文章编号:1004-0609(2012)07-2116-09

氧气底吹铜熔池熔炼过程的机理及产物的微观分析

刘 柳1,闫红杰1,周孑民1,高 强1,张振杨1,刘方侃1,崔志祥2

(1. 中南大学 能源科学与工程学院,长沙 410083;2. 东营方圆有色金属有限公司,东营 257091)

摘 要:对氧气底吹熔炼过程气体喷吹行为、造锍熔炼化学反应机理及熔炼炉内热工作状态进行理论分析及水模型实验和取样分析验证。结果表明,氧气底吹气流能使熔体形成均匀的扩散区,实现熔体的搅拌,在气体连续相区和液体连续相区,气-液、液-液之间的相互作用强烈,为炉内化学反应及传热传质提供了良好的动力学条件;氧气底吹熔炼过程在零配煤的情况下能达到自热熔炼,在节能减排方面,该工艺具有很强的优势;获得了铜渣、冰铜和蘑菇头中各组分的形貌,确定了铜渣、冰铜和蘑菇头的物相组成,渣样主要由冰铜相、磁铁矿相、铁橄榄石相和玻璃体相组成,熔炼内的氧势和硫势分布有利于反应的进行,能有效抑制Fe3O4的形成以及降低渣含铜。

关键词:铜熔炼;氧气底吹;熔炼机理;氧势;硫势;熔炼产物;微观分析

中图分类号:TF811 文献标志码:A

Mechanism of copper smelting process by oxygen bottom blowing and microanalysis of smelting products

LIU Liu1, YAN Hong-jie1, ZHOU Jie-min1, GAO Qiang1, ZHANG Zhen-yang1, LIU Fang-kan1, CUI Zhi-xiang2

(1. School of Energy Science and Engineering, Central South University, Changsha 410083, China;

2. Dongying Fangyuan Nonferrous Metal Co., Ltd., Dongying 257091, China)

Abstract: The theoretical analysis and verification by water modeling experiment, and the sampling test analysis was carried out to study the behavior of gas injection, the chemical reaction mechanism and the thermal status of matte smelting in the oxygen bottom blowing smelting process. The results show that the melt can be stirred to form a homogeneous diffusion region by the flow in oxygen bottom blowing. In the region of continuous gas or liquid phase, the intense interactions between gas and liquid or pure liquid provide a good kinetic condition for the chemical reaction and heat and mass transfer in the furnace. Without coal blending, the autogenous smelting process can be achieved in oxygen- enriched bottom blowing process which has a great advantage in the energy saving and emission reduction. The morphology of each component in the copper slag, copper matte and mushroom was identified, and the phase composition was determined. The slag samples are mainly composed of matte phase, magnetite phase, fayalite phase and vitreous phase, the distribution of oxygen potential and sulfur potential has a favorable effect on the reaction in the furnace and can effectively restrain the formation of Fe3O4 and reduce copper in the slag.

Key words: copper smelting; oxygen bottom blowing; smelting mechanism; oxygen potential; sulfur potential; smelting product; microanalysis

氧气底吹熔池熔炼是我国自主研发的具有自主知识产权的新一代熔池强化熔炼技术,又叫氧气底吹造锍捕金技术。该熔炼技术具有高效、节能、投资少及环保友好的优势。因此,这种熔炼技术应用于多金属矿综合提取,不仅提高了资源利用率,增加了企业经济效益,也符合我国倡导的节能减排、科学发展的要求,达到了利国利民的效果。目前,该技术已得到了工业应用,从3 a的工业实践中发现,该工艺具有很强的优势,因此,氧气底吹熔池熔炼的相关研究成为了重要的应用理论研究课题。在氧气底吹熔炼炉内,利用底吹气体的喷吹作用,实现炉内熔体的激烈搅拌,炉内所有的化学反应、传热、传质和动量传递都在这种条件下进行,为了更好地掌握氧气底吹熔池熔炼过程的底吹气体流出行为和熔炼反应机理,了解熔炼炉内的热工作状态和氧势、硫势的分布,提高熔炼反应速度,使反应高效地朝着有利的方向进行,优化熔炼过程,有必要对熔炼过程进行理论分析,并从微观形貌和成分上对熔炼过程产物进行取样化验,查明各熔炼产物的存在形态和成分组成。有关铜熔炼机理的研究,主要集中在化学反应热力学特性的研究[1-5],而对动力学方面的研究较少[6-8],对于熔池内气体喷吹行为的研究,THEMELIS等[9]、KATO等[10]、BRIMACOMBE和HOEFELE[11]、OZAWA和MORI[12]、萧泽强[13]进行了很多研究;而有关炼铜产物的微观特性的研究主要集中在炉渣和冰铜微观特性等方面[14-24]。对于氧气底吹铜熔炼过程的熔炼机理并结合产物的微观分析研究,目前还未见报道,因此,对该工艺的熔炼机理及产物(熔炼渣、冰铜和蘑菇头)的微观分析进行研究,具有现实意义和创新意义。

1 氧气底吹熔炼机理及热工作状态分析

图1所示为氧气底吹熔炼炉的原理示意图。图1中,炉料从熔炼炉顶部加入,富氧空气通过底部氧枪送入熔池内搅动熔池并参与反应,入炉物料在熔池中完成加热、熔化、氧化、造渣和造锍等过程,产出的冰铜、炉渣和烟气分别从放锍口、放渣口和排烟口排出。因此,在熔炼炉内,底部气体的喷吹搅拌、炉内的化学反应以及炉内的热工作状态共同决定了熔炼过程的好坏。

图1 氧气底吹熔池熔炼炉示意图

Fig. 1 Schematic diagram of oxygen-enriched bottom blowing bath furnace

1.1 氧气底吹熔炼过程气体喷吹行为理论分析及水模型验证

氧气底吹熔炼过程中,气体从底部以喷射锥的形式进入液体区,形成气-液两相体系,该气-液两相体系可分为纯气流区、气体连续相区(该区存在液滴)和液体连续相区[13](该区存在大量气泡)。气体从氧枪喷入熔体区后,在喷口处形成纯气相区;接着气体在上升的过程中,由于分裂液滴的作用以及不稳定的气-液剪切作用,液滴不断地被卷入气相区,形成气体连续相区,在这一区域,气体与液体进行剧烈的动量交换,气体带入熔池的绝大多数动能都被消耗掉,从而实现对熔池的搅拌,这一区域主要存在于熔池的中下部。气流股到达熔池的中上部后,将在液体介质中分散成无数的气泡并与液体混合,在熔池中形成强烈搅拌的沸腾状态,即液体连续相区[25]。

从氧气底吹熔炼过程的气体流出行为可以看出,底吹气流能使熔体形成均匀的扩散区,实现搅拌,其自身的动能却逐渐降低,不致损伤炉衬甚至击穿熔体区。另外,在气体和液体连续相区,气-液、液-液之间的相互作用强烈,为炉内化学反应及传热和传质提供了良好的动力学条件。为了观测氧气底吹过程的气体流出行为,运用高速摄影仪拍摄了水模型实验中的气体底吹过程,结果如图2所示。从图2可以看出,气体从氧枪喷出后,在熔池内形成了3个特征不同的气-液两相体系,熔池底部喷口处有一个明显的气团,为纯气流区,中部气团中夹杂着液滴,为气体连续相区,上部液体和气泡的混合区域,为液体连续相区,这一结果验证了理论分析结果的正确性。

图2 水模型实验中的气体底吹行为

Fig. 2 Behavior of gas bottom blowing in water modeling experiment

1.2 氧气底吹造锍熔炼的化学反应机理分析

氧气底吹造锍熔炼时,炉料在熔炼炉内主要发生以下反应[13]。

1) 高阶硫化物的分解

=

= (1)

(1)

2FeS2=2FeS+S2 (2)

2) 硫化物的氧化

=

= (3)

(3)

=

= (4)

(4)

在强氧化气氛下,还会发生式(5)所示反应:

=

= (5)

(5)

同时,Fe3O4还可进一步与FeS发生式(6)所示反应:

=

= (6)

(6)

3) 造锍反应

上述反应产生的FeS和Cu2O在高温下将发生式(7)所示反应:

=

= (7)

(7)

4) 造渣反应

=

= (8)

(8)

=

= (9)

(9)

底吹熔炼过程中,富氧空气从熔池底部吹入锍层,氧气首先将与硫化物反应,即发生反应(3)和(4),当氧势较高时,发生反应(5),但由于熔炼过程中给料速率和供氧速率是一定的,炉料的不断加入将使锍中FeS的活度维持在一定的值,FeS的存在避免了FeO的过氧化,同时,FeS与Fe3O4将发生反应(6),从而避免了FeO大量氧化成Fe3O4。再者,由于底吹喷射气流形成了均匀的锍-气混合搅拌区,即1.1节中的气体连续相区,为锍层中已经被氧化的Fe3O4和Cu2O与从熔池上部落下的铜锍液滴进行硫化反应(6)和(7)提供了良好的动力学条件。富氧空气从底部吹入铜锍 层,与铜锍反应后再进入渣层,故在渣层内氧势大大降低,Fe3O4不易生成,同时渣层内卷有大量生料,硫势高,这也抑制了Fe3O4的生成,因此,在渣层内Fe3O4的还原条件要优于其生成条件,从而有效地控制了Fe3O4的生成。

另一方面,富氧空气吹入铜锍层后,与铜锍反应生成了大量SO2气体,气泡夹带着细小的冰铜粒子上浮,到达熔池的上部,即渣层区,这一区域亦是1.1节中的液体连续相区,该区域的气-液混合流中硫化物液珠在强烈的搅拌下相遇的几率大大增加,从而加速了铜锍粒子的聚集长大和渣-锍相分离,降低了渣含铜。

综上所述,氧气底吹熔池熔炼的物理化学过程主要在铜锍区(对应喷吹的气体连续相区)和渣层区(对应喷吹的液体连续相区)进行。在铜锍区,氧势高,硫势也高,且搅拌充分,气-液及液-液交互作用充分,造锍过程反应速率快。处于熔池上表面的渣层区,虽然氧势低,但是气泡破碎充分,气体停留时间长,气-液-固三相接触面积很大,传质条件好,反应速率也快,同时渣层区的低氧势和高硫势能有效抑制Fe3O4的形成。由此可知,氧气底吹熔炼过程的气体喷吹特性和炉内氧势、硫势的分布有利于反应高效地进行,能有效抑制Fe3O4的生成,降低渣中铜含量。

1.3 熔炼炉内热工作状态分析

在传统的炼铜方法中,由于没有充分利用铜精矿的自身热能,在造锍熔炼阶段,都需要配入一定量的燃料,通过燃料的发热保证熔炼过程的热平衡。但对于氧气底吹熔炼炉,工业实践表明,在零配煤的情况下,也可以实现自热熔炼,从理论上分析,主要有以下几个原因。

1) 由于富氧空气(氧气浓度达73%,体积分数)的应用,熔炼产生的烟气量少,烟气带走的热量少。

2) 氧气从底部喷吹进入熔炼炉,能对炉内的熔体进行较好的搅拌,形成较好的对流传热条件,热效 率高。

3) 富氧空气流在上升过程中实现破碎,形成很多小气泡,增大了气-液、气-固及气-液-固的接触面积,有利于气-液-固之间的对流传热及传质,加快了炉内的反应放热,为炉料的熔化及反应提供了良好的热力学和动力学条件。

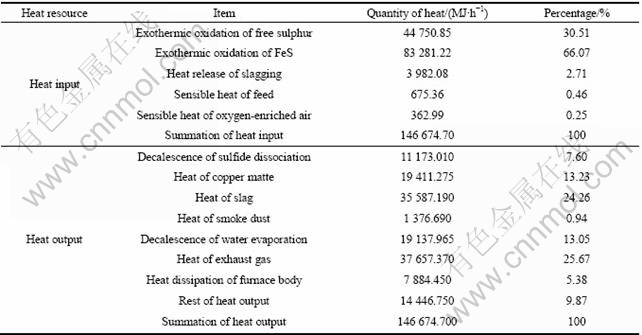

表1所列为某公司d 4.4 m×16.5 m氧气底吹熔炼炉在投料量为55 t/h时的热量平衡数据。表1验证了氧气底吹炉的自热熔炼,从表1中可以看出,氧气底吹熔炼过程在没有配入燃料的情况下达到了热平衡,不仅节约了生产成本,创造了更高的经济效益,同时也有利于环境保护,符合当前国家倡导的节能减排政策。因此,在节能减排方面,氧气底吹熔池熔炼工艺具有很强的优势。

表 1 氧气底吹熔炼炉热量平衡数据

Table 1 Thermal balance data of oxygen bottom-blowing smelting furnace

2 熔炼产物微观分析

从氧气底吹熔炼过程气体喷吹行为的理论分析和造锍熔炼化学反应机理分析可知,该工艺在反应动力学上具有很强的优势,为了更深入地了解熔炼过程反应机理,并与理论分析相比较,对熔炼过程的中间产物进行取样分析,通过扫描电镜和X射线衍射分析查明熔炼产物的形貌及物相。

2.1 试验取样及分析设备

取自某公司氧气底吹熔炼车间,所取试样为熔炼渣、冰铜和蘑菇头,取样和制样所依据的基本原理是均匀化法。第一次取样直接用样品勺在现场进行取样,取样时未隔离空气,取样后在空气中自然冷却;第二次取样用坩埚进行密闭取样,待样自然冷却后,取坩埚中心部位的样品作为测试样品。两次取样后,均对样品进行粉碎研磨至粒径小于75 μm,并充分混匀,获得均匀分析样品,进行检测分析。

在本研究中,形貌分析采用型号为JSM-6360LV的电子扫描显微镜,物相分析采用型号为D/ruax2550PC的X射线衍射分析仪。

2.2 铜渣的形貌及物相分析

2.2.1 铜渣的形貌分析

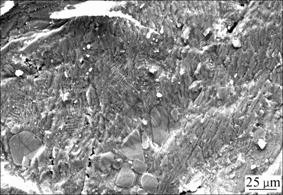

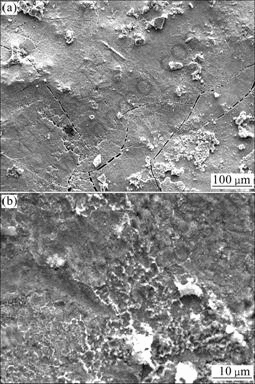

铜渣的SEM像如图3所示。

从渣样的SEM像(图3)可以看到,渣样中存在多种形态不同的物相,各物相相互交混存在。各物相呈现不同的晶体形状,根据矿物学相关知识,可以初步判断出渣样中各晶体的物相。从形貌图中可看出,所取渣样中主要有硫化物(冰铜)相、磁铁矿(Fe3O4)相、以橄榄石(2FeO·SiO2)为主的硅酸盐相以及玻璃体等4种物相。

图3 铜渣的SEM像

Fig. 3 SEM image of copper slag

1) 冰铜相

冰铜相的主要组成为xCu2S-yFeS,呈亮白色。如图3所示,亮白色颗粒状物质为冰铜相。从图3中还可以看到,渣中含有各种粒径的冰铜粒子,多数为独立体,呈圆形、椭圆形或不规则形状。还有的冰铜粒子被磁性氧化铁所包裹或与磁性氧化铁相互嵌连生长。在高倍镜下还可以观察到大量未聚集长大的细小冰铜粒子分散在玻璃相和硅酸盐相中。

2) 磁铁矿相

磁铁矿相呈浅灰色,属高熔点矿物(熔点为1 579 ℃),由于它的熔点比其他相的熔点高,所以,在渣中最早结晶。它主要呈大颗粒自形晶(半自形晶)和多边形颗粒状晶体(发育完全);图3中形状似脚掌、结构突出明显的为发育完全的磁铁矿晶体。还有的磁铁矿晶体发育不完全,呈树枝状或针状。图4所示为发育不完全的磁铁矿晶体的SEM像。从图4可以看到,该磁铁矿晶体呈树枝状,并有继续发育的趋势。更多的磁铁矿晶体为独立体,广泛分布于玻璃相基质中,部分与冰铜复合包裹或嵌连生长。磁铁矿相包裹冰铜将影响冰铜粒子的聚集长大,从而使冰铜在渣中的沉降速度减小,影响冰铜与渣的分离,导致渣中夹杂的冰铜增多,渣中铜的损失增加。

图4 发育不完全的磁铁矿晶体的SEM像

Fig. 4 SEM image of underdeveloped magnetite crystals

3) 铁橄榄石相

铁橄榄石相呈深灰色或为柱状或板状结构,晶粒大小不一,结晶好的呈连续条柱状晶体,在长度方向有时可达数毫米。

4) 玻璃相

玻璃相为黑色,呈不规则形状填充于铁橄榄石和磁铁矿间,其他各相均分布其上。它是磁铁矿和铁橄榄石等结晶后留下的残液。

2.2.2 铜渣的物相分析

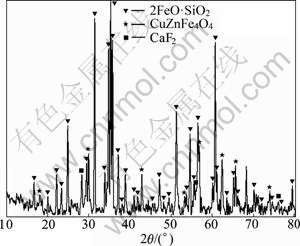

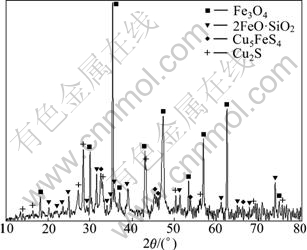

渣样的第一次XRD谱如图5所示。

从渣样的XRD分析结果可知,渣样中可分辨的结晶相有铁橄榄石(2FeO·SiO2)、冰铜相、磁铁矿相和石英石。这与电子显微镜的观察结果相吻合,另外,电子显微镜下某些填充物,可能由于其物相过于复杂或者本身为非结晶态,XRD未能提供更多组成信息,还可能由于其含量过低导致XRD分析未能分辨。

图5 铜渣1的XRD谱

Fig. 5 XRD pattern of copper slag 1

渣中Fe3O4的含量很高,这与熔炼机理理论分析结果不符。渣中Fe3O4的含量高可能是由于该工况下熔 炼过程的氧气严重过量,渣中的氧势很高,FeO进一步氧化生成了高价铁氧化物Fe3O4,也可能是由于在取样过程中未隔离空气,高温熔渣中的FeO与空气接触被氧化形成的。为了得到确切的原因,对该工况下熔炼过程的理论需氧量进行计算,计算结果表明,熔炼过程中直接供给的氧气并不过量,因此,取样过程的氧化是渣中Fe3O4含量高的主要原因。同时,渣样的XRD谱也表明,熔炼渣中的Cu都是以Cu2S的形式存在,并未检测到Cu2O,这说明熔炼炉渣层内氧势不高,这也间接证实了高含量Fe3O4不是由于氧势高产生的,而是在取样的过程中FeO的氧化造成的。基于这个原因,用密闭取样的方法对熔炼渣进行第二次取样分析,结果如图6所示。从图6可以看出,渣相中检测不出Fe3O4,产生这种现象的原因可能是所取渣样周围精矿较多(硫势高),Fe3O4的生成受到抑制;熔炼过程氧气不过量,渣中氧势低,有效抑制了Fe3O4的生成。

Fe3O4的形成对渣含铜将产生不利的影响,主要体现在以下几个方面:

1) Fe3O4含量增加使炉渣的黏度增大,渣的流动 性降低,从而影响锍和渣的分离。

2) 由于Fe3O4的黏度和密度都比较高,容易在渣层与锍层之间富集,析出时形成一层隔膜,降低了含Cu微粒的沉降速度。

3) Fe3O4含量的增加将减小熔渣与熔锍之间的界面张力,不利于冰铜微粒的聚集与沉降。

4) Fe3O4含量的增加使炉渣中Fe3O4的活度增加,FeS的活度降低,不利于反应(7)的进行,造成渣中铜损失增大。

因此,在实际生产中,必须严格控制Fe3O4的形成,从以上微观分析可知,氧气底吹铜熔池熔炼工艺在有效控制Fe3O4的生成上具有很大的优势,验证了熔炼机理理论分析的正确性。

2.3 冰铜的形貌及物相分析

2.3.1 冰铜的形貌分析

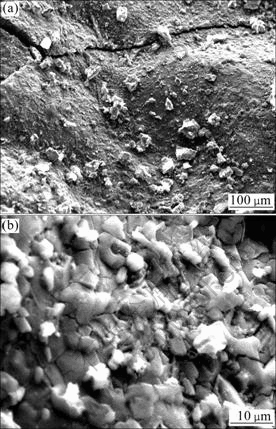

冰铜的SEM像如图7所示。

图6 铜渣2的XRD谱

Fig. 6 XRD pattern of copper slag 2

图7 冰铜的SEM像

Fig. 7 SEM images of copper matte: (a) Lower magnification; (b) Higher magnification

由于对冰铜进行电镜扫描时,扫描的是表面部 分,从图片中无法确定各晶体的形状,冰铜的物相组成将通过X射线衍射分析进行确定。

2.3.2 冰铜的物相分析

冰铜(样品1)的 XRD谱如图8(a)所示。

从图8(a)中可以看出,冰铜中可分辨的结晶相有冰铜、Cu2S、磁铁矿和PbS。

根据熔炼机理分析,冰铜中的硫势高,FeO不应过氧化生成Fe3O4,为了确证冰铜中磁铁矿相的来源,采用密封的方法对冰铜进行二次取样分析,分析结果如图8(b)所示。图8(b)中并未发现Fe3O4的存在,因此,可以确定该部分Fe3O4是在取样时氧化生成的。图8(b)中主要物相为Cu5FeS4、Cu2S、ZnS和少量的PbS和Cu。Cu5FeS4可能是造锍熔炼的中间产物,也可能是由于冰铜冷却时FeS和CuS相互反应生成的。

图8 冰铜的XRD谱

Fig. 8 XRD patters of copper matte: (a) Sample 1; (b) Sample 2

2.4 蘑菇头的形貌及物相分析

在氧气底吹熔池熔炼过程中,氧枪内环喷出的是工业氧气,在氧枪氧气通道的外围通入高速流动的空气,空气对氧枪有冷却作用。氧枪周围的高温熔体遇

冷的气体将生成结瘤,这一结瘤习惯上称为蘑菇头。蘑菇头使氧枪端头及其四周耐火材料与熔液隔开,有效地保护了氧枪及其四周的耐火材料,大大延长了氧枪的使用寿命[26]。通过对蘑菇头进行现场取样分析其形貌及物相组成,可以了解氧枪喷口处的熔炼反应机理,掌握蘑菇头形成机理,使生成的蘑菇头更好地保护氧枪,从而延长氧枪的使用寿命。

2.4.1 蘑菇头的形貌分析

蘑菇头的SEM像如图9所示。

图9 蘑菇头的SEM像

Fig. 9 SEM images of mushroom: (a) Lower magnification; (b) Higher magnification

从图9(a)可以看到,蘑菇头中也存在多种形态不同的物相,各物相相互交混存在,且各物相呈现不同的晶体形状,由于图9(a)放大倍数较低,难以判断出各个晶体的具体物相组成,而图9(b)是对图9(a)中同一个晶相进行放大所得到的图像,所以根据这些SEM像也无法确定蘑菇头中各物相的具体组成。

根据熔池熔炼过程中蘑菇头的形成机理和铜熔池熔炼的化学反应过程,可以判断蘑菇头中应该含有冰铜和Fe3O4。由于冰铜相的颜色是白色的,且冰铜一般呈颗粒状形态,故可判断图9(a)和(b)中的白色颗粒状和片状晶体为冰铜。从图9还可以看到,蘑菇头中冰铜的粒径不一,且相互层叠排列。

蘑菇头中其他相无法从SEM谱上确定,而可通过X射线衍射对蘑菇头进行物相组成的确定。

2.4.2 蘑菇头的物相分析

蘑菇头的XRD谱如图10所示。

图10 蘑菇头的XRD谱

Fig. 10 XRD pattern of mushroom

从图10可以看到,蘑菇头中可分辨的结晶相有磁铁矿相(Fe3O4)、冰铜相、铁橄榄石相(2FeO·SiO2)和 Cu2S。

图10表明,在蘑菇头中,Fe3O4的含量高,除取样时的氧化作用外,由于氧枪出口处氧势高,硫势最低,有利于Fe3O4的生成,且Fe3O4的熔点最高,在氧枪内空气的冷却下,氧枪周围熔体中Fe3O4最先析出,随着冷却的进行,析出的Fe3O4不断增加,所以在蘑菇头中,其含量最高。蘑菇头中高含量的Fe3O4可提高其熔点和 高温抗氧化性,有利于蘑菇头的稳定,从而更好地保护氧枪,延长氧枪的使用寿命。因此,该工艺下蘑菇头中的成分有利于其更好地保护氧枪。

蘑菇头中铜元素以铜锍和Cu2S的形式存在,这表明,在氧枪周围,一部分Cu2S与FeS结合形成了铜锍,而还有一部分Cu2S没有生成铜锍,而是单独存在,这可能是由于在氧枪周围,铜精矿未能分解生成足够多的FeS与Cu2S造锍,造成Cu2S遇冷析出,也可能是由于Cu2S与FeS还未来得及发生造锍反应即被冷却 析出。

在蘑菇头附近的高氧势和低硫势作用下,Cu2S参与反应(4)生成Cu2O,但是从XRD谱中并未发现铜的氧化物,而只有铁的氧化物,再结合渣样和冰铜样的XRD谱,同样未发现Cu2O,只有FeO的存在,由此说明,熔炼的氧化过程中FeS优先于Cu2S氧化,硫和铁的氧化是氧化过程的主要反应。

由于在气-锍-渣相之间存在氧势和硫势的差异,熔炼的氧化过程和脱硫过程才得以进行,通过上述讨论可知,在底吹熔炼过程中,炉内的氧势和硫势的分布有利于反应高效地进行。

3 结论

1) 氧气底吹熔炼过程中,铜锍区的氧势高,硫势也高,且搅拌充分,造锍过程反应速率快。处于熔池上表面的渣层区,虽然氧势低,但是气泡破碎充分,气-液-固三相接触面积很大,反应速率快,同时渣层区的低氧势和高硫势能有效抑制Fe3O4的形成。熔炼过程FeS的氧化优先于Cu2S的氧化,硫和铁的氧化是氧化过程的主要反应,炉内氧势和硫势的分布有利于炉内反应高效地进行。

2) 氧气底吹熔炼过程在零配煤的情况下能达到自热熔炼,在节能减排方面,该工艺具有很强的优势。

3) 铜渣主要由冰铜相、磁铁矿相、铁橄榄石相和玻璃体相组成,各相的形态与其在渣中的含量密切相关。蘑菇头中含有大量的Fe3O4,提高了其熔点和高温抗氧化性,有利于蘑菇头的稳定,从而能更好地保护氧枪,延长氧枪的使用寿命。

REFERENCES

[1] SERGEI A D, ARTHUR D P. A thermodynamic database for copper smelting and converting [J]. Metallurgical and Materials Transactions B, 1999, 30(4): 661-669.

[2] YAZAWA A. Thermodynamic considerations of copper smelting [J]. Canadian Metallurgical Quarterly, 1974, 13(3): 443-453.

[3] SRIDHAR R, TOGURI J M, SIMEONOV S. Copper losses and thermodynamic considerations in copper smelting [J]. Metallurgical and Materials Transactions B, 1997, 28(2): 191- 200.

[4] MACKEY P J. The physical chemistry of copper smelting slags—A review[J]. Canadian Metallurgical Quarterly, 1982, 21(3): 221-260.

[5] NAGAMORI M, MACKEY P J. Thermodynamics of copper matte converting: Part 1. Fundamentals of the Noranda process [J]. Metallurgical and Materials Transactions B, 1978, 9(3): 255- 265.

[6] AJERSCH F, TOGURI J M. Oxidation rates of liquid copper and liquid copper sulfide [J]. Metallurgical and Materials Transactions B, 1972, 3(8): 2187-2193.

[7] ASAKI Z. Kinetic studies of copper flash smelting furnace and improvements of its operation in the smelters in Japan [J]. Mineral Processing and Extractive Metallurgy Review, 1992, 11(3): 163-185.

[8] OTERO A, BRIMACOMBE J K, RICHARDS G G. Kinetics of the flash reaction of copper concentrates [C]// Proceedings of the Copper 91—Cobre 91 International Symposium. Ottawa: Pergamon Press Inc, 1991: 459-473.

[9] THEMELIS N J, TARASOFF P, SZEKELY J. Gas-liquid momentum transfer in a copper converter [J]. Transactions of the Metallurgical Society of AIME, 1969, 245(5): 2425-2433.

[10] KATO Y, NOZAKI T, NAKANISHI K, FUJII T, EMI T. Model study of gas-liquid momentum transfer to design optimum tuyere dimensions for bottom and top/bottom blown converters [J]. Tetsu-to-Hagane/Journal of the Iron and Steel Institute of Japan, 1984, 70(3): 380-387.

[11] BRIMACOMBE J K, HOEFELE E O. Flow regimes in submerged gas injection [J]. Metallurgical and Materials Transactions B, 1979, 10(4): 631-648.

[12] OZAWA Y, MORI K. Characteristics of jetting observed in gas injection into liquid [J]. Transactions of the Iron and Steel Institute of Japan,1983, 23(9): 764-768.

[13] 萧泽强. 冶金中单元过程和现象的研究[M]. 北京: 冶金工业出版社, 2006: 72-77.

XIAO Ze-qiang. Studies on unit processes and unit phenomena in metallurgy [M]. Beijing: Metallurgical Industry Press, 2006: 72- 77.

[14] MOHAPATRA B K, NAYAK B D, RAO G V. Microstructure and metal distribution in Indian copper converter slags-study by scanning-electron microscopy [J]. Trans Inst Min Metall C, 1994, 103: 217-220.

[15] BUSOLIC D, PARADA F, PARRA R, SANCHEZ M, PALACIOS J, HINO M. Recovery of iron from copper flash smelting slags [J]. Trans Inst Min Metall C, 2011, 120: 32-36.

[16] GORAI B, JANA R K, PREMCHAND. Characteristics and utilisation of copper slag—A review [J]. Conservation and Recycling, 2003, 39(4): 299-313.

[17] MITEVSKAN.Copperdistributionbetweenreverbfurnacesmeltingproducts [J].JOM,2004,56(11):178-186.

[18] MAVROGENS J A, HAGNI R D, MORRIS A E. Reflected light microscopic study of submerged bath smelter Co-Ni mattes [C]// Proceedings of International Symposium on Applied Mineralogy (MAC-ICAM-CAM). Las Vegas: Minerals, Metals & Materials Society, 1990: 399-409.

[19] PHILIP K G, VALENTINA M, CHARLES Q J. Characterization of smelter slags [J]. J Environ Sci Health, 2000, 35(2): 147-159.

[20] 孙铭良,黄克雄, 李新海.炼铜炉渣的显微分析与渣含铜[J].中国有色金属学报,1998,8(1):106-112.

SUN Ming-liang, HUANG Ke-xiong, LI Xin-hai. Microanalysis for slag of copper matte smelting and loss of copper in slag [J]. The Chinese Journal of Nonferrous Metals, 1998,8(1):106-112.

[21] 蔡振平,远忠森, 赵国权.白银铜炉渣的微观组成及金属分布[J].有色金属:冶炼部分,1998(3):19-20,25.

CAI Zhen-ping, YUAN Zhong-sen, ZHAO Guo-quan. Microscopic composition and metal distribution of copper slag in Baiyin copper smelting process [J]. Nonferrous Metals: Extractive Metallurgy, 1998(3):19-20,25.

[22] 秦庆伟,黄自力, 刘 琼, 朱 露, 廖广东.反射炉渣中铜铁的赋存状态研究[J].武汉科技大学学报,2008, 31(5):482-486.

QIN Qing-wei, HUANG Zi-li, LIU Qiong, ZHU Lu, LIAO Guang-dong. Occurrence of Cu and Fe in reverberatory furnace slag [J]. Journal of Wuhan University of Science and Technology, 2008, 31(5):482-486.

[23] 刘安明.降低电炉渣含铜研究[J].有色金属: 冶炼部分,2007(2):36-39.

LIU An-ming. Study on reduction of copper loss in slag from electric furnace [J]. Nonferrous Metals: Extractive Metallurgy, 2007(2):36-39.

[24] 黄自力, 何甜辉, 秦庆伟, 李 密, 刘缘缘. 炼铜反射炉水淬渣的矿物学研究及可选性分析[J]. 矿业研究与开发, 2010, 30(6): 35-37.

HUANG Zi-li. HE Tian-hui, QIN Qing-wei, LI Mi, LIU Yuan-yuan. Mineralogical study and beneficiability analysis of a water-quenched slag from copper smelting reverberatory furnace [J]. Mining Research and Development, 2010, 30(6): 35-37.

[25] 朱祖泽, 贺家齐. 现代铜冶金学[M]. 北京: 科学出版社, 2003: 320-322.

ZHU Zu-ze, HE Jia-qi. Current copper metallurgy [M]. Beijing: Science Press, 2003: 320-322.

[26] 高长春, 袁培新, 陈汉荣.氧气底吹熔炼氧枪浅析[J].中国有色冶金,2006(6):13-18.

GAO Chang-chun, YUAN Pei-xin, CHEN Han-rong. Study on oxygen lance for oxygen bottom-blown smelting [J]. China Nonferrous Metallurgy, 2006(6):13-18.

(编辑 陈卫萍)

基金项目:国家高技术研究发展计划资助项目(2010AA065201);中南大学自由探索计划项目(2011QNZT097)

收稿日期:2011-08-29;修订日期:2012-02-20

通信作者:闫红杰,教授,博士;电话:13873102530;E-mail: s-rfy@mail.csu.edu.cn