DOI:10.19476/j.ysxb.1004.0609.2018.12.12

采用低温度梯度HRS工艺制备的镍基单晶高温合金雀斑组织

陈晶阳,吴文津,李 青,张明军,汤 鑫,肖程波

(北京航空材料研究院 先进高温结构材料重点实验室,北京 100095)

摘 要:通过在高速凝固法(HRS)定向凝固过程中调整隔热挡板与壳型之间的间隙,获得了较低的定向凝固温度梯度(~30℃/cm),制备了含有雀斑组织的单晶高温合金试棒。结果表明:采用常规HRS工艺(温度梯度~50℃/cm)制备的合金一次枝晶间距为323μm,含有1.70%铸态共晶;而采用较低温度梯度HRS工艺制备的合金一次枝晶间距达到了704μm,是常规HRS工艺的2.2倍,并且合金的二次枝晶及三次枝晶较为发达;此外,雀斑组织区域包含较多平均晶粒尺寸为200μm的等轴晶晶粒和4.64%的铸态共晶,同时分布着富集Ta元素的MC碳化物。定向凝固过程中较低的温度梯度增大了合金的一次枝晶间距并使合金元素的凝固偏析加重,导致糊状区液相发生对流的倾向增大,从而促进了雀斑组织的形成。

关键词:高温合金;低温度梯度;定向凝固缺陷;雀斑;凝固偏析

文章编号:1004-0609(2018)-12-2494-05 中图分类号:TG249.5 文献标志码:A

镍基单晶高温合金因其具有良好的高温综合性能,是当前航空发动机和燃气轮机涡轮叶片及导向叶片的首选材料[1-4]。随着航空发动机及地面燃气轮机涡轮叶片外型和内腔结构复杂程度的增加,叶片尺寸的增大以及合金中难熔元素含量的增加,铸造单晶高温合金涡轮叶片在凝固缺陷控制方面面临越来越大的挑战[5-7]。

雀斑是单晶高温合金中的一种凝固缺陷,一般认为雀斑组织是由于高温合金在定向凝固过程中合金元素的微观偏析引起对流而形成的垂直排列、近共晶成分的一系列细小等轴晶[8-9]。通过数值模拟及透明有机物的定向凝固实验研究,发现雀斑的形成与凝固过程中的热质对流密切相关[10-11]。研究表明,影响雀斑形成的因素较多,合金成分[12-13]、凝固参数[8, 14]、铸件形状和尺寸[15]等因素均会影响凝固过程中的热质对流,进而对雀斑的形成造成影响。在雀斑组织方面,雀斑常出现于单晶铸件的表面[16],腐蚀后雀斑区域颜色较深,在低倍下为深色的斑点[15]。YANG等[17]采用能谱分析表明,IN625合金雀斑区域会出现MC碳化物、Laves相和δ-Ni3Nb等析出相。然而,有关第一代单晶高温合金的雀斑组织的研究尚不多见。

本研究通过在高速凝固法(HRS)定向凝固过程中增大隔热挡板与壳型之间的间隙,人为地制造出较低的定向凝固温度梯度(~30℃/cm),从而制备出包含雀斑组织的单晶试棒,并对常规HRS工艺制备的合金组织和包含雀斑的合金组织进行了对比研究。

1 实验

本研究所用材料为北京航空材料研究院自主研制的燃气轮机用第一代耐热腐蚀镍基单晶高温合金DD488,该合金性能与第一代单晶高温合金PWA1483相当。定向凝固实验在国产高速凝固法(HRS)15kg定向凝固炉上进行。设置两组定向凝固实验,分别为低温度梯度组和常规温度梯度组,其中,低温度梯度组定向凝固中通过调整定向凝固炉加热区与冷却区之间隔热挡板的位置,增大试棒壳型与挡板之间的横向间隙,从而获得较低的定向凝固温度梯度(~30℃/cm),常规温度梯度组的定向凝固则在正常炉况下进行(温度梯度~50℃/cm)。为了便于描述,将两组试棒分别命名为雀斑合金和常规合金。

金相试样采用1%HF+33%HNO3+33%CH3COOH+33%H2O溶液浸蚀。采用光学显微镜观察雀斑合金和常规合金的横截面枝晶组织,并统计其一次枝晶间距和共晶含量。沿雀斑组织切取纵截面试样,采用电子背散射衍射(EBSD)统计雀斑组织中的等轴晶晶粒尺寸。采用场发射扫描电子显微镜(FE-SEM)观察雀斑区域的微观组织,并利用扫描电子显微镜附带的能谱仪(EDS)分析雀斑组织中的碳化物成分。此外,利用EDS对雀斑合金和常规合金枝晶干与枝晶间的元素偏析系数Si进行测量,元素偏析系数Si定义为式(1)。

(1)

(1)

式中: 和

和 分别为元素i在枝晶干和枝晶间的浓度。Si>1表示合金元素i偏析于枝晶干,而Si<1表示合金元素i偏析于枝晶间。

分别为元素i在枝晶干和枝晶间的浓度。Si>1表示合金元素i偏析于枝晶干,而Si<1表示合金元素i偏析于枝晶间。

2 结果与分析

2.1 雀斑组织

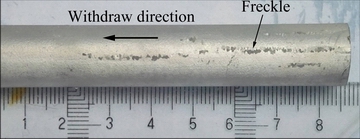

图1 雀斑组织的典型宏观形貌

Fig. 1 Macrography of freckle

雀斑合金试棒经低倍腐蚀后的典型宏观形貌如图1所示。由图1可见,大量细小的等轴晶呈链状分布于试棒的末端,与抽拉方向基本平行。由于HRS定向凝固工艺固有的特征,凝固初始阶段距离水冷结晶器比较近,凝固过程中热量散失得比较快,相应的温度梯度较高,避免了雀斑组织的产生;随着定向凝固过程的进行,散热方式由热传导向热辐射过渡,温度梯度大幅降低,随之产生的是合金元素凝固偏析的加重以及枝晶组织的粗化,因此雀斑组织多出现于铸件远离水冷结晶器的位置。

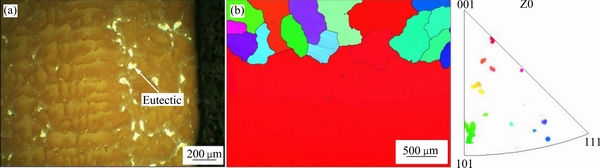

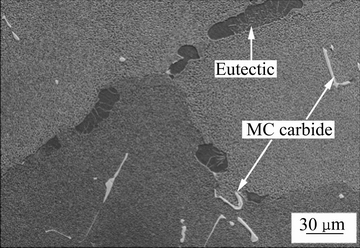

雀斑合金纵截面组织观察表明,雀斑组织区域的主要组成部分是等轴晶晶粒,此外还含较多的共晶组织(约4.64%),如图2(a)所示。这些小的等轴晶、枝晶碎片及共晶组织往往平行于重力方向,是凝固过程中发生热质对流冲断的枝晶形核并长大而成的。采用EBSD对雀斑组织中的等轴晶晶粒尺寸进行统计,结果表明其等轴晶晶粒平均尺寸为200μm。在扫描电镜下还能观察到在这些等轴晶的晶内和晶界上分布着颗粒状及棒状的碳化物,如图3所示。EDS能谱分析表明雀斑组织区域的碳化物为富含Ta元素的MC型碳化物。

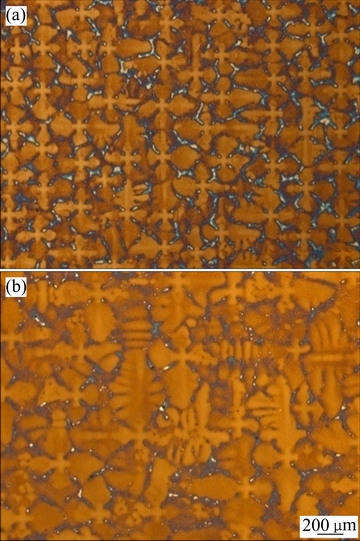

图4所示为雀斑合金与常规合金铸态枝晶光学组织。常规合金枝晶组织较为细小,一次枝晶间距仅为323μm,如图4(a)所示,而雀斑合金一次枝晶很粗大,其一次枝晶间距达到了704μm(见图4(b))。此外,相比常规合金,雀斑合金的二次及三次枝晶组织均比较发达。

2.2 合金元素凝固偏析

两种合金中Ti、Ta、Mo、Co、W等主要元素的偏析系数比较如图5所示。根据元素偏析系数的定义,元素偏析系数越接近1则偏析程度越小。对比常规合金和雀斑合金的元素偏析系数可以发现,雀斑合金中Ti、Ta、Mo等元素向枝晶间的偏析程度更为严重,而Co和W等元素向枝晶干的偏析更为严重。

2.3 雀斑形成机理分析

2.3.1 枝晶间距的影响

根据雀斑组织形成的瑞利数预测模型可以知道,当只考虑定向凝固温度梯度(G)和抽拉速率(R)时,可以将瑞利数(Ra)的表达式简化为式(2)所示的形式[16],可以看出,定向凝固过程的参数(定向凝固温度梯度和抽拉速率)对雀斑组织的形成有着很大的影响,而且定向凝固温度梯度和抽拉速率对瑞利数的影响程度不同,相对于抽拉速率,随着定向凝固温度梯度的降低瑞利数的变化更大。

图2 雀斑的纵截面光学组织(a)及EBSD晶粒取向(b)

Fig. 2 Optical image(a) and EBSD crystal orientation(b) of longitudinal section of freckle

图3 雀斑区域的扫描电镜组织

Fig. 3 SEM micrograph in region of freckles

图4 常规合金与雀斑合金铸态光学组织

Fig. 4 Optical images of as-cast normal alloy(a) and freckle alloy (b)

图5 常规合金和雀斑合金中主要元素的偏析系数(Si)比较

Fig. 5 Comparison of segregation coefficient (Si) of major elements between normal alloy and freckle alloy

(2)

(2)

一般来说,一次枝晶间距(λ1)是评价定向凝固温度梯度的重要指标之一。

在定向凝固过程中,温度梯度越小,冷却速率(G·V)就越低,形成的单晶合金组织的一次枝晶间距就越大。本实验中,常规合金由于在较高的温度梯度(~50℃)下进行定向凝固,从而合金的枝晶组织较细密,一次枝晶间距相应减小(见图2(b)),糊状区被枝晶分割成微小的熔池,抑制了微观偏析引起的对流,从而避免了雀斑组织的出现;而雀斑合金中的枝晶组织粗大,粗大的一次枝晶间距导致合金液在糊状区内的流动阻力减小,从而促进对流通道的形成并导致雀斑组织的出现。

2.3.2 凝固偏析的影响

定向凝固过程中元素偏析引起的密度反转程度是发生热质对流的主要驱动力,先进单晶高温合金中大量的难熔元素Re、W的添加,使合金抗蠕变性能提高的同时也使合金的凝固偏析加重。POLLOCK等[12]研究表明,随着Re、W含量的增加和Ta含量的减小,雀斑数量明显增加。本研究所用到的合金为不含Re的第一代单晶高温合金,根据凝固偏析系数的对比,雀斑合金中密度较大的W元素向枝晶干偏析的程度加大,增大了枝晶干熔体的密度,而密度较小的Ti元素向枝晶间偏析的程度加重,降低了枝晶间熔体的密度,这就使密度反转程度增大,即凝固界面前沿与糊状区内合金液的密度差增加,最终增大了枝晶干和枝晶间熔体对流的驱动力,促进雀斑组织形成。尽管雀斑合金中偏析于枝晶间的密度较大的Ta元素偏析程度也有所增加,然而需要注意的是Ta元素为枝晶间MC碳化物的主要形成元素,MC碳化物的形成消耗了大量的Ta元素,从而弱化了Ta元素对增大枝晶间熔体密度的作用,因此总体来说,合金的密度反转程度加重。综上所述,在涡轮叶片的定向凝固过程中,需要采取各种措施尽可能提高固液界面前沿的温度梯度,并且在保证凝固组织为定向或单晶的条件下尽可能地提高抽拉速率,从而达到抑制雀斑组织形成的目的。

3 结论

1) 通过在HRS法定向凝固过程中调整隔热挡板与壳型之间的间隙,获得了较低的定向凝固温度梯度(~30℃/cm)。

2) 采用低温度梯度HRS定向凝固工艺制备出了含有雀斑组织的试棒,其一次枝晶间距达到704μm,是常规HRS工艺合金的2.2倍。雀斑组织中含有较多平均晶粒尺寸为200μm的等轴晶晶粒,较多共晶组织及少量MC碳化物。

3) 低的定向凝固温度梯度使合金的一次枝晶间距增大,从而减小合金液在糊状区发生对流的阻力;此外,低的温度梯度增大了合金元素的凝固偏析程度,加重了固液界面前沿的密度反转程度,从而进一步增大了糊状区发生对流的趋势,并促进雀斑组织的产生。

REFERENCES

[1] REED R C. The superalloys: Fundamentals and applications[M]. Cambridge, UK: Cambridge University Press, 2006.

[2] POLLOCK T M, TIN S. Nickel-based superalloys for advanced turbine engines: Chemistry, microstructure and properties[J]. Journal of Propulsion and Power, 2006, 22(2): 361-374.

[3] POLLOCK T M. Alloy design for aircraft engines[J]. Nature Materials, 2016, 15: 809-815.

[4] KEARSEY R M, BEDDOES J C, JONES P, AU P. Compositional design considerations for microsegregation in single crystal superalloy systems[J]. Intermetallics, 2004, 12(7/9): 903-910.

[5] LIU Lin, HUANG Tai-wen, ZHANG Jun, FU Heng-zhi. Microstructure and stress rupture properties of single crystal superalloy CMSX-2 under high thermal gradient directional solidification[J]. Materials Letters, 2007, 61(1): 227-230.

[6] 高斯峰, 刘 林, 张 军, 肖俊峰, 张 炯. 镍基单晶高温合金DD403显微偏析[J]. 材料科学与工程学报, 2015, 33(6): 800-803.

GAO Si-feng, LIU Lin, ZHANG Jun, XIAO Jun-feng, ZHANG Jiong. Microsegregation of nickel-based single crystal superalloy DD403[J]. Journal of Material Science and Engineering, 2015, 33(6): 800-803.

[7] LI Ya-feng, LIU Lin, HUANG Tai-wen, SUN De-jian, ZHANG Jun, FU Heng-zhi. The formation mechanism, influencing factors and processing control of stray grains in nickel-based single crystal superalloys[C]// HARDY M, HURON E, GLATZEL U, et al. Proceedings of Superalloys 2016. Champion, PA: TMS, 2016: 293-301.

[8] ELLIOTT A J. Directional solidification of large cross-section nickel base superalloy castings via liquid-metal cooling[D]. Ann Arbor, MI: The University of Michigan, 2005.

[9] GIAMEI A, KEAR B. On the nature of freckles in nickel base superalloys[J]. Metallurgical and Materials Transactions B, 1970, 1(8): 2185-2192.

[10] COPLEY S M, GIAMEI A F,JOHNSONS M, HORNBECKER M F. The origin of freckles in unidirectionally solidified castings[J]. Metallurgical Transactions, 1970, 1: 2193-2204.

[11] SCHNEIDER M C, GU J P, BECKERMANN C, BOETTINGER W J, KATTNER U R. Modeling of micro-and macrosegregation and freckle formation in single-crystal nickel base superalloy directional solidification[J]. Metallurgical and Materials Transactions A, 1997, 28: 1517-1531.

[12] POLLOCK T M, MURPHY W H, GOLDMAN E H, URAM D L, TU J S. Grain defect formation during directional solidification of nickel base single crystals[C]// ANTOLOHCH S D, STUSRUD R W, MACKAY R A, et al. Proceedings of Superalloys 1992. Champion, PA: TMS, 1992: 125-134.

[13] TIN S. Carbon additions and grain defect formation in directionally solidified nickel base superalloys[D]. Ann Arbor, MI: The University of Michigan, 2001.

[14] 王 玲. 凝固参数对高温合金偏析行为和糊状区稳定性的影响研究[D]. 北京: 北京科技大学, 2007.

WANG Ling. Investigation of effects of solidification parameters on segregation behavior and stability in mushy zone of superalloys[D]. Beijing: University of Science and Technology Beijing, 2007.

[15] 马德新. 定向凝固的复杂形状高温合金铸件中的雀斑形成[J]. 金属学报, 2016, 52(4): 426-436.

MA De-xin. Freckle formation during directional solidification of complex castings of superalloys[J]. Acta Metallurgica Sinica, 2016, 52(4): 426-436.

[16] 高斯峰, 刘 林, 胡小武, 葛丙明, 张 军, 傅恒志. 镍基高温合金定向凝固过程中雀斑缺陷研究进展[J]. 材料科学与工程学报, 2010, 28(1): 145-151.

GAO Si-feng, LIU Lin, HU Xiao-wu, GE Bing-ming, ZHANG Jun, FU Heng-zhi. Review of freckle defects under directional solidification of nickel-based superalloys[J]. Journal of Material Science and Engineering, 2010, 28(1): 145-151.

[17] YANG Wan-hong, CHEN Wei, CHANG Keh-minn, MANNAN S, DEBARBADILLO J. Freckles in remelted niobium containing superalloys[C]// LORIA E A. Proceedings of Superalloys 718, 625, 706 and Various Derivatives. Champion, PA: TMS, 2001: 113-122.

Freckle of Ni-based single crystal superalloy prepared by low thermal gradient HRS process

CHEN Jing-yang, WU Wen-jin, LI Qing, ZHANG Ming-jun, TANG Xin, XIAO Cheng-bo

(Science and Technology on Advanced High Temperature Structural Materials Laboratory, Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The low thermal gradient during directional solidification was obtained by adjusting the distance between the baffle and the shell mold during traditional Bridgman (HRS) directional solidification process, and the single crystal superalloy bars containing freckles were prepared. The results show that the primary dendrite arm spacing of the normal HRS process alloy is 323μm, which contains 1.70% cast eutectic. The primary dendrite arm spacing of the alloy prepared by lower temperature gradient HRS process reaches 704μm,which is 2.2 times of that prepared by the normal HRS process. In addition, the secondary dendrite arm and thirdly dendrite arm are extremely developed under the low temperature gradient HRS process. The region of the freckles contains a large amount of equiaxed grains with a grain size of about 200μm and 4.64% eutectic, and there are MC carbides enriched in Ta. The coarsen primary dendrite arm spacing and aggravated solidification segregation, caused by low thermal gradient during directional solidification, increase the tendency of convection of the liquid phase in the mushy zone, and promote the formation of freckles.

Key words: superalloy; low thermal gradient; directional solidification defects; freckle; solidification segregation

Foundation item: Project(2016YFB0701402) supported by the National Key R&D Program of China;Project (51771020) supported by the National Natural Science Foundation of China;Project(2015ZE21006) supported by the Aeronautical Science Foundation of China

Received date: 2017-11-01; Accepted date: 2018-02-28

Corresponding author: CHEN Jing-yang; Tel: +86-10-62498316; E-mail: jychen126@126.com

(编辑 何学锋)

基金项目:国家重点研发计划资助项目(2016YFB0701402);国家自然科学基金资助项目(51771020);航空科学基金资助项目(2015ZE21006)

收稿日期:2017-11-01;修订日期:2018-02-28

通信作者:陈晶阳,高级工程师,博士;电话:010-62498316;E-mail: jychen126@126.com