文章编号:1004-0609(2011)08-1794-07

Mg15Al镁合金ECAP变形过程中β相的

碎化机理及动态析出行为

王红霞1, 2,周康康1, 2,梁 伟1, 2,龚家林1, 2,曹晓卿1,赵兴国1, 2

(1. 太原理工大学 材料科学与工程学院,太原 030024;

2. 太原理工大学 新材料界面科学与工程教育部重点实验室,太原 030024)

摘 要:为了改善Mg-Al系合金中β-Mg17Al12相的形态、大小和分布,充分发挥其沉淀强化作用,利用能产生强塑性变形的等通道转角挤压法挤压Mg15Al高铝镁合金;采用XRD、SEM、EDS和TEM研究不同道次ECAP挤压后Mg15Al高铝镁合金中β-Mg17Al12相的演变。结果表明:ECAP强塑性变形能够有效地碎化Mg15Al高铝镁合金中粗大的网状共晶β-Mg17Al12相;随挤压道次的增加,β-Mg17Al12相尺寸逐渐减小,挤压4道次后,网状共晶β-Mg17Al12相被破碎成尺寸在5 μm以下的小块,分布得到一定改善;由于高应力与高温的共同作用,挤压2道次后,部分β-Mg17Al12相发生回溶,挤压4道次后,在α-Mg基体中动态析出许多尺寸在200 nm以下的粒状β-Mg17Al12相。

关键词:Mg15Al高铝镁合金; β-Mg17Al12相;碎化机理;动态析出行为

中图分类号:TG 146.2 文献标志码:A

Fragmentation mechanism and dynamic precipitation behavior of β phase in Mg15Al magnesium alloy during ECAP

WANG Hong-xia1, 2, ZHOU Kang-kang1, 2, LIANG Wei1, 2, GONG Jia-lin1, 2, CAO Xiao-qing1, ZHAO Xing-guo1, 2

(1. College of Materials Science and Engineering, Taiyuan University of Technology, Taiyuan 030024, China;

2. Key Laboratory of Interface Science and Engineering in Advanced Materials, Ministry of Education,

Taiyuan University of Technology, Taiyuan 030024, China)

Abstract: In order to improve the morphology, size and distribution of β-Mg17Al12 phase in the Mg-Al alloy and fulfill the precipitation strengthening effect of β-Mg17Al12 phase, Mg15Al high-aluminum magnesium alloy was processed by equal channel angular pressing. The evolution of β-Mg17Al12 phase in the Mg15Al high-aluminum magnesium alloy after equal channel angular pressing (ECAP) for different passes was investigated by XRD, SEM, EDS and TEM. The results show that the coarse network eutectic β-Mg17Al12 phase in Mg15Al high aluminum-magnesium alloy can be effectively fragmentized by ECAP. With increasing extrusion passes, the size of β-Mg17Al12 decreases. After ECAP for 4 passes, β phase is fragmentized into small lump-shaped particles with size of less than 5 μm and the distribution of β phase becomes more homogeneous. Meanwhile, due to the large shear stress and high temperature, the dissolution of β phase in matrix occurs after ECAP for 2 passes and a large number of granular β phase with the size below 200 nm precipitates from the matrix after ECAP for 4 passes.

Key words: Mg15Al high-aluminum magnesium alloy; β-Mg17Al12 phase; fragmentation mechanism; dynamic precipitation behavior

等通道转角挤压技术是近年来发展的一种制备块体超细晶、甚至纳米晶材料的新工艺。此工艺在挤压过程中不改变试样的尺寸,容易实现深度塑性变形,从而获得超细晶粒或纳米晶粒,同时可使合金强塑性提高[1]。因此,等通道转角挤压技术具有极大的工业应用潜力。目前,人们已成功地利用ECAP法制备了铝合金[2]、铜合金[3]、钛合金[4]、低碳钢[5]和镁合金[6-7]的块体超细晶材料,并对其进行了大量的研究。但这些研究主要集中在如何利用强变形使合金晶粒细化至纳米级,以大幅度提高合金的力学性能。与此相应的微观研究也主要集中在强变形工艺方法及其对合金基体晶粒细化、位错亚结构研究。然而,ECAP过程中,第二相的碎化机理尚未得到深入研究。王素梅等[8]研究了ECAP挤压对2A12铝合金的影响,指出组织中的Al2Cu化合物在剪切力的作用下由针状变成颗粒状,这是由于变形过程中大量的位错将第二相粒子切断所致。HORITA等[9]研究了ECAP后Al-Mg-Si合金第二相的变化,发现棒状Mg2Si由于ECAP多道次的剪切变形形成形状圆滑的块状,并有部分发生溶解。彭北山等[10]研究了Al-Cu二元合金的θ′相在ECAP挤压作用下的破碎行为,认为θ′相在亚晶界面、扭转带及剪切带界面的溶解导致其破碎和球化。以上研究表明,ECAP对铝合金中的第二相碎化作用的研究较多,而对镁合金中第二相的碎化机理尚未见报道。Mg-Al合金中的β-Mg17Al12相对其有很好的强化作用,但β-Mg17Al12相一般在Mg-Al合金凝固末期形成,易聚集在晶界连成网状,对合金力学性能有极大损坏[11]。因此,研究β-Mg17Al12相碎化及其碎化机理非常有意义。本文作者选择β-Mg17Al12相含量较多的Mg15Al合金为研究对象,对其进行ECAP挤压,考察挤压过程中第二相的变化,分析其碎化机理及析出行为。

1 实验

实验用99.8%纯镁和99.9%纯铝配制Mg15Al二元合金。镁合金熔炼试验在SXZ-5-2电阻炉中进行,使用涂刷ZnO涂料的不锈钢坩锅,一次装炉量400 g,熔炼时先加入镁锭,用RJ-2熔剂保护,熔炼温度为973 K。镁锭熔化后添加15%纯Al,待其熔清后搅拌2 min,静置10 min,最后浇入d 20 mm×150 mm的圆柱形金属模中。在距金属模试样底部25 mm处截取铸态检测试样后,将其余棒料线切割加工成10 mm×10 mm×50 mm试样,利用WDW-100KN型电子万能试验机在553 K、挤压速率为2.4 mm/min,以BC方式进行等通道挤压1、2和4次(每次挤压前,试样按相同的方向旋转90°,再进行下一道次的挤压[12]),挤压前或两次挤压间,试样要在电阻加热炉中保温 15 min,以便使试样与模具温度保持一致。挤压使用带有起偏角的模具[13],模具参数为Ψ=20?、Φ=90?,模具起偏角可起到相当于增加背压力的作用,降低试样开裂倾向。润滑剂为石墨。挤压后在试样中部沿平行于挤压方向的侧面取样,如图1所示。采用KY2 2000型X射线衍射仪(XRD)对Mg15Al合金进行物相分析,利用JSM-6700F扫描电镜和JEM-2010透射电镜进行组织观测。

图1 挤压态合金取样及组织观察方向示意图

Fig.1 Schematic diagram showing sampling and observing direction of ECAP sample: (a) Sampling position and microstructure observing direction; (b) Die for ECAP

2 结果与分析

2.1 铸态Mg15Al镁合金的物相分析及β相的形貌

利用SEM、EDS和XRD对铸态Mg15Al合金进行分析,其结果如图2所示。图2(a)所示为铸态Mg15Al镁合金的SEM像,图2(b)和(c)所示为对应于图2(a)不同组织的EDS谱分析结果,图2(d)所示为与图2(a)对应试样的XRD谱。由图2(a)可见,铸态Mg15Al合金由深灰色的基体相和亮灰色,并连成网状的第二相组成。根据图2(b)和(c)可知,深灰色的基体相是α-Mg固溶体,其中Al的固溶量为9.85%(质量分数)。亮灰色的相也是由Mg和Al两种元素组成,但是Mg与Al的摩尔比为51.21:39.94(约为1.28),接近于β-Mg17Al12相。这与XRD检测一致(见图2(d))。因此,结合Mg-Al二元相图[11],铸态Mg15Al镁合金是由含Al量较高的α-Mg固溶体和网状共晶β-Mg17Al12相组成。

图2 铸态Mg15Al合金的SEM像、EDS和XRD谱

Fig.2 SEM image(a), EDS spectra((b), (c)) and XRD pattern(d) of as-cast Mg15Al magnesium alloy

2.2 ECAP变形过程中共晶β相的形貌与分布变化

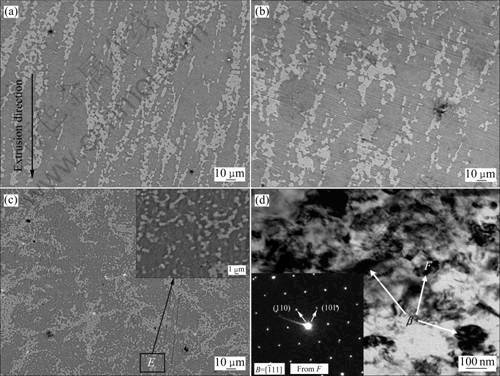

图3所示为通过不同道次等通道挤压后Mg15Al镁合金的SEM及TEM像,图3清楚地显示了变形过程中β-Mg17Al12相的变化。由图3(a)可见,经过1道次ECAP挤压,粗大网状β-Mg17Al12相沿着挤压方向伸长,部分网仍然连着,但已经严重变形,部分网已被挤碎且分离开来;经2道次挤压后,β相基本断网,形成不规则的块状,部分小块已经弥散开,部分仍然聚集在一起,如图3(b)所示;经4道次挤压后,块状β相继续破碎,形成5 μm以下的形状不规则的小块(见图3(c)右上角小图),弥散度增加,但仍有部分小颗粒聚集在一起,没有完全弥散开,见图3(c),而且通过高倍TEM观察发现,初晶α-Mg基体中还析出许多尺寸小于200 nm且均匀细小的粒状β相,如图3(d)所示。

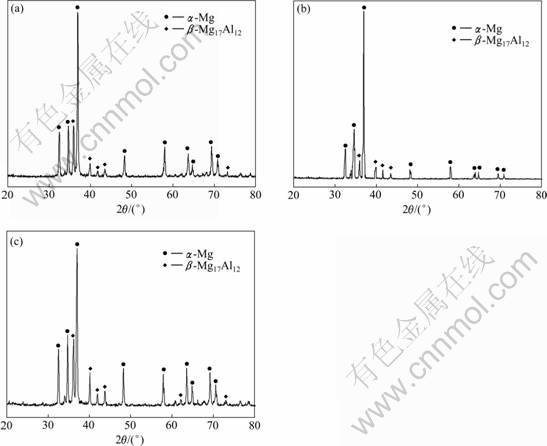

图4所示为挤压不同道次的Mg15Al合金的XRD谱,对比图1(d)可知,等通道挤压后,合金的相组成没有发生变化,依然由α-Mg和β-Mg17Al12相组成。但对比图4(a)、(b)和(c)可知,经不同道次挤压后,α-Mg衍射峰强度变化不大,而β-Mg17Al12相衍射峰强度则明显不同。挤压1道次后,与铸态时β-Mg17Al12相衍射峰强度相比基本不变;挤压2道次后,β-Mg17Al12相衍射峰强度急剧下降;挤压4道次后,β-Mg17Al12相衍射峰强度大幅升高,超过了铸态时β-Mg17Al12相衍射峰强度。由此可见,在等通道挤压过程中,挤压2道次后,β-Mg17Al12相发生了回溶,数量明显下降,挤压4道次后,可能析出了大量的β-Mg17Al12相,使其数量急剧增加,这与图3的组织观察结果一致。

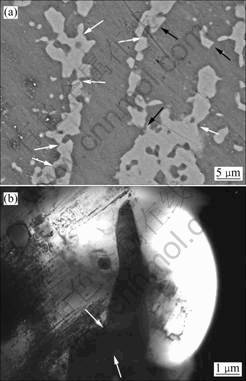

图5所示为挤压1道次后β相的高倍SEM和TEM像。由图5(a)可见,挤压1道次后,铸态组织网状共晶β相明显断开,在共晶β相较薄的部位出现许多缩颈与沟槽,这是溶解和弯折现象(见图5(a)中白色箭头),有些部位出现因应力而拉断现象,两半β相边部较粗糙,类似断口,有些部位有明显剪断现象,β相断边非常平整(见图5(a)中黑色箭头)。图5(b)所示的TEM照片中白色箭头所指部位也清楚地显示了共晶β相在大变形作用下出现弯折,弯折处聚集了大量位错,β相在此处出现缩颈。

2.3 共晶β相的碎化机制

在挤压过程中,第二相颗粒断裂的机制主要有如下4种[14]:1) 弯曲折断机制。对于弯曲状或树枝状颗粒,如共晶粒子,一个大角度弯曲很容易在瞬间发生并使颗粒发生断裂;2) 短纤维加载机制。对于长条 状颗粒,由于高的拉应力的转移与颗粒纵横比成一定比例,此时的应力将使它发生断裂;3) 剪切机制。对于等轴晶粒,当它通过挤压模壁区域时,若受到的剪切应力足够大时将发生断裂;4) 溶解、扩散和熔断机制。轴承钢中网状碳化物一般依据这种机制破碎。

图3 ECAP挤压不同道次后Mg15Al合金的SEM和TEM像

Fig.3 SEM and TEM images of ECAP Mg15Al alloys after different passes: (a) 1 pass; (b) 2 passes; (c), (d) 4 passes

图4 ECAP挤压不同道次Mg15Al合金的XRD谱

Fig.4 XRD patterns of ECAP Mg15Al alloys after different passes: (a) 1 pass; (b) 2 passes; (c) 4 passes

图5 ECAP挤压1道次后β相的SEM和TEM像

Fig.5 SEM and TEM images of β-Mg17Al12 after ECAP 1pass: (a) SEM image of β phase; (b) Pile-up of dislocation at β phase and bend of β phase

Mg15Al合金中的β-Mg17Al12相具有体心立方点阵,一个单胞内含有58个原子(34个Mg原子,24个Al原子),结构较复杂,点阵平移周期较长,通常难以变形,室温下表现为脆性相。但β相熔点只有710 K(437 ℃),高温热稳定性较低,从室温加热到473 K时,β相的硬度减小50%~60%[15],高温等通道挤压时表现出很好的流变性能[16]。因此,在553 K进行ECAP挤压时,试样放入垂直通道保温15 min后开始挤压时,β相已开始软化,具有少量塑性特性,在上方压力的排挤下,β相与α-Mg基体在三向应力作用下向下运动,当通过通道转角时,大的剪切应力使β相发生弯折,α-Mg基体内产生大量位错,位错在β相弯折处发生塞积(见图5(b))。此处β/α界面处的原子处于非常混乱的高能状态,而强变形引入的高密度位错成为天然的原子扩散管道,加速了Al原子的扩散,最终使得β相在位错聚集较多的β/α界面处首先发生溶解形成缩颈;随挤压道次增加,变形加大,位错继续增加,使得β相在这些界面缺陷处溶解加快,形成更多缩颈,缩颈更细,这些缩颈处强度很低,在大应力的作用下拉断或切断,使β相破碎成小块。因此,根据β相的碎化机制可以认为,这是由β相在位错聚集的β/α界面处的溶解和大变形力剪切共同作用导致的。

2.4 ECAP变形过程中β相的动态析出

由图3和4可知,当ECAP挤压1和2道次后,初晶α-Mg内基本没有析出β-Mg17Al12相,而且挤压2道次后,β-Mg17Al12相由于发生回溶,数量急剧减少;而挤压4道次后,在初晶α-Mg基体中析出了许多细小的β-Mg17Al12相,使其衍射峰强度急剧增加。但这些β-Mg17Al12相没有像在传统热处理中由于沉淀相与基体之间存在惯习面而呈片层状,而是呈现出粒状特征。这与β-Mg17Al12相的脱溶析出条件有关。根据第二相脱溶热力学公式[17]:

(1)

(1)

式中:B为溶质元素; 为母相;

为母相; 为脱溶后的基体相;

为脱溶后的基体相; 为第二相;

为第二相; 为第二相脱溶驱动力;

为第二相脱溶驱动力; 为B在α基体中的初始固溶量;

为B在α基体中的初始固溶量; 为元素B在α1中的偏摩尔自由能;

为元素B在α1中的偏摩尔自由能; 为B在

为B在 中的偏摩尔自由能;

中的偏摩尔自由能; 为B在

为B在 中的活度;

中的活度; 为B在α中的活度。可见β-Mg17Al12相的脱溶驱动力与Al在α-Mg中的固溶度和温度成正比,Al的固溶度越高,温度越高,β-Mg17Al12相的脱溶驱动力越大,β-Mg17Al12相越易析出。而且根据文献[18]可知,第二相析出还与保温时间的长短有关,保温达到一定时间后,才可以析出第二相,且随着时间的延长,析出相数量增加。黎文 献[19]研究认为,Mg-Al合金时效脱溶时,不像典型的Al-Cu合金,不经过GP区和过渡相,而是在晶界、亚晶界、位错线、夹杂物及其他晶体缺陷可提供高形核能量的地区直接脱溶析出。对于挤压合金Mg15Al,根据Mg-Al二元相图[11],15%的Al含量已经超过了Al在 Mg中的最大固溶度12.7%。而合金采用金属型铸造,原始组织中成分偏析较大,基体α-Mg中Al的固溶量为9.85%(见图2(b));而在553 K的ECAP挤压温度下,Al在Mg中的固溶度仅为5.5%,那么合金在553 K挤压过程中,β-Mg17Al12相必将脱溶析出。

为B在α中的活度。可见β-Mg17Al12相的脱溶驱动力与Al在α-Mg中的固溶度和温度成正比,Al的固溶度越高,温度越高,β-Mg17Al12相的脱溶驱动力越大,β-Mg17Al12相越易析出。而且根据文献[18]可知,第二相析出还与保温时间的长短有关,保温达到一定时间后,才可以析出第二相,且随着时间的延长,析出相数量增加。黎文 献[19]研究认为,Mg-Al合金时效脱溶时,不像典型的Al-Cu合金,不经过GP区和过渡相,而是在晶界、亚晶界、位错线、夹杂物及其他晶体缺陷可提供高形核能量的地区直接脱溶析出。对于挤压合金Mg15Al,根据Mg-Al二元相图[11],15%的Al含量已经超过了Al在 Mg中的最大固溶度12.7%。而合金采用金属型铸造,原始组织中成分偏析较大,基体α-Mg中Al的固溶量为9.85%(见图2(b));而在553 K的ECAP挤压温度下,Al在Mg中的固溶度仅为5.5%,那么合金在553 K挤压过程中,β-Mg17Al12相必将脱溶析出。

挤压1、2道次时,由于保温与挤压时间较短,且初晶α-Mg晶内的缺陷较少,可提供形核的高能量区较少,故β相基本不析出。且由于挤压温度较高,部分β相发生回溶,使α-Mg中固溶的Al进一步增加,增加了β-Mg17Al12相的脱溶驱动力;挤压4道次时,一方面,由于前3道次发生了大塑性变形,使基体中α-Mg晶内位错密度急剧增加,并形成缠结之后重排形成了许多亚晶界,晶粒明显细化,晶界大幅增加,这些晶界、亚晶界及位错线为β相形核提供了丰富的形核位置;另一方面,细小的晶粒使Al原子的扩散距离缩短,高密度位错和空位等缺陷又为Al原子的快速扩散提供了可能,促进了β相的析出,故4道次挤压后析出大量β相,使其衍射峰强度急剧增加(见图4(c))。这实质上就是高温高应力下,合金发生了时效,β相在基体中的连续沉淀析出。析出的β相形态呈粒状,而不是片层状,这是由于一方面在ECAP强塑性变形过程中,α-Mg晶内将产生高密度位错,且α-Mg基体晶格形成强烈的无序化,这能够阻碍基体与沉淀相之间的形成惯习面[20-21];另一方,面ECAP每道次变形时间只有20 min,时间较短,β相析出后来不及长大,因此此时脱溶析出了大量的细小粒状β相。

3 结论

1) ECAP强塑性变形对Mg15Al合金中网状共晶β-Mg17Al12相有强烈的碎化作用,且随着挤压道次的增加,碎化作用加强,挤压4道次后,β-Mg17Al12相被破碎成5 μm以下的小块,但没有完全弥散开,仍有部分聚集在一起。

2) β-Mg17Al12相在ECAP强塑性变形作用下出现弯折,弯折处易聚集大量位错,β-Mg17Al12相在位错聚集的β/α界面处发生溶解,产生缩颈,在大应力的作用下拉断或切断,导致β-Mg17Al12相的破碎。

3) 在ECAP强塑性变形过程中,Mg15Al镁合金将在高应力和高温共同作用下沉淀析出较多的纳米级粒状β-Mg17Al12相。

REFERENCES

[1] VALIEV R Z, ISLAMGALIEV R K, ALEXANDROV I V. Bulk nano-structured materials from severe plastic deformation[J]. Progress Material Science, 2000, 45(2): 103-189.

[2] NIEH T G, HSIUNG L M, WADSWORTH J, KA IBYSHEV R. High strain rate superplasticity in continuously recrystallized Al-6%Mg-0.3% Sc alloy[J]. Acta Materialia, 1998, 46(8): 2789-2800.

[3] VALIEV R Z, ALEXANDROV I V. Nanostructured materials from severe plastic deformation[J]. Nanostructured Materials, 1999, 12: 35-40.

[4] VALIEV R Z. Obtaining a nanostructure in Ti by equal-channel angular pressing[J]. Metal Science and Heat Treatment, 2000, 42: 361-365.

[5] DOBATKIN S V, VALIEV R Z, RAAQB G I. Structure and properties of steel st3 after hot equal-channel angular pressing[J]. Metal Science and Heat Treatment, 2000, 42: 366-369.

[6] KIM W J, AN C W, KIM Y S, HONG S I. Mechanical properties and microstructures of an AZ61 Mg Alloy produced by equal channel angular pressing[J]. Scripta Materialia, 2002, 47: 39-44.

[7] MATHIS K, GUBICZAC J, NAMC N H. Microstructure and mechanical behavior of AZ91 Mg alloy processed by equal channel angular pressing[J]. Journal of Alloys and Compounds, 2005, 394: 194-199.

[8] 王素梅, 孙康宁, 刘 睿, 毕见强. 第二相粒子对ECAP挤压的2A12铝合金晶粒细化的影响[J]. 材料科学与工艺, 2007, 15(1): 115-117.

WANG Su-mei, SUN Kang-ning, LIU Rui, BI Jian-qiang. Effect of the second phase on grain refinement of 2A12 aluminum alloy by ECA pressing[J]. Materials Science & Technology, 2007, 15(1): 115-117.

[9] HORITA Z, OHISHI K, KANEKO K. Microstructure control using severe plastic deformation[J]. Science and Technology of Advanced Materials, 2006, 7: 649-654.

[10] 彭北山, 刘志义, 宁爱林, 许晓嫦, 党 朋, 曾苏民. ECAP 变形过程中θ′相的碎化及溶解行为分析[J]. 稀有金属材料与工程, 2008, 37(11): 1930-1932.

PENG Bei-shan, LIU Zhi-yi, NING Ai-lin, XU Xiao-chang, DANG Peng, ZENG Su-min. Behavior of fragmentation and dissolution of θ′ phase during ECAP pressing[J]. Rare Metal Materials and Engineering, 2008, 37(11): 1930-1932.

[11] DAHLE A K, LEE Y C, NAVE M D, SCHAER P L, DAVID H S. Development of the as-cast microstructure in magnesium- aluminium alloys[J]. Journal of Light Metals, 2001, 1: 61-72.

[12] VALIEV R Z, LANGDON T G. Principles of equal-channel angular pressing as a processing tool for grain refinement[J]. Progress in Materials Science, 2006, 51: 881-981.

[13] WANG S Q, LIANG W, WANG Y, BIAN L P, CHEN K H. A modified die for equal channel angular pressing[J]. Journal of Material Process Technology, 2009, 209(7): 3182-3186.

[14] GALIYEV A, KAIBYSHEV R, GOTTSTEIN G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60[J]. Acta Materialia, 2001, 49(7): 1199-1207.

[15] 袁广银, 孙扬善, 王 震. Sb低合金化对Mg-9Al基合金显微组织和力学性能的影响[J]. 中国有色金属学报, 1999, 9(4): 779-783.

YUAN Guang-yin, SUN Yang-shan, WANG Zhen. Effect of antimony on microstructure and mechanical properties of Mg9Al based alloy[J]. The Chinese Journal of Nonferrous Metals, 1999, 9(4): 779-783.

[16] 赵 琦. 等通道转角挤压高铝镁合金的组织与性能[D]. 太原: 太原理工大学, 2007.

ZHAO Qi. The microstructure and mechanical properties of high-aluminium magnesium alloy processed by equal channel angular pressing[D]. Taiyuan: Taiyuan University of Technology, 2007.

[17] 徐 瑞, 荆天辅. 材料热力学与动力学[M]. 哈尔滨: 哈尔滨工业大学出版社, 2003.

XU Rui, JIN Tian-fu. The material thermodynamics and dynamics[M]. Harbin: Harbin Institute of Technology Press, 2003.

[18] 葛凯晨. 固溶时效处理对AZ80镁合金组织及力学性能的影响[D]. 西安: 西安理工大学, 2008.

GE Kai-chen. The effect of solution and aging treatment on the microstructure and mechanical properties of AZ80 magnesium alloy[D]. Xi’an: Xi’an University of Technology, 2008.

[19] 黎文献. 镁及镁合金[M]. 长沙: 中南大学出版社, 2004: 1-14.

LI Wen-xian. Magnesium and magnesium alloys[M]. Changsha: Central South University Press, 2004: 1-14.

[20] SU C W, LU L, LAI M O. A model for the grain refinement mechanism in equal channel angular pressing of Mg alloy from microstructural studies[J]. Materials Science and Engineering A, 2006, 434: 227-236.

[21] JANECEK M, POPOV M, KRIEGER M G, HELLMIG R J, ESTRIN Y. Mechanical properties and microstructure of a Mg alloy AZ31 prepared by equal-channel angular pressing[J]. Materials Science and Engineering A, 2007, 462: 116-120.

(编辑 龙怀中)

基金项目:山西省青年科技研究基金资助项目(2008021033);太原市明星专项基金资助项目(09121002);山西省自然科学基金资助项目(2010011033-1);山西高校科技研究开发项目(2007110)

收稿日期:2010-01-12;修订日期:2010-04-26

通信作者:王红霞,副教授,博士;电话:0351-6018398;E-mail: wanghxia1217@163.com