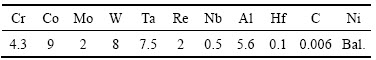

文章编号:1004-0609(2015)-11-3077-07

不同使用温度下DD6单晶高温合金的组织演变行为

史振学,刘世忠,熊继春,李嘉荣

(北京航空材料研究院 先进高温结构材料重点实验室,北京 100095)

摘 要:对完全热处理后的第二代单晶高温合金DD6分别在1100、1150、1200、1250、1300和1320 ℃温度下保温1 h后再进行空冷处理。用扫描电镜(SEM)分析经不同温度处理后合金的显微组织,通过JMatPro相图计算和差热分析讨论合金的组织演变机理。结果表明:DD6合金在1100、1150和1200 ℃保温处理后,γ′相尺寸稍有增大;1250 ℃保温处理后,γ′相尺寸明显增大,大小分布极不均匀,大部分γ′/γ相界面为锯齿状;1300 ℃保温处理后,少部分未完全回溶的γ′相具有锯齿状的γ′/γ相界面,大部分γ′相回溶后重新析出不规则、细小的γ′相;1320 ℃保温处理后,γ′相完全回溶后重新析出不规则、细小的γ′相。合金经不同温度处理后,γ′相长大或溶解、或重新析出的相大小、形态和体积分数均不相同。在1100 ℃热处理后,合金中γ′相体积分数比完全热处理合金稍有增加;在其他温度下处理后,合金中γ′相体积分数比完全热处理合金的均不同程度地减小。合金完全热处理后和经过1320 ℃保温处理后,基体通道中没有二次γ′相析出;而在1100~1300 ℃热处理后,基体通道中析出细小的二次γ′相。合金在不同温度处理后得到明显不同特征的组织,表明使用温度对合金的组织有显著的影响。

关键词:单晶高温合金;DD6合金;γ′相;组织演变

中图分类号:TG132.3 文献标志码:A

Microstructure evolution behavior of DD6 single crystal superalloy at different using temperatures

SHI Zhen-xue, LIU Shi-zhong, XIONG Ji-chun, LI Jia-rong

(Science and Technology on Advanced High Temperature Structural Materials Laboratory,

Beijing Institute of Aeronautical Materials, Beijing 100095, China)

Abstract: The second generation single crystal superalloy DD6 after standard heat treatment was heat-treated at 1100, 1150, 1200, 1250, 1300 and 1320 ℃ for 1 h, respectively, and was then air cooled. The microstructures of the alloy heat-treated at different temperatures were investigated by SEM. The microstructure evolution mechanism of the alloy was estimat using JMatPro software and DSC.The results show that the size of γ′ phase slightly increases after DD6 super alloy heat-treatment at 1100, 1150 and 1200 ℃. The size of γ′ phase increases apparently and its size distribution is very uneven after heat treatment at 1250 ℃. The small part of γ′ phase has serrated γ′/γ phase surface as a result of incomplete solution and the irregular small γ′ phase is major after heat-treatment at 1300 ℃. While the irregular small γ′ phase precipitates again, followed complete solution after heat-treatment at 1320 ℃. The size, shape and volume fraction of γ′ phase vary with the heat treatment temperatures because it grows, dissolves or precipitates again. The volume fraction of γ′ phase decreases to different degrees after heat-treatment at different temperatures except 1100 ℃. There is no fine second γ′ phase in the γ matrix channel of the alloy after standard heat-treatment and heat-treatment at 1320 ℃. But the fine second γ′ phase precipitates in the γ matrix channel after heat-treatment at temperature range of 1100-1300 ℃. Different microstructures are obtained after heat-treatment at different temperatures, which indicates that the using temperature has obvious effect on the microstructure of the alloy.

Key words: single crystal superalloy; DD6 alloy; γ′ phase; microstructure evolution

镍基单晶高温合金具有优良的高温性能,良好的抗氧化性能和抗热腐蚀性能,良好的抗疲劳强度、断裂韧性和塑性等综合性能,现在已替代传统的多晶高温合金,是目前制造先进航空发动机涡轮叶片的主要材料[1-4]。DD6合金为我国自主研制的第二代镍基单晶高温合金,具有高温强度高、综合性能好、组织稳定及铸造工艺性能好等优点,其拉伸、持久、抗氧化及耐热腐蚀等性能达到甚至部分超过国外广泛应用的第二代单晶高温合金PWA1484、René N5、CMSX-4的性能[5-6]。与第一代DD3单晶高温合金相比,DD6合金承温能力提高了约40 ℃,适用于制作1100 ℃以下工作的具有复杂内腔的燃气涡轮工作叶片等高温零件[7]。为了提高航空发动机的性能,关键是提高涡轮叶片的工作温度,这对单晶高温合金的承温能力提出了更高的要求[8]。对确定成分的单晶高温合金,性能主要取决于合金组织。不同的合金组织对应于不同的合金性能[9-10]。镍基单晶高温合金完全热处理后的显微组织主要由γ 基体和γ′强化相组成,其力学性能在很大程度上取决于γ′强化相的尺寸、形态、分布和体积分数[11-12]。涡轮叶片工作条件苛刻,所受温度环境条件十分复杂,使用过程中有时会超过合金理想状态的使用温度。γ′相的形貌受界面能和应变能控制,较高的使用温度肯定对合金的组织产生影响,进而影响合金的性能。因此,有必要开展较高使用温度对合金组织影响的研究,为合金的发展和安全使用提供依据。通过这方面工作的系统研究,将使用温度与组织建立对应关系,就能够通过解剖分析服役过叶片的显微组织,大致推算出涡轮叶片工作的最高温度,为发动机设计人员提供技术支持。本文作者对标准热处理DD6合金在不同温度进行保温热处理,以模拟合金的使用温度,分析了不同使用温度下合金的组织演变特征,并通过相图计算和差热分析讨论了合金组织演变机理。

1 实验

实验用DD6母合金的名义化学成分如表1所列。在高温度梯度真空定向凝固炉中采用螺旋选晶法制备[001]取向的DD6单晶高温合金试棒。用劳埃X射线背反射法确定单晶试棒的结晶取向,试棒的[001]结晶取向与主应力轴方向的偏差在10°以内。试样经(1290 ℃,1 h)+(1300 ℃,2 h)+(1315 ℃,4 h,AC)+(1120 ℃,4 h,AC)+(870 ℃,32 h,AC)标准热处理后,分别在1100、1150、1200、1250、1300和1320 ℃温度下保温1 h后进行空冷处理。用扫描电镜观察合金标准热处理组织和不同温度处理后的组织,采用单位面积计算法测定合金γ′相的体积分数,采用JMatpro软件对合金进行热力学计算,采用热分析法确定合金的相转变温度。采用d3 mm×2 mm的小圆片试样,在NETZSCH STA409型热分析仪上进行热分析,升温速率和降温速率均为10 ℃/min。

表1 DD6合金的名义成分

Table 1 Nominal chemical compositions of DD6 alloy (mass fraction, %)

2 结果与分析

2.1 合金的标准热处理组织

图1所示为DD6合金经过固溶与二级时效处理后的标准热处理组织。单晶高温合金的铸态组织中存在共晶、枝晶偏析等组织不均匀性。通过固溶和时效处理,使单晶高温合金获得立方化较好、合适尺寸、高体积分数的γ′相组织,使单晶高温合金具有最优的综合性能,因此,单晶高温合金使用前都要进行热处理。对DD6合金采用两步热处理:固溶处理以消除共晶、组织均匀化,减小合金元素偏析;时效热处理以调整γ′相的数量、尺寸和形状, 获得合适的γ′相组织。由图1看出,合金经标准热处理后,γ′相立方化良好,平均尺寸为0.43 μm,体积分数约为61%(见表2),γ基体通道的平均宽度为51 nm,基体通道中无细小的二次 γ′相析出,这与文献[13]的研究结果相同。

图1 经标准热处理后DD6合金的SEM像

Fig. 1 SEM images of DD6 alloys after standard heat treatment

2.2 不同温度处理后DD6合金的显微组织

图2所示为不同温度处理后DD6合金的γ′相组织。合金经1100 ℃保温处理后,合金中γ′相立方化程度稍有增加,尺寸稍有增加;基体通道变得比较平直,通道中有细小的二次γ′相析出,γ′相的体积分数比标准热 处理后的稍有增加。1150 ℃保温处理后,合金中γ′相立方化程度增加,尺寸稍有增大,而且其尺寸大小均匀化程度最好;基体通道更加平直,通道中也有细小的二次γ′相析出。1200 ℃保温处理后,合金中γ′相立方化程度增大,其尺寸大小、均匀化程度均降低;基体通道明显变宽,通道中析出尺寸较大的二次γ′相。1250 ℃保温处理后,合金中γ′相尺寸明显增大,其尺寸大小非常不均匀,γ′/γ相界面为锯齿状;基体通道中也析出了细小的二次γ′相。1300 ℃保温处理后,合金中少部分为锯齿状界面的γ′相,大部分为不规则、近似立方、尺寸较小的新析出γ′相;基体通道中也析

出了细小的二次γ′相。1320 ℃保温处理后,组织中全部为不规则、尺寸较小的新析出相γ′相;基体通道中没有析出二次γ′相。

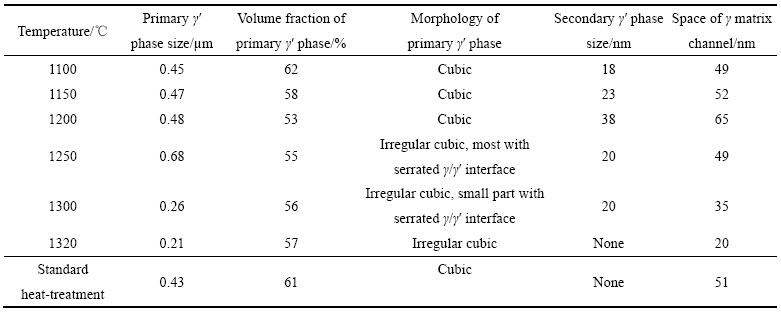

2.3 合金不同组织的定量分析

对图2中不同温度处理后合金的组织特征进行了详细的定量统计分析,并与图1标准热处理组织进行对比,结果见表2。从1100~1200 ℃,随着热处理温度的升高,基体通道变宽,对应于γ′相的体积分数逐渐减小;在1200~1300 ℃,基体通道变窄,对应于γ′相的体积分数又逐渐增加。但相对于标准热处理后,不同温度处理后,γ′相的体积分数都出现不同程度的减小。合金中γ′相的形态在1100、1150、1200 ℃保温处理后影响不大,而在1250和1300 ℃保温处理后γ′相的形态变化较大。

3 讨论

3.1 相图计算和差热分析

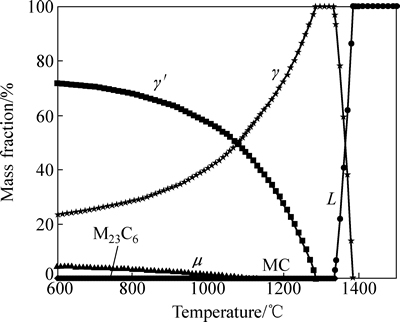

DD6合金在不同温度下处理得到不同特征的组织,主要是因为在不同温度下处理后,γ′相长大、溶解或析出,造成组织特征不同。采用JMatPro计算软件和热分析法分别分析了合金的凝固特征。首先分析了γ′相的溶解温度。图3所示为利用JMatPro相图计算软件及相应的单晶高温合金数据库计算出的DD6合金平衡相与温度的关系。

由图3看出,在1100~1320 ℃的温度区间内,合金主要由γ基体和γ′相及极少量的碳化物组成。由于DD6合金中C含量极少,因此,其含量随温度升高几乎不变化。而γ′相随着温度增加逐渐回溶到γ基体中,完全回溶温度接近1300 ℃。

表2 不同温度热处理后DD6合金的组织特征

Table 2 Microstructure characteristics of DD6 alloy after heat treatment at different temperatures

图2 经不同温度热处理后DD6合金的显微组织

Fig. 2 Microstructures of DD6 alloy after heat-treatment at different temperatures

图3 DD6合金平衡相与温度的关系

Fig. 3 Calculated content of precipitation phases with temperature for DD6 alloy

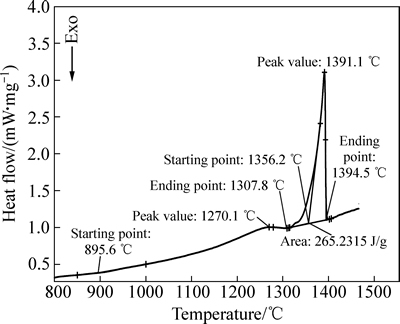

图4所示为DD6合金升温的DSC曲线。由图4可看出,DD6合金在895.6 ℃时γ′相开始回溶,1270.1 ℃时有一个较小的吸热峰,这里对应大量γ′相的回溶温度,γ′相完全回溶温度为1307.8 ℃,合金的初熔温度为1325 ℃。

图4 DD6合金的DSC曲线

Fig. 4 DSC curve of DD6 alloy

3.2 DD6合金组织演变

DD6合金标准热处理后,基体通道中没有析出二次γ′相。本文作者所在课题组的前期研究表明,DD6 合金在固溶和一次时效处理后,基体通道内也存在大量的二次γ' 相,但在870 ℃二次时效保温过程中,基体通道内的二次γ′相得到完全溶解;并且在随后冷却过程中,基体中γ′相形成元素的过饱度较小,γ′相析出驱动力降低,基体通道内没有二次γ′相析出[13]。这与KAKEHI 在单晶高温合金热处理研究中的结果相同[14]。

DD6合金在1100、1150、1200和1250 ℃保温处理时,热处理温度低于γ′相的大量回溶温度。在这样的温度保温过程中,两个过程同时进行,一方面为γ′相长大过程,一方面为γ′相的回溶过程。γ′相按照Ostwald方式长大,大的γ′相长大,小的γ′相溶解。γ′相的长大受合金元素扩散的控制,其长大规律遵循LSW粗化理论[15]:

(1)

(1)

式中:rt为沉淀粒子在时效t后的平均半径;r0为沉淀粒子在时效前的平均半径;K为与时效温度有关的系数;t为时效时间。根据Arrhenius公式[16]:

D=D0 exp[-Q/(RT)] (2)

式中:D为扩散系数;D0为扩散常数;R为摩尔气体常数;Q为激活能;T为温度。

由式(2)可知,温度是影响合金元素扩散的主要因素,温度越高,扩散系数越大,合金元素的扩散速度越快,γ′相的长大速度越快。因而热处理温度越高,经过相同热处理时间,一次γ′相的尺寸越大。由表2看出,热处理温度在1100~1250 ℃时,一次γ′相的尺寸逐渐增加。

在保温过程中,部分γ′相得到回溶,基体通道宽度增加。随后在空冷过程中,基体通道中重新析出细小的二次γ′相。从1100 ℃到1150 ℃再到1200 ℃时,随着热处理温度的升高,γ′相回溶量增加,基体通道变宽,二次γ′相尺寸也相应增加。但在1250 ℃较高温度的保温过程中,γ′相尺寸增加量较大,γ′相回溶量也较大,基体通道也较宽,在冷却过程中γ′相的析出方式与较低温度处理时的有所不同。γ′相有两种析出方式:一种是依附于已时效析出的γ′相上继续长大;由于这种长大方式具有异质形核的方式,因此这种析出长大方式比较容易进行。MIYAZAKI等[17]指出,考虑到γ′相各向异性的弹性应变能以及界面能,此时由于γ′相局部存在较高的弹性应变能,再次析出的γ′相将沿(011)面析出使能量降低[17]。因此γ′相析出长大具有方向性,沿着(011)面析出长大较快,这就造成了γ′/γ相界面呈现除锯齿状的界面,如图2(d1)~(d3)所示。另一种析出方式与1100 ℃、1150 ℃或1200 ℃较低温度下处理时的相同。由于γ′相形成元素距原析出γ′相的距离较远,来不及扩散到γ′/γ相界面上,因而在基体通道中析出了细小的二次γ′相[18]。

当合金在1300 ℃热处理时,由于温度高于γ′相大量回溶温度而又低于γ′相的完全回溶温度,因此,在保温过程中,绝大部分γ′相回溶,从图2(e1)中也可看出,只剩下少量部分γ′相未回溶。在冷却过程重新析出大量的、细小不规则的γ′相,只有很少的部分γ′相依附于未完全回溶的原γ′相重新析出,形成了锯齿状界面。在锯齿状界面之间基体通道中,距离未完全回溶的原γ′相较远处,析出了细小的二次γ′相。

DD6合金在1320 ℃热处理时,由于温度高于γ′相的完全回溶温度而小于合金的初熔温度,因此,在此温度保温过程中,γ′相完全回溶变成γ相,合金未形成初熔组织。在冷却过程中重新析出细小不规则的γ′相。由于γ′相全部回溶后又重新析出,没有机会形成细小的二次γ′相。

相计算表明,1300 ℃以上时,DD6 合金平衡状态的γ′相含量接近0;而在600 ℃以下时,DD6 合金平衡状态的γ′相质量分数为72%,在1100、1150、1200、1250 ℃下合金平衡状态的γ′相质量分数分别为47%、37%、28%和15%。DD6 合金在1315 ℃完全固溶后直接冷却到室温,基体中γ′相形成元素高度过饱和,促使γ′相在冷却过程中大量析出。再经过二级时效处理,γ′相的体积分数为61%。不同温度处理后,γ′相的体积分数经历先增加后降低又增加的过程。合金在不同温度处理时,γ′相的长大、溶解又重新析出的相大小、形态和体积分数不同,一次γ′相的体积分数变化要具体分析。合金在1100 ℃处理时,γ′相长大为主要因素,基体通道变小,一次γ′相的体积分数增加。在1150和1200 ℃热处理时,γ′相溶解逐渐增多,冷却过程中基体通道中析出细小的γ′相,基体通道变大,因此,一次γ′相的体积分数又逐渐降低。在1250、1300和1320 ℃热处理时,γ′相溶解进一步增多乃至全部回溶,冷却过程中析出的γ′相也相对增加,因此,一次γ′相的体积分数又逐渐增加。

综上所述,合金在不同温度处理后得到明显不同特征的组织,表明使用温度对合金的组织有显著的影响,对合金性能产生的影响还需进一步的研究。

4 结论

1) DD6合金标准热处理后,γ′相立方化良好。在1100、1150、1200 ℃保温处理后,γ′相的尺寸稍有增加。1250 ℃保温处理后,γ′相尺寸明显增加,大小分布极不均匀,大部分γ′/γ相界面为锯齿状。在1300 ℃保温处理后,少部分未完全回溶的γ′相为锯齿状的γ′/γ相界面,大部分为γ′相回溶后重新析出不规则、细小的γ′相。在1320 ℃保温处理后,γ′相全部回溶后重新析出不规则、细小的γ′相。

2) 在不同温度处理后,γ′相的体积分数经历先增加后降低又增加的过程。DD6合金在不同温度处理后,γ′相的长大、溶解或重新析出使其大小、形态和体积分数不同。在1100 ℃处理时,γ′相长大为主要因素,γ′相的体积分数增加。在1150 ℃、1200 ℃处理时,γ′相溶解逐渐增多,冷却析出细小的γ′相,基体通道变大,γ′相的体积分数逐渐降低。在1250、1300、1320 ℃处理时,γ′相溶解继续增加乃至全部回溶,冷却析出的γ′相也相对增加,γ′相的体积分数又逐渐增加。与标准热处理后的合金相比,除1100 ℃处理后γ′相体积分数稍有增加外,其他温度处理后的都不同程度地减小。

3) DD6合金在标准热处理后和经过1320 ℃保温处理后,基体通道中没有二次γ′相,而在1100~1300 ℃处理后,基体通道中都析出了细小的二次γ′相。

4) DD6合金在不同温度处理后得到明显不同特征的组织,表明使用温度对合金组织具有显著的影响。

REFERENCES

[1] ARGENCE D, VERNAULT C, DESVALLEES Y, FOURNIER D. MC-NG: Generation single crystal superalloy for future aeronautical turbine blades and vanes[C]//POLLOCK T M, POLLOCK T M, KISSINGER R D, BOWMAN R R, GREEN K A, MCLEAN M, OLSON S, SCHIRRA J J. Superalloys 2000. Warrendale: TMS, 2000: 829-837.

[2] WALSTON S, CETEL A, MACKAY R, O′HARA K, DUHL D, DRESHFIELD R. Joint development of a fourth generation single crystal superalloy[C]//GREEN K A, POLLOK T M, HARADA H, HOWSON T W, REED R C, SCHIRRA J J, WALSTON S. Superalloys 2004. Pennsylvania, PA: TMS, 2004: 15-24.

[3] 田素贵, 李秋阳, 郭忠革, 薛永超, 曾 征, 舒德龙, 谢 君. 固溶温度对单晶镍基合金成分偏析和蠕变行为的影响[J]. 中国有色金属学报, 2014, 24(3): 668-677.

TIAN Su-gui, LI Qiu-yang, GUO Zhong-ge, XUE Yong-chao, SHU De-long, XIE Jun. Influence of solution temperature on composition segregation and creep behaviors of single crystal nickel based superalloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(3): 668-677.

[4] SHI Z X, LI J R, LIU S Z, WANG X G. Creep properties and microstructure evolution of a nickel-based single crystal superalloy at different conditions[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(8): 2536-2543.

[5] LI J R, ZHONG Z G, TANG D Z, LIU S Z, WEI P, WU Z T, HUANG D, HAN M. A low-cost second generation single crystal superalloy DD6[C]//POLLOCK T M, KISSINGER R D, BOWMAN R R, GREEN K A, MCLEAN M, OLSON S, SCHIRRA J J. Superalloys 2000. Warrendale, PA: TMS, 2000: 777-783.

[6] LI J R, ZHAO J Q, LIU S Z, HAN M. Effects of low angle boundary on the mechanicla properties of single crystal superalloy DD6[C]//REED R C, GREEN K A, CARON P, GABB T P, FAHRMANN M G, HURON E S, WOODARD S A. Superalloys 2006. Pennysylvania: TMS, 2008: 443-451.

[7] 中国航空材料手册编辑委员会. 中国航空材料手册编辑委员会[M]. 2版. 北京: 中国标准出版社, 2002: 812-813.

The editional committee of China aefonautical materials handbook. China aeronautical materials handbook[M]. 2nd ed. Beijing: China Standard Press, 2002: 812-813.

[8] WALSTON W S, O′HARA K, ROSS E W, POLLOCK T M, MURPHY W H. RenéN6: Third generation single crystal superalloy[C]//KISSINGER R D, DEYE D J, ANTON D L, CETEL A D, NATHAL M V, POLLOCK, T M, WOODFORD D A. Superalloys 1996. Warrendale, PA: TMS, 1996: 27-34.

[9] WILSON B C, CUTLER E R, FUCHS G E. Effect of solidification parameters on the microstructures and properties of CMSX-10[J]. Materials Science and Engineering A , 2008, 479: 356-364.

[10] LAMM M, SINGER R F. The effect of casting conditions on the high-cycle fatigue properties of the single crystal nickel-base superalloy[J]. Metallurgical and Materials Transactions A, 2007, 38: 1177-1183.

[11] SHI Z X, LIU S Z, W X G, LI J R. Effect of solution cooling method on the microstructure and stress rupture properties of a single crystal superalloy[J]. Materials Science Forum, 2015, 816: 513-517.

[12] WANG J, ZHANG L T, CHEN K, SUN N R, SHAN A D. Morphology and chemical composition of γ′/γ phases in Re-containing Ni-based single crystal superalloy during two-step aging[J]. Transaction Nonferrous Metal Society of China, 2011, 21(7): 1513-1517.

[13] 喻 健, 李嘉荣, 史振学, 王效光, 刘世忠, 赵金乾. DD6 单晶高温合金二次γ'相的析出[J]. 稀有金属材料与工程, 2013, 42(8): 1654-1658.

YU Jian, LI Jia-rong, SHI Zhen-xue, WANG Xiao-guang, LIU Shi-zhong, ZHAO Jin-qian. Precipitation of secondary γ' phase of DD6 single crystal superalloy[J]. Rare Metal Materials and Engineering, 2013, 42(8): 1654-1658.

[14] KAKEHI K. Influence of secondary precipitates and crystallographic orientation on the strength of single crystals of a Ni-based superalloy[J]. Metallurgical and Materials Transactions A, 1999, 30(5): 1249-1259.

[15] LIFSHITZ M, SLYOZOV V V. The kinetics of precipitation from supersaturated solid solution[J]. Journal of Physics and Chemistry of Solids, 1961, 19: 35-50.

[16] 冯 端. 金属物理[M]. 北京: 科学技术出版社, 1998: 492-493.

FENG Duan. Metal physics[M].Beijing: Science and Technology Press, 1998: 492-493.

[17] MIYAZAKI T, KOYAMA T, DOI M.Effect of coherent strain energy on γ′/γ phase in Ni-Al-Ti alloys[J]. Acta Metallurgical Material, 1994, 42(10): 3417-3424.

[18] 任英磊, 金 涛, 管恒荣, 胡壮麒. 热处理制度对一种单晶镍基高温合金γ′相形貌演化的影响[J]. 机械工程材料, 2001, 25(4): 7-10.

REN Ying-lei, JIN Tao, GUAN Heng-rong, HU Zhuang-qi. The effect of long aging time at high temperature on the structure evolution of γ′ phase for a nickel base single crystalline superalloy[J]. Materials for Mechanical Engineering, 2001, 25(4): 7-10.

(编辑 龙怀中)

收稿日期:2015-02-19;修订日期:2015-09-05

通信作者:史振学,高级工程师,博士;电话:13651102659,010-62498312;E-mail:shizhenxue@126.com