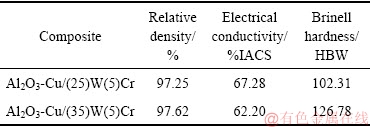

图1所示为两种触头材料的金相照片和扫描电镜下的EDS分层叠加图像。从图1可以看出,两种电触头材料结构致密,W和Cr颗粒较均匀地分布在弥散铜基体上,大颗粒为Cr相,小颗粒为W相,无明显孔洞和团聚现象。

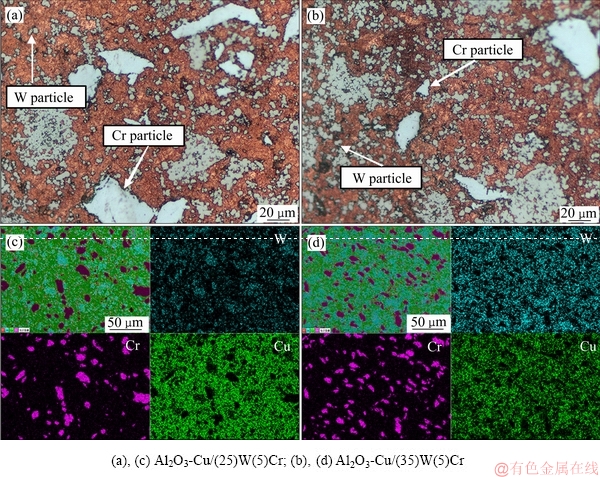

Al2O3-Cu/(35)W(5)Cr触头材料的TEM像如图2所示。由图2(a)可见,纳米Al2O3颗粒弥散分布在铜基体上,Al2O3颗粒钉扎位错并引起了位错塞积,从而起到弥散强化的作用,使触头材料的高温性能得到提高。

2.2 电弧引起的触头材料转移

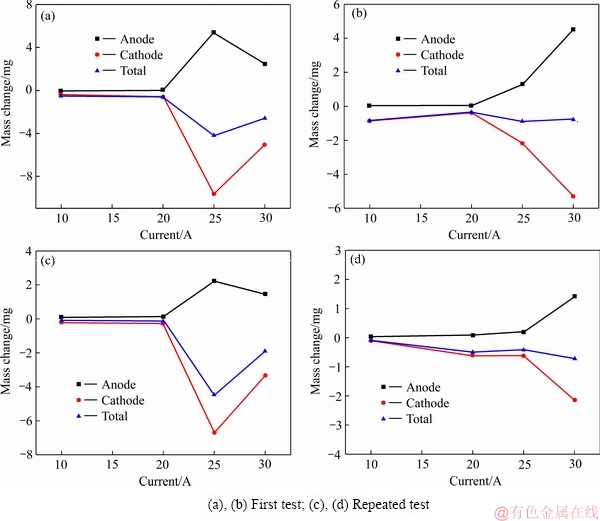

电触头在电弧作用下引起的材料转移和损耗直接影响着开关电器中触头的使用寿命。图3所示为Al2O3-Cu/(25)W(5)Cr和Al2O3-Cu/(35)W(5)Cr触头材料在DC 30 V和不同电流下电接触试验前后的触头质量变化。首次试验 (见图3(a)和(b)) 和重复试验(见图3(c)和(d)) 的结果相比,同一种触头材料的不同试样质量变化趋势基本相同。在每一次电接触实验中,阳极和阴极触头总的质量变化量全部为负数,这就意味着在电弧侵蚀过程中,有少部分材料散失到周围环境中造成材料的损耗。对于Al2O3-Cu/(25)W(5)Cr触头,电流从10 A增加至25 A时,材料的转移量大体上呈增加趋势;但当电流增加至30 A时,材料的转移量有所下降。然而,对于Al2O3-Cu/(35)W(5)Cr触头,随着电流从10 A增加至30 A,材料的转移量逐渐增加;在25~30 A 之间,Al2O3-Cu/(25)W(5)Cr与Al2O3-Cu/ (25)W(5)Cr触头呈现一种相反的变化趋势。

图1 Al2O3-Cu/(W, Cr)复合材料烧结态微观组织的金相照片和EDS分层图

Fig. 1 Optical images((a), (b)) and EDS layered graph((c), (d)) of Al2O3-Cu/(W, Cr) composites

图2 Al2O3-Cu/(35)W(5)Cr触头材料的TEM像

Fig. 2 TEM images of Al2O3-Cu/(35)W(5)Cr composite

分析原因如下:电流较小时,电弧弧柱温度较低,因而电离产生的带电粒子较少。为了维持电弧稳定,只能靠阴极表面发射电子,于是阳离子在阴极表面聚集以提高电场强度。与此同时,阴极区电弧发生收缩,以便提高电流密度,从而使靠近阴极的区域发生电离,弥补电场发射的不足。最终阳离子的聚集和电弧弧柱的收缩造成电弧输入阴极的热流密度增加,材料从阴极转移至阳极[12]。电流增加时,弧柱温度升高,维持电弧所需要的带电粒子增多,不再依赖阴极发射电子和阴极收缩区的电离,阴极区电弧收缩现象消失。为了维持电弧且弧压最小,阳极区弧柱发生收缩,电弧对阳极触头有瞬时而集中的热流输入,从而使材料从阳极转移至阴极。因此,对于Al2O3-Cu/(25)W(5)Cr触头,当电流增加至30 A时有少部分材料发生了从阳极到阴极的转移,但从阴极到阳极的材料转移仍然主导着最终的材料转移方向。然而对于W含量较高的Al2O3-Cu/(35)W(5)Cr触头,由于W具有高熔点和低的饱和蒸汽压,电流增加到30 A时,维持电弧燃烧的带电粒子增加幅度不大,仍然需要依靠阳离子的聚集和阴极电弧收缩维持电弧燃烧,从阳极到阴极的材料转移不能发生。因此随着电流从10 A增加至30 A,材料一直从阴极转移至阳极,且转移量逐渐增大。

另外,为了解释在电弧放电过程中的材料转移现象,CHEN等[13]提出了PSD(Particle sputtering and deposition)模型:具有不同导电性能的粒子在金属蒸气电弧和气体电弧阶段发挥着不同的作用。在金属蒸气阶段,电子、金属离子和金属原子在阴阳极表面电场力的作用下轰击阳极表面导致金属离子沉积在阴极表面;在气体电弧阶段,气体离子、气体分子等轰击阴极表面造成熔融金属的飞溅并沉积在阳极表面,从而材料从阴极转移到阳极。也有研究认为触头在断开时随着触头间距的增加和金属蒸汽的减少,金属电弧最后转变为气体电弧;当触头间距继续增加时,电弧的侵蚀作用越来越弱直至电弧熄灭[14-15]。电弧侵蚀是这几个阶段综合作用的结果,其中优势过程最终决定两极触头的材料转移方向。在弥散铜基体中加入W,电弧侵蚀后留下的硬质骨架结构可以限制熔融金属的流动从而减少电弧侵蚀过程中的质量转移和损耗。对Al2O3-Cu/(W, Cr)触头材料而言,气体电弧侵蚀对于材料的转移和损耗起主导作用。

2.3 触头电弧侵蚀形貌

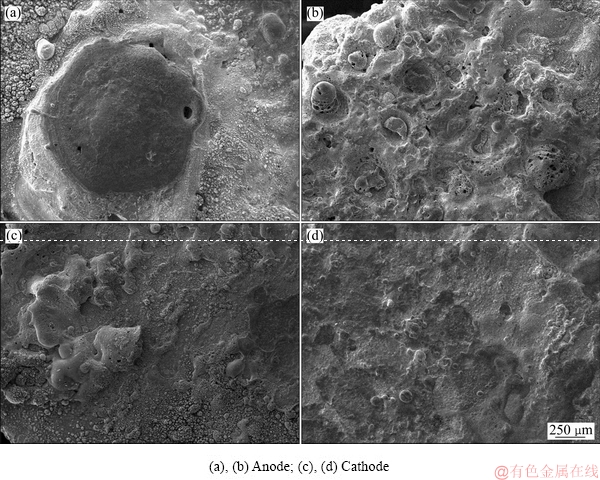

图4所示为Al2O3-Cu/(25)W(5)Cr和Al2O3-Cu/ (35)W(5)Cr复合材料在DC(30 V,30 A)条件下开闭10000次之后触头电接触表面侵蚀形貌。

低倍下对DC(30 V,30 A)试验条件下两种触头材料的阴极表面侵蚀形貌进行观察分析发现,在电弧作用下阳极表面形成许多凸起,阴极表面都形成了许多凹坑。当触头材料中的W含量由25%增加到35%时,阴极触头的灼坑变少,侵蚀程度变轻。因此在该试验条件下W含量的增加有助于提高电触头的抗电弧侵蚀能力。

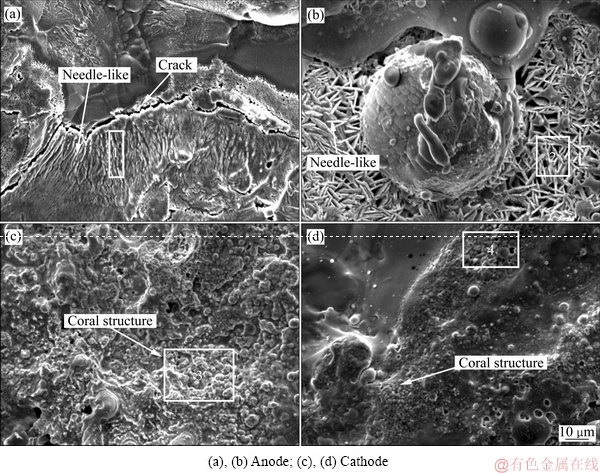

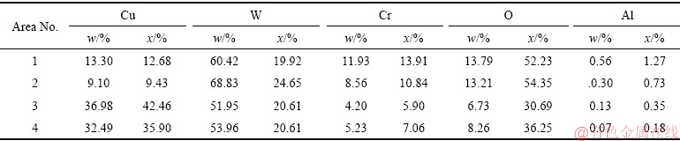

在DC(30 V,30 A)试验条件下电弧对两种触头材料的阳极和阴极的侵蚀形貌的高倍电镜照片如图5所示。在触头表面形成了液滴、针状结构、凹坑和凸起等典型的电弧侵蚀形貌。对图5高倍电镜下的侵蚀形貌中局部微区进行能谱成分(EDS)分析,数据如表3所列。

图3 电触头材料质量变化与电流的关系

Fig. 3 Relationship between contacts material mass change and current of Al2O3-Cu/(25)W(5)Cr((a), (c)) and Al2O3-Cu/ (35)W(5)Cr((b), (d))

图4 低倍电镜下两种电触头的整体形貌

Fig. 4 Low-magnification images of arc erosion morphology of Al2O3-Cu/(25)W(5)Cr((a), (c)) and Al2O3-Cu/(35)W(5)Cr((b), (d))

图5 高倍电镜下两种电触头材料的电弧侵蚀形貌

Fig. 5 High-magnification images of arc erosion morphology of Al2O3-Cu/(25)W(5)Cr((a), (c)) and Al2O3-Cu/(35)W(5)Cr((b), (d))

表3 电触头材料电弧侵蚀后不同微区的能谱分析

Table 3 EDS analysis of different areas after arc erosion

对图5(a)中选区1和选区2的针状骨架进行EDS分析显示W的质量分数高达60.42%和68.83%,这是因为材料的熔沸点越高,在电弧侵蚀过程中相同的温度下蒸发量就越小,蒸发和喷溅过程中材料的损失主要以铜为主[16-17]。在电弧燃弧过程中,当Cu、W形成的毛细管中的Cu在电弧作用下飞溅或蒸发后,表面的某些W粒子便裸露于介质中,在电弧高温作用下这些W粒子会发生再烧结现象,表面效应使W粒子球化或向表面转移,W颗粒逐渐聚集最终形成骨架状结构,而且这种骨架状结构的导电性差且脆,容易产生裂纹。图5(d)中电弧侵蚀后的阴极触头表面右侧有液体铺展现象,在右侧分布有珊瑚状的结构。图5(c)、(d)中选区3和4的珊瑚状组织EDS分析显示W元素质量分数分别是51.95%和53.96%,所以珊瑚状组织也含有大量的W元素。

2.4 不同电流不同材料熔焊力的变化

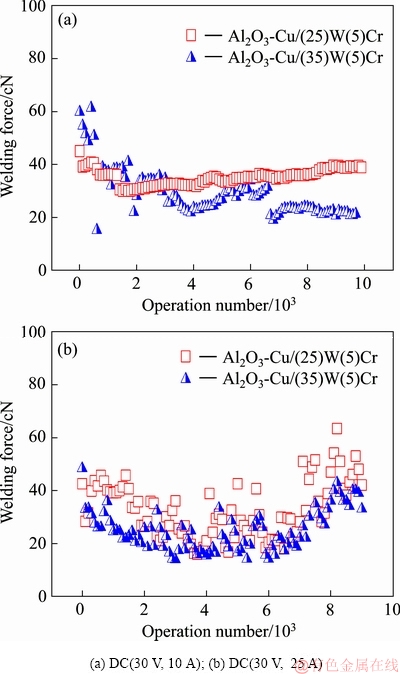

在DC(30 V,10 A)和DC(30 V,25 A)试验电流下,选取Al2O3-Cu/(25)W(5)Cr和Al2O3-Cu/(35)W(5)Cr电触头每100次操作的熔焊力的平均值建立熔焊力和操作次数的函数关系如图6所示。

熔焊是触头闭合时形成的电弧加热触头表面直至熔融,熄弧后熔池凝固而形成焊点的现象[18]。陶麒鹦等[19]提出熔焊面和材料的抗拉强度对触头的熔焊力影响很大,当材料的抗拉强度增大时材料的熔焊力相应增加;王振宇等[20]的研究表明W对银镍触头的抗熔焊性能影响显著:在银镍中添加1.5%的W能够降低最大熔焊力并减少电弧侵蚀量;于力等[21]的研究表明触头材料的熔点、熔化潜热、气化潜热和导电导热率与其抗熔焊性能呈正比。从图6(a)可以看出,10 A时在试验的起始阶段熔焊力波动较大,这是因为在试验的起始阶段由于触头表面粗糙度和初始形貌的不同导致接触压力的变化,从而对熔焊力造成了一定影响,尤其是表面粗糙度对熔焊力影响显著。两种触头在DC 30 V-25 A条件下的平均熔焊力分别 为0.31 N和0.23 N,即W含量从25%提高至35%后,平均熔焊力下降了0.08 N。当触头材料中的W含量由25%增加至35%时,抗熔焊性能有所提高。这是因为在弥散铜基体中加入W,由于W和Cu互不相溶,大量分散的硬质点W在熔焊区形成骨架状结构,对熔焊程度有较大的消弱作用。

图6 不同电触头材料在不同电流条件下的熔焊力变化

Fig. 6 Welding force variation of different electrical contacts under different current values

3 结论

1) 利用真空热压烧结和内氧化结合的方法制备了两种触头材料,纳米Al2O3颗粒钉扎位错引起位错缠结,W颗粒和Cr颗粒均匀分布在弥散铜基体上,无明显团聚现象。

2) 在DC(30 V,10~30 A)试验条件下Al2O3-Cu/ (25)W(5)Cr和Al2O3-Cu/(35)W(5)Cr电触头材料在试验前后阳极质量增加,阴极质量减小;Al2O3-Cu/ (25)W(5)Cr触头在30 A时有少部分材料从阳极转移至阴极,但两种触头材料最终的转移方向是从阴极转移至阳极。

3) 两种触头材料在电弧侵蚀后形成了凸起、凹坑、针状结构和珊瑚状组织等典型的电弧侵蚀形貌;当W的含量由25%增加至35%时,阴极表面更加平整,凹坑变少。

4) 在弥散铜基体中添加W之后,随着W的添加量的增加,电触头的熔焊力下降,抗熔焊性能有所提高。

REFERENCES

[1] 郭凤仪, 陈忠华. 电接触理论及其应用技术[M]. 北京: 中国电力出版社, 2008: 1-10.

GUO Feng-yi, CHEN Zhong-hua. Electrical contact theory and application technology[M]. Beijing: China Electric Power Press, 2008: 1-10.

[2] 陈文革, 陈勉之, 邢力谦, 李金山, 洪 峰. 掺杂对WCu电触头材料电弧特性的影响[J]. 中国有色金属学报, 2009, 19(11): 2029-2037.

CHEN Wen-ge, CHEN Mian-zhi, XING Li-qian, LI Jin-shan, HONG Feng. Effect of doping on electrical arc characteristic of WCu electrical contact materials[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(11): 2029-2037.

[3] 山岸宣行. 电触头材料[J]. 电工材料, 2011(2): 41-48.

NOBUYUKI Y. Electrical contact materials[J]. Electrical Engineering Materials, 2011(2): 41-48.

[4] 陈文革, 黎 斌. CuW触头材料的制备及失效分析[J]. 电工材料, 2010(4): 9-14.

CHEN Wen-ge, LI Bin. Fabrication and failure analysis of CuW composite contact materials[J]. Electrical Engineering Materials, 2010(4): 9-14.

[5] 田保红, 宋克兴, 刘 平. 高性能弥散强化铜基复合材料及其制备技术[M]. 北京: 科学出版社, 2011: 21-35.

TIAN Bao-hong, SONG Ke-xing, LIU Ping. High performance dispersion reinforced copper matrix composite and its fabrication technology[M]. Beijing: Science Press, 2011: 21-35.

[6] 范景莲, 严德剑, 黄伯云, 刘 军, 汪澄龙. 国内外钨铜复合材料的研究现状[J]. 粉末冶金工业, 2003, 13(2): 9-14.

FAN Jing-lian, YAN De-jian, HUANG Bo-yun, LIU Jun, WANG Cheng-long. Current study of R&D of W-Cu composite materials in China and abroad[J]. Powder Metallurgy Industry, 2003, 13(2): 9-14.

[7] 万 成, 李继文, 王 展, 马窦琴, 魏世忠, 张国赏, 徐流杰. 高致密细晶W-25Cu触头材料的电接触性能[J]. 中国有色金属学报, 2017, 27(3): 504-513.

WAN Cheng, LI Ji-wen, WANG Zhan, MA Dou-qin, WEI Shi-zhong, ZHANG Guo-shang, XU Liu-jie. Performances of high-density fine-grain W-25Cu electrical contact materials[J]. The Chinese Journal of Nonferrous Metal, 2017, 27(3): 504-513.

[8] 彭清艳. CuWCr复合材料击穿特性的研究[D]. 西安: 西安理工大学, 2005: 35-46.

PENG Qing-yan. Study on breakdown characteristics of CuWCr composites[D]. Xi’an: Xi’an University of Technology, 2005: 35-46.

[9] 冼爱平. 大功率真空开关铜铬触头材料[J]. 中国有色金属学报, 2001, 11(5): 731-740.

XIAN Ai-ping. Cu-Cr contact material for high power vacuum interrupters[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(5): 731-740.

[10] 黄锡文. 电触头材料的导电性探讨[J]. 电工合金, 1998(3): 26-32.

HUANG Xi-wen. Study on electrical conductivity of electrical material[J]. Electrical Engineering Materials, 1998(3): 26-32.

[11] 殷 婷. Cu-W-Ti电接触材料组织及性能研究[D]. 洛阳: 河南科技大学, 2015: 10-17.

YIN Ting. Study on microstructure and properties of Cu-W-Ti electrical contact materials[D]. Luoyang: Henan University of Science and Technology, 2015: 10-17.

[12] 荣命哲, 赵志远, 杨 武. 低压电器中电触头材料的转 移[J]. 低压电器, 1998(5): 16-18.

RONG Ming-zhe, ZHAO Zhi-yuan, YANG Wu. Contact material transfer of low voltage apparatus[J]. Low Voltage Apparatus, 1998(5): 16-18.

[13] CHEN Z K, SAWA K. Effect of arc behavior on material transfer: A review[J]. IEEE Trans Components, Packaging & Manufacturing Technology, 1998, 21: 310-321.

[14] SLADE P G. Opening electrical contacts: The transition from the molten metal bridge to the electric arc[J]. IEICE Transactions on Electronics, 2010, 93-C(9): 1380-1386.

[15] LAURENT M, NOUREDINE B J, DIDIER J. Make arc erosion and welding in the automotive area[J]. IEEE Transactions on Components and Packaging Technologies, 2000, 23(1): 240-246.

[16] 田保红, 程新乐, 张 毅, 刘 勇. 放电等离子烧结Cu-Mo-WC复合材料电接触特性[J]. 稀有金属材料与工程, 2018, 47(3): 943-948.

TIAN Bao-hong, CHENG Xin-le, ZHANG Yi, LIU Yong. Electrical contact characteristics of Cu-Mo-WC composites prepared by spark plasma sintering process[J]. Rare Metal Materials and Engineering, 2018, 47(3): 943-948.

[17] 韩 波, 史庆南, 谢 明, 陈亮维, 王效琪, 起华荣, 孟庆猛. 直流条件下W-15wt%Cu电接触材料燃弧特性研究[J]. 稀有金属材料与工程. 2012, 41(6): 994-997.

HAN Bo, SHI Qing-nan, XIE Ming, CHEN Liang-wei, WANG Xiao-qi, QI Hua-rong, MENG Qing-meng. Arc erosion characteristics of W-15wt%Cu electric contact materials under DC condition[J]. Rare Metal Materials and Engineering, 2012, 41(6): 994-997.

[18] 李震彪, 徐金玲, 黄 良, 徐 坚. 电磁继电器触点动熔焊机理分析[J]. 低压电器, 2007(5): 1-3.

LI Zhen-biao, XU Jin-ling, HUANG Liang, XU Jian. Mechanism analysis on dynamic welding of electromagnetic relay contacts[J]. Low Voltage Apparatus, 2007(5): 1-3.

[19] 陶麒鹦, 周晓龙, 周允红, 张 浩. AgCuO电触头材料的电接触性能[J]. 中国有色金属学报, 2015, 25(5): 1244-1249.

TAO Qi-ying, ZHOU Xiao-long, ZHOU Yun-hong, ZHANG Hao. Electrical contact properties of AgCuO electrical contact materials[J]. The Chinese Journal of Nonferrous Metal, 2015, 25(5): 1244-1249.

[20] 王振宇, 刘 晗, 黄锡文, 张天锦, 李 波. 钨和氧化钨对银镍触头材料性能的影响[J].电工材料, 2015(2): 3-12.

WANG Zhen-yu, LIU Han, HUANG Xi-wen, ZHANG Tian-jin, LI Bo. Effects of tungsten oxide particles on contact performance for silver-nickel contacts[J]. Electrical Engineering Materials, 2015(2): 3-12.

[21] 于 力, 刘志远, 王 东, 苑 舜, 王文彬, 王小军, 王季梅. 真空断路器触头熔焊性能的研究综述[J]. 高压电器, 2008, 44(1): 64-68.

YU Li, LIU Zhi-yuan, WANG Dong, YUAN Shun, WANG Wen-bin, WANG Xiao-jun, WANG Ji-mei. Review of welding phenomena of vacuum circuit breaker contacts[J]. High Voltage Apparatus, 2008, 44(1): 64-68.

Electrical contact properties of Al2O3-Cu/(W, Cr) composites prepared by vacuum hot-pressing sintering and internal oxidation methods

ZHANG Xiao-hui1, 2, TIAN Bao-hong1, 2, LIU Yong1, 2, ZHANG Yi1, 2, SONG Ke-xing1, 2, LI Quan-an1, 2

(1. School of Materials Science and Engineering, Henan University of Science and Technology, Luoyang 471023, China;

2. Collaborative Innovation Center of Nonferrous Metals, Luoyang 471023, China)

Abstract: The Al2O3-Cu/(25)W(5)Cr and Al2O3-Cu/(35)W(5)Cr composites were prepared by vacuum hot-pressing sintering and internal oxidation methods. Their relative density, electrical conductivity and Brinell hardness were measured, respectively. The microstructure was analyzed by scanning electron microscope. The JF04C electrical contact testing system was used to investigate the welding force and electric contact performance. The results shows that the pining effect of nano-Al2O3 particles causes tangle and intersecting of dislocations. The Al2O3-Cu/(25)W(5)Cr contact has a little mass transfer from the anode to cathode. But the final mass transfer direction of the two composites is from the cathode to anode. With the melting, evaporation and sputtering of Cu, W particles gathers and transforms into needle-shaped skeleton. Finally, pip and crater are presented on the anode and cathode surface, respectively. When the content of W in the dispersed copper matrix increases from 25% to 35% (mass fraction), the welding force reduces obviously.

Key words: hot-pressing sintering; electrical contact; arc erosion; material transfer; welding force

Foundation item: Project(182106000018) supported by Henan Science and Technology Open Cooperation, China; Project (U1704143) supported by the National Natural Science Foundation of China

Received date: 2018-07-09; Accepted date: 2018-11-04

Corresponding author: TIAN Bao-hong; Tel: +86-379-65627356; E-mail: bhtian007@163.com

(编辑 王 超)

基金项目:河南省科技开放合作项目(182106000018);国家自然科学基金资助项目(U1704143)

收稿日期:2018-07-09;修订日期:2018-11-04

通信作者:田保红,教授,博士;电话:0379-65627356;E-mail:bhtian007@163.com