DOI: 10.11817/j.issn.1672-7207.2015.08.011

Al-5Ti-0.2C细化剂对7085铝合金形核及过冷度的影响

宁佳杰,李晓谦,蒋日鹏,黄明哲

(中南大学 机电工程学院,高性能复杂制造国家重点实验室,湖南 长沙,410083)

摘要:在7085铝合金凝固过程中添加不同质量分数的Al-5Ti-0.2C细化剂,对比其铸锭凝固组织,并用DSC测定其凝固过程熔体过冷度,探讨Al-5Ti-0.2C细化剂对铝熔体形核与过冷度的影响。研究结果表明:Al-5Ti-0.2C细化剂能够明显细化晶粒,当细化剂质量分数为0.5%时细化效果最好;细化剂质量分数的差异对DSC曲线中的熔化曲线影响较小,而凝固曲线有明显差异;在凝固过程中增大细化剂质量分数,铝熔体形核过冷度与最大过冷度都呈递减趋势,当细化剂质量分数超过0.5%时,过冷度不再有明显递减趋势;TiC颗粒是铝熔体异质形核的核心,凝固过程中TiC颗粒的发生团聚,从而增大形核基底颗粒粒度,减小润湿角与临界形核能,最终减小熔体中形核所需过冷度。

关键词:7085铝合金;Al-5Ti-0.2C细化剂;过冷度;形核

中图分类号:TG249.9;TB559 文献标志码:A 文章编号:1672-7207(2015)08-2837-06

Effect of Al-5Ti-0.2C refiner on nucleation and undercooling degree of 7085 aluminum alloy

NING Jiajie, LI Xiaoqian, JIANG Ripeng, HUANG Mingzhe

(State Key Laboratory of High Performance Complex Manufacturing,

School of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China)

Abstract: Different mass fractions of Al-5Ti-0.2C refiner were added during the solidification of 7085 aluminum alloy, the microstructures of ingots with different mass fractions of Al-5Ti-0.2C refiner were compared, and DSC was used to measure the undercooling degree of the melt during solidification. The effects of Al-5Ti-0.2C refiner on nucleation and undercooling degree during the solidification of 7085 aluminum alloy were investigated. The results show that the microstructure is refined with Al-5Ti-0.2C refiner and 0.5% mass fraction of refiner can achieve the best performance. The melting curves are not influenced by the change of mass fraction of refiner, while the cooling curves make some difference: the nucleation undercooling degree and maximum undercooling degree of the melt both decrease with the increase of mass fraction of Al-5Ti-0.2C refiner but decrease little when the mass fraction is over 0.5%. TiC particles are the nucleants of heterogeneous nucleation, and these particles will gather to increase the substrate size, which decreases the contact angle and the critical nucleation energy and decreases the undercooling degree needed for nucleation in the end.

Key words: 7085 aluminum alloy; Al-5Ti-0.2C refiner; undercooling degree; nucleation

7085铝合金是美国铝业2003年开发的新一代高强厚板材铝合金,相比传统的7系铝合金,7085铝合金Zn质量分数较高,且Cu质量分数较低,具有较好的韧性及较低的淬透性[1-2]。铝合金大型铸件的性能很大程度上由凝固过程中微观组织结构决定,而控制其凝固组织和性能的关键因素之一在于促使凝固过程中更多的柱状晶向等轴晶转变(columnar to equiaxed transition,CET)。凝固过程中等轴晶主要有2个来源[3]:1) 凝固过程中添加细化剂,促进熔体中晶体在外来形核基底上形核;2) 在无添加细化剂的情况下,熔体凝固过程中枝晶破碎游离形成新的等轴晶。目前工业上广泛应用的晶粒细化剂主要是AlTiB和AlTiC,AlTiC细化剂中所含TiC粒子的粒度小于AlTiB粒子的粒度,且不易发生聚集沉淀,对Zr和Cr等具免疫功能[4],为达到良好的细化效果,实验所用的铝合金为7085铝合金,采用Al-5Ti-0.2C作为7085铝合金的细化剂。在凝固过程中,影响CET过程的2个重要因素是有效形核基底密度和形核过冷度[5-6],对于有效形核基底密度可通过测量凝固组织晶粒密度得到。而过冷度在凝固过程中较难精确测量,目前对凝固过程中过冷度的测量主要采用差示扫描量热法(differential scanning calorimetry,DSC)。本文作者通过改变7085铝合金凝固过程AlTiC细化剂的质量分数,对其进行DSC测量出过冷度,且对比凝固组织,探讨Al-5Ti-0.2C细化剂对7085铝熔体形核与过冷度的影响。

1 实验材料与方法

1.1 实验材料

实验材料为7085铝合金,取自半连续铸造成型的长×宽为1 100 mm×550 mm铸锭。运用立式直读光谱仪(SPECTRO-MAXx)测得实验用材料的合金质量分数如表1所示,其成分质量分数满足7085铝合金成分指标[7]。

表1 实验用7085铝合金成分(质量分数)

Table 1 Chemical composition of 7085 aluminum alloy used in experiment %

1.2 实验方案

将7085铝合金大铸锭截成小块,每次实验前称取3 kg铝合金置于石墨坩埚,放入电阻丝加热炉加热到750 ℃进行熔炼,完全熔化后对熔体充分搅拌,添加铝打渣剂净化熔体。当熔体温度降至约700 ℃时添加Al-5Ti-0.2C细化剂,充分搅拌后保温10 min,然后熔体随炉冷却至室温。分别进行6次实验,每次实验添加不同质量分数的Al-5Ti-0.2C细化剂:1) 0;2) 0.1%;3) 0.2%;4) 0.5%;5) 1.0%;6) 1.5%。

经6次实验后得6个质量相同的铸锭,在6个铸锭心部取样,用立式直读光谱仪(SPECTRO-MAXx)测取样品中Ti质量分数,如表2所示。实验使用的Al-5Ti-0.2C细化剂中Ti质量分数约为4.8%,细化剂质量分数的差异在铸锭中应体现为Ti的质量分数的差值,对铸锭进行Ti质量分数(含细化剂中的Ti以及制样过程增加的Ti)进行检测,结果表明细化剂在铝熔体中均匀分布。

表2 含不同Al-5Ti-0.2C细化剂质量分数铸锭中Ti的质量分数

Table 2 Ti mass fraction of ingots with different mass fractions of Al-5Ti-0.2C refiner

在6个铸锭上表面下50 mm处切取一厚度为20 mm的截面,截取截面中心长×宽×高为10 mm×10 mm×10 mm的金相试样,将试样置于BUEHLER自动研磨机上进行打磨和抛光,抛光面经强酸腐蚀后,在Leica台式金相显微镜下观察其金相组织。

从上述6个铸锭截面中心切取规格为直径×高度为5 mm×1 mm的DSC试样,试样经打磨后质量约为20 mg。放入PerkinElmer DSC8500差示扫描量热仪的封闭陶瓷坩埚内,对样品室内以10 ℃/min的速率从室温加热到700 ℃,将铝合金融化后使试样在700 ℃下保温10 min,最后,以10 ℃/min的速率冷却到50 ℃,使铝合金凝固。运用差示扫描量热法,在程序控温下,测量输入到铝合金样品和参比物的能量差与温度(或时间)的关系,得熔化与凝固过程中温度与热流的关系。

2 实验结果与分析

2.1 Al-5Ti-0.2C细化剂对凝固组织的影响

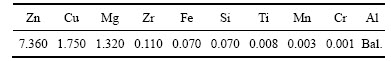

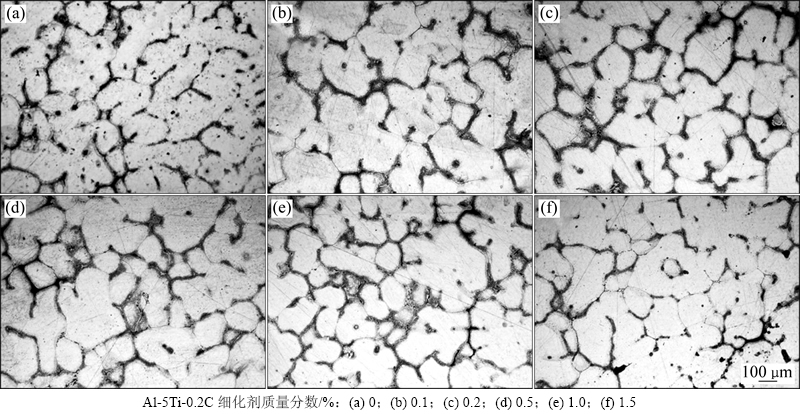

图1所示为采用Lecia DMI 5000M型金相显微镜观察试样表面的微观组织,按照GB/T 6394—2002金属平均晶粒度测定法规定[8],使用直线截点法测定平均晶粒粒度。实验所得平均晶粒粒度测量结果如图2所示。由图2可以看出:1) 在未添加细化剂时,枝晶相对发达且连成一体;添加Al-5Ti-0.2C细化剂后,得到相对均匀细小的等轴晶;2) 当Al-5Ti-0.2C细化剂质量分数为0.1%时,与未添加细化剂时相比,细化效

果明显,增大细化剂的质量分数可以继续细化晶粒,当细化剂质量分数为0.5%时细化效果最明显,当细化剂质量分数继续增大时,铸锭凝固组织细化效果没有明显变化。

图1 7085铝合金铸锭微观组织图

Fig. 1 Microstructures of 7085 aluminum alloy ingots with different mass fractions of Al-5Ti-0.2C refiner

图2 Al-5Ti-0.2C细化剂质量分数对7085铝合金铸锭晶粒粒度的影响

Fig. 2 Effect of mass fraction of Al-5Ti-0.2C refiner on grain size of 7085 aluminum alloy ingots

在铝熔体中添加Al-5Ti-0.2C细化剂,细化剂溶解后为铝熔体提供异质形核基底颗粒,当铝熔体在冷却过程中达到临界形核过冷度时,基底颗粒活化开始发生异质形核。铝熔体中基底颗粒活化形核所需临界过冷度△Tfg[9]为

(1)

(1)

式中:σ为固液界面能;△Sv为单位体积熔化熵;d为颗粒直径。σ与△Sv可以认为是常量,由式(1)可知直径大的颗粒在熔体达到较小的过冷度时,可优先进行异质形核。直径大的颗粒形核后开始结晶,由于结晶潜热释放,将使熔体中过冷度不再增大。若熔体过冷度不能达到直径小的颗粒所需的形核过冷度,则这些颗粒将无法形核,在最终凝固组织中的晶界聚集。

由以上分析可以推断:Al-5Ti-0.2C细化剂对铝合金的细化效果不是随细化剂质量分数增大而无限提高,在某一特定质量分数下细化效果达到最佳,当超过该质量分数时,细化效果不会发生明显变化。对7085铝合金,Al-5Ti-0.2C细化剂质量分数为0.5%时达到最佳细化效果。

2.2 Al-5Ti-0.2C细化剂对过冷度的影响

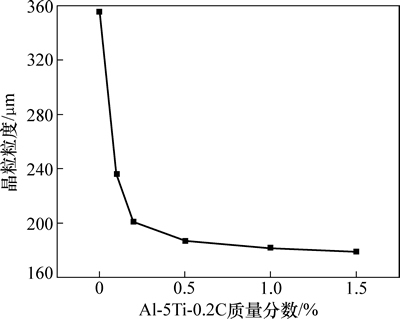

图3所示为对不同Al-5Ti-0.2C细化剂质量分数的铝合金进行DSC测量结果。从图3(a)可以看出:细化剂的质量分数对铝合金熔化过程几乎没有影响,吸热峰值温度相差不大,依据GB/T 1425—1996定义热流峰值为铝合金液相线温度[10],实验所用7085铝合金液相线温度基本保持不变,约为643.7 ℃。细化剂质量分数对图3(b)所示凝固曲线影响较大,随Al-5Ti-0.2C细化剂质量分数的增大,铝熔体放热起始温度提高,且放热峰值温度也升高。取放热起始温度为熔体形核起始温度,放热峰值温度为熔体再辉起始温度[11]。

在经典的Maxwell-Hellawell(M-H)模型中[12],假设熔体温度分布均匀,且晶体形核过程在整个熔体中进行,那么形核过程从形核起始温度开始,至再辉起始温度结束,如图4所示。熔体在过冷度△T>△Tn的情况下开始形核:

(2)

(2)

(3)

(3)

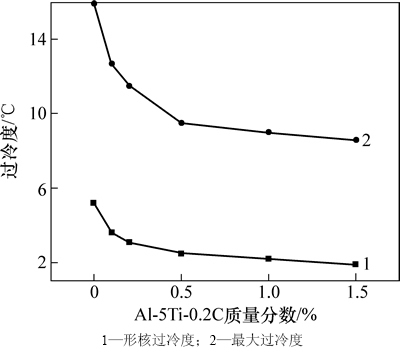

式中:△Tn为熔体形核过冷度,即铝熔体开始形核所需最小过冷度;△Tmax为熔体最大过冷度,即铝熔体中形核所能达到最大过冷度;Teq为液相线温度;Tn为形核起始温度;Tre为再辉起始温度。用DSC测得结果计算得不同Al-5Ti-0.2C细化剂质量分数的形核过冷度△Tn与最大过冷度△Tmax,结果如图5所示。

图3 不同Al-5Ti-0.2C细化剂质量分数的7085铝合金DSC曲线

Fig. 3 DSC curves of 7085 aluminum alloy with different mass fractions of Al-5Ti-0.2C refiner

从图5中可以看出:随Al-5Ti-0.2C细化剂质量分数增大,铝熔体形核过冷度与最大过冷度都呈递减趋势;当细化剂质量分数为0.5%时,形核过冷度与最大过冷度减小幅度较明显;当细化剂质量分数继续增大时,形核过冷度与最大过冷度也随之减小,但减小趋势变缓。

图4 凝固过程M-H模型冷却曲线示意图

Fig. 4 Illustration of typical cooling curve of M-H model during solidification

图5 不同Al-5Ti-0.2C细化剂质量分数的铝熔体形核过冷度与最大过冷度

Fig. 5 Nucleation undercooling and the maximum undercooling of aluminum melt with different mass fractions of Al-5Ti-0.2C refiner

2.3 中间合金TiC的细化机理

在Al-Ti-C细化理论研究过程中,早期理论[13]认为TiAl3粒子与α-Al晶胞类型相似,晶面具有稳定的共格关系,这为铝基体在TiAl3粒子表面上形核并向外生长创造了有利条件,并最终形成以TiAl3为核心的异质晶体。目前,许多学者意识到TiC粒子是细化剂细化能力的关键,Banerji等[14]通过电子探针微区分析仪(EPMA)在被细化的晶粒中发现了Ti和C的富集区,进一步证实了TiC粒子的细化作用。TiC粒子结构与Al原子结构相似,晶格常数接近,同为面心立方。TiC粒子可由固溶于铝熔体中的C与Ti发生反应而得,由于TiC粒子熔点很高,可以在铝熔体中稳定存在,因此,TiC是使凝固组织得到细化的有效异质形核的核心[15]。

高义民[16]认为促进异质形核作用的关键因素是基底(固体物质)的润湿角。润湿角小的合金具有好的触媒剂特征。异质形核的临界形核能ΔG*为

(4)

(4)

式中: 为单位表面自由能;Teq为合金液相线温度;Lm为结晶潜热;△T为熔体过冷度;θ为晶核与基底平面接触角(润湿角)。当θ=0时,cosθ=1,△G*=0 J,即在该形核基底上形核时,不存在自由能势垒,可以在过冷度△T=0 ℃的情况下形核。因而,减小润湿角可以降低基底进行异质形核所需临界形核能,同时也减小形核所需过冷度。熔体中TiC颗粒表面为凸面,TiC颗粒的形核能力受润湿角的影响,凸曲面形核的过程可类似理解为润湿角由θ增加到θ+α的过程。润湿角计算公式为

为单位表面自由能;Teq为合金液相线温度;Lm为结晶潜热;△T为熔体过冷度;θ为晶核与基底平面接触角(润湿角)。当θ=0时,cosθ=1,△G*=0 J,即在该形核基底上形核时,不存在自由能势垒,可以在过冷度△T=0 ℃的情况下形核。因而,减小润湿角可以降低基底进行异质形核所需临界形核能,同时也减小形核所需过冷度。熔体中TiC颗粒表面为凸面,TiC颗粒的形核能力受润湿角的影响,凸曲面形核的过程可类似理解为润湿角由θ增加到θ+α的过程。润湿角计算公式为

(5)

(5)

式中:R为粒子半径;r为临界形核半径,

(6)

(6)

由式(5)和(6)可以看出:润湿角θ随颗粒半径R的增加而减小。Al-5Ti-0.2C细化剂由TiAl3,TiC和铝基组成,TiC粒子与铝液的润湿性差,且易聚集成较大的粒子团[17]。而TiAl3粒子在铝液中会逐渐溶解,产生游离的Ti原子,游离的Ti原子向TiC粒子团周围偏聚,可以增大颗粒半径R,减小润湿角θ,降低基底颗粒形核所需临界形核能,同时减小形核所需过冷度,最终形成以TiC粒子为核心的α-Al晶粒。增大Al-5Ti-0.2C细化剂的质量分数,将给溶液提供更多TiAl3与TiC粒子,TiAl3粒子溶解得更多的游离Ti原子,在TiC粒子团周围偏聚,并且TiC粒子团的数目也会增多,在溶液中产生的大颗粒有效形核基底也会增加,因而,整个熔体在较小的过冷度下,形成更多的晶核,增大熔体形核密度,利于生成细小的等轴晶组织。

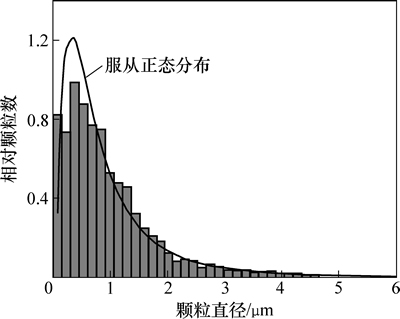

Quested等[18]在测量AlTiC细化剂中异质形核基底颗粒TiC粒度时发现,这些不同粒径颗粒的分布大致服从正态分布:

(7)

(7)

式中:N0为颗粒总数量;σ为几何标准差;d为颗粒直径;d0为特征直径。以TiC颗粒分布最多的粒度区间为1,其他颗粒粒度区间与其的比值为相对颗粒数,则得N(d)的相对颗粒数服从如图6所示的正态分布。

图6 Al-5Ti-0.2C细化剂中TiC颗粒粒度分布

Fig. 6 Size distribution of nucleant TiC particles in Al-5Ti-0.2C refiner

由式(1)可知:铝熔体中直径大的基底颗粒在相对小的过冷度下,能优先进行异质形核。添加Al-5Ti-0.2C细化剂相当于在熔体中增大了形核基底颗粒数量,同时也增加了粒度相对较大的TiC颗粒数量,当熔体在较小的过冷度时,这些大粒度颗粒便开始形核。大粒度颗粒形核后开始结晶,当形成的晶核达到一定数量,这些晶核长大过程中释放结晶潜热,若释放的热量与外部的热交换相平衡,则熔体温度不再降低,结晶潜热的释放不断增大,熔体温度将开始经历1个上升过程(再辉),熔体过冷度将不会增大。对于未形核的小粒度颗粒,熔体过冷度若不能达到其形核所需过冷度,则这些颗粒将无法形核,因此,熔体温度经历再辉之后便不再有新的形核。

增大细化剂的质量分数,熔体中大粒度TiC颗粒数量也将增大,熔体开始形核所需过冷度就相应减小且趋于稳定,且总体形核数量将提前进入饱和状态,因而熔体中再辉起始温度将提高,最大过冷度减小。当熔体中晶核数量趋于饱和状态时,增大细化剂质量分数,将会使更多小粒度TiC颗粒不能形核,熔体最大过冷度也将减小且趋于稳定,这些增多的TiC颗粒由于不能形核,在已经形核晶粒的生长过程中不断被推挤,并最终聚集在晶界中。在7085铝合金凝固实验中,当细化剂质量分数超过0.5%时,熔体过冷度不再发生明显变化,熔体形核处于饱和状态,继续添加细化剂不能提高细化效果,由此推断Al-5Ti-0.2C细化剂的质量分数为0.5%时细化效果最佳。

3 结论

1) 在 7085 铝合金凝固过程中添加Al-5Ti-0.2C细化剂能够明显细化晶粒,当添加细化剂质量分数为0.5%时细化效果最好;继续增加细化剂质量分数,不能明显提高铸锭凝固组织细化效果。

2) 对不同Al-5Ti-0.2C细化剂质量分数的7085铝合金铸锭进行DSC测量,熔化曲线基本保持一致,液相线温度约为643.7 ℃;凝固曲线差别较大:随细化剂质量分数增大,铝熔体形核过冷度与最大过冷度都呈递减趋势;当细化剂质量分数超过0.5%后,熔体过冷度不再有明显变化,熔体形核处于饱和状态。

3) 添加细化剂的铝熔体中TiC是异质形核核心,TiC颗粒能团聚成大粒度形核基底颗粒,减小润湿角θ与基底颗粒临界形核能,最终减小形核所需过冷度。TiC颗粒粒度大致服从正态分布,增大细化剂的质量分数会增加大粒度TiC颗粒数量,减小起始形核过冷度,熔体中总体形核数量将提前进入饱和状态,从而减小熔体最大过冷度。

参考文献:

[1] 肖代红, 巢宏, 陈康华, 等. 微量 Sc 对 AA7085 铝合金组织和性能的影响[J]. 中国有色金属学报, 2008, 18(12): 2145-2150.

XIAO Daihong, CHAO Hong, CHEN Kanghua, et al. Effect of minor Sc addition on microstructure and properties of AA7085 alloy[J]. The Chinese Journal of Nonferrous Metals, 2008, 18(12): 2145-2150.

[2] 肖代红, 陈康华, 罗伟红. 固溶热处理对 AA7085 铝合金组织与性能的影响[J]. 稀有金属材料与工程, 2010, 39(3): 494-497.

XIAO Daihong, CHEN Kanghua, LUO Weihong. Effect of solution heat treatment on microstructure and properties of AA7085 aluminum alloys[J]. Rare Metal Materials and Engineering, 2010, 39(3): 494-497.

[3] 马幼平, 许云华. 金属凝固原理及技术[M]. 北京: 冶金工业出版社, 2008: 158-175.

MA Youping, XU Yunhua. Principle and technology of metal solidification[M]. Beijing: Metallurgical Industry Press, 2008: 158-175.

[4] 丁万武, 夏天东, 赵文军, 等. 中间合金中第二相粒子TiC 和TiAl3对纯铝的细化作用[J]. 中国有色金属学报, 2009, 19(6): 1025-1031.

DING Wanwu, XIA Tiandong, ZHAO Wenjun, et al. Refining performances of TiC and TiAl3 phases in master alloys on pure aluminum[J]. The Chinese Journal of Nonferrous Metals, 2009, 19(6): 1025-1031.

[5] Jung H, Mangelinck-noel N, Bergman C, et al. Determination of the average nucleation undercooling of primary Al-phase on refining particles from Al-5.0wt%Ti-1.0wt%B in Al-base alloys using DSC[J]. Journal of Alloys and Compounds, 2009, 477(1/2): 622-627.

[6] Li Y L, Feng H K, Cao F R. Effect of high density ultrasonic on the microstructure and refining property of Al-5Ti-0.25C grain refiner alloy[J]. Materials Science and Engineering A, 2008, 487(1): 518-523.

[7] Chakrabarti J D, Liu J, Sawtell R R. New generation high strength high damage tolerance 7085 thick alloy product with low quench sensitivity[J]. Materials Forum, 2004(28): 969-974.

[8] GB/T 6394—2002, 金属平均晶粒度测定方法[S].

GB/T 6394—2002, Metal-methods for estimating the average grain size[S].

[9] Quested T E, Greer A L. Grain refinement of Al alloys: Mechanisms determining as-cast grain size in directional solidification[J]. Acta Materialia, 2005, 53(17): 4643-4653.

[10] GB/T 1425—1996, 贵金属及其合金熔化温度范围的测定热分析试验方法[S].

GB/T 1425—1996, Determination of melting temperature range for precious melts and their alloys: Testing method of thermal analysis[S].

[11] ZHAI Wei, WANG Weili, GENG Delu, et al. A DSC analysis of thermodynamic properties and solidification characteristics for binary Cu-Sn alloys[J]. Acta Materialia, 2012, 60(19): 6518-6527.

[12] Qian M, Cao P, Easton M A, et al. An analytical model for constitutional supercooling-driven grain formation and grain size prediction[J]. Acta Materialia, 2010, 58(9): 3262-3270.

[13] 杨明, 钟毅. 铝及铝合金晶粒细化剂的研究[J]. 有色金属加工, 2006, 35(1): 3-6.

YANG Ming, ZHONG Yi. Study on grain refiner for aluminum and aluminum alloys[J]. Nonferrous Metals Processing, 2006, 35(1): 3-6.

[14] Banerji A, Reif W. Development of A1-Ti-C grain refiners containing TiC[J]. Metallurgical Transactions A, 1986, 17(12): 2127-2136.

[15] 孙雪迎. Al-Ti-B、Al-Ti-C 中间合金细化铝及铝合金机制研究[D]. 北京: 清华大学材料科学与工程学院, 2011: 2-9.

SUN Xueyin. Study on refinement mechanism of Al-Ti-B and Al-Ti-C master alloys in aluminum and its alloys[D]. Beijing: Tsinghua University. School of Materials Science and Engineering, 2011: 2-9.

[16] 高义民. 金属凝固原理[M]. 西安: 西安交通大学出版社, 2010: 39-44.

GAO Yimin. Metal solidification principle[M]. Xi’an: Xi’an Jiaotong University Press, 2010: 39-44.

[17] Bondan T S, Daniel J K, Lukfawan T. Grain refinement of AA333 aluminum cast alloy by Al-Ti granulated flux[J]. Materials and Design, 2010, 31(Suppl 1): 36-43.

[18] Quested T E, Dinsdale A T, Greer A L. Thermodynamic modeling of growth-restriction effects in aluminium alloys[J]. Acta Materialia, 2005, 53(5): 1323-1334.

(编辑 刘锦伟)

收稿日期:2014-08-17;修回日期:2014-11-01

基金项目(Foundation item):国家重点基础研究发展规划(973 计划)项目(2010CB731706,2012CB619504) (Projects (2010CB731706, 2012CB619504) supported by the National Basic Research Development Program (973 Program) of China)

通信作者:李晓谦,博士,教授,从事冶金机械材料制备工艺研究;E-mail:meel@mail.csu.edu.cn