文章编号:1004-0609(2015)04-0900-10

析出相对Al-Cu-Mg合金蠕变行为的影响

陈宇强1, 2,潘素平3,刘文辉1, 2,蔡志华1,唐思文1,唐昌平1, 2

(1. 湖南科技大学 机电工程学院,湘潭 411201;

2. 湖南科技大学 高温耐磨材料及制备技术湖南省国防技术重点实验室,湘潭 411201;

3. 中南大学 高等研究中心,长沙 410083)

摘 要:利用不同的热处理制度制备T4、欠时效、峰时效和过时效4种状态的合金,并通过恒应力蠕变拉伸实验和显微组织观察分别对不同状态合金在150 ℃、225 MPa和200 ℃、200MPa的蠕变行为进行分析。结果表明:合金在150 ℃蠕变时,变形主要依靠晶内的位错滑移,细小弥散分布的析出相以及固溶原子对位错的钉扎有利于降低合金的蠕变速率;4种合金在该蠕变条件下均经历较长的稳态蠕变阶段,其中峰时效合金的蠕变速率最低;合金在200 ℃蠕变时,变形主要依靠晶界滑移;在蠕变过程中,峰时效态和过时效态合金中形成明显的无沉淀析出带,导致其蠕变速率显著增加,并且几乎没有出现明显的稳态蠕变阶段;欠时效态合金在该蠕变条件下的蠕变速率最低。

关键词:Al-Cu-Mg合金;蠕变行为;析出相;显微组织

中图分类号:TG146.2 文献标志码:A

Effect of precipitates on creep behaviors of Al-Cu-Mg alloy

CHEN Yu-qiang1, 2, PAN Su-ping3, LIU Wen-hui1, 2, CAI Zhi-hua1, TANG Si-wen1, TANG Chang-ping1, 2

(1. College of Electromechanical Engineering, Hunan University of Science and Technology, Xiangtan 411201, China;

2. Key Laboratory of High Temperature Wear Resistant Materials Preparation Technology of Hunan Province,

Hunan University of Science and Technology, Xiangtan 411201, China;

3. Advanced Research Center, Central South University, Changsha 410083, China)

Abstract: Alloys at four different heat treatment states (T4, underaged, peakaged and overaged) were prepared, and their creep behaviors under the conditions of 150 ℃, 225 MPa and 200 ℃, 200 MPa were studied through constant-stress tensile creep experiments and microstructure observations. The results indicate that, when crept at 150 ℃, the deformation of alloys mainly depends on the dislocation slip within the grains. The pinning effect of dispersed tiny precipitates and solutes on the dislocations can decrease the creep rate of alloys effectively. All four alloys experience a long term steady creep stage and the peakaged state alloy possesses the lowest creep rate. When crept at 200 ℃, the main deformation of alloys switches to grain boundary (GB) sliding. Precipitate-free zones (PFZs) form in the peakaged and overaged state alloys during creeping, which increases the creep rate of alloys remarkably and disappears the steady creep stage of these alloys. The underaged state alloy possesses the lowest creep rate at this creep condition.

Key words: Al-Cu-Mg alloy; creep behavior; precipitate; microstructure

Al-Cu-Mg合金具有强度高、韧性好、耐热性能优越等一系列优点,在航空航天以及轨道交通等领域有着非常广泛的应用[1-3]。飞机在高速飞行过程中,其表面与空气摩擦,温度迅速升高。在正常巡航速度下,飞机蒙皮的温度局部可达150 ℃。而在特殊情况下,其温度甚至可超过200 ℃[4]。随着科技水平的不断提高,运输工具不断高速化、大型化。航空构件承受的服役温度越来越高,承受的加载条件越来越苛刻[5-6]。在这种应力和温度场的耦合作用下,构件有可能发生蠕变失效而对航空安全造成严重威胁[7-8]。作为重要的航空结构材料,研究Al-Cu-Mg合金的蠕变行为就显得尤为重要。

目前,针对Al-Cu-Mg合金的蠕变行为,国内外研究学者已经开展了一定的研究工作[9-11]。其中,早期的研究大多集中于蠕变条件对合金蠕变行为的影响。LIN等[12]研究了Al-Cu-Mg合金在200~350 ℃温度下的蠕变行为,其研究发现,蠕变温度和蠕变应力对合金的断裂行为有显著影响。同样地,ZHANG等[10]的研究也表明,温度和应力是决定合金蠕变行为的两个重要因素。

随后,为了更深层次地了解合金的蠕变机理从而提高其抗蠕变性能,研究人员将更多的关注集中于合金微结构特征与其蠕变行为的相互作用机理研究。在合金微结构特征中,析出相特征被认为对其蠕变行为具有极为重要的影响[13-15]。LUMLEY等[13]对比了Al-Cu-Mg-Ag合金在欠时效状态和峰时效状态的蠕变行为并发现,在欠时效状态下合金中,细小弥散的析出相以及基体中过饱和的溶质原子对位错运动具有强烈的阻碍作用,使得合金的抗蠕变性能有明显提高。本文作者的前期研究工作[14]发现,在150~200 ℃的蠕变过程中,Al-Cu-Mg合金出现明显的第二相析出。这些析出的第二相与变形过程中产生的位错发生交互作用。这种相互作用不但会明显加速第二相的粗化速率,而且会对合金的蠕变行为产生显著影响。

综上所述,蠕变温度和蠕变应力对Al-Cu-Mg合金蠕变行为起着十分重要的影响,而合金中析出相的形貌特征又是影响合金蠕变行为的关键因素。在此,本文作者利用热处理制备了不同析出相形貌的Al-Cu-Mg合金,并结合蠕变拉伸实验和微观组织观察对合金的蠕变行为开展研究。旨在揭示在不同蠕变条件下合金析出相形貌特征与其蠕变行为之间的关系,为Al-Cu-Mg合金的服役安全提供理论指导和实验依据。

1 实验

实验原材料采用西南铝业集团有限责任公司提供的2.0 mm厚铝合金冷轧板,其化学成分(质量分数,%)为:4.20Cu、1.38Mg、0.58Mn、0.11Fe、0.15Cr、0.15Si、Al余量。实验前,先将原材料进行500 ℃、40min的固溶处理,经水淬后,在190 ℃进行不同时间的人工时效。然后,根据硬度测试选取不同状态的合金进行蠕变实验。

蠕变实验在RC-950蠕变持久试验机上进行。蠕变试验机主要技术参数如下:负荷精度±1%;控温精度±3 ℃,梯度≤3 ℃。实验标准参照GB/T 2039—80,取样方向沿板材的轧制方向。实验选取150和200 ℃两个蠕变温度,并依据文献[9, 14]选取两个温度下的实验应力分别为225 MPa和200 MPa。

实验中采用POLYVER-MET型金相显微镜对合金的晶粒尺寸和形貌进行分析。采用FEI Sirion 200场发射扫描电镜(SEM)和TecnaiG2 F20透射电镜(TEM)对合金第二相的形貌和分布进行观察。透射电镜样品在-25 ℃以下利用MT-PI型双喷电解减薄仪进行减薄,双喷液采用25%硝酸+75%甲醇(体积分数)混合溶液。

2 实验结果

2.1 合金的室温力学性能

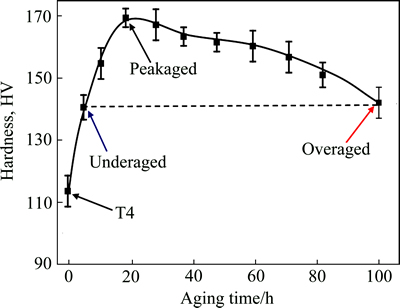

图1所示为合金经固溶处理后在190 ℃等温时效的硬化曲线。由图1可见,合金存在明显的时效硬化特征。在时效前期,合金的硬度值迅速升高,在时效18 h时达到峰值。随后,继续延长时效时间,合金的硬度逐渐下降。合金在190 ℃时效100 h后的硬度值与时效5 h时的硬度值基本相当。根据图1的时效硬化曲线,实验选取4种状态的合金,即T4状态(固溶淬火后不经过人工时效,仅进行自然时效)、欠时效状态(190 ℃人工时效5 h)、峰时效状态(190 ℃人工时效18 h)、过时效状态(190 ℃人工时效100 h)。

图1 Al-Cu-Mg合金在190 ℃时的时效硬化曲线

Fig. 1 Age hardening curve of Al-Cu-Mg alloy aged at 190 ℃

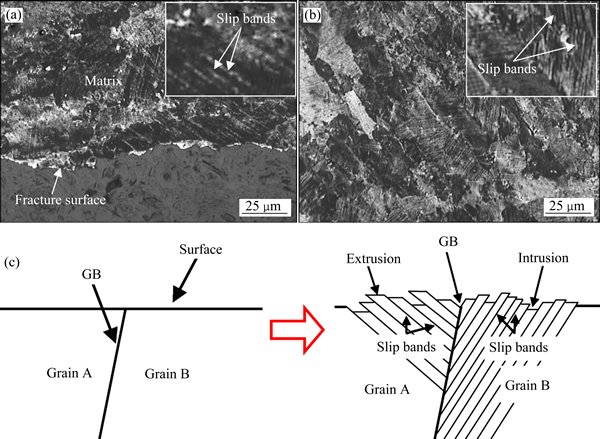

为了更直观地了解合金力学性能的基本情况,实验中对4种热处理状态的合金分别进行了力学拉伸测试,结果如表1所列。由表1可以看出,合金的屈服强度(σ0.2)和抗拉强度(σb)的变化趋势与硬度测试结果相似。T4状态合金的强度最低,峰时效的强度最高,而欠时效和过时效的强度值相近。4种合金均拥有较高的塑性,伸长率(δ)都在15%以上。合金在T4状态下伸长率最高,达到26.3%。经过人工时效后,合金的伸长率都明显降低。其中,峰时效状态合金的伸长率最低。这说明4种状态合金伸长率的变化趋势与其强度的变化趋势刚好相反,而这也与其他研究报道的结果[16]基本一致。

表1 不同热处理状态的Al-Cu-Mg合金在室温下的拉伸性能

Table 1 Room temperature tensile properties of Al-Cu-Mg alloy at different heat treatment states

2.2 合金的蠕变曲线

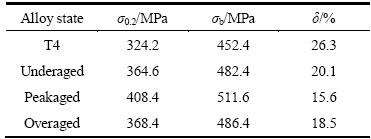

图2(a)所示为4种热处理状态的合金在150 ℃、225 MPa的蠕变应变-蠕变时间关系曲线。对于铝合金来说,其蠕变一般可以分为3个阶段[17],即初始蠕变阶段(第一阶段)、稳态蠕变阶段(第二阶段)和加速蠕变阶段(第三阶段)。由图2(a)可知,在该蠕变条件下,4种状态下合金的变形量均较小,并且在100 h以内的蠕变过程中,4种合金均只经历了初始蠕变阶段和稳态蠕变阶段,而没有出现加速蠕变阶段。

合金的蠕变速率对应着蠕变应变与蠕变时间的比值。通过计算图2(a)中各曲线的斜率可知,在4种状态的合金中,T4态合金在蠕变前10 h的应变速率较高,而后应变速率迅速降低,其稳态蠕变速率约为1.33×10-7 s-1。而过时效态合金虽然蠕变前期的应变速率较低,但第二阶段的蠕变速率明显高于其他3种状态的合金,其稳态蠕变速率达到7.88×10-7 s-1。峰时效和欠时效态的稳态蠕变速率较为接近,但峰时效态合金前期的蠕变速率明显更低。

图2(b)显示了4种热处理状态的合金在200 ℃、200 MPa的蠕变应变-蠕变时间的关系曲线。通过对比图2(a)和图2(b)的斜率可知,相比于150 ℃、225 MPa,4种合金在200 ℃、200 MPa条件下的蠕变速率大幅增加,且出现了明显的加速蠕变阶段。此外,在该蠕变条件下,4种热处理状态合金的蠕变速率差异更加显著。可以看出,过时效和峰时效态合金的蠕变速率最快。试样几乎没有经历明显的稳态蠕变阶段就快速进入了加速蠕变阶段。4种合金中,欠时效态合金的蠕变速率最慢,其稳态蠕变过程一直保持至90 h左右,稳态蠕变速率为3.48×10-6 s-1。当蠕变时间超过90 h后,合金的蠕变速率缓慢增加,进入加速蠕变阶段。值得注意的是,在200 ℃、200 MPa条件下,T4态合金的蠕变速率要明显低于峰时效状态的。

图2 4种状态合金在不同蠕变状态下的应变-蠕变时间曲线

Fig. 2 Creep strain-creep time curves of four heat treatment state alloys under different creep conditions

2.3 合金蠕变的变形特征

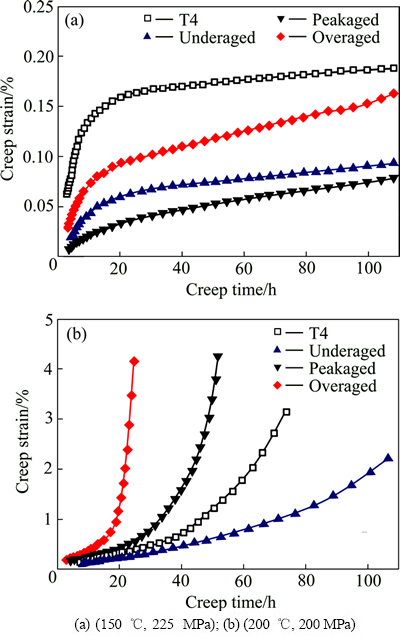

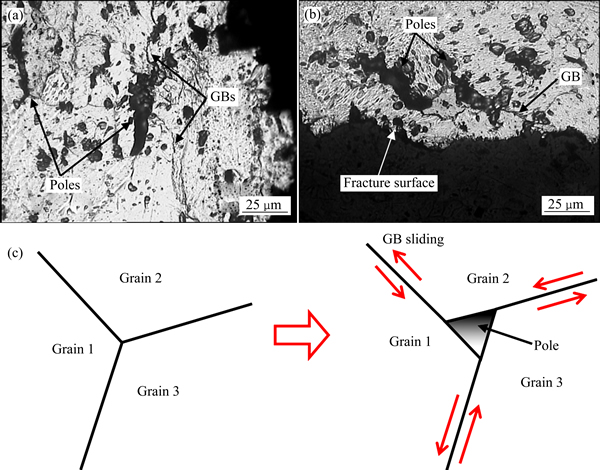

为了分析合金的蠕变变形行为,实验对合金蠕变断口附近区域的金相组织进行了观察。在150 ℃、225 MPa条件下,4种合金断口附近区域的晶粒中均出现大量的平行条带(见图3(a)和图3(b))。这些条带的形成源于位错沿滑移系某些晶面滑移时在试样表面形成的挤出或凹入型台阶[1],即滑移带(见图3(c))。大量滑移带的形成表明,在该蠕变条件下,合金的变形主要依靠晶内的位错滑移。

4种合金在200 ℃、200 MPa条件下的蠕变组织特征与150 ℃、225 MPa蠕变时的明显不同。图4所示为过时效态和欠时效态合金在200 ℃、200 MPa蠕变条件下断口附近区域的金相组织以及晶界处微孔形成的示意图。由图4可知,合金断口附近区域没有出现明显的滑移带特征,但在晶界处均出现了不同程度的细小孔洞。

图3 T4和欠时效态合金在150 ℃、225 MPa蠕变条件下断口附近区域的金相组织以及试样表面挤出或凹入型台阶的形成示意图

Fig. 3 Optical images of T4(a) and underaged alloys(b) at different heat treatment states when being crept at 150 ℃ and 225 MPa and schematic diagram of extrusions and intrusions on specimen surface(c)

图4 过时效态和欠时效态合金在200 ℃、200 MPa蠕变条件下断口附近区域的金相组织以及晶界处微孔形成的示意图

Fig. 4 Optical images of overaged(a) and underaged alloys(b) at different heat treatment states when being crept at 200 ℃ and 200 MPa and schematic diagram of poles caused by GB sliding(c)

对于铝合金而言,晶界处的原子通常排列紊乱且存在较大的晶格畸变。在室温下,晶界区域的这种结构特征对位错的运动可以起到较强的阻碍作用,因此,在宏观上表现为对合金的明显强化效果。此外,原子紊乱排布而产生的畸变能使得晶界附近区域存在较高的能量[17]。一方面,在高温下,随着原子振动加剧,晶界变得不稳定,对位错的阻碍作用显著下降[14]。另一方面,元素扩散速率的增加可以促使塞积在晶界附近的位错发生攀移,有利于晶界通过滑移、扭转等方式发生变形[17]。当晶界发生滑移时,各晶界的连接部位往往存在较大的应力集中。由于高温下晶界强度显著弱化,因此,晶界的连接处容易优先形成裂纹并逐渐演化为孔洞,如图4(c)所示。

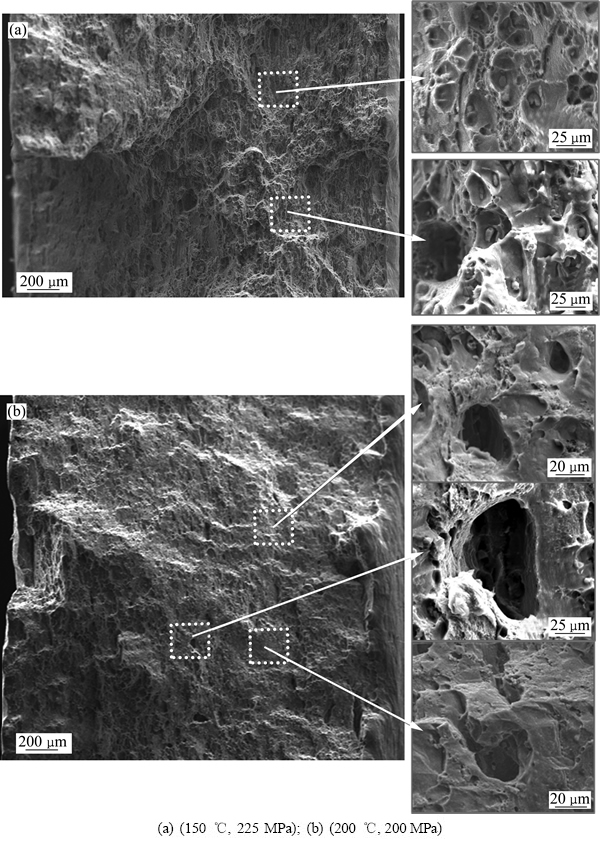

为了进一步分析合金的变形特征,实验中对合金的蠕变断口进行了SEM形貌观察。整体上来说,4种状态合金在相同蠕变条件下的断口特征差异并不十分明显,但不同蠕变条件下的断口形貌却存在显著差 异。图5所示为过时效态合金在150 ℃、225 MPa和200 ℃、200 MPa蠕变条件下的断口形貌。由图5可见,类似于合金在室温拉伸时的断口形貌特征,合金在150 ℃、225 MPa蠕变后,合金断面粗糙不平,均匀分布了大量椭圆形的韧窝,并且韧窝内存在明显的第二相粒子,说明合金表现为明显的韧窝型穿晶断裂特征。这也进一步证实了合金在150 ℃、225 MPa蠕变时,变形方式主要为晶内的位错滑移。合金在200 ℃、200 MPa蠕变后的断面较为平整,展现出明显的沿晶断裂特征,同时断面可以观察到数量众多且尺寸不一的孔洞。这也与图3和图4的分析结果吻合,说明合金在该蠕变条件下变形方式主要表现为晶界滑移。

图5 过时效态合金在不同蠕变条件下的断口形貌

Fig. 5 Fracture surface morphologies of overaged alloy crept under different conditions

2.4 合金的TEM组织观察

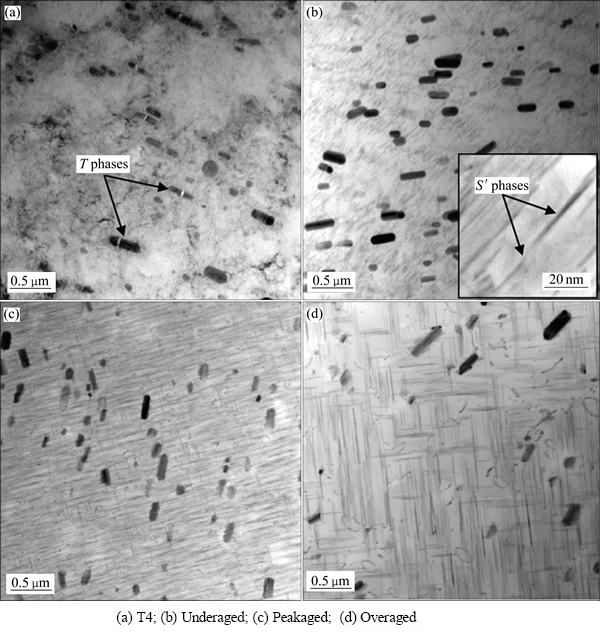

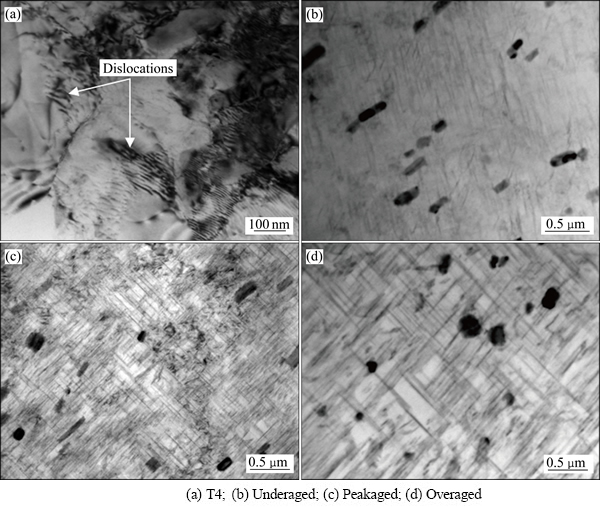

图6所示为蠕变前4种热处理状态合金的TEM像。对于T4态合金而言,由于合金经固溶淬火后未经过人工时效处理,所以晶内没有明显的第二相粒子析出,而仅有一些弥散分布的T相粒子,如图6(a)所示。由文献[18]可知,这些T相粒子在合金的均匀化处理过程中形成,且在后续的加工处理过程中十分稳定,因此在时效处理过程中不会有明显的变化。在欠时效态合金中(见图6(b)),除了T相粒子外,还可以观察到少量尺寸在50 nm左右的针状S′相粒子。在峰时效态合金中(见图6(c)),合金晶内的S′相分布十分密集,且尺寸约在300 nm左右。而在过时效态合金中(见图6(d)),S′相粒子尺寸更为粗大(约为600 nm),且粒子之间的间距也明显加宽。

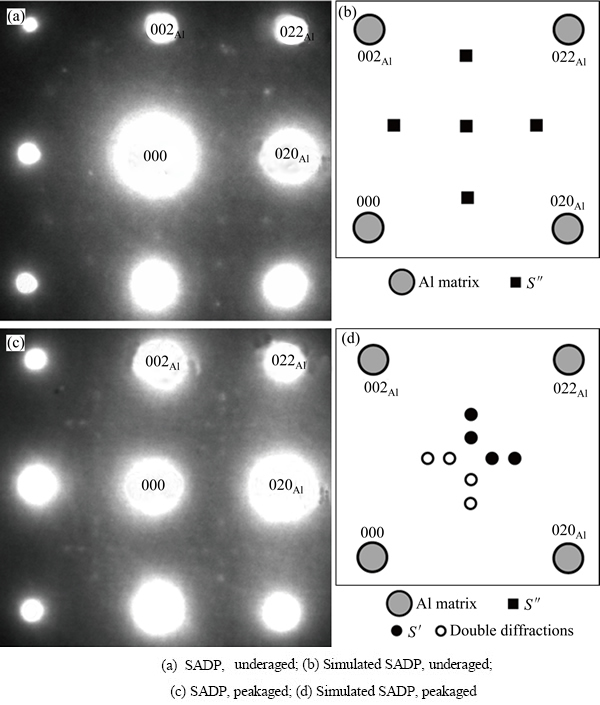

图7所示为欠时效和峰时效态合金在<100>Al入射方向的选取衍射花样。虽然依据图6(b)的观察发现,欠时效态合金中已经有少量S′相粒子析出,然而由图7(a)和(b)分析可知,欠时效态合金的主要强化相为S″相。S″相属于S′相的前驱体,通常出现在Al-Cu-Mg合金的时效早期。其尺寸在几个纳米以内而且与基体之间的界面不清晰,因此,一般较为难于在TEM明场像中观察到。由图7(c)和(d)可知,不同于欠时效态合金,峰时效态合金中的主要强化相为S′相。

图6 蠕变前4种热处理状态合金在<100>Al入射方向的TEM像

Fig. 6 TEM images of alloy at different heat treatment states viewed along <100>Al zone axis

图7 欠时效和峰时效态合金在<100>Al入射方向的选取衍射花样及其所对应的示意图

Fig. 7 SADPs and simulated SADP of alloys at different heat treatment states viewed along <100>Al zone axis

图8所示为合金在150 ℃、225 MPa蠕变断口附近区域的TEM像。4种状态的合金在该条件蠕变后,析出相的形貌差别并不明显。但是,合金晶内都出现了不同程度的位错聚集现象,这主要是因为在该温度下合金的变形主要由晶内的位错滑移主导。

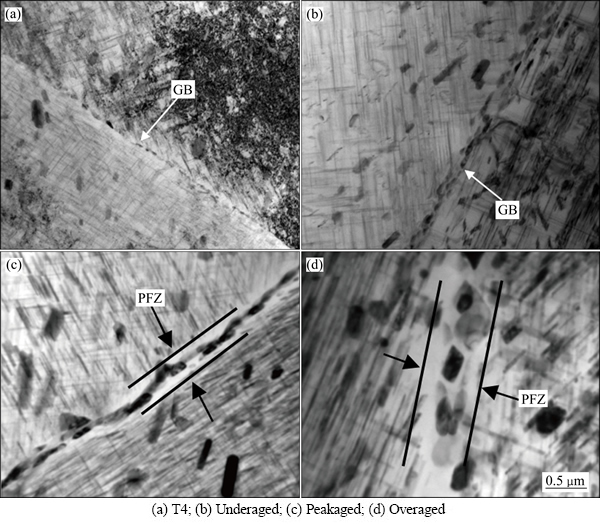

图9所示为4种热处理状态合金在200 ℃、200 MPa蠕变断口附近区域的TEM像。由于蠕变温度较高,T4态合金中析出了大量针状的S′相(见图9(a))。这些S′相尺寸在300 nm左右,与蠕变前的峰时效态合金S′相粒子尺寸相当。同时,经过蠕变后,欠时效态合金晶内S′相粒子的尺寸也增加至800 nm左右(见图9(b)),超过了蠕变前过时效态合金的析出相尺寸。此外,峰时效态和过时效态合金经过蠕变后,析出相的尺寸也都有明显增加(见图9(c)和(d))。其中,以过时效态合金更为明显,其晶内析出相粒子的尺寸甚至超过了1 μm。值得注意的是,在蠕变后的峰时效态合金和过时效态合金中都观察到晶界附近出现了明显的无沉淀析出带。

3 分析与讨论

在蠕变条件中,蠕变温度和施加应力是影响铝合金蠕变行为的两个关键因素。其中,LIN等[19]的研究认为,在150~200 ℃、185~225 MPa的蠕变条件范围内,蠕变温度对Al-Cu-Mg合金的力学行为的影响要比蠕变应力的影响大得多。同样地,在本实验中,4种热处理状态的合金在150 ℃、225 MPa蠕变过程中的应变速率比在200 ℃、200 MPa蠕变条件下的应变速率至少低一个数量级。这也进一步证实了在该蠕变条件范围内,温度对合金力学行为的影响更为显著。此外,Al-Cu-Mg合金在不同温度下的蠕变特征有着明显差异。在150 ℃蠕变时,由于大量滑移系的开启,合金的变形主要依靠晶内位错滑移。在200 ℃蠕变时,合金晶界弱化,主要变形方式转变为晶界滑移。

图8 合金在150 ℃、225 MPa蠕变断口附近区域在<100>Al入射方向的TEM像

Fig. 8 TEM images of alloys at different heat treatment states crept at 150 ℃ and 225 MPa viewed along <100>Al zone axis

图9 合金在200 ℃、200 MPa蠕变断口附近区域的TEM像

Fig. 9 TEM images of alloys at different heat treatment states crept at 200 ℃ and 200 MPa viewed along <100>Al zone axis

除了蠕变条件外,合金的显微组织对其蠕变行为也存在显著影响。对于铝合金而言,析出相无疑是影响合金蠕变行为的一个重要因素。一般认为,弥散分布且均匀细小的析出相粒子会对合金蠕变过程中的位错运动起到明显的阻碍作用[20],从而减小合金的蠕变速率。然而,对于多数热处理可强化合金来说,合金在蠕变条件下由于温度较高,强化相会存在不同程度的粗化现象。这种强化相的粗化大大降低了其对位错的阻碍作用,从而导致合金的蠕变速率显著增加。

在150 ℃蠕变时,由于温度不高,4种热处理状态的Al-Cu-Mg合金析出相的形貌特征并没有发生显著的改变,其蠕变断口的形貌也与室温力学拉伸断口形貌相似。这说明合金在该温度下的变形特征与室温下的变形特征较为接近。从图2(a)的蠕变曲线可以看出,合金的抗蠕变性能与其室温拉伸强度有一定关系。在100 h的蠕变过程中,室温下强度最高的峰时效态合金蠕变量最小,而室温下强度最低的T4态合金蠕变量最大。这主要是由于峰时效态合金晶内细小弥散的S′相对位错具有较好的钉扎作用。在T4态合金中,由于晶内缺乏S′相的析出,导致其蠕变速率较快。对比欠时效态合金和过时效态合金的蠕变曲线发现,尽管两者在室温下的强度十分接近(见表1和图1),但是过时效态合金的蠕变速率要明显高于欠时效态合金的,这主要与合金基体中的固溶原子对位错[21]的阻碍作用有关。相比室温而言,合金中的固溶原子在高温下的运动速率更快。受到应力的影响,这些固溶原子可能聚集在位错附近区域从而显著阻碍位错的运动(已经有一些研究发现,该合金中的固溶原子容易聚集在位错线上形成析出相的形核核心)。由于欠时效态合金元素的过饱和程度要高于过时效态的,其位错运动受到固溶原子的阻碍作用要明显高于过时效态合金的,因此蠕变速率更低。

在200 ℃蠕变时,由于温度较高,合金中位错的可动性大大增加并且析出相显著粗化,导致4种热处理状态合金的蠕变速率都显著增加。此外,合金的变形机制也发生了明显改变。由于高温下晶界的弱化,晶界滑移占据了主导地位。由图9(c)和(d)可知,峰时效态和过时效态合金中都出现了较宽的无沉淀析出带。在无沉淀析出带中,既没有第二相析出同时又是固溶原子浓度较低的区域,因此,通常认为是合金最为薄弱的一个环节[22]。无沉淀析出带的出现对于合金在高温下的蠕变行为影响显著,相比于T4和欠时效态合金,峰时效和过时效态合金的蠕变速率均显著增加。

4 结论

1) 在150 ℃蠕变条件下,合金析出相变化不明显,其变形以晶内的位错滑移为主。细小弥散分布的S′相粒子以及固溶原子对位错的钉扎都有利于降低合金的蠕变速率。此外,合金的抗蠕变性能与其室温拉伸强度密切关系。在100 h的蠕变过程中,室温拉伸强度较高的合金蠕变量较小。

2) 在200 ℃蠕变条件下,合金中的S′相粒子显著粗化,合金变形以晶界滑移为主,断口表面出现大量微孔。在该蠕变条件下,合金的抗蠕变性能与室温拉伸强度没有明显关系。4种热处理状态合金的蠕变速率存在显著差异,其中欠时效态合金的蠕变速率最低。峰时效和过时效态合金由于在蠕变过程中形成了明显的无沉淀析出带,蠕变速率显著增加。

REFERENCES

[1] CHEN Y Q, PAN S P, ZHOU M Z, YI D Q, XU D Z, XU Y F. Effects of inclusions, grain boundaries and grain orientations on the fatigue crack behaviors in 2524-T3 aluminum alloy[J]. Materials Science and Engineering A, 2013, 580: 150-158.

[2] DING J K, WANG D P, WANG Y, DU H. Effect of post weld heat treatment on properties of variable polarity TIG weldedAA2219 aluminium alloy joints[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(5): 1307-1316.

[3] 宋艳芳, 潘清林, 丰 雷, 王 迎, 李 晨. Mg含量对Al-Cu-Mg-Ag合金组织与力学性能的影响[J]. 中国有色金属学报, 2013, 23(7): 1812-1818.

SONG Yan-fang, PAN Qing-lin, FENG Lei, WANG Ying, LI Chen. Effects of Mg content on microstructure and mechanical properties of Al-Cu-Mg-Ag alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(7): 1812-1818.

[4] 赵英涛. 美国大型客机结构用铝合金的发展[J]. 材料工程, 1993, 52(2): 45-48.

ZHAO Ying-tao. The development and prospect of structural aluminium alloy used in large-type passenger plane of united states[J]. Journal of Materials Engineering, 1993, 52(2): 45-48.

[5] DURSUN T, SOUTIS C. Recent developments in advanced aircraft aluminium alloys[J]. Materials and Design, 2014, 56: 862-871.

[6] SCHIJVE J. Fatigue damage in aircraft structures, not wanted, but tolerated?[J]. International Journal of Fatigue, 2009, 31: 998-1011.

[7] WILLIAMS J C, STARKE J E A. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51: 5775-5799.

[8] HEINZA A, HASZLER A, KEIDELl C, MOLDENHAUER S, BENEDICTUS R, MILLER W S. Recent development in aluminium alloys for aerospace applications[J]. Materials Science and Engineering A, 2000, 280: 102-107.

[9] 陈宇强, 易丹青, 潘素平, 黄 霞, 周明哲, 王 斌. 蠕变温度对Al-Cu-Mg合金晶内S′相析出过程的影响[J]. 稀有金属材料与工程, 2011, 40(1): 63-68.

CHEN Yu-qiang, YI Dan-qing, PAN Su-ping, HUANG Xia, ZHOU Ming-zhe, WANG Bin. Effects of creep temperatures on the precipitation of S′ phases in Al-Cu-Mg alloys[J]. Rare Metal Materials and Engineering, 2011, 40(1): 63-68.

[10] ZHANG J, DENG Y L, LI S Y, CHEN Z Y, ZHANG. X M Creep age forming of 2124 aluminum alloy with single/double curvature[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(6): 1922-1929.

[11] 湛利华, 李 杰, 黄明辉, 李炎光. 2524铝合金的蠕变时效行为[J]. 中国有色金属学报, 2013, 23(2): 320-326.

ZHAN Li-hua, LI Jie, HUANG Ming-hui, LI Yan-guang. Creep ageing behavior of 2524 aluminum alloy[J]. The Chinese Journal of Nonferrous Metals, 2013, 23(2): 320-326.

[12] LIN Y C, XIA Y C, MA X S, JIANG Y Q, CHEN M S. High temperature creep behavior of Al-Cu-Mg alloy[J]. Materials Science and Engineering A, 2012, 550: 15-130.

[13] LUMLEY R N, MORTON A J, POLMEAR I J. Enhanced creep resistance in underaged aluminum alloys[J]. Materials Science Forum, 2002, 331/337(3): 1495-1500.

[14] 陈宇强, 易丹青, 潘素平, 黄 霞, 王 斌, 周明哲. 温度对2024铝合金蠕变行为的影响[J]. 中国有色金属学报, 2010, 20(4): 632-639.

CHEN Yu-qiang, YI Dan-qing, PAN Su-Ping, HUANG Xia, WANG Bin, ZHOU Ming-zhe. Effect of temperature on creep behavior of 2024 aluminum alloy[J]. Journal of Nonferrous Metals, 2010, 20(4): 632-639.

[15] 周 亮, 邓运来, 晋 坤, 张新明. 预处理对 2124 铝合金板材蠕变时效微结构与力学性能的影响[J]. 材料工程, 2012, 2: 81-84.

ZHOU Liang, DENG Yun-lai, JIN Kun, ZHANG Xin-ming. Effect of pre-treatment on microstructures and mechanical properties of 2124 Al alloy creep aging sheet[J]. Journal of Materials Engineering, 2010, 2: 81-84.

[16] 周明哲. 航空用2E12 合金热处理工艺与疲劳行为的相关基础问题研究[D]. 长沙: 中南大学, 2010: 52-65.

ZHOU Ming-zhe. Research on the technology for heating processing and fatigue behaviors of aerial 2E12 alloy[D]. Changsha: Central South University, 2010: 52-65.

[17] 吴诗悙. 金属超塑性变形理论[M]. 北京: 国防大学出版社, 1997: 37-65.

WU Shi-heng. Metal superplastic deformation theory[M]. Beijing: National Defense University Press, 1997: 37-65.

[18] CHEN Y Q, YI D Q, JIANG Y, WANG B, XU D Z, LI S C. Twinning and orientation relationships of T-phase precipitates in an Al matrix[J]. Journal of Materials Science, 2013, 48: 3225-3231.

[19] LIN Y C, JIANG Y Q, XIA Y C, ZHANG X C, ZHOU H M, Deng J. Effects of creep-aging processing on the corrosion resistance and mechanical properties of an Al-Cu-Mg alloy[J]. Materials Science and Engineering A, 2014, 605: 192-202.

[20] KNIPLING K E, DUNAND D C. Creep resistance of cast and aged Al-0.1Zr and Al-0.1Zr-0.1Ti (at.%) alloys at 300-400 ℃[J]. Scripta Materialia, 2008, 59: 387-390.

[21] LUMLEY R N, MORTON A J, POLMEAR I J. Enhanced creep performance in an Al-Cu-Mg-Ag alloy through underageing[J]. Acta Materialia, 2002, 50: 3597-3608.

[22] CHEN Y Q, YI D Q, JIANG Y, WANG B, LIU H Q. Concurrent formation of two different type precipitation-free zones during the initial stage of homogenization[J]. Philosophical Magazine, 2013, 93: 2269-2278.

(编辑 龙怀中)

基金项目:国家自然科学基金青年基金资助项目(51405153,51475162);湖南省自然科学基金资助项目(14JJ5015)

收稿日期:2014-07-21;修订日期:2014-10-28

通信作者:陈宇强,讲师,博士;电话/传真:0731-58290019;E-mail: yqchen1984@163.com