文章编号: 1004-0609(2005)06-0865-05

二维搅拌摩擦焊接过程的数值模拟

赵衍华, 林三宝, 贺紫秋, 吴 林

(哈尔滨工业大学 现代焊接生产技术国家重点实验室, 哈尔滨 150001)

摘 要: 将搅拌摩擦焊接过程中材料的流动看作是层流、 粘性、 非牛顿流体绕过旋转的圆柱体, 并基于流体力学理论, 建立了二维搅拌摩擦焊缝金属塑性流动的数值分析模型。 计算结果表明: 只有很少一部分靠近搅拌头探针的材料在焊接过程中受到探针的作用而发生变形, 直接影响到材料的流动; 在大多数的模拟条件下, 探针直径范围内的材料仅仅在回撤边一侧沿旋转方向绕过探针, 而不是在探针两侧绕流; 绕过探针以后, 焊缝金属材料又以恒定的速度, 继续向前移动; 变形区域内流变材料的流动速度大于探针直径范围外流变材料的流动速度。 采用“标记嵌入技术”对焊缝金属流动进行了可视化研究, 并对实验结果与模拟结果进行了验证, 模拟结果能很好地预测塑性金属流动趋势。

关键词: 搅拌摩擦焊; 流动; 数值模拟; 2014铝合金

中图分类号: TG453 文献标识码: A

Numerical simulation of 2D friction stir welding process

ZHAO Yan-hua, LIN San-bao, HE Zi-qiu, WU Lin

(State Key Laboratory of Advanced Welding Production Technology,

Harbin Institute of Technology, Harbin 150001, China)

Abstract: The material transport in the welding process was regarded as a laminar, viscous and non-Newtonian liquid flows past a rotating cylinder pin. Based on fluid mechanics a two-dimensional friction stir welding (FSW) process model was developed. The results of the simulation show that just a little material close to the pin is affected during the welding process, and the material has experienced extreme deformation. Material within the pin diameter passes the pin only on the retreating side in the rotation direction and not on both sides of the pin. The speed of the material in the region affected by the pin is faster than the material outside of the deformed region. Material flow visualization experiments of “marker insert technology” are used to validate the simulated results. The experimental images agree well with the simulated results and the two-dimensional model predicts many of the trends observed in the experiments.

Key words: friction stir welding; flow; numerical simulation; 2014Al alloy

搅拌摩擦焊(friction stir welding, 简称FSW)是一种固相连接技术, 产生的焊缝质量高, 与传统熔化焊相比具有许多优点。 当前FSW的研究主要集中于搅拌摩擦焊缝微观组织及性能上[1-4], 对于搅拌摩擦焊接过程, 尤其是焊缝金属在焊接中的塑性流动机理, 尚处于探索阶段。

对搅拌摩擦焊过程中材料流动的研究目前主要包括材料流动的可视化以及计算机模拟两个方面。 通过实验方法了解焊缝金属的流动, 虽然取得了一定的成绩, 但由于FSW过程的复杂性和FSW本身的特点(无法直接看到材料流动的过程)而受到很大的限制[5-8]。 随着计算机技术的发展, 运用解析和数学建模的方法来研究分析焊接过程中材料的流动也成为一种重要的研究手段。

Xu等[9]应用固体力学方法建立了摩擦模型和滑移界面模型两种模型, 并将实验获得的温度分布作为模型的温度边界条件, 采用解偶方法应用Arbitrary Lagrangian-Eulerian 有限元方法进行了数学模拟。 二维模型仅仅包括搅拌头探针而忽略了材料的一些与速度有关的参数。 栾等[10]在铝合金搅拌摩擦焊接头行为分析中介绍了搅拌摩擦焊接头塑性流变数值模拟所得到的结果, 模拟结果显示了搅拌头肩台下大约1.5mm处搅拌摩擦焊前进边的塑性流体结构中存在的不稳定区域——紊流区。 文献[11]采用商用计算流体力学软件Fluent建立了搅拌摩擦焊过程中金属材料流动模型, 建立了TrivexTM搅拌头和TrifluteTM搅拌头的三维滑动模型。 这些模型揭示了围绕探针的三维流动情况, 并预测了横向压力和向下方向的压力。 Colegrove[12]建立了FSW焊接过程模型, 在那个模型中热量仅仅是由轴肩产生。 模型包括一个球状热源和一个搅拌头附近的局部热源两部分。 由于Colegrove应用了一个比较粗糙的网格, 搅拌头附近区域的一些重要细节都没有考虑。

国内外对FSW过程数值模拟的研究尚处于探索阶段, 且由于FSW是一个非常复杂的过程, 现在的研究仍然存在大量的问题。 本文作者应用Fluent商用计算软件, 建立了FSW基于流体力学的二维过程模型, 对焊缝金属的流动进行了分析。

1 二维搅拌摩擦焊接过程模型

1.1 模型的建立

将搅拌摩擦焊接过程中材料的流动看作是层流、 粘性、 非牛顿流体绕过旋转的圆柱体, 应用欧拉流动公式, 采用商用计算流体力学软件Fluent进行建模。 因为在搅拌摩擦焊接过程中, 材料粘度在较高的温度和较高应变率的情况下仍然非常高, 粘度在这个模型中起着非常重要的作用, 热量完全由材料粘度耗散产生。 另外, 本模型仅仅考虑了FSW过程中稳态时焊缝金属的流动。

1.2 材料物性

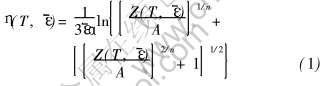

应用流体理论来建模需要粘度方程来模拟铝合金流动行为, 粘度在流场计算中是一个非常重要的物理参数, 它与温度和应变率有关。 根据文献[13], 材料的黏度可表示为

式中 α, lnA, n为与材料有关的常数, 文献[14]给出了1××××~7×××系列铝合金对应的常数值, 本模型选用的参数主要为: α=0.0152MPa-1, ΔH=144408J/mol, lnA=24.41s-1, n=3.55, 通用摩尔气体常数R=8.314J/(mol·K)。 根据文献[15], 2014Al合金的密度为2800kg/m3, 对2014Al合金热物理性能参数进行曲线拟合处理, 得到2014Al合金的热传导率(λ)和比热容(cp)分别为

λ=103.264+0.241T

cp=754.08+0.3729T+0.0012T2;

1.3 控制方程

采用的控制方程包括质量守恒方程(连续性方程)、 动量守恒方程和能量守恒方程。 分别如下:

式(5)右边的两项分别代表热传导和黏度耗散。

由式(2), (3), (5)组成一个非线性、 全耦合的控制方程, 用来描述稳态、 非牛顿、 不可压、 忽略体积力的流体流动。

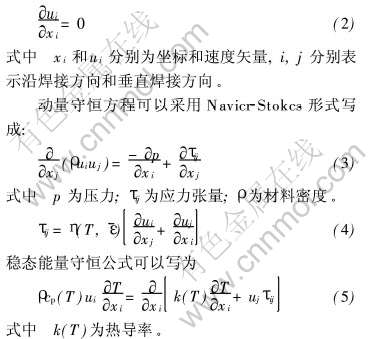

1.4 模拟区域网格划分和边界条件设定

模拟的流体区域为200mm×130mm的长方形区域, 里面有一个直径为7.5mm的圆柱体代表探针。 前进边和回撤边一侧的边界设置为移动墙。 流体流动入口和出口也被设置为移动墙。 焊接过程中, 搅拌头固定, 板材相对于搅拌头做平动, 因此, 模型中可以设定流体从流动入口以焊接速度向流动出口运动, 流动过程中绕过逆时针旋转的搅拌头。 由于材料变形流动主要发生在探针附近较小区域内, 故在探针附近网格划分较细密, 并且在探针周围划分一层四边形的边界层。 第一层网格厚度为0.015mm, 此后每层以1.2倍率增加, 共划分10层, 约1.3mm厚。 边界层认为是材料与搅拌头接触并相互作用的范围, 材料的大变形也主要发生这里, 并且网格方向与流动方向一致, 这样更利于计算。 网格划分如图1所示。 在模型中, 将探针认为是绝热体, 前进边和回撤边一侧的移动墙设置为300K。

图1 二维搅拌摩擦焊接过程模型网格的划分

Fig.1 Mesh plot of 2D FSW process model

2 模拟结果与分析

对于方程的解算, 采用隐式、 线性、 分离解算器进行计算并对网格进行离散。 在解的过程中, 采用二阶离散方程计算压力, 采用二阶逆风方程计算动量方程。 整个模拟过程达到收敛大约需要20000~30000步迭代。 模拟结果包括材料流动的流线图、 速度分布图、 流体区域的压强分布图和温度分布图等, 本文讨论的模拟结果主要包括流线图和速度分布图。

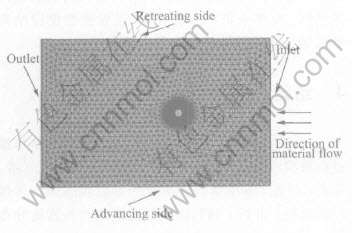

图2所示为焊接速度0.002m/s, 旋转速度400r/min时流场流线模拟结果。 从图中可以看出, 整个板材流体区域可以分为两个部分, 一个是受搅拌头探针影响发生变形区域, 一个是未受探针影响仍然以焊接速度继续向前运动的区域。 整个模型中大部分区域都是未受搅拌头影响区域, 这部分材料可以看作是刚体运动, 没有发生变形也没有能量散失。 仅仅靠近探针附近有很小一部分区域材料发生变形, 而且流动速度发生变化。 在图2中, 材料从右向左流过逆时针旋转的搅拌头。 流体区域的流线图表明: 在探针直径范围内的材料绕过探针发生转移, 移动方向与搅拌头的旋转方向一致。 探针直径范围内的材料都是沿回撤边绕过探针, 在前进边上没有发生材料绕流现象。 因为所有发生变形的材料都会在回撤边一侧绕过探针, 所以发生变形区域的宽度在回撤边要比在前进边大一些。 从图2中还可以看出, 受搅拌头作用发生变形并绕过探针流动的材料, 在绕过探针前和绕过探针后相对于焊缝中心线的位置几乎是不变的(即如果不考虑绕流, 材料流动可以看作是沿直线运动)。 由于假定是层流, 流线也不会发生交叉现象。 另外, 可以看出, 靠近搅拌头探针附近, 流线并不是紧靠在探针上, 两者之间大约有0.1mm厚度的空白区域, 这部分区域的材料也发生绕探针循环流动。

图2 流场流线的二维模拟结果

Fig.2 Result of path lines by 2D simulation

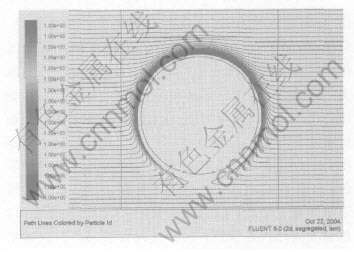

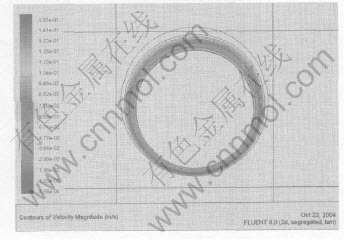

图3所示为搅拌头附近材料流动速度的分布。 从图中可以看出, 搅拌头附近材料的速度非常高, 紧靠近探针的薄层(即图2中所示探针周围空白区域)速度最高可以达到0.151m/s, 与搅拌头旋转速度0.157m/s相当, 这一薄层材料可以认为与探针

图3 材料流动速度分布的二维模拟结果

Fig.3 Result of contribution of velocity magnitude by 2D simulation

一起旋转, 相对速度几乎为零。 由于本模型的建立以流体力学理论为基础, 速度梯度导致的粘度耗散是热量产生的根源, 探针附近材料速度与探针旋转速度相当是合理的。 薄层的厚度与材料的物理性能及焊接工艺参数等有关。 从图2和图3可以看出, 受探针影响发生变形的材料, 在绕过搅拌头探针流动的时候, 速度有了较大的变化, 流动速度远远高于未发生变形时材料流动速度(即焊接速度0.002m/s)。

3 实验验证

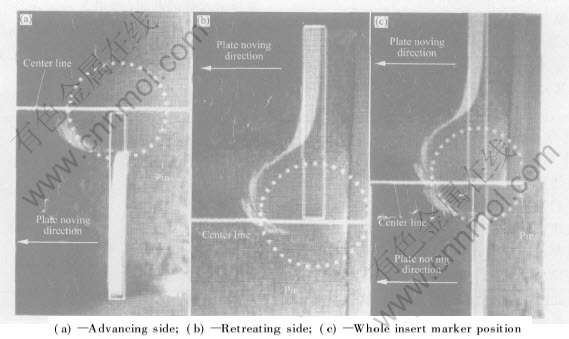

为了检测FSW过程中材料的流动, 本研究采用“标记嵌入技术”来实现焊缝材料流动的可视化。 焊接前, 在2014Al合金母材上采用机械方法加工带状沟槽, 然后将标记材料LF5嵌入到沟槽里面去。 焊接后, 标记材料被转移到搅拌头后方并在焊缝中沉积下来, 留下一定的迹线。 这些迹线从侧面反映了焊缝金属材料流动的轨迹。 截取焊缝中间厚度上的标记材料图片进行模拟结果验证, 图片中黑色的为母材金属, 白亮色的为标记材料, 白色实线表示焊缝中心线, 白色箭头指示板材运动方向, 白色虚线圆环代表探针, 探针逆时针旋转, 白色矩形表示标记材料焊接前的原始位置。 图4(a)所示为前进边上的标记材料焊接后迹线, 图4(b)所示为回撤边标记材料焊接后迹线, 图4(c)所示为将前进边和回撤边标记材料迹线照片组合起来。 由图4可以看出, 发生变形的标记材料比探针直径稍大一些, 在回撤边上明显的看到探针与标记材料之间有一个间隙, 可以认为这与模拟结果中探针附近的空白区域薄层相对应, 这一间隙的厚度与焊接工艺参数及材料物理性能有关。 在“标记嵌入技术”实验中, 所有标记材料都是从探针回撤边一侧绕过探针, 在探针后部沉积, 探针前进边无材料绕流现象, 这也与模型模拟结果相一致。 前进边的标记材料仍然在前进边发生沉积, 回撤边的材料在回撤边发生沉积, 仅仅在焊缝中心线部位有部分材料沉积位置稍微有偏差。 笔者认为这是由于标记材料嵌入时的误差因素所致。 整体来讲, 二维FSW过程模型模拟结果和流场可视化结果基本吻合。

4 结论

1) 建立了基于流体力学的二维搅拌摩擦焊接过程模型。 搅拌摩擦焊接过程被模拟成一个二维、 稳态、 层流、 非牛顿流体流经一个旋转的圆柱体探针的过程, 得到了材料流动流线图和材料速度分布图。

2) 在大多数的模拟条件下, 在探针直径范围内的材料仅仅在回撤面一侧绕过探针, 而不是在探针两侧绕流; 绕过探针以后, 材料又以恒定的焊接速度继续逆着焊接方向运动。 与未受探针影响的材料而言, 探针附近发生变形材料的速度增大。

3) 仅有很少材料在探针附近发生变形和绕流 现象; 紧靠近探针附近有一厚度大约为0.1mm的薄层材料“粘贴”在探针上, 与探针一起旋转运动。

图4 焊缝中部标记材料位置图像

Fig.4 Marker material images in middle height weld

4) 采用“标记嵌入技术”对模拟结果进行实验验证, 模拟结果和实验结果基本吻合, 二维FSW过程模型能较好的预测材料流动趋势。

REFERENCES

[1]Dickerson T L, Przydatek J. Fatigue of friction stir welds in aluminium alloys that contain root flaws[J]. International Journal of Fatigue, 2003, 25(12): 1399-1409.

[2]Prado R A, Murr L E, Shindo D J, et al. Tool wear in the friction-stir welding of aluminum alloy 6061+20% Al2O3: a preliminary study[J]. Scripta Materialia, 2001, 45(1): 75-80.

[3]Prado R A, Murr L E, Soto K F, et al. Self-optimization in tool wear for friction-stir welding of Al 6061+20% Al2O3 MMC[J]. Mater Sci Eng A, 2003, A349(1-2): 156 - 165.

[4]张华, 林三宝, 吴林, 等. 镁合金AZ31搅拌摩擦焊接头的微观组织[J]. 中国有色金属学报, 2003, 13(6): 1510-1513.

ZHANG Hua, LIN San-bao, WU Lin, et al. Microstructure of friction stir welds in AZ31 magnesium alloy[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(6): 1510-1513.

[5]Colligan K. Material flow behavior during friction stir welding of aluminum[J]. Welding Journal (Miami, Fla), 1999, 78(7): 229 - 237.

[6]Seidel T U, Reynold A P. Visualization of the material flow in AA2195 friction-stir welds using a marker insert technique[J]. Metallurgical and Materials Transactions A: Physical Metallurgy and Materials Science, 2001, 32(11): 2879-2884.

[7]Guerra M, Schmidt C, McClure J C, et al. Flow patterns during friction stir welding[J]. Materials Characterization, 2002, 49(2): 95-101.

[8]Ouyang J H, Kovacevic R. Material flow and microstructure in the friction stir butt welds of the same and dissimilar aluminum alloys[J]. Journal of Materials Engineering and Performance, 2002, 11(1): 51-63.

[9]Xu S, Deng X. Two-and three-dimensional finite element models for the friction-stir welding process[A]. Proceedings of 4th International Symposium on Friction Stir Welding[C]. Park City, Utah, USA: CFSWT, 2003. 14-16.

[10]栾国红, North T H, 郭德伦, 等. 铝合金搅拌摩擦焊接头行为分析[J]. 焊接学报, 2002, 23(6): 62-66.

LUAN Guo-hong, North T H, GUO De-lun, et al. Characterizations of friction stir welding on aluminum alloy[J]. Transactions of the China Welding Institution, 2002, 23(6): 62-66.

[11]Colegrove P A, Shercliff H R, Philip L. Threadgill. Modelling and development of the TrivesTM friction stir welding tool[A]. Proceedings of 4th International Symposium on Friction Stir Welding[C]. Park City, Utah, USA: CFSWT, 2003. 14-16.

[12]Colegrove P A. 3-dimensional flow and thermal modelling of the friction stir welding process[A]. Proceedings of 2nd International Symposium on Friction Stir Welding[C]. Gothenburg Sweden, 2000. 26-28.

[13]Seidel T U. The Development of a Friction Stir Welding Process Model Using Computational Fluid Dynamics[D]. Columbia, SC: The University of South Carolina, 2001.

[14]Sheppard T, Jackson A. Constitutive equations for use in prediction of flow stress during extrusion of aluminium alloys[J]. Materials Science and Technology, 1997, 13(1): 203-209.

[15]工程材料实用手册编辑委员会. 工程材料实用手册(3): 铝合金 镁合金 钛合金[M]. 北京: 中国标准出版社, 1989. 215.

The Compile Committee of the Practice Manual of Engineering Material. Practice Manual of Engineering Material(3): Al alloy Mg alloy and Ti alloy[M]. Beijing: Chinese Standard Press, 1989. 215.

(编辑陈爱华)

基金项目: 国家高技术研究发展计划资助项目(2002AA331160)

收稿日期: 2004-11-02; 修订日期: 2005-01-24

作者简介: 赵衍华(1977-), 男, 博士研究生.

通讯作者: 林三宝, 副教授, 博士; 电话: 0451-86418844; E-mail: sblin@hit.edu.cn