等温自由锻温度对7085铝合金组织与性能的影响

梁信,陈康华,陈学海,陈送义,彭国胜

(中南大学 粉末冶金国家重点实验室,湖南 长沙,410083)

摘要:通过金相组织观察、扫描电镜分析和室温拉伸力学性能及剥落腐蚀实验,分析探讨等温自由锻温度对7085铝合金显微组织、力学性能和剥落腐蚀的影响。研究结果表明:在370 ℃和400 ℃等温自由锻时,合金发生严重再结晶,强度较低,伸长率稍高,剥蚀抗力较差;在420 ℃锻造时,合金出现大量细小且分布均匀的亚晶粒,抗拉强度、屈服强度、伸长率和剥蚀抗力均较好,分别达到533.2 MPa,495 MPa,13.3%和EA。在450 ℃锻造时,该合金的晶粒开始长大,强度下降,伸长率稍有升高,剥蚀抗力较差。综合考虑显微组织、强度、塑性和剥落腐蚀等因素,确定420 ℃为合金等温自由锻最佳锻造温度。

关键词:7085铝合金;等温自由锻;再结晶;显微组织;力学性能;剥蚀抗力

中图分类号:TG146.4 文献标志码:A 文章编号:1672-7207(2012)03-0900-06

Effects of isothermal free forging temperature on microstructure and properties of 7085 aluminum alloy

LIANG Xin, CHEN Kang-hua, CHEN Xue-hai, CHEN Song-yi, PENG Guo-sheng

(State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The microstructure, mechanical and corrosion property of 7085 aluminum alloy deformed at different isothermal free forging temperatures were analyzed using optical microscope (OM), scanning electron microscope (SEM), mechanical tensile test and exfoliation corrosion. The experimental results show that serious recrystallization occurs at 370 ℃ or 400 ℃, resulting in the strength severely decreases, the elongation increases slightly and exfoliation corrosion gets worse. At 420 ℃, the alloy exhibits small and uniform sub-grain structure, leading to better strength, elongation and exfoliation resistance. The ultimate strength, yield strength and elongation achieve 533.2 MPa, 495 MPa and 13.3%, respectively. Exfoliation corrosion grade reaches EA. While the deformation temperature rises 450 ℃, the grains begin to grow up. The strength and exfoliation resistance decrease, but the elongation increases slightly. Considering the factors of microstructure, strength, plastic and exfoliation resistance, 420 ℃ is determined to be the best isothermal free forging temperature.

Key words: 7085 aluminum alloy; isothermal free forging; recrystallization; microstructure; mechanical properties; exfoliation resistance

Al-Zn-Mg-Cu系铝合金由于密度小、比强度和比刚度高等优点,已大量用在各个工业部门,其锻压件已成为世界各国航空、航天、交通运输等领域不可缺少的结构材料[1-2]。经过几十年的发展,Al-Zn-Mg-Cu系铝合金已先后成功开发出了7075,7475,7050和7150等系列铝合金,得到了广泛的应用。随着新一 代飞机的发展,上述Al-Zn-Mg-Cu系高强铝合金存 在淬火敏感性高的问题,难以满足当今对超大厚度(150 mm以上)航空铝合金锻件、预拉伸板制品提出的紧迫需 求[3-5]。为此,美国铝业公司于2003年在国际上率先推出具有高强韧性和低淬火敏感性的7085合金(Al-7.5Zn-1.5Mg-1.6Cu-0.12Zr),据文献[6-8]报道:7085-T7状态预拉伸超厚板(152 mm)与同厚度7050-T7合金板相比,其强度提高了15%,抗应力腐蚀性能和断裂韧性KIC值则基本相当,综合性能全面超过7050系列合金性能,特别适合现代飞机上大厚度整体式结构件的制造,制成迄今为止最大的一个飞机模锻件并应用在A380飞机后翼梁上,尺寸为6.4 m×1.9 m,质量约为3.9 t。因此,针对7085铝合金锻造工艺的研究具有十分重要的意义。Al-Zn-Mg-Cu系铝合金的工业产品主要是通过铸造、挤压、轧制或锻造工艺生产的。除铸件外,其铝制品的80%都是通过热变形使材料显微结构优化以获得所需要的使用性能。锻件和挤压产品大都无需后续形变加工,热加工后只经适当的热处理就决定了产品自身的性能,因而热加工及热处理过程中显微组织的演变对产品质量和性能有决定性作用。等温锻造是一种先进的锻造技术,由于其可精确控制加工工艺参数(锻造温度、锻造速率等),可使产品具有均匀一致且稳定的微观组织和优良的力学性能,使得等温锻造工艺成为当前研究的热点。刘鸣等[9]研究了不同等温锻造温度对2B70铝合金显微组织与力学性能的影响,结果表明采用等温锻造工艺,显微组织不具有明显的方向性,晶粒多为等轴晶,具有优良的组织均匀性和稳定性。因此,确定合理的锻造工艺参数是获得高质量锻件的关键问题。对于7085铝合金的锻造工艺参数仍处于专利保护之中,相关研究国内外也鲜有报道。因此,开展对7085铝合金等温锻造工艺的深入研究,确定其合理的锻造工艺参数具有十分重要的意义。本文作者在370~450 ℃之间的4个不同温度下对7085铝合金进行等温自由锻实验,研究合金在不同的锻造温度下的组织演变规律,分析其性能的变化规律,最终确定合金的最佳等温自由锻造温度。为7085铝合金锻件的成形工艺及有效地预测和控制锻件的微观组织结构及性能提供参考数据,具有十分重要的理论和实际应用价值。

1 实验

以纯铝、纯锌、纯镁以及Al-Cu、Al-Zr中间合金为原料,按7085名义成分(Al-7.5Zn-1.5Mg-1.6Cu- 0.12Zr)配料熔炼,熔炼温度为760~800 ℃。除气剂采用六氯乙烷(C2 Cl6),浇注前进行除气,扒渣,静置约30 min后浇入预热铁模(直径85 mm)中。随后将铸锭在空气炉中进行均匀化退火(450 ℃,24h+470 ℃,38 h),空冷。

将均匀化后的7085铝合金圆锭加工成为直径70 mm,高110 mm的圆柱体。试样在5 000 kN四柱液压机上以10-1 s-1的恒应变速率沿高度方向进行等温自由锻造,锻造工艺如图1所示,每次变形量均为50%,最终锻成长为150 mm,宽为60 mm,高为46 mm的方形锻件。锻造温度分别为370,400,420和450 ℃。锻造前采用自行设计与制造的安装在压力机工作台面上的等温自由锻造加热保温炉进行加热和保温,其时间分别为1 h。为了防止铝合金锻造时粘模,锻造前在试样和垫板上涂抹润滑剂(机油+石墨)。锻造后,采用标准热处理制度在470 ℃温度下于空气炉中进行固溶处理,保温1 h 后立即淬入冷水中。淬火后马上在鼓风干燥箱中进行T6峰值时效(120 ℃,24 h)。

在锻件中心部分取样,样品经机械抛光后用Graff Sargent试剂腐蚀,Graff Sargent试剂成分为3 g CrO3+0.5 mL HF+ 84 mL H2O+15.5 mL HNO3。腐蚀后试样在光学显微镜下观察合金固溶时效后的显微组织,分别在低倍和高倍下观察其再结晶情况和亚晶尺寸。拉伸实验按照国标GB228—87在CSS-44100型电子拉伸机上进行,样品受力直径为6 mm。用JEOL扫描电镜观察断口形貌。

图1 等温自由锻锻造工艺图

Fig.1 Schematic of isothermal free forging process

剥落腐蚀试验参照HB5455—90标准进行, 腐蚀介质采用标准的EXCO溶液(4 mol/L NaCl+0.4 mol/L KNO3+0.1 mol/L HNO3),试验溶液体积与试验溶液面积之比为25 mL/cm2,样品除试验面外其余各面由环氧树脂密封,试验时间为48 h,试验温度为25 ℃。间断观察腐蚀样品的腐蚀情况,并拍摄样品腐蚀后的宏观形貌,同时按标准对腐蚀试样进行评级。评级代号:N为无明显腐蚀;P为点蚀;EA,EB,EC和ED分别代表剥落腐蚀逐渐加重。

2 结果与分析

2.1 锻造温度对固溶时效态组织的影响

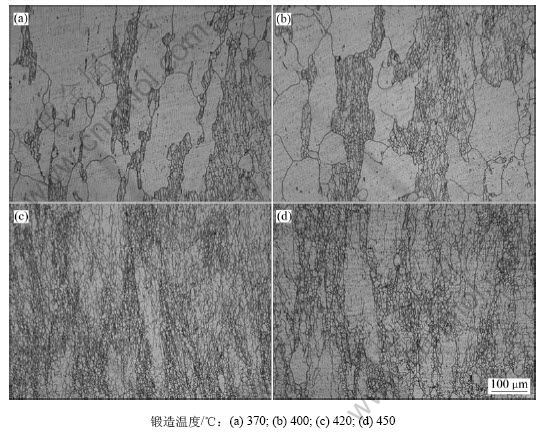

图2所示为7085铝合金试样在不同温度下等温自由锻及热处理后的显微组织,其中白色区域为再结晶组织,黑色区域为未再结晶组织。由于Graff Seagent试剂优先腐蚀晶界和亚晶界[10],未再结晶部分由于存在大量亚结构而被腐蚀呈黑色。由图2可以看出:当锻造温度为370 ℃时(图2(a)), 合金组织出现大量的白色区域,即再结晶组织,再结晶分数达到80%以上;当锻造温度为400 ℃时(图2(b)),再结晶体积分数减小;当锻造温度为420 ℃时(图2(c)),合金组织出现大量细小且分布均匀的亚晶粒,再结晶体积分数很少;当锻造温度升高到450 ℃时(图2(d)),合金组织只有少量的亚晶粒,大部分亚晶粒已经长大且分布不均匀。

铝合金热加工时,同时存在加工硬化和动态软化2个矛盾的过程。变形时的位错增殖和位错间的交互作用导致加工硬化;位错通过攀移或交滑移并在热激活和外应力作用下发生相互合并、销毁和重组使材料发生动态回复而软化[11-12]。当锻造温度为370 ℃时,变形过程只发生少量的动态回复。塑性变形过程中大量的应变能被保留下来,降低了合金的再结晶温度,因而在固溶时发生严重再结晶[13]。当锻造温度升高到400 ℃时,动态回复较多,塑性变形过程中的应变能被保留下来相对较少,导致固溶时再结晶分数降低。当锻造温度为420 ℃时,变形产生的位错增殖和位错销毁之间达到动态平衡,合金中的亚晶平均尺寸、亚晶间平均取向差以及平衡位错密度均保持基本不变,合金仅发生“重复多边形化”,表现强烈的动态回复行为,应变能得到充分回复。固溶时,基本不发生再结晶。当锻造温度升高到450 ℃时,原子被激活发生位移,导致亚晶合并和长大。

图2 不同锻造温度下合金的金相显微组织

Fig.2 Optical micrographs of studied alloys at different forging temperatures

2.2 锻造温度对力学性能的影响

图3所示为7085铝合金试样在不同温度下等温自由锻及固溶时效热处理后的室温拉伸性能曲线。由图3可以看出:随着锻造温度的升高,合金的屈服强度(σ0.2)和抗拉强度(σb)先缓慢上升,然后再迅速下降,伸长率(δ)先下降后升高。当锻造温度为370 ℃和400 ℃时,屈服强度和抗拉强度都较低,分别为470 MPa和510 MPa左右,伸长率约为14.5%。当锻造温度为420 ℃时,屈服强度和抗拉强度达到最高,分别为495 MPa和533 MPa,伸长率相应降低(13.3%)。锻造温度再升高时,合金的强度开始下降,伸长率稍有升高。根据Hall-Petch关系[14],合金的强度与晶粒尺寸相关。晶粒越小,强度越高。当锻造温度为420 ℃时,合金组织出现大量细小且分布均匀的亚晶粒,对应强度较 高,实验结果与理论分析一致。当锻造温度升高或降低时,合金组织分别发生了晶粒长大和再结晶,导致强度下降。

图3 不同锻造温度对合金力学性能的影响

Fig.3 Influence of different forging temperatures on mechanical properties of alloy

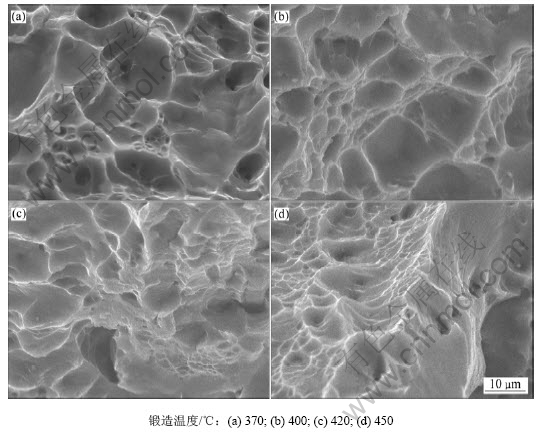

图4所示为7085铝合金试样在不同温度下等温自由锻及固溶时效热处理拉伸断口SEM像。由图4可以看出:合金在370~450 ℃的4个不同锻造温度下的断口照片都是以穿晶断裂为主,沿晶断裂为辅。锻造温度为370 ℃和400 ℃时(图4(a)和图4(b)),由于合金发生严重再结晶现象,晶粒粗大,使其断口表面上的韧窝大且深,伸长率较高。锻造温度为420 ℃时(图4(c)),断口表面分布大量细小均匀且浅的韧窝。锻造温度升高到450 ℃时(图4(d)),晶粒发生长大,对应拉伸断口的韧窝也较大。

图4 不同锻造温度下合金拉伸断口SEM像

Fig.4 Fracture surfaces of alloys at different forging temperatures

2.3 锻造温度对剥落腐蚀的影响

图5所示为7085铝合金试样在在不同温度下等温自由锻及固溶时效热处理剥蚀样品的表面宏观形貌。在浸泡初期,合金表面最先出现轻微的点蚀,随着浸泡时间的延长,点蚀不断加重,引起层间剥蚀。锻造温度为370 ℃和400 ℃时(图5(a)和图5(b)),试样出现大量开裂“起皮”现象。锻造温度为420 ℃时(图5(c)),试样在点状腐蚀基础上出现“鼓泡”,只出现极小量的“起皮”现象。锻造温度升高到450 ℃(图5(d)),“起皮”数量增加。剥落腐蚀评级结果如表1所示。

一般认为剥落腐蚀是一种特殊的晶间腐蚀,当晶间腐蚀在扁平的、平行于合金表面的晶粒组织中进行时,不溶性腐蚀产物的体积大于所消耗金属的体积,从而产生“楔入效应”,撑起上面没有腐蚀的金属,引起分层剥落,所以对于剥落腐蚀,晶界起着非常重要的作用[15-16]。锻造温度为370 ℃和400 ℃时,试样发生严重再结晶,再结晶晶粒由于晶界角度较大,能量较高,时效析出相容易优先形核,形成连续分布且粗大的粒子,构成了阳极腐蚀通道,从而使合金的耐蚀性能恶化。锻造温度为420 ℃时,试样未发生明显再结晶,未再结晶晶粒晶界角度较小,能量较低,时效析出相在未再结晶晶界富集的程度低于再结晶晶界富集的程度,不易形成连续的晶界析出相且析出相粒子较小,晶间腐蚀较难深入,腐蚀程度低;锻造温度升高到450 ℃时,亚晶粒出现合并长大现象,晶界角度变大,晶界能量变高,时效析出相变连续且粗大,晶间腐蚀较易发生。

图5 不同锻造温度下合金剥落腐蚀表面形貌

Fig.5 Surfaces of exfoliation corrosion of studied alloys at different forging temperatures

表1 不同锻造温度下合金剥落腐蚀等级

Table 1 Degree of exfoliation corrosion of studied alloys at different forging temperatures

3 结论

(1) 7085铝合金在370 ℃和400 ℃等温锻造时,合金组织发生严重的再结晶;在420℃等温锻造时,合金组织出现大量细小且分布均匀的亚晶粒;锻造温度升高到450 ℃时,亚晶粒发生合并长大现象。

(2) 在370~450 ℃的锻造温度范围内,合金的强度变化较大,伸长率变化较小,剥蚀抗力变化较大。综合分析组织与力学性能的试验结果,7085铝合金最佳锻造温度为420 ℃,其抗拉强度、屈服强度、伸长率和剥蚀等级分别为533.2 MPa,495 MPa,13.3%和EA。

参考文献:

[1] 王祝堂, 田荣璋. 铝合金及其加工手册[M] . 长沙: 中南工业大学出版社, 1988: 98-101.

WANG Zhu-tang, TIAN Rong-zhang. Aluminum alloy and processing manual[M]. Changsha: Central South University of Technology Press, 1988: 98-101.

[2] 邱惠中, 吴志红. 航空用高性能金属材料的新进展[J]. 宇航材料工艺, 1996, 24(3): 18-13.

QIU Hui-zhong, WU Zhi-hong. New development of high performance metallic materials for aerospace[J]. Aerospace Materials and Technology, 1996, 24(3): 18-13.

[3] Warner T. Recently-developed aluminum solutions for aerospace applications[J]. Mater Sci Forum, 2006, 519/520/521(2): 1271-1278.

[4] Miller W S, Zhuang L, Bottema J, et al. Recent development in aluminium alloys for the automotive industry[J]. Mater Sci Eng A, 2000, 280(3): 37-49.

[5] Starke E A, Staley J T. Application of modern aluminum alloys to aircraft[J]. Progress in Aerospace Science, 1996, 32(2/3): 131.

[6] Chakrabarti D J, Liu J, Sawtell R R, et al. New generation highstrength high damage tolerance 7085 thick alloy product with low quench sensitivity[C]//Proceedings of ICAA9. Melbourne: Institute of Materials Engineering Australasia Ltd, 2004: 969-974.

[7] 陈文. 先进铝合金在A380上的应用[J]. 航空维修与工程, 2005, 4(2): 40-41.

CHEN Wen. Application of advanced aluminum alloys in A380 structures[J]. Aviation Maintenance & Engineering, 2005, 4(2): 40-41.

[8] John L. Advanced aluminum and hybrid aerostructure for future aircraft[J]. Mater Sci Forum, 2006, 519: 1271-1278.

[9] 刘鸣, 郭鸿镇, 梁业, 等. 等温锻造温度对2B70铝合金组织性能的影响[J]. 热加工工艺, 2008, 37(5): 9-15.

LIU Ming, GUO Hong-zhen, LIANG Ye, et al. Effect of isothermal forging temperature on microstructure and mechanical properties of 2B70 aluminum alloy[J]. Hot Working Technology, 2008, 37(5): 9-15.

[10] Robson J D, Prangnell P B. Predicting the recrystallized volume fraction in AA7050 hot rolled plate[J]. Materials Science and Technology, 2002, 18(6): 607-619.

[11] 沈健. AA7005铝合金的热加工变形特性[J]. 中国有色金属学报, 2001, 11(4): 593-597.

SHEN Jian. Hot formation behaviors of AA7005 aluminium alloy[J]. The Chinese Journal of Nonferrous Metals, 2001, 11(4): 593-597.

[12] 王立忠, 王经涛, 郭成, 等. 等径弯曲通道变形制备超细晶铝合金的组织性能[J]. 西安交通大学学报, 2004, 38(5): 457-461.

WANG Li-zhong, WANG Jin-tao, GUO Cheng, et al. Microstructure and properties of ultrafine-grained aluminium based alloy processed by equal channel angular pressing[J]. Journal of Xi’an Jiaotong University, 2004, 38(5): 457-461.

[13] Vasudevan A K, Doherty R D. Aluminum alloys-contemporary research and applications[M]. New York: Academic Press, 1989: 137-169.

[14] 冯端. 金属物理学[M]. 3版. 北京: 科学出版社, 1999: 360-370.

FENG Duan. Metal physics[M]. 3rd ed. Beijing: Science Press, 1999: 360-370.

[15] 李芳芳. 高强铝合金剥落腐蚀的研究综述[J]. 湖南冶金职业技术学院学报, 2009, 9(2): 9-12.

LI Fang-fang. Study on exfoliation corrosion of high-strength aluminum alloys[J]. Journal of Hunan Metallurgical Professional Technology College, 2009, 9(2): 9-12.

[16] 杨胜, 易丹青, 钟利, 等. 航空Al-Cu-Mg合金剥落腐蚀行为[J]. 北京科技大学学报, 2007, 29(2): 216-219.

YANG Shen, YI Dan-qin, ZHONG Li, et al. Exfoliation corrosion behavior of Al-Cu- Mg alloys for aerospace applications[J]. Journal of University of Science and Technology Beijing, 2007, 29(2): 216-219.

(编辑 陈爱华)

收稿日期:2011-04-18;修回日期:2011-07-04

基金项目:国家重点基础研究发展计划(“973”计划)项目(2012CB619502, 2010CB731701);国家自然科学基金委员会创新研究群体科学基金资助项目(51021063)

通信作者:陈康华(1962-),男,浙江宁波人,博士,教授,从事铝合金强韧耐蚀研究;电话:0731-88830714;E-mail: khchen@csu.edu.cn