DOI: 10.11817/j.ysxb.1004.0609.2020-37463

快速冷冲及再结晶退火对Al-Cu-Mg合金微观组织和力学性能的影响

胡泽艺1,范才河1,刘文良1,阳建君1,欧 玲1,陈喜红2

(1. 湖南工业大学 冶金与材料工程学院,株洲 412007;

2. 中国中车 株洲电力机车有限公司,株洲 412007)

摘 要:采用扫描电镜(SEM)、透射电镜(TEM)、电子背散射技术(EBSD) 、能谱仪(EDS)和拉伸测试等手段,研究快速冷冲及再结晶退火对喷射成形快速凝固细晶Al-Cu-Mg合金微观组织和力学性能的影响。结果表明:细晶Al-Cu-Mg合金在快速冷冲及再结晶退火过程中析出相主要以平衡相S相为主,还有少量较粗的Al6Mn相,随着变形道次的增加,析出相的密度不断增大、尺寸显著减小。快速冷冲引入的缺陷有助于Al-Cu-Mg合金脱溶和再结晶形核,促进S相和再结晶的形核与长大,从而有效细化晶粒、获得均匀纳米晶组织和促进S相弥散分布。快速冷冲Al-Cu-Mg合金的主要强韧化机制是细晶强化和析出强化,经4道次快速冷冲后合金的极限抗拉强度和伸长率分别达578MPa和17.5%,与1道次快速冷冲合金试样的相比较,极限抗拉强度提高48.5%,伸长率提高44.6%。

关键词:喷射成形;Al-Cu-Mg合金;快速冷冲;再结晶退火;析出相;力学性能

文章编号:1004-0609(2020)-10-2306-10 中图分类号:TG292 文献标志码:A

Al-Cu-Mg合金因具有强度高、加工成形性及耐 热性好等优点,已被广泛应用于航空航天及军工领域[1-2]。析出强化是Al-Cu-Mg合金主要的强化方式,细化晶粒是该合金主要的强韧化途径。在常规T6热处理状态下,低m(Cu)/m(Mg)的Al-Cu-Mg合金主要强化相为S(Al2CuMg相),高m(Cu)/m(Mg)的Al-Cu-Mg合金主要强化相为 (Al2Cu)相[3-6]。形变加时效工艺不仅能够使材料获得良好的加工硬化性能,而且在形变过程中引入大量位错并在时效过程中释放形变应力的同时促进析出相弥散形核和长大,甚至还可以改变析出相的特征和析出序列,在一定程度上细化晶粒组织和提高合金力学性能[7-10]。STYLES等[11]研究了Al-Cu-Mg合金过饱和固溶体的分解顺序与平衡相S相在合金中的形成关系,S相在高温下形成的时间远小于低温环境下的形成时间。杨培勇等[12]研究了外加应力对Al-Cu-Mg合金中

(Al2Cu)相[3-6]。形变加时效工艺不仅能够使材料获得良好的加工硬化性能,而且在形变过程中引入大量位错并在时效过程中释放形变应力的同时促进析出相弥散形核和长大,甚至还可以改变析出相的特征和析出序列,在一定程度上细化晶粒组织和提高合金力学性能[7-10]。STYLES等[11]研究了Al-Cu-Mg合金过饱和固溶体的分解顺序与平衡相S相在合金中的形成关系,S相在高温下形成的时间远小于低温环境下的形成时间。杨培勇等[12]研究了外加应力对Al-Cu-Mg合金中 相和

相和 相的析出过程的影响,发现外加应力通过改变竞争析出过程中

相的析出过程的影响,发现外加应力通过改变竞争析出过程中 相和

相和 相的力量对比,阻碍了

相的力量对比,阻碍了 相的析出,从而促进了

相的析出,从而促进了 相的析出。尹美杰等[13]研究了中断时效工艺对Al-Cu-Mg合金力学性能和显微结构的影响,发现中断时效没有促进S相的明显增加,合金韧性明显提高,但硬度略有降低。LI等[14]研究了预变形对高纯Al-Cu-Mg合金组织的影响发现,随着预变形量的提高,合金中

相的析出。尹美杰等[13]研究了中断时效工艺对Al-Cu-Mg合金力学性能和显微结构的影响,发现中断时效没有促进S相的明显增加,合金韧性明显提高,但硬度略有降低。LI等[14]研究了预变形对高纯Al-Cu-Mg合金组织的影响发现,随着预变形量的提高,合金中 (Al2CuMg)相的密度增大,尺寸减小,合金峰值硬度和强度显著提高。可见,已有的研究主要是在常规形变及时效温度条件下探讨Al-Cu-Mg合金的微结构演变及力学性能特征,目前尚没有快速冷冲和再结晶退火工艺条件下关于Al-Cu-Mg合金微观组织演变及力学性能研究的报道。

(Al2CuMg)相的密度增大,尺寸减小,合金峰值硬度和强度显著提高。可见,已有的研究主要是在常规形变及时效温度条件下探讨Al-Cu-Mg合金的微结构演变及力学性能特征,目前尚没有快速冷冲和再结晶退火工艺条件下关于Al-Cu-Mg合金微观组织演变及力学性能研究的报道。

本实验基于喷射成形快速凝固细晶Al-Cu-Mg合金坯料,采用快速冷冲和再结晶退火相结合的工艺制备铝合金药筒,研究了快速冷冲和再结晶退火过程中合金晶粒形貌和析出相的演变规律,探讨了快速冷冲和再结晶退火对析出相特征、晶粒细化的影响及强韧化机制。

1 实验

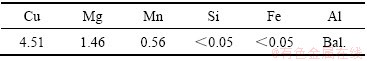

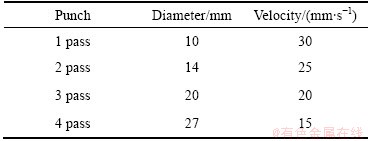

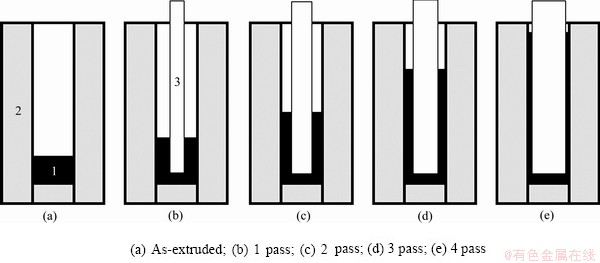

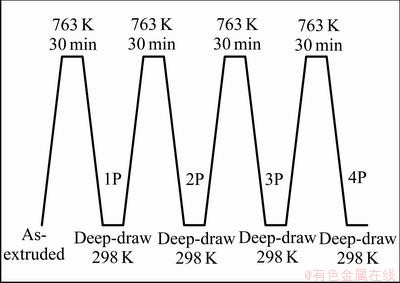

在自行研制的SD380大型喷射成形装置上制备喷射成形快速凝固细晶Al-Cu-Mg合金圆柱坯,合金的化学成分如表1所列。在1250 t挤压机上将圆柱坯挤压成d 30 mm的圆棒,挤压温度为723 K,挤压比为15:1;在线切割机上将圆棒切割成d 30 mm×20 mm长的小圆柱,置于自行设计的冲压成型模具中经4道次快速冷冲和再结晶退火,制备出铝合金药筒,快速冷冲铝合金药筒示意图如图1所示,快速冷冲和再结晶退火工艺参数如图2所示,再结晶退火温度为763 K,采用快速加热方式,加热速度为623 K/min,保温30 min后空冷到室温进行下一道次快速冷冲。快速冷冲工艺参数如表2所列。

表1 实验样品的合金成分

Table 1 Compositions of experimental sample (mass fraction, %)

表 2 快速冷冲工艺参数

Table 2 Technological parameter of rapid cold punching

在药筒的筒壁上选取试样进行微观组织观察和力学性能分析。采用Titan G2 60-300型透射电镜(TEM)和利用Helios Nanolab 600i型扫描电镜(SEM)的电子背散射成像技术(EBSD)分析试样的微观结构,透射试样采用机械预减薄至80 μm左右后进行双喷电解,电解液为硝酸+甲醇(体积比为1:3),温度低于248 K;EBSD试样采用电解抛光,电解液的成分为10%高氯酸+90%无水乙醇(体积分数),抛光电压20 V,电流1.0 A,抛光时间30 s,温度低于248 K;EBSD试样实验数据采用TSL OIM软件进行分析和处理,加速电压20 kV,角度70°,扫描步长0.05 um。在透射电镜上进行能谱分析(EDS),在Instron 3369拉伸机上进行试样的室温拉伸性能测试,拉伸速度为1.0 mm/min。

2 实验结果

2.1 晶粒组织演变

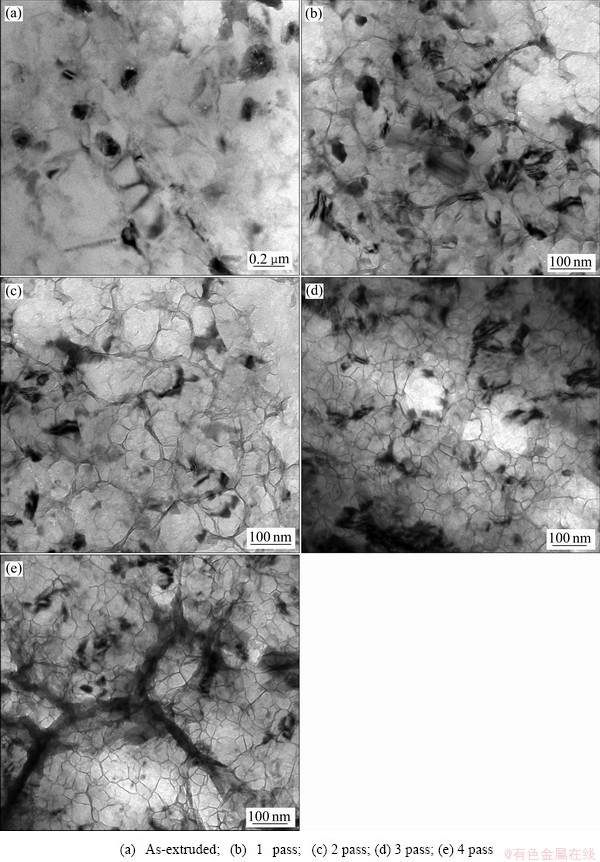

图3所示为不同道次快速冷冲Al-Cu-Mg合金再结晶退火后的晶粒形貌TEM像。由图3可见,随着变形道次的增多,试样变形量不断增加,再结晶程度越来越大,晶粒尺寸越来越细,晶粒组织更为均匀。挤压态合金试样经763 K保温30 min再结晶退火,发生了不完全再结晶(见图3(a))。试样经1道次快速冷冲后再结晶退火,可观察到少量高位错密度区域,再结晶程度明显增大,但仍为不完全再结晶,大角度晶界明显增多(见图3(b))。试样经2~3道次快速冷冲后再结晶退火,发生了完全再结晶,组织趋于均匀,没有粗大再结晶晶粒,再结晶晶粒组织全部为纳米晶,平均晶粒尺寸小于100 nm(见图3(c)和(d))。试样经4道次快速冷冲后再结晶退火,完全再结晶组织更为均匀,再结晶晶粒形貌主要为等轴晶,与前3道次快速冷冲试样相比较,晶粒尺寸进一步细化,平均晶粒尺寸小于50 nm;但由于试样变形程度增大、应变速率提高,快速冷冲变形产生的高位错密度仍在局部区域存在(见图3(e))。

图1 快速冷冲合金试样示意图

Fig. 1 Sketch maps of rapid cold punching process (1—Sample; 2—Drawing die; 3—Punch)

图2 快速冷冲及再结晶退火工艺图

Fig. 2 Technological map of rapid cold punching and recrystallization annealing

2.2 析出相演变

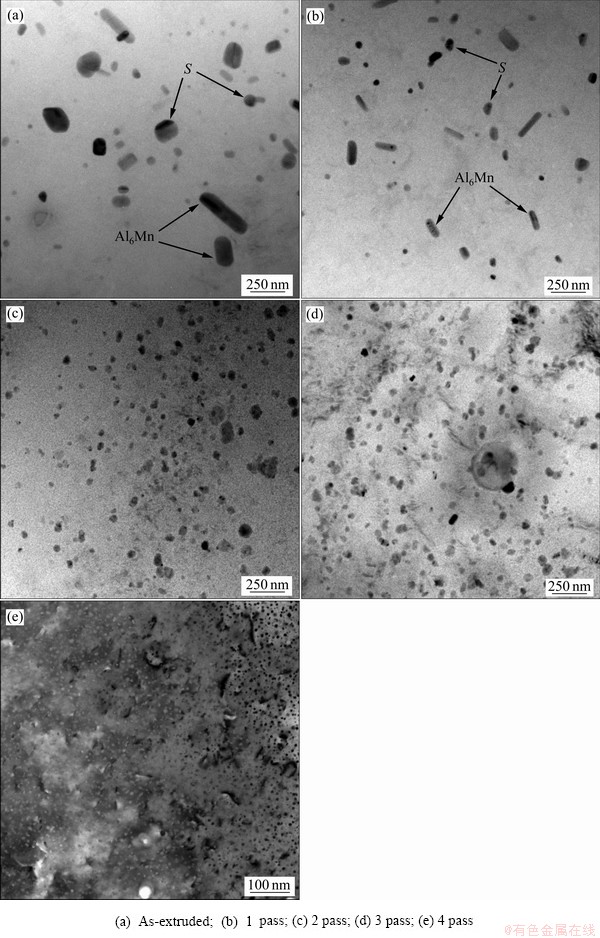

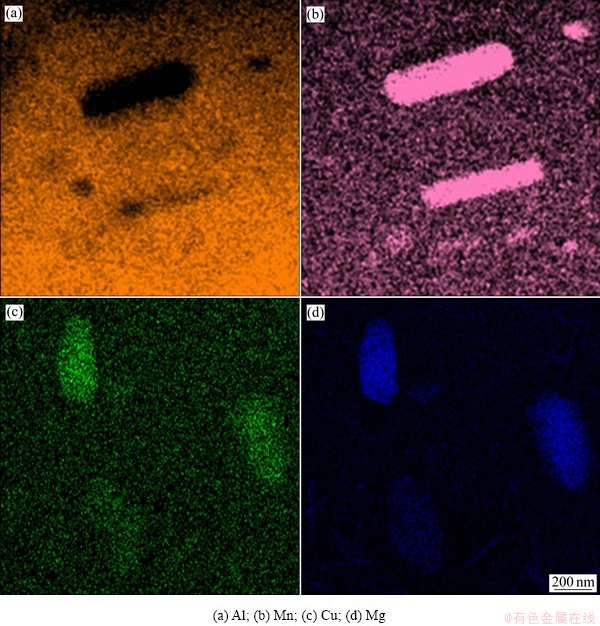

图4所示为不同道次快速冷冲Al-Cu-Mg合金试样的析出相形貌TEM像,选取挤压态Al-Cu-Mg合金长条状析出相附近区域进行EDS分析,如图5所示。由图4和图5可见,合金的主要析出相为S相(Al2CuMg),由于添加了一定量的Mn,还可以观察到长条状的Al6Mn相。随着变形道次的增多,试样变形量不断增加,析出相密度不断增大、尺寸不断减小,越趋于弥散分布。热挤压态合金变形温度高,偏聚在晶界附近的Mn促进了Al6Mn相的形核和长大,合金中可观察到粗大的Al6Mn相和S相(见图4(a))。挤压态试样经1道次快速冷冲后,析出相尺寸明显减小,数量不断增多,尤其是Al6Mn相细化明显,呈长条状(见图4(b))。试样经2~3道次快速冷冲后,Al6Mn相和S相尺寸进一步减小,数量进一步增多,在基体中的分布更趋于均匀;长条状Al6Mn相不断减少,球状Al6Mn相明显增多(见图4(c)、(d))。与前3道次冷冲试样相比较,经4道次快速冷冲后试样需在更大倍数下才能清晰观察到析出相,发现纳米级析出相均匀弥散分布在基体中,析出相的尺寸和形貌基本一致(见图4(e))。

图3 不同状态下Al-Cu-Mg合金试样的晶粒形貌

Fig. 3 Grain morphologies of Al-Cu-Mg alloy samples at different passes

图4 不同状态下Al-Cu-Mg合金试样的析出相特征

Fig. 4 Characteristic of precipitated phase in Al-Cu-Mg alloy samples at different passes

2.3 力学性能

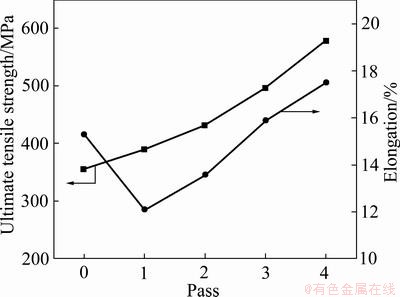

图6所示为不同道次快速冷冲Al-Cu-Mg合金试样的室温力学性能变化曲线。由图6可见,随着变形道次的增多,Al-Cu-Mg合金试样的极限拉伸强度显著提高,伸长率先降后升。挤压态合金极限拉伸强度低、塑性较好,极限抗拉强度和伸长率分别为355 MPa和15.3%,经1道次快速冷冲变形后,合金试样的极限拉伸强度明显提高,但伸长率明显降低,极限抗拉强度和伸长率分别为389 MPa和12.1%;试样在2~4道次快速冷冲变形过程中,极限抗拉强度和伸长率均不断提高,经4道次快速冷冲变形试样的极限抗拉强度和伸长率分别为578 MPa和17.5%,与1道次快速冷冲合金试样相比较,极限抗拉强度增加48.5%,伸长率增加44.6%。

图5 挤压态Al-Cu-Mg合金析出相EDS谱

Fig. 5 EDS maps of precipitated phase in as-extruded Al-Cu-Mg alloy

图6 不同状态下Al-Cu-Mg合金试样的力学性能

Fig. 6 Mechanical property of Al-Cu-Mg alloy samples at different passes

3 分析和讨论

3.1 快速冷冲和再结晶退火对析出相特征的影响

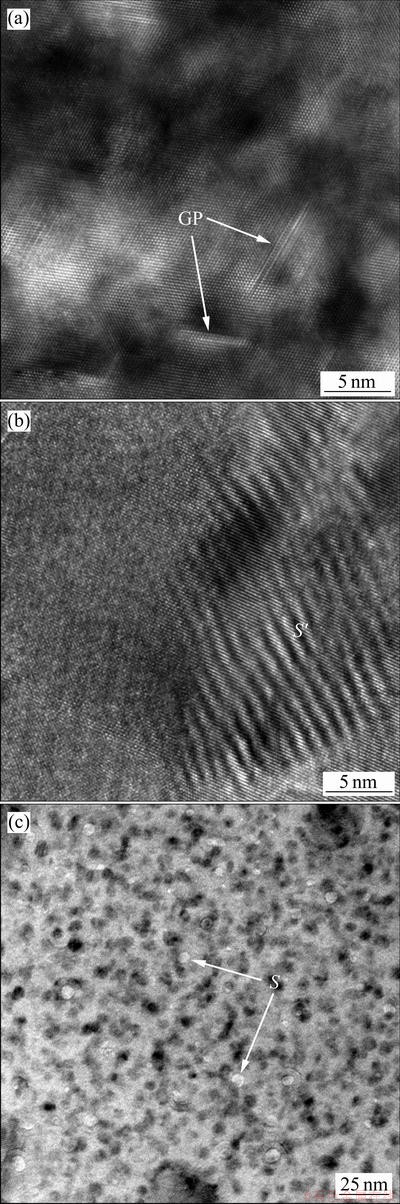

Al-Cu-Mg系合金的脱溶序列一般是:GP区→ S'(Al2CuMg)→S(Al2CuMg),GP区由富集在{110}晶面上的Cu 和Mg原子偶组成[1](见图7(a)),这种原子偶以钉扎位错的机制强化合金,在较高温度主要形成与基体共格的 相[14](见图7(b)),在低温条件下主要形成非共格平衡相S相[13],平衡相呈颗粒状(见图7(c))。

相[14](见图7(b)),在低温条件下主要形成非共格平衡相S相[13],平衡相呈颗粒状(见图7(c))。

图7 快速冷冲和再结晶退火过程中Al-Cu-Mg合金试样的GP区、 和S相的微观形貌

和S相的微观形貌

Fig.7 GP zones(a),  (b) and S(c) phases morphologies of Al-Cu-Mg alloy samples at rapid cool punching and recrystallization annealing

(b) and S(c) phases morphologies of Al-Cu-Mg alloy samples at rapid cool punching and recrystallization annealing

已有研究表明[15-16],Al-Cu-Mg合金析出相的析出序列与加热温度、变形量及变形后的晶粒尺寸有关;若加热温度足够消除强变形产生的高应力,则析出顺序为过渡相→稳定相;若加热温度不能消除变形产生的高应力,且晶粒超细化,则再析出时过渡相被抑制,直接生成稳定相。本试验基于喷射成形快速凝固技术来制备细晶Al-Cu-Mg合金坯料,采用多道次快速冷冲、高温再结晶退火以及快速加热和慢速冷却的方法来制备Al-Cu-Mg合金药筒,随着变形道次的增加,析出相的密度不断增大、尺寸显著减小(见图4),且在试样中可以观察到大量的 相(见图7),这说明药筒成形过程中的主要脱溶过程是过渡相→稳定相;同时试样在快速冷冲和再结晶退火过程中,晶粒组织趋于均匀,晶粒显著细化为纳米晶(见图3)。进一步分析表明,造成上述实验现象的主要原因是细晶合金试样在快速冷冲变形及高温再结晶退火工艺条件下析出相与再结晶相互作用的结果[5-6]。快速冷冲显著提高试样的位错密度,新增位错成为空位最有效的吸收源,使扩散到位错的空位数量增加,而

相(见图7),这说明药筒成形过程中的主要脱溶过程是过渡相→稳定相;同时试样在快速冷冲和再结晶退火过程中,晶粒组织趋于均匀,晶粒显著细化为纳米晶(见图3)。进一步分析表明,造成上述实验现象的主要原因是细晶合金试样在快速冷冲变形及高温再结晶退火工艺条件下析出相与再结晶相互作用的结果[5-6]。快速冷冲显著提高试样的位错密度,新增位错成为空位最有效的吸收源,使扩散到位错的空位数量增加,而 相一般优先在位错处形核,快速冷冲引入的高密度位错给

相一般优先在位错处形核,快速冷冲引入的高密度位错给 相提供了有效的形核位置,从而使

相提供了有效的形核位置,从而使 相的形核数目随快速冷冲道次的增加而增加[11, 16]。研究表明,过饱和固溶体在形变后再结晶退火过程中,脱溶和再结晶两个过程互相竞 争和互相影响,再结晶进程取决于两者的瞬时平衡[17]。

相的形核数目随快速冷冲道次的增加而增加[11, 16]。研究表明,过饱和固溶体在形变后再结晶退火过程中,脱溶和再结晶两个过程互相竞 争和互相影响,再结晶进程取决于两者的瞬时平衡[17]。

3.2 快速冷冲和再结晶退火对晶粒细化的影响

本试验中,快速冷冲引入的缺陷促进脱溶和再结晶形核,脱溶析出相颗粒反过来钉扎晶界从而影响再结晶形核和长大,以延缓再结晶。进一步研究发现,快速冷冲和再结晶退火工艺明显促进了喷射成形Al-Cu-Mg合金的再结晶发生,显著细化了试样的合金组织。主要原因有:首先,本试验中快速加热使影响再结晶的脱溶颗粒来不及产生,有效降低了再结晶温度,促进再结晶的发生,导致随后再结晶退火过程中形成的足以影响再结晶的析出相在已再结晶晶粒中进行,显然再结晶退火温度是影响析出相与再结晶晶粒的关键因素[18]。其次,再结晶晶粒尺寸DN与析出相体积分数f、颗粒半径r之间存在简单的几何关系[18-19]:

DN≈2rf -1/3 (1)

由式(1)可知,析出相体积分数越大、颗粒半径越小,再结晶晶粒越细,这与本试验的研究结果一致。再次,形变量越大,位错密度越大,从而提高形变储存能,增加再结晶的驱动力;同时,形变量越大,析出相边缘的最大取向差越大,而大的取向梯度有利于再结晶形核,从而促进合金晶粒组织均匀和细化。最后,本试验合金中还加入了一定量的Mn,由于Mn本身的晶界吸附现象而易导致晶内偏析,晶界附近高含量的Mn在快速冷冲及再结晶退火冷却过程中易形成长条状Al6Mn相(见图4(b)),较粗大的Al6Mn相能进一步提高试样的形变储存能和增大析出相边缘的取向差,从而促进再结晶的发生[1, 8]。

3.3 强韧化机制

由图6可知,对挤压态Al-Cu-Mg合金试样进行1道次快速冷冲后,试样的强度升高、塑性降低,这主要是因为加工硬化造成的。但随着快速冷冲和再结晶退火次数的增加,Al-Cu-Mg合金试样的强度和塑性均明显增大,结合本实验结果进行分析,主要的强韧化机制是细晶强化和析出相强化。

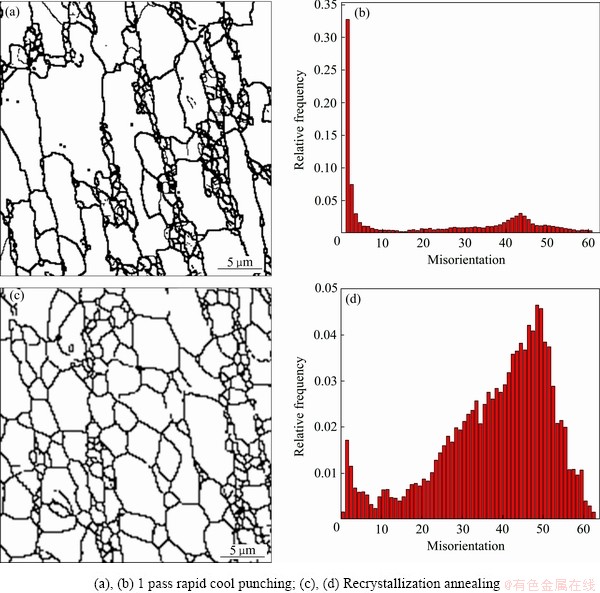

Al-Cu-Mg合金试样在快速冷冲和再结晶退火的交替作用下,经过反复的位错增殖和连续再结晶,形成了主要由大角度晶界组成的显微组织结构(见图8(c)),与挤压态试样相比较,晶粒显著细化,经4道次变形和退火后平均晶粒尺寸约为50 nm(见图3(a)),根据Hall-Petch公式[20],这将显著提高Al-Cu-Mg合金的屈服强度。已有研究表明[21],晶粒越细,晶界面积越大,快速冷冲过程中阻碍位错运动的位置越多,位错就越易聚集,从而起到强化合金的作用;同时,高层错能铝合金多晶体在大变形过程中,晶界面积随应变增加而增加,据此可获得晶粒厚度H随应变ε变化的几何关系[21]:

H=D0exp(-ε) (2)

由式(2)可知,原始晶粒尺寸D0越小,应变ε越大,晶粒厚度H就越小。本试验合金为喷射成形快速凝固组织,原始晶粒尺寸小、组织均匀,经快速冷冲大应变塑性变形形成大量不稳定的小角度晶界(见图8(a),(b)),在再结晶退火过程中形成几乎全部由大角度晶界构成的显微组织(见图8(c),(d));同时,试验合金在快速冷冲大应变变形过程中,形成大量的胞状结构或亚晶,这些胞状结构或亚晶在塑性变形过程中一般不会发生很大的变化,在再结晶退火过程中作为再结晶核心显著促进再结晶的发生,从而有效细化晶粒,增大晶界面积,提高合金的强度和韧性。

图8 经1道次快速冷冲和再结晶退火后Al-Cu-Mg合金的EBSD像及晶粒取向分布图

Fig. 8 EBSD micrographs((a), (c)) and grain orientation distribution diagrams((b), (d)) of Al-Cu-Mg alloy at different conditions

研究表明[10],Al-Cu-Mg合金的形变量越大,析出相的直径越小,同时由于溶质原子总数量相同,故析出相直径越小,其数量密度越大,钉扎和阻碍位错运动的能力越强,析出强化效果越明显。本实验合金经快速冷冲和再结晶退火交替作用,获得了硬度远高于基体的硬度且弥散分布的S相(见图7(c)),因此合金在变形过程中,位错无法切过S相,也因S相之间的间距小而难以拱弯绕过,因此本实验快速冷冲工艺条件下析出相强化是Al-Cu-Mg合金主要的强化机制之一。

4 结论

1) 快速冷冲和再结晶退火相结合可显著提高Al-Cu-Mg合金药筒的室温拉伸性能,经4道次快速冷冲后合金的极限抗拉强度和伸长率分别达578 MPa和17.5%,与1道次快速冷冲合金试样相比较,极限抗拉强度提高48.5%,伸长率提高44.6%。

2) 快速冷冲Al-Cu-Mg合金的主要强韧化机制是细晶强化和析出强化,快速冷冲通过引入的缺陷促进试样脱溶和再结晶形核,有助于S'相和再结晶的形核与长大,从而获得纳米晶组织和弥散的S相。

3) Al-Cu-Mg合金在快速冷冲及再结晶退火过程中析出相主要以平衡相S相为主,还有少量较粗的Al6Mn相,随着变形道次的增加,析出相的密度不断增大、尺寸显著减小。

REFERENCES

[1] 王祝堂, 田荣璋. 铝合金及其加工手册[M]. 3版. 长沙: 中南大学出版社, 2007.

WANG Zhu-tang, TIAN Rong-zhang. User manual for Al alloys and processing version[M]. 3rd ed. Changsha: Central South University Press, 2007.

[2] WILLIAMS J C, STARKE J E. Progress in structural materials for aerospace systems[J]. Acta Materialia, 2003, 51(19): 5775-5799.

[3] 伍翠兰, 周 斌, 牛凤姣, 段石云, 巩向鹏, 陈江华. 高Cu/Mg比AlCuMg 合金的形变诱导Ω相析出强化[J]. 湖南大学学报, 2018, 45(6): 1-10.

WU Cui-lan, ZHOU Bin, NIU Feng-jiao, DUAN Shi-yun, GONG Xiang-peng, CHEN Jiang-hua. Deformation-induced Ω phase precipitation strengthening of AlCuMg alloy with high Cu/Mg atomic ratio[J]. Journal of Hunan University, 2018, 45(6): 1-10.

[4] GAZIZOV M, KAIBYSHEV R. Effect of pre-straining on the aging behavior and mechanical properties of an Al-Cu-Mg-Ag alloy[J]. Materials Science and Engineering A, 2015, 625(14): 119-130.

[5] ZHAO Y L, YANG Z Q, ZHANG Z. Double-peak age strengthening of cold-worked 2024 aluminum alloy[J]. Acta Materialia, 2013, 61(5): 1624-1638.

[6] ZUIKO I S, GAZIZOV M R, KAIBYSHEV R O. Effect of thermomechanical treatment on the microstructure, phase composition, and mechanical properties of Al-Cu-Mn-Mg-Zr alloy[J]. Physics of Metals and Metallography, 2016, 117(9): 906-919.

[7] 胥福顺, 张 劲, 邓运来, 张新明.蛇形轧制对Al-Cu-Mg合金板材强韧性能及微观组织的影响[J].中国有色金属学报, 2017, 27(10): 2005-2011.

XU Fu-shun, ZHANG Jin,DENG Yun-lai,ZHANG Xin-ming. Effect of snake rolling on strength, toughness and microstructure of Al-Cu-Mg alloy plate[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(10): 2005-2011.

[8] MIRZAEI M, ROSHAN M R, JENABALI JAHROMI S A. Microstructure and mechanical properties relation in cold rolled Al2024 alloy determined by X-ray line profile analysis[J]. Materials Science and Engineering A, 2015, 620: 44-49.

[9] AN Li-hui, CAI Yang, LIU Wei, YUAN Shi-jian, ZHU Shi-qiang, MENG Fan-cheng. Effect of pre-deformation on microstructure and mechanical properties of 2219 aluminum alloy sheet by thermomechanical treatment[J]. Transactions of Nonferrous Metals Society of China, 2012, 22(2): 370-375.

[10] 李周兵, 沈 健, 雷文平, 闫亮明, 李俊鹏, 毛柏平. 预拉伸对 Al-Cu-Mg-Ag 合金析出相与力学性能的影响[J]. 中国有色金属学报, 2010, 20(8): 1508-1512.

LI Zhou-bing, SHEN Jian, LEI Wen-ping, YAN Liang-ming, LI Jun-peng, MAO Bai-ping. Effects of pre-stretching on precipitated phase and mechanical properties of Al-Cu-Mg-Ag alloy[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(8): 1508-1512.

[11] STYLES M J, MARCEAU R K W, BASTOW T J, BRAND H E A, GIBSON M A, HUTCHINSON C R. The competition between metastable and equilibrium S(Al2CuMg) phase during the decomposition of Al-Cu-Mg alloys[J]. Acta Materialia, 2015, 98(1): 64-80.

[12] 杨培勇, 郑子樵, 胥福顺, 李世晨, 李 剑, 周 明. 外加应力对高Cu/Mg比Al-Cu-Mg合金沉淀动力学及析出相形态的影响[J]. 稀有金属, 2006, 30(3): 324-328.

YANG Pei-yon, ZHENG Zi-qia, XU Fu-shun, LI Shi-chen, LI Jian, ZHOU Ming. Effect of external stress on kinetics of precipitation and morphologies of precipitates in Al-Cu-Mg alloy with high Cu/Mg ratio[J]. Rare Metals, 2006, 30(3): 324-328.

[13] 尹美杰, 陈江华, 刘春辉. 中断时效处理对AA2024铝合金力学性能和显微结构的影响[J]. 中国有色金属学报, 2015, 25(12): 3271-3281.

YIN Mei-jie, CHEN Jiang-hua, LIU Chun-hui. Effect of interrupted ageing on mechanical property and microstructure of AA2024 alloy[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(12): 3271-3281.

[14] LI Hui-zhong, LIU Ruo-mei, LIANG Xiao-peng, DENG Min, LIAO Hui-juan, HUANG Lan. Effect of pre-deformation on microstructures and mechanical properties of high purity Al-Cu-Mg alloy[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(6): 1482-1490.

[15] ZHAO Yun-long, YANG Zhi-qing, ZHANG Zhen, SU Guo-yue, MA Xiu-liang. Double-peak age strengthening of cold-worked 2024 aluminum alloy[J]. Acta Materialia, 2013, 61(6): 1624-1638.

[16] MOGHANAKI S K, KAZEMINEZHAD M. Effects of non-isothermal annealing on microstructure and mechanical properties of severely deformed 2024 aluminum alloy[J]. Transactions of Nonferrous Metals Society of China, 2017, 27(1): 1-9.

[17] 周泽鹏, 张 劲, 邓运来, 张新明. Al-Cu-Mg合金蠕变成形热处理工艺[J]. 中国有色金属学报, 2017, 27(8): 1607-1614.

ZHOU Ze-peng, ZHANG Jing, DENG Yun-lai, ZHANG Xin-ming. Creep forming heat treatment technology of Al-Cu-Mg alloy[J]. The Chinese Journal of Nonferrous Metals, 2017, 27(8): 1607-1614.

[18] PONGE D, GOTTSTEIN G. Necklace formation during dynamic recrystallization: Mechanisms and impact on flow behavior[J]. Acta Materialia, 1998, 46(1): 69-80.

[19] HUMPHREYS F J. A unified theory of recovery, recrystallization and grain growth, based on the stability and growth of cellular microstructures-I[J]. Acta Materialia, 1997, 45(10): 4231-4240.

[20] 范才河, 严红革, 彭英彪, 周 伟, 周兴灵. 大应变热轧喷射成形高镁铝合金的微观结构及力学性能[J]. 中国有色金属学报, 2017, 27(1): 64-71.

FAN Cai-he, YAN Hong-ge, PENG Ying-biao, ZHOU Wei, ZHOU Xing-ling. Microstructures and mechanical properties of spray-forming high magnesium aluminum alloy during large strain hot rolling[J]. TheChinese Journal of Nonferrous Metal, 2017, 27(1): 64-71.

[21] 余永宁. 金属学原理[M]. 第2版. 北京: 冶金工业出版社, 2013.

YU Yong-ling. Principles of metallography[M]. 2nd ed. Beijing: Metallurgical Industry Press, 2013.

Effect of fast cold punching and recrystallization annealing on microstructure and mechanical properties of Al-Cu-Mg alloy

HU Ze-yi1, FAN Cai-he1, LIU Wen-liang1, YANG Jian-jun1, OU Ling1, CHEN Xi-hong2

(1. School of Metallurgical and Material Engineering, Hunan University of Technology, Zhuzhou 412007, China;

2. CRRC Zhuzhou Electric Locomotive Co., Ltd., Zhuzhou 412007, China)

Abstract: The effect of rapid cold punching and recrystallization annealing on the microstructure and mechanical properties of Al-Cu-Mg alloy with fine grain produced by spray forming process was studied by the analysis methods, such as scanning electron microscopy (SEM), transmission electron microscopy (TEM), electron back scatter diffraction(EBSD), energy disperse spectroscopy (EDS) and the tensile test. The results indicate that S phase as the equilibrium phase is precipitated in the Al-Cu-Mg alloy matrix in the process of the rapid cold punching and the recrystallization annealing, and a small amount of coarse phase Al6Mn is also precipitated at the same time. The density of the precipitated phase becomes larger and the particle size becomes smaller with increasing of the passes number. The crystal defects made in the process of the rapid cold stamping are useful for the alloy phase ex-solution, and also benefit for the nucleation and growth of the S phase, which is effective to obtain the refined grain, the homogeneous nanocrystalline structure, and uniformly distributed S phase. The main strength mechanism of the Al-Cu-Mg alloy prepared by rapid cold punching is fine grain strengthening and precipitation strengthening. Ultimate tensile strength and elongation of the alloy after 4 passes are 578 MPa and 17.5%, respectively. And the ultimate tensile strength and elongation of the alloy with 4 passes are increased by 48.5% and 44.6% compared with the alloy with 1 pass.

Key words: spray forming; Al-Cu-Mg alloy; rapid cold punching; recrystallization annealing; precipitated phase; mechanical property

Foundation item: Project(51704107) supported by the National Natural Science Foundation of China; Project (2019JJ60050) supported by the Natural Science Foundation of Hunan Province, China

Received date: 2018-12-07; Accepted date: 2020-09-17

Corresponding author: FAN Cai-he; Tel: +86-731-22183432; E-mail: 369581813@qq.com

(编辑 王 超)

基金项目:国家自然科学基金资助项目(51704107);湖南省自然科学基金资助项目(2019JJ60050)

收稿日期:2018-12-07;修订日期:2020-09-17

通信作者:范才河,教授,博士;电话:0731-22183432;E-mail: 369581813@qq.com