文章编号:1004-0609(2012)10-2805-06

快速凝固对Sn-6.5Zn钎料合金特性及

钎料/Cu焊点力学性能的影响

赵国际,盛光敏,罗 军

(重庆大学 材料科学与工程学院,重庆 400044)

摘 要:利用单棍快淬工艺制备快速凝固态Sn-6.5Zn合金薄带,对比分析快速凝固制备工艺对钎料微观结构、熔化与铺展特性的影响,并利用拉伸-剪切试验对比研究了钎料/Cu焊点力学性能。结果表明:快速凝固能够显著细化Sn-6.5Zn合金微观组织,初生β-Sn相快速分枝并形成网状枝晶结构,Zn相呈尺寸为0.5~2 μm的细小颗粒分布于β-Sn基体中;经快速凝固后,Sn-6.5Zn合金熔化区间减小了约3.7 ℃;快速凝固态Sn-6.5Zn合金具有优于常态钎料的钎焊工艺性能,能够促进钎料/Cu焊点形成均匀界面并改善力学性能。

关键词:快速凝固;Sn-6.5Zn钎料;焊点;微观结构;力学性能

中图分类号:TG454 文献标志码:A

Influence of rapid solidification on characteristics of

Sn-6.5Zn solder alloy and mechanical properties of solder/Cu joints

ZHAO Guo-ji, SHENG Guang-min, LUO Jun

(College of Materials Science and Engineering, Chongqing University, Chongqing 400044, China)

Abstract: The rapidly solidified Sn-6.5Zn alloy foils were prepared by melt-spinning method. Through comparison, the effects of rapid solidification process on the microstructure, thermodynamic characteristic and spreading properties of Sn-6.5Zn solder alloys were analyzed. The tensile-shear tests were used to evaluate the mechanical properties of solder/Cu joints. The results show that the rapid solidification process can greatly refine the solidification structure of Sn-6.5Zn alloy. A netlike dendrite structure is formed due to the rapid branch of β-Sn and the Zn phases are distributed in β-Sn matrix in granular form with size of 0.5-2 μm. After rapid solidification, the pasty range is reduced by about 3.7 ℃. The rapidly solidified Sn-6.5Zn alloy has an excellent wettability under test compared with as-solidified solder. The mechanical properties of solder/Cu joints are also obviously improved by using the rapidly solidified Sn-6.5Zn solder alloy, which results in the formation of uniform interface.

Key words: rapid solidification; Sn-6.5Zn solder; soldering joint; microstructure; mechanical properties

铅及其化合物由于具有毒性而被世界上多个国家禁止用于电子工业领域,因此,高性能无铅钎料的研究与开发成为近年来保证与提高微连接可靠性的关键技术之一[1-2]。目前,可用于电子封装的各合金系中,Sn-Zn合金共晶温度为198.5 ℃,与传统Sn-Pb共晶合金最为接近,并且具有材料成本低和焊点力学性能优良等优点,被认为是一种能够替代传统Sn-Pb钎料的合金[2-4]。但由于Zn性质活泼,使得Sn-Zn钎料的铺展性和抗氧化性能较差,限制了其应用。研发新型助焊剂和对钎料合金化是通常被用来改善Sn-Zn合金铺展性和抗氧化性的两个方法,尤其是关于通过添加合金元素对钎料进行改性的研究报道较多[5]。但由于所添加的合金元素多为贵金属或难熔金属,如Ag、RE、Cr等,增大了合金精确熔炼的难度,显著提高了钎料合金的制造成本,所以二元合金在材料成本和制造工艺方面具有研究和应用优势。目前,关于Sn-Zn二元钎料的研究主要集中在Sn-9Zn合金[3-4],而魏秀琴等[6-7]和MAHMUDI等[8]的研究表明,与共晶Sn-9Zn合金相比,亚共晶Sn-6.5Zn钎料具有更好的铺展性和优良的焊点性能,具有一定的应用前景。

基金项目:国家自然科学基金资助项目(50675234)

收稿日期:2011-09-16;修订日期:2012-03-08

通信作者:盛光敏,教授,博士;电话:15923026226;E-mail: gmsheng@cqu.edu.cn

在20世纪70年代,快速凝固技术就被作为一种重要的非平衡制造工艺用于合金制备以改善其性能[9],并逐渐用于加工钎料合金[9-11]。近年来,关于利用快速凝固技术对Sn基无铅钎料进行改性制备也已经取得了一定的研究进展,表明快速凝固能够显著改变钎料合金性质并提高连接性能。对于Sn-Zn系合金,关于不同凝固条件下合金性能的报道主要包括:CARCIA等[4]研究了水冷条件下Sn-Zn合金的组织差异;SHEPELEVICH和GUSAKOVA[12-13]报道了快速凝固Sn-Zn薄带的微观结构及时效行为,研究了快速凝固Sn-Zn-Bi合金的结构特征。截至目前,关于具有优良性能的亚共晶Sn-6.5Zn的快速凝固制备及钎焊性能分析尚未见文献报道。

本文作者在先期开展的关于快速凝固态无铅Sn基钎料研究的基础上[14],利用单棍快淬工艺制备了快速凝固态Sn-6.5Zn合金薄带,以常态Sn-6.5Zn钎料合金作为参照物,研究快速凝固工艺对合金微观结构、熔化与铺展特性以及钎料/Cu焊点力学性能的影响,为快速凝固态Sn-Zn系合金的研发开展了基础试验。

1 实验

试验用Sn-6.5Zn合金利用纯度为99.99%(质量分数)的纯Sn、纯Zn按照质量分数比并考虑烧损,在ZG-001真空炉中进行熔炼和两次浇注而成,熔炼温度为600 ℃,抽真空后充氩气保护。将熔炼好的块状Sn-6.5Zn合金装入石英管,使用SP009A型半自动非金属系带制造器,利用单辊法制备快速凝固态Sn-6.5Zn钎料薄带,铜辊直径为350 mm,转速为25 r/s。利用Mettler-Toledo TGA/DSC 1/1100热分析仪,对两种状态的Sn-6.5Zn合金进行差示扫描量热法(DSC)分析,试样质量为20 mg,加热速度为10 ℃/min,加热温度区间为30~250 ℃。利用TESCAN VegaⅡ LMU 与VEGA3 TESCAN型扫描电子显微镜(SEM)对钎料合金的微观结构和钎料/Cu焊点断口进行微观观察,金相试样腐蚀剂为3% HCl+5% HNO3+92% CH3OH(体积分数)溶液。

铺展对比试验基板选用尺寸为20 mm×20 mm×0.2 mm的T2纯Cu片,试验前经800#金相砂纸磨光后用丙酮清洗。试验在SX-12箱式炉中进行,钎料质量为0.1 g,使用市售活性松香助焊剂作为钎剂覆盖钎料,进行不同时间与温度条件下的钎料铺展试验,每个工艺条件下试验3次。将试验后的铺展焊点进行数码照相后,利用CAD软件测量铺展面积。

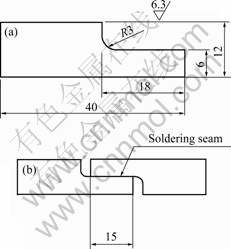

利用拉伸-剪切试验对不同状态Sn-6.5Zn钎料/Cu接头力学性能进行评估,接头形式与尺寸见图1。钎焊试验在SX-12箱式电阻炉中进行,钎焊温度为240 ℃,钎剂为市售松香性松香助焊剂;拉伸-剪切试验使用ANS电子万能试验机,拉伸速度为0.5 mm/min。

图1 钎焊焊点试样结构示意图

Fig. 1 Schematic diagram of test specimen for soldering joint (mm): (a) Base metal; (b) Soldering joint

2 结果与分析

2.1 微观结构

本试验条件下制备的快速凝固态Sn-6.5Zn合金薄带厚度约60 μm,其凝固散热方式可以认为属于牛顿冷却方式,瞬时冷却速度可通过下式计算[15-16]:

(1)

(1)

式中:h为界面传热系数;ρ为合金熔体的密度;cp为定压比热容;z0为薄带厚度;Tm为熔体的熔点温度;TA为冷模温度。

文献[12-13]研究表明,该工艺条件下合金冷却速度可达到106 K/s。

常态Sn-Zn钎料合金的组织已经有了较多的研究报道,结合Sn-Zn二元相图,可以推断常态Sn-6.5合金显微组织是由初生β-Sn相与共晶组织组成[4, 8]。在不同的冷却条件下,Sn-Zn合金微观组织形态会明显不同[4, 12-14],随着冷却速度的增大,初生相与共晶组织均显著细化,层片状组织有向颗粒状组织转变的趋势[15-16]。

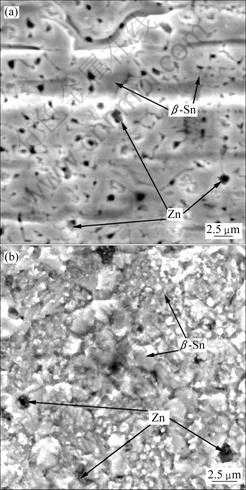

快速凝固态Sn-6.5Zn钎料合金薄带微观结构见图2,其中,图2(a)所示为薄带平面,图2(b)所示为薄带横截面。图2中富Zn相由于耐蚀性差,腐蚀后其所在位置形成了黑色的凹坑。

图2 快速凝固态Sn-6.5Zn合金薄带的SEM像

Fig. 2 SEM images of Sn-6.5Zn alloy foils prepared by rapidly solidified: (a) Flat surface; (b) Cross section

由图2可看出,经快速凝固后,Sn-6.5Zn合金中的富Zn相以尺寸为0.5~2 μm的细小颗粒形态分布于β-Sn基体中,部分初生相β-Sn也发生了由层片状向颗粒状的转变。图2(b)还表明,在形成的颗粒状β-Sn相周围,形成了细针状的凝固组织,这是在急冷快速凝固条件下由于初生相快速生长与分枝所形成的网络状枝晶。由Sn-Zn二元相图可知,Zn原子能够少量溶解于初生相β-Sn中,而Sn原子不溶于Zn相。经快速凝固的合金处于亚稳态,溶质在溶剂中的溶解度大于平衡最大固溶度,该固溶度主要受凝固速率影响[15-16]。AZIZ提出的描述快冷时有效分配系数 的模型为[17]

的模型为[17]

(2)

(2)

(3)

(3)

式中: 为平衡时的液相成分;

为平衡时的液相成分; 为平衡时的固相成分;k为平衡分配系数;Di为界面处i溶质的扩散系数;v为凝固速度;λ为原子跳跃距离。

为平衡时的固相成分;k为平衡分配系数;Di为界面处i溶质的扩散系数;v为凝固速度;λ为原子跳跃距离。

与界面对流程度强弱有关;β值实质上反映了固-液界面前进速度与溶质原子在液相中从固-液界面扩散出去的速度间的竞争,冷却速度极大时,

与界面对流程度强弱有关;β值实质上反映了固-液界面前进速度与溶质原子在液相中从固-液界面扩散出去的速度间的竞争,冷却速度极大时, →1,表明溶质原子没有充分时间扩散出去,溶质原子被部分捕获,在溶剂中的溶解度增大,形成过饱和固溶体。因此,可以推断快速凝固Sn-6.5Zn合金中形成了过饱和的β-Sn固溶体,未溶解的Zn相呈细小颗粒状被包覆于β-Sn枝晶中。微观结构分析表明,快速凝固工艺能够显著细化晶粒并抑制Sn-6.5Zn合金中Zn相的长大。

→1,表明溶质原子没有充分时间扩散出去,溶质原子被部分捕获,在溶剂中的溶解度增大,形成过饱和固溶体。因此,可以推断快速凝固Sn-6.5Zn合金中形成了过饱和的β-Sn固溶体,未溶解的Zn相呈细小颗粒状被包覆于β-Sn枝晶中。微观结构分析表明,快速凝固工艺能够显著细化晶粒并抑制Sn-6.5Zn合金中Zn相的长大。

2.2 熔化与铺展特性

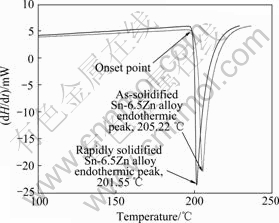

常态与快速凝固态Sn-6.5Zn钎料DSC分析结果见图3。

图3 常态与快速凝固态Sn-6.5Zn合金的DSC分析结果

Fig. 3 DSC analysis results of as-solidified and rapidly solidified Sn-6.5Zn alloys

图3中DSC曲线均只有一个吸热峰,表明合金在加热熔化过程中没有发生相变。DSC分析结果表明,本试验条件下,快速凝固制备工艺对Sn-6.5Zn合金熔点不会产生明显影响,但是能够显著减小钎料的熔化区间。图3分析结果表明,与常态Sn-6.5Zn合金相比,快速凝固态合金熔化区间减小了约3.7 ℃。合金的快速凝固过程是一个典型的非平衡凝固过程,大冷却速度条件下形成的快速凝固态合金吸收了大量结晶潜 热[18];加热过程中,合金释放结晶潜热,能够有效地促进熔化过程的进行。熔化区间的减小表明钎料能够在较短的钎焊时间内实现熔化与铺展,这有利于提高效率并防止或减小钎焊过程对电子元器件造成的热 损伤。

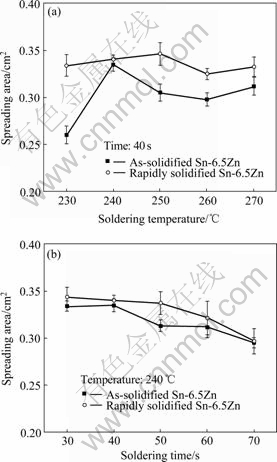

钎料对基板的润湿与铺展性能是评价钎料钎焊工艺性能的一个重要指标,已有研究表明Sn-6.5Zn合金具有优良的铺展性能[6-8]。常态和快速凝固态Sn-6.5Zn钎料铺展对比试验结果见图4。

图4 常态与快速凝固态Sn-6.5Zn合金铺展对比试验结果

Fig. 4 Comparison of spreading test results of as-solidified and rapidly solidified Sn-6.5Zn alloys at various temperatures for 40 s(a) and at 240 ℃ for various times(b)

由图4可见,与常态Sn-6.5Zn钎料相比,在相同钎焊时间(t=40 s)条件下,快速凝固态Sn-6.5Zn合金能够在较低温度条件下(本试验条件下为230 ℃)时即形成良好的铺展(图4(a));在相同钎焊温度(240 ℃)条件下,钎焊时间对Sn-6.5Zn合金铺展性能的影响不明显(图4(b))。快速凝固态Sn-6.5Zn合金处于热力学亚稳定状态,在加热过程中会释放结晶潜热促进熔化和铺展,这对于快速完成钎焊工艺过程非常有利;待钎料完全熔化形成液态后,快速凝固态钎料与常态钎料并无不同,随着钎焊时间的延长,由于钎料氧化形成的反润湿现象,两类钎料的铺展面积均呈现下降趋势。

铺展试验结果表明,处于亚稳态的快速凝固态的Sn-6.5Zn钎料在较低温度条件下的铺展性能明显优于常态钎料的;随着钎焊温度的升高或是钎焊时间的延长,两者差异减小并呈现一致的变化趋势。

2.3 焊点力学性能

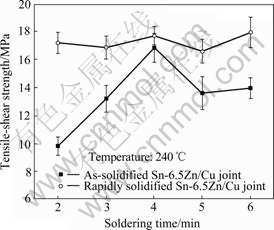

常态与快速凝固态Sn-6.5Zn钎料/Cu焊点拉伸-剪切试验结果见图5。

图5 常态与快速凝固态Sn-6.5Zn钎料/Cu焊点拉伸-剪切性能

Fig. 5 Tensile-shear strength of as-solidified and rapidly solidified Sn-6.5Zn/Cu solder joints at different soldering times

拉伸-剪切试验结果表明:使用常态Sn-6.5Zn钎料时,随着钎焊时间的延长,焊点强度先增大而后减小;与常态Sn-6.5Zn钎料相比,使用快速凝固态钎料能够显著改善焊点结合强度,这主要表现在两个方面,一是能够在较短钎焊时间即实现高性能连接,二是焊点强度受钎焊时间影响不大。

钎料合金DSC分析(见图3)与铺展试验(见图4)结果表明,快速凝固态Sn-6.5Zn钎料在钎焊过程中的熔化和铺展速度明显高于常态钎料的,这使得钎焊时钎料能够迅速地填充接头间隙;同时,钎缝中均匀的液态钎料层对结合面形成了良好的保护,能够在一定程度上减弱氧的不利影响,有利于钎料组元与基板元素间的反应和扩散以及致密连接的形成,焊点强度较高且受钎焊时间的影响不大。常态钎料的熔化和铺展速度相对较慢,钎焊过程中,随着钎焊时间的延长,钎料的逐步熔化和铺展增大了焊合区域,焊点强度趋于上升;而随着钎焊时间的进一步延长,持续发生的氧化反应对液态钎料在钎缝中的铺展产生越来越强的阻碍作用,导致液态钎料难以对基板实现完全均匀铺展,焊点结合区域的致密性下降,结合强度下降。此外,常态钎料由于凝固速度较低,必然存在明显的成分偏析,从而造成某些局部有害脆性相的富集,不利于结合性能。快速凝固能够显著细化合金凝固组织、减小枝晶臂间距,使得合金表现出的显微偏析很小,同时快速凝固态钎料中过饱和固溶元素在钎焊过程中能够析出大量弥散细小的第二相粒子[15],这些都促进了钎焊时均匀界面反应层的形成,有利于提高结合强度。

3 结论

1) Sn-6.5Zn合金在本试验快速凝固条件下,初生β-Sn相快速生长与分枝形成网络状枝晶;在形成过饱和β-Sn固溶体的同时,Zn相的长大被抑制,呈尺寸为0.5~2 μm的细小颗粒状被包覆于β-Sn枝晶中。

2) 与常态Sn-6.5Zn合金相比,处于热力学亚稳定状态的快速凝固态合金熔化区间减小了约3.7 ℃,并能在加热过程中释放结晶潜热促进熔化和铺展,具有优良的钎焊工艺性能。

3) 与常态Sn-6.5Zn钎料相比,使用快速凝固态钎料能够促进钎焊时均匀界面反应层的形成,从而在较短钎焊时间即实现高性能连接,且焊点强度受钎焊时间的影响不大。

REFERENCES

[1] ABTEW M, SELVADURAY G. Lead-free solders in microelectronics[J]. Materials Science and Engineering R: Reports, 2000, 27(5/6): 95-141.

[2] 张新平, 尹立孟, 于传宝. 电子和光子封装无铅钎料的研究和应用进展[J]. 材料研究学报, 2008, 22(1): 1-9.

ZHANG Xin-ping, YIN Li-meng, YU Chuan-bao. Advances in research and application of lead-free solders for electronic and photonic packaging[J]. Chinese Journal of Materials Research, 2008, 22(1): 1-9.

[3] SUGANUMA K, KIM K S. Sn-Zn low temperature solder[J]. Journal of Materials Science: Materials in Electronics, 2007, 18(1/3): 121-127.

[4] GARCIA L R, OSORIO W R, PEIXOTO L C, GARCIA A. Mechanical properties of Sn-Zn lead-free solder alloys based on the microstructure array[J]. Materials Characterization, 2010, 61(2): 212-220.

[5] ZHANG L, XUE S B, GAO L L, SHENG Z, YE H, XIAO Z X, ZENG G, CHEN Y, YU S L. Development of Sn-Zn lead-free solders bearing alloying elements[J]. Journal of Materials Science: Materials in Electronics, 2010, 21(1): 1-15.

[6] 魏秀琴, 黄惠珍, 周 浪, 张 萌. 亚共晶Sn-Zn系合金无铅焊料的性能[J]. 中国有色金属学报, 2006, 16(12): 1993-1998.

WEI Xiu-qin, HUANG Hui-zhen, ZHOU Lang, ZHANG Meng. Properties of Sn-Zn alloys as lead-free solders[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(12): 1993-1998.

[7] WEI X Q, HUANG H Z, ZHOU L, ZHANG M, LIU X D. On the advantages of using a hypoeutectic Sn-Zn as lead-free solder material[J]. Materials Letters, 2007, 61(3): 655-658.

[8] MAHMUDI R, GERANMAYEH A R, NOORI H, SHAHABI M. Impression creep of hypoeutectic Sn-Zn lead-free solder alloys[J]. Materials Science and Engineering A, 2008, 491(1/2): 110-116.

[9] LAVERNIA E J, SRIVATSAN T S. The rapid solidification processing of materials: Science, principles, technology, advances and applications[J]. Journal of Materials Science, 2010, 45(2): 287-325.

[10] JONES H. A perspective on the development of rapid solidification and nonequilibrium processing and its future[J]. Materials Science and Engineering A, 2001, 304/306: 11-19.

[11] YANG W, LIU F, WANG H F, LU B P, YANG G C. Non-equilibrium transformation kinetics and primary grain size distribution in the rapid solidification of Fe-B hypereutectic alloy[J]. Journal of Alloys and Compounds, 2011, 509(6): 2903-2908.

[12] SHEPELEVICH V G, GUSAKOVA O V. Structure and properties of rapidly solidified Sn-Zn foils[J]. Inorganic Materials, 2008, 44(5): 485-489.

[13] GUSAKOVA O V, SHEPELEVICH V G. Structure and properties of rapidly solidified foils of alloys of Sn-Zn-Bi system[J]. Inorganic Materials: Applied Research, 2010, 1(4): 344-349.

[14] 赵国际, 张柯柯, 罗 键. 快速凝固Sn2.5Ag0.7Cu钎料中金属间化合物的形态及对焊点性能的影响[J]. 中国有色金属学报, 2010, 20(10): 2025-2031.

ZHAO Guo-ji, ZHANG Ke-ke, LUO Jian. Micro-morphology of intermetallic compounds in rapid solidification Sn2.5Ag0.7Cu solder alloy and its effects on performance of solder joint[J]. The Chinese Journal of Nonferrous Metals, 2010, 20(10): 2025-2031.

[15] 陈 光, 傅恒志. 非平衡凝固新型金属材料[M]. 北京: 机械工业出版社, 2004: 48-49.

CHEN Guang, FU Heng-zhi. Advanced materials fabricated by non-equilibrium solidification process[M]. Beijing: China Machine Press, 2004: 26-34.

[16] 胡壮麒, 宋启洪, 张海峰, 刘 正. 亚稳金属材料[M]. 北京: 科学出版社, 2006: 7-8.

HU Zhuang-lin, SONG Qi-hong, ZHANG Hai-feng, LIU Zheng. Metastable metal materials[M]. Beijing: Science Press, 2006: 7-8.

[17] AZIZ M J. Model for solute redistribution during rapid solidification[J]. Journal of Applied Physics, 1982, 53(2): 1158-1168.

[18] 刘丽琴, 张忠明, 徐春杰, 郭学锋. 深过冷Cu-20%Pb亚偏晶合金凝固组织的细化机制[J]. 金属学报, 2007, 43(11): 1138-1144.

LIU Li-qin ZHANG Zhong-ming XU Chun-jie GUO Xue-feng. Refinement mechanism of the solidification structure of Cu-20%Pb hypomonotectic alloy by deeply undercooled treatment[J]. Acta Metallurgica Sinica, 2007, 43(11): 1138-1144.

(编辑 李艳红)