DOI: 10.11817/j.issn.1672-7207.2018.01.008

单β相镁锂合金Mg-11Li-3Al-0.4Y中温拉伸行为

丁洪波1, 2,周海涛1, 2,秦径为1, 2,李夏雷1, 2,刘克明3

(1. 中南大学 材料科学与工程学院,湖南 长沙,410083;

2. 中南大学 有色金属材料科学与工程教育部重点实验室,湖南 长沙,410083;

3. 江西省科学院 江西省铜钨新材料重点实验室,江西 南昌,330029)

摘要:采用熔铸、大变形轧制及退火等工艺制备厚度为1 mm的Mg-11Li-3Al-0.4Y合金板材,结合扫描电子显微镜、高温拉伸试验机等实验方法,研究合金在温度范围为50~200 ℃和应变速率范围为0.001~0.1 s-1的中温变形行为、再结晶行为和组织性能。在Arrhenius双曲正弦型方程的基础上构建适用于单β相含稀土镁锂合金的塑性变形本构方程。研究结果表明:对于单β相Mg-11Li-3Al-0.4Y合金,流变应力随变形温度的升高和应变速率的降低而降低,且真应力-真应变曲线中的锯齿波符合动态应变时效中的Portevin-Le Chatelier效应,这是首次在单β相Mg-Li-Al合金中观察到Portevin-Le Chatelier效应。结合断口分析,发现热轧合金板材在中温拉伸过程中,随着温度的升高,合金拉伸断裂方式由较低温度时的准解理断裂转变为较高温度下的韧窝断裂。

关键词:Mg-11Li-3Al-0.4Y合金;热变形;Portevin-Le Chatelier效应;动态再结晶;本构方程

中图分类号:TG146.2+2 文献标志码:A 文章编号:1672-7207(2018)01-0055-09

Tensile behavior of β-phase Mg-11Li-3Al-0.4Y alloy at medium temperature

DING Hongbo1, 2, ZHOU Haitao1, 2, QIN Jingwei1, 2, LI Xialei1, 2, LIU Keming3

(1. School of Materials Science and Engineering, Central South University, Changsha 410083, China;

2. Key Laboratory of Nonferrous Metal Materials Science and Engineering of Ministry of Education, Central South University, Changsha 410083, China;

3. Jiangxi Key Laboratory of Advanced Copper and Tungsten Materials,

Jiangxi Provincial Academy of Science, Nanchang 330029, China)

Abstract: New β-phase Mg-11Li-3Al-0.4Y alloy sheet with thickness of 1 mm was prepared by casting, hot-rolling and annealing processes. The fracture morphology and mechanical properties were investigated with scanning electron microscope and medium-temperature stretch test machine, respectively. Additionally, constitutive equation including flow stress, strain rate and deformation temperature was established by hyperbolic sine model with Zene-Hollomon parameter. The results show that the flow stress decreases with the increase of deformation temperature and reduction of strain rate. A pronounced post-relaxation effect followed by a serrated flow curve is shown in true stress-strain curves with low strain rate, which is also called the Portevin-Le Chatelier effect, and it is the first time that Portevin-Le Chatelier effect appears in β-phase Mg-Li-Al alloy. Cleavage fracture is replaced by dimple fracture with the increase of deformation temperature, according to the observation of electron microscope.

Key words: Mg-11Li-3Al-0.4Y alloy; thermal deformation; Portevin-Le Chatelier effect; dynamic recrystallization; constitutive equation

镁合金作为目前先进的轻质结构材料,在室温下具有高比强度、高比刚度和良好的抗震性等优点,已广泛应用于汽车、航天、国防、电子等领域[1-3]。但是在室温条件下,由于密排六方结构等原因,镁合金具有较差的室温延展性和成形性,所以很多学者通过多种手段来提高镁合金的室温可加工性能,如添加适量的合金元素和改变塑性变形温度等[2-7]。其中,作为仅有的可以显著降低镁合金密度的合金元素,锂元素的加入得到了广泛的关注[2-3, 7]。同时,根据镁锂合金平衡相图[8],镁锂合金中锂质量分数小于5.5%时,合金仅由具有密排六方结构(HCP)的α相组成;当锂质量分数介于5.5%~10.3%之间时,合金由α相和具有体心立方结构(BCC)的β相组成,β相中Li元素的固溶导致晶格c/a比降低,从而降低室温条件下α相柱面滑移系统的临界分切应力(CRSS),使合金能在较低温度下开启更多的滑移系,显著改善合金在室温下的加工塑性[9];当锂质量分数添加到大于10.3%时,合金由单一的β相组成,室温延展性和成形性进一步提升。但是β相较软,使合金强度降低,可通过添加Al,Zn和稀土等元素以及优化的塑性加工工艺加以改善[7, 10-12]。近年来,镁合金在高温下的变形行为一直是国内外讨论的热点,但是关于镁锂合金的中温变形行为与性能的研究很少。DROZD等[13-14]研究了Mg-Li-Al(LA43和LA45,其中数字分别表示Li和Al元素质量分数,下同)在高温下的变形行为,他们发现随着温度的提高,滑移系等软化机制的开动将显著改善合金高温下的力学性能。而KARAMI等[15]则对单β相的Mg-Li-Zn(LZ121)合金在温度范围为200~300 ℃和应变速率范围为1.2×10-3~6.0×10-2 s-1的高温力学行为进行了分析,并得到了合金的高温本构方程。在已有的文献报道中,对于含稀土元素的单β相镁锂合金的中温变形行为相关研究很少,因此,本文作者旨在对含稀土的新型超轻镁锂合金Mg-11Li-3Al-0.4Y在温度范围为50~200 ℃和应变速率范围为0.001~0.1 s-1的中温变形行为和再结晶行为进行研究分析,构建塑性变形本构关系,以期对此类合金的冷热变形条件和参数进行指导和优化;同时,在低应变速率的真应力-真应变拉伸曲线中,首次在单β相Mg-Li-Al合金中观察到Portevin-Le Chatelier (PLC)效应。

1 实验

1.1 实验材料

样品制备过程中以纯镁(纯度为99.95%)、纯锂(纯度为99.95%)、纯铝(纯度为99.92%)和镁钇中间合金(钇质量分数为30%)为原料,在熔剂(熔剂成分为氯化锂和氟化锂,其质量比为3:1)与氩气的共同保护下,利用电阻炉将原料熔铸成直径×长度为130 mm×240 mm的铸锭。合金的化学成分通过电感耦合等离子体原子发射光谱仪(ICP-AES)测试,其成分如表1所示。本实验试样取自铸锭中心部分,利用线切割将试样切割成直径×长度为80 mm×90 mm圆柱体,在电阻炉中均匀化处理后经热挤压制得厚为4.5 mm,宽为90 mm的板材。挤压工艺如下:挤压温度为280 ℃、挤压速度为2 mm/s。后经7道次热轧制得实验用厚度为1 mm的薄板。轧制工艺如下:轧制温度为260 ℃、道次压下量为20%、中间退火制度为260 ℃+15 min。

表1 Mg-11Li-3Al-0.4Y合金的化学成分(质量分数)

Table 1 Chemical composition of Mg-11Li-3Al-0.4Y alloy %

1.2 性能测试及组织观察

在高温拉伸试验机上对薄板进行恒应变速率拉伸实验,拉伸试样尺寸如图1所示。拉伸过程中将试样以5 ℃/s的速度分别升温至50,100,150和200 ℃,各温度下保温5 min,以变形速率分别为0.001,0.01和0.1 s-1进行拉伸实验,变形结束后在油中快冷。采用Origin 8.5软件绘制真应力-真应变曲线。用金相显微镜(OM)观察拉伸前后的微观组织变化,用扫描电子显微镜(SEM)观察合金中温拉伸断口形貌。

图1 中温拉伸试验试样尺寸

Fig. 1 Geometry of medium temperature tensile test sample

2 结果与讨论

2.1 真应力-真应变曲线分析

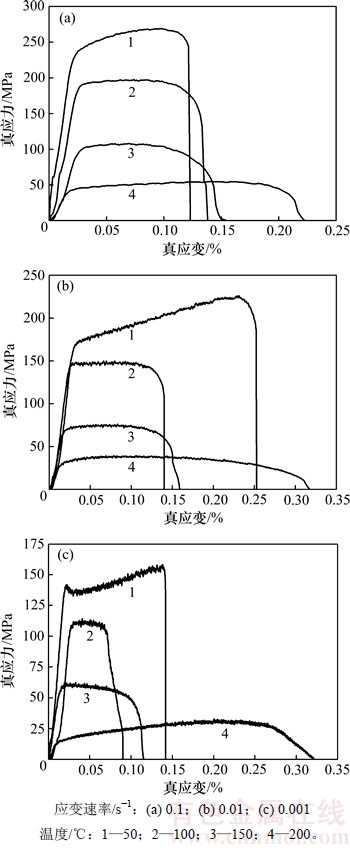

图2所示为Mg-11Li-3Al-0.4Y合金分别在应变速率为0.001~0.1 s-1和变形温度为50~100 ℃范围内的恒应变速率下的真应力-真应变曲线。由图2可知:当温度为50 ℃时,随着应变的增加,真应力经过弹性应变后转入塑性应变阶段,在塑性应变阶段,由于温度较低,合金发生动态回复和动态再结晶程度极低,合金加工硬化趋势明显。当流变应力接近最大值时,试样断裂。当温度大于50 ℃时,应变转入塑性阶段时,流变应力趋于稳定或者略微下降,这主要是由于变形初期,位错密度迅速增加,位错间的剪切缠结作用使变形所需的应力随之增大。当真应力达到峰值时,动态回复和动态再结晶发生,软化机制和加工硬化机制达到动态平衡,因此,流变应力趋于稳定状态。在相同应变速率下,真应力随温度的升高而降低。这是因为变形温度的升高,合金原子活动能力增加,原子间相互间的结合力和临界剪切应力下降,各种缺陷扩散速度加快,使变形易于进行,导致流变应力降低。此外,较高温度下合金的动态回复和动态再结晶作用随着温度的升高而加强,将明显消除塑性变形而产生的加工硬化效应,显著降低合金的流变应力[16]。由再结晶经验公式[17]

(1)

(1)

可粗略估计,Mg-11Li-3Al-0.4Y合金的再结晶温度在-13~159 ℃范围内,再结合图2所示的真应力-真应变曲线以及上述讨论可知,Mg-11Li-3Al-0.4Y合金的再结晶温度大于50 ℃,小于100 ℃。

由图2可知:当变形温度由50 ℃提高到100 ℃时,合金的延展性未有明显的提升或者有明显的下降,尤其50 ℃条件下伸长率的变化波动较大。而一般情况下,随着变形温度的提高,金属和合金的延展性会有一定程度的提升,这是因为温度的升高增强了原子活动力,原子和缺陷的扩散速度加快,合金协调变形机制更加完善,微裂纹不易扩展,合金的塑性应该有一定的提高。然而,对于镁锂合金,合金在再结晶温度以上就会发生脱锂的情况[7, 18],使α相从β相基体中析出,由于合金中Li元素质量分数的降低,这将大大影响合金塑性。此外,由于Li元素相对比较活泼,所以镁锂合金在高温下易被氧化,SCHWARTZ等[19]研究发现镁锂合金(特别是β相镁锂合金)在高于室温的情况下,蠕变性能差。镁锂合金断裂伸长率受到拉伸速率、温度和脱Li程度的影响,对于不同的拉伸速率合金伸长率表现不一。结合这些因素,Mg-11Li-3Al-0.4Y合金塑性变形过程中当变形温度由50 ℃提高到100 ℃时,塑性未有明显提升亦或者显著下降。

图2 Mg-11Li-3Al-0.4Y合金的在相同应变速率和不同温度下的真应力-真应变曲线

Fig. 2 True stress-strain curves of Mg-11Li-3Al-0.4Y alloy at various initial strain rates and temperatures

由图2(b)和2(c)可知:在低应变速率的真应力-真应变拉伸曲线中,Mg-11Li-3Al-0.4Y合金存在Portevin-Le Chatelier (PLC)效应,即当应变速率恒定时,应变达到某一临界应变量后,真应力-真应变曲线就不再是光滑曲线,而是出现锯齿形波浪。PLC效应在Al,Cu,γ-铁等面心立方结构(FCC)和BCC结构的合金中早已被发现并证实,但是对于镁合金(HCP结构),PLC效应只在AZ系[20]、ZE系[21-22]、稀土镁合金[23-24]和α单相镁锂合金[25-26] 等有报道,之前尚未发现PLC效应发生在单β相Mg-Li-Al合金中。根据文献[27-29]可知:PLC效应的锯齿波归为A型、B型和C型3种类型,而本文中Mg-11Li-3Al-0.4Y合金真应力-真应变曲线的锯齿波属于B型,这种波形的最大特点就是滑移带在波峰处产生后并不扩展,而是随着塑性变形继续进行,新的滑移带依次生成,直至断裂。也就是林位错脱钉后,由于溶质原子扩散速度很快,立刻在下一个位置被溶质原子气团钉扎,之后钉扎和脱钉过程反复进行,形成了连续的锯齿波真应力-真应变曲线。

PLC效应是动态应变时效机制(DSA)的典型特 征[30],如前文所述,温度大于等于100 ℃时,真应力-真应变曲线中出现了明显的稳态流变应力,发生了明显的动态再结晶过程。在一般情况下,在动态应变时效过程中,真应力-真应变曲线形成锯齿形并逐渐小幅上升的曲线,这是因为在动态应变时效过程中,由于位错的钉扎效应,产生了时效硬化的效果。随着合金中动态再结晶的发生,时效硬化、加工硬化和动态再结晶软化过程达到了一个动态平衡。这就是锯齿状稳态流变应力曲线形成的原因。

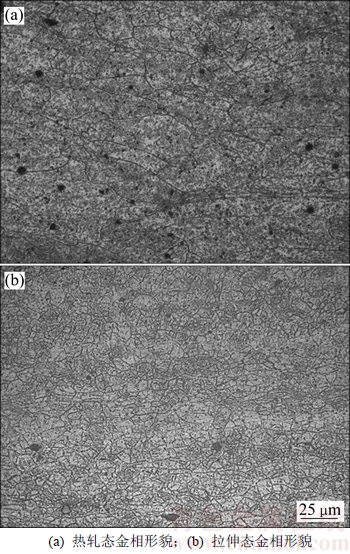

图3所示为合金热轧态薄板横截面和100 ℃,0.01 s-1条件下拉伸后断口附近横截面的显微组织。从图3可知:合金经热轧和拉伸后晶粒均破碎明显,并伴有等轴晶的出现,说明合金发生了动态再结晶,对合金力学性能有一定提升。

图3 Mg-11Li-3Al-0.4Y合金热轧横截面和100 ℃、0.01 s-1拉伸条件下横截面显微组织

Fig. 3 Optical micrographs of Mg-11Li-3Al-0.4Y alloy for hot-rolling and tensile-testing at 100 ℃ and 0.01 s-1

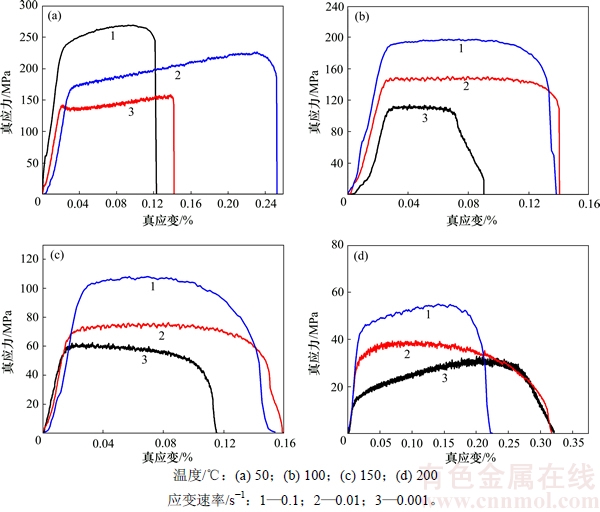

图4所示为Mg-11Li-3Al-0.4Y合金分别在应变速率为0.001~0.1 s-1和应变温度为50~200 ℃范围内的相同温度下的真应力-真应变曲线。在相同温度下,随着应变速率的升高,合金的屈服强度和稳态流变应力值都有明显的提高,即合金的应变速率敏感系数( )始终保持在一个相对稳定值。并且随着应变速率的升高,PLC效应明显减弱。当应变速率达到0.1 s-1时,PLC效应几乎消失,这是因为林位错的运动速度已经大于溶质原子的扩散速度,溶质原子气团未对林位错形成明显的钉扎作用,而动态再结晶软化机制趋势依旧和硬化机制始终保持在一个动态平衡的水平中。

)始终保持在一个相对稳定值。并且随着应变速率的升高,PLC效应明显减弱。当应变速率达到0.1 s-1时,PLC效应几乎消失,这是因为林位错的运动速度已经大于溶质原子的扩散速度,溶质原子气团未对林位错形成明显的钉扎作用,而动态再结晶软化机制趋势依旧和硬化机制始终保持在一个动态平衡的水平中。

2.2 本构方程的建立

材料热变形加工发生动态再结晶的过程受应力σ、热力学温度T 及应变速率 为变量的热激活过程控制,可通过包含热变形激活能Q和变形温度T在内的双曲正弦形式修正Arrhenius 关系来表述这种热激活稳态变形行为[31-34]:

为变量的热激活过程控制,可通过包含热变形激活能Q和变形温度T在内的双曲正弦形式修正Arrhenius 关系来表述这种热激活稳态变形行为[31-34]:

图4 Mg-11Li-3Al-0.4Y合金的在相同温度和不同应变速率下的真应力-真应变曲线

Fig. 4 True stress-strain curves of Mg-11Li-3Al-0.4Y alloy at various initial strain rates and temperatures

(2)

(2)

(3)

(3)

(4)

(4)

式中: 为应变速率,s-1;

为应变速率,s-1; 为真应力,MPa;Ai (i=1, 2, 3);n1,n和

为真应力,MPa;Ai (i=1, 2, 3);n1,n和 均为与温度无关的常数;Q为变形激活能,kJ/mol;T为热力学温度,K;R为摩尔气体常数,其值为8.314 J/(mol·K)。

均为与温度无关的常数;Q为变形激活能,kJ/mol;T为热力学温度,K;R为摩尔气体常数,其值为8.314 J/(mol·K)。

在热变形的本构方程研究中,由图2可知,峰值应力( )所对应的真应变差距太大,这对于本构方程将产生明显的误差,所以,构建过程中选用真应变接近的稳态应力(

)所对应的真应变差距太大,这对于本构方程将产生明显的误差,所以,构建过程中选用真应变接近的稳态应力( )。假定热变形激活能Q与变形温度T无关,对式(2)~(4)两边分别取自然对数,则有:

)。假定热变形激活能Q与变形温度T无关,对式(2)~(4)两边分别取自然对数,则有:

(5)

(5)

(6)

(6)

(7)

(7)

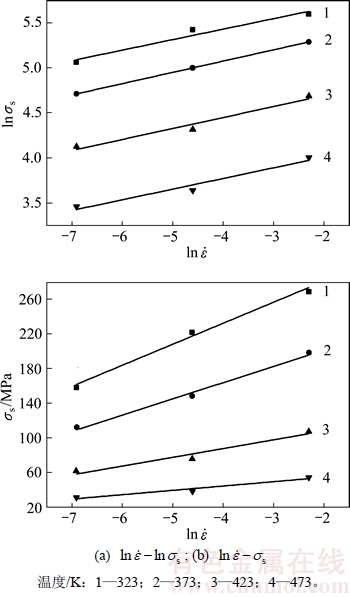

将不同拉伸条件下的Mg-11Li-3Al-0.4Y合金试样的稳态应力随应变速率变化情况代入式(5)和式(6),利用线性回归方程分别绘制出 和

和 的关系曲线,如图5所示。从图5可以看出:当变形温度一定时,稳态应力与应变速率之间的线性关系明显,同时n1和

的关系曲线,如图5所示。从图5可以看出:当变形温度一定时,稳态应力与应变速率之间的线性关系明显,同时n1和 分别为

分别为 和

和 拟合曲线的斜率。对拟合曲线斜率求取平均值可得

拟合曲线的斜率。对拟合曲线斜率求取平均值可得 ,

, ,所以

,所以 。

。

将 =0.008 28代入式(5),绘制

=0.008 28代入式(5),绘制 的曲线关系,如图6所示。由图6可知,直线斜率即为1/n,求取平均值得n=5.2。

的曲线关系,如图6所示。由图6可知,直线斜率即为1/n,求取平均值得n=5.2。

ZENER等[35]提出可用Zener-Hollomon参数Z表示应变速率 和变形温度T之间的关系:

和变形温度T之间的关系:

图5 Mg-11Li-3Al-0.4Y合金稳态应力与应变速率之间的关系

Fig. 5 Relationship between steady stress and strain rate for Mg-11Li-3Al-0.4Y alloy

图6 Mg-11Li-3Al-0.4Y合金双曲正弦应力与应变速率之间的关系

Fig. 6 Relationship between hyperbolic sine stress and strain rate for Mg-11Li-3Al-0.4Y alloy

(8)

(8)

假定一定温度范围内Q不变,在恒应变速率条件下则有:

(9)

(9)

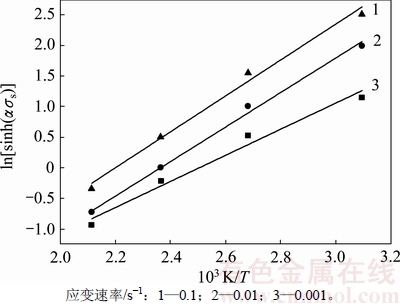

将各个流变应力数值代入式(9),绘制 的曲线关系,如图7所示。从图7可知:应变速率相同时,Mg-11Li-3Al-0.4Y合金中温拉伸流变应力

的曲线关系,如图7所示。从图7可知:应变速率相同时,Mg-11Li-3Al-0.4Y合金中温拉伸流变应力 的双曲正弦对数值与温度T的倒数呈明显的线性关系,表明

的双曲正弦对数值与温度T的倒数呈明显的线性关系,表明 与T之间满足Arrhenius关系,该合金塑形变形受热激活过程控制[32]。

与T之间满足Arrhenius关系,该合金塑形变形受热激活过程控制[32]。

图7 Mg-11Li-3Al-0.4Y合金双曲正弦应力与变形温度之间的关系曲线

Fig. 7 Relationship between hyperbolic sine stress and deformation temperature for Mg-11Li-3Al-0.4Y alloy

以上讨论表明,Mg-11Li-3Al-0.4Y合金在中温塑性变形过程中,应变速率、稳态应力和变形温度满足双曲正弦本构关系。因此,可以通过式(7)求解合金在塑形变形中的变形激活能和其他材料参数。考虑到温度及应变速率对变形激活能的影响,为计算热变形激活能Q,对式(7)两边取偏微分可得

(10)

(10)

根据图6和图7的斜率可求出式(10)中的导数值,由于不同的应变速率和变形温度,导致合金的 和

和  曲线斜率略微有些差距,因此,对变形激活能Q取平均值,得Q=118.528 2 kJ/mol。

曲线斜率略微有些差距,因此,对变形激活能Q取平均值,得Q=118.528 2 kJ/mol。

根据式(8),有:

(11)

(11)

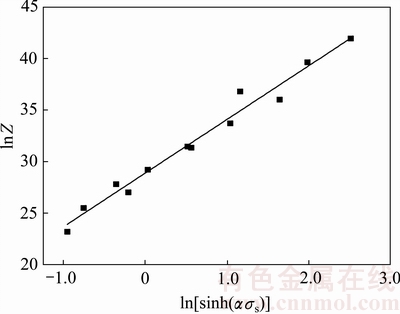

利用式(10)求得的Q,讨论Z参数(不同温度和不同应变速率下)与稳态应力之间的关系,结合线性回归分析,绘制 的曲线关系,如图8所示。其中,

的曲线关系,如图8所示。其中, 为直线截距,为A=3.525 3×1012。

为直线截距,为A=3.525 3×1012。

对式(11)变形,代入上述数值,可得Mg-11Li-3Al-0.4Y合金的塑性变形本构关系为

2.3 显微断口分析

图9所示为Mg-11Li-3Al-0.4Y合金热轧板材在应变速率为0.001 s-1时,变形温度为50~200 ℃范围内的中温拉伸显微断口SEM形貌。从宏观形貌可以看出:当温度为50 ℃时,合金断口表面较宽且平整;当温度升高到200 ℃时,合金断口宽度仅为20 μm。随着变形温度的升高,合金试样在拉伸过程中颈缩现象越来越明显,并且颈缩区域有明显的扩展。从图9(a)可以清晰地观察到显微断口中拥有较多的同方向的解理台阶、撕裂棱以及少量的韧窝,这是准解理断裂的典型特征[36]。随着温度的升高,解理台阶明显减少,当拉伸温度到达200 ℃时,合金较窄的断口上密集的分布着细小的韧窝和撕裂棱,解理台阶几乎完全消失,变形方式从准解理断裂转变为韧窝断裂[37]。此外,结合图2所示的PLC效应,可以从图9(b)~(d)颈缩部位中发现滑移带,随着温度升高,滑移带从粗大稀疏变得更加细小密集,这与真应力-真应变曲线中的锯齿状曲线相符。

图8 Mg-11Li-3Al-0.4Y合金温热变形Z参数与稳态应力间的关系

Fig. 8 Relationship between Z parameter and steady stress for Mg-11Li-3Al-0.4Y alloy

图9 Mg-11Li-3Al-0.4Y合金的中温拉伸显微断口形貌

Fig. 9 Tensile fracture surfaces of Mg-11Li-3Al-0.4Y alloy at elevated temperatures

3 结论

1) 对于Mg-11Li-3Al-0.4Y合金,当变形温度和应变速率一定时,随着变形量逐渐增加,合金流变应力随之增大,变形量达到一定值后,合金发生动态再结晶,流变应力趋于稳定或略有降低。变形温度一定时,流变应力随应变速率的增加而增大;应变速率一定时,流变应力随变形温度的升高而减少。合金拉伸真应力-真应变曲线中的锯齿形曲线是由于Portevin-Le Chatelier效应引发,这是首次在单β相Mg-Li-Al合金中观察到PLC效应。

2) 在Arrhenius方程的基础之上,基于流变应力曲线,建立了Mg-11Li-3Al-0.4Y合金双曲正弦方程的各种常数与真应变的函数关系式,从而构建了包含应变速率、变形温度和变形量等在内的双曲正弦方程形式的Mg-11Li-3Al-0.4Y合金的塑性变形本构关系:

3) 在总压下率为80%的热轧Mg-11Li-3Al-0.4Y合金板材中温拉伸过程中,随着温度升高,合金拉伸断裂方式由较低温度时的准解理断裂转变为较高温下的韧窝断裂。

参考文献:

[1] 张津, 章宗和. 镁合金及应用[M]. 北京: 化学工业出版社, 2004: 12-24.

ZHANG Jin, ZHANG Zonghe. Magnesium alloys and its applications[M]. Beijing: Chemical Industry Press, 2004: 12-24.

[2] YAN Y D, ZHANG M L, HAN W, et al. Electrochemical formation of Mg-Li alloys at solid magnesium electrode from LiCl-KCl melts[J]. Electrochimica Acta, 2008, 53(8): 3323-3328.

[3] 秦径为, 彭谦之, 周海涛, 等. Mg-8Li-3Al-Y 镁锂合金板材热轧及退火组织与性能[J]. 稀有金属, 2015, 39(7): 577-582.

QIN Jingwei, PENG Qianzhi, ZHOU Haitao, et al. Microstructure and mechanical properties of hot-rolled and annealed Mg-8Li-3Al-Y alloys[J]. Chinese Journal of Rare Metals, 2015, 39(7): 577-582.

[4] LI R H, PAN F S, JIANG B, et al. Effects of yttrium and strontium additions on as-cast microstructure of Mg-14Li-1Al alloys[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(4): 778-783.

[5] WU L B, CUI C L, WU R Z, et al. Effects of Ce-rich RE additions and heat treatment on the microstructure and tensile properties of Mg-Li-Al-Zn-based alloy[J]. Materials Science and Engineering: A, 2011, 528(4): 2174-2179.

[6] MAHMUDI R, KABIRIAN F, NEMATOLLAHI Z. Microstructural stability and high-temperature mechanical properties of AZ91 and AZ91 + 2RE magnesium alloys[J]. Materials & Design, 2011, 32(5): 2583-2589.

[7] PENG Q Z, ZHOU H T, ZHONG F H, et al. Effects of homogenization treatment on the microstructure and mechanical properties of Mg-8Li-3Al-Y alloy[J]. Materials & Design, 2015, 66: 566-574.

[8] 刘楚明, 朱秀荣, 周海涛. 镁合金相图集[M]. 长沙: 中南大学出版社, 2006: 33.

LIU Chuming, ZHU Xiurong, ZHOU Haitao. Magnesium Alloys Phase Atlas[M]. Changsha: Central South University Press, 2006: 33.

[9] LIN M C, TSAI C Y, UAN J Y. Converting hcp Mg-Al-Zn alloy into bcc Mg-Li-Al-Zn alloy by electrolytic deposition and diffusion of reduced lithium atoms in a molten salt electrolyte LiCl-KCl[J]. Scripta Materialia, 2007, 56(7): 597-600.

[10] DONG H W, PAN F S, JIANG B, et al. Evolution of microstructure and mechanical properties of a duplex Mg-Li alloy under extrusion with an increasing ratio[J]. Materials & Design, 2014, 57: 121-127.

[11] CHEN Z Y, DONG Z C, YU C, et al. Microstructure and properties of Mg-5.21Li-3.44Zn-0.32Y-0.01Zr alloy[J]. Materials Science and Engineering A, 2013, 559(1): 651-654.

[12] QU Z K, WU L B, WU R Z, et al. Microstructures and tensile properties of hot extruded Mg-5Li-3Al-2Zn-xRE (Rare Earths) alloys[J]. Materials & Design, 2014, 54: 792-795.

[13] DROZD Z, TROJANOVA Z, KUDELA S. Deformation behaviour of Mg-Li-Al alloys[J]. Journal of Alloys and Compounds, 2004, 378(1): 192-195.

[14] TROJANOVA Z, DROZD Z Z, LUKAC P, et al. Deformation behaviour of Mg-Li alloys at elevated temperatures[J]. Materials Science and Engineering: A, 2005, 410(1): 148-151.

[15] KARAMI M, MAHMUDI R. Hot shear deformation constitutive analysis and processing map of extruded Mg-12Li-1Zn bcc alloy[J]. Materials & Design, 2014, 53: 534-539.

[16] 张密林, 约尔金. 镁锂超轻合金[M]. 北京: 科学出版社, 2010: 57-60.

ZHANG Milin, ELKIN F M. Super light magnesium lithium alloy[M]. Beijing: Science Press, 2010: 57.

[17] 潘金生, 仝健民, 田民波. 材料科学基础[M]. 北京: 清华大学出版社, 1998: 39-45.

PAN Jinsheng, TONG Jianmin, TIAN Minbo. Foundation of material science[M]. Beijing: Tsinghua University Press, 1998: 39-45.

[18] RAMAMURTY U, BANDYOPADHYAY A, DWARAKADASA E S. Effect of heat treatment environment on Li depletion and on mechanical properties in Al-Li alloy sheets[J]. Journal of Materials Science, 1993, 28(23): 6340-6346.

[19] SCHWARTZ D M, MITCHELL J B, DORN J E. The mechanism of prismatic creep in Mg-12at.% li[J]. Acta Metallurgica, 1967, 15(3): 485-490.

[20] DOBRON P, BOHLEN J, CHMELIK F, et al. Acoustic emission during stress relaxation of pure magnesium and AZ magnesium alloys[J]. Materials Science and Engineering: A, 2007, 462(1): 307-310.

[21] LUKAC P, TROJANOVA Z. Hardening and softening in selected magnesium alloys[J]. Materials Science and Engineering A, 2007, 462(1): 23-28.

[22] YANG J, WANG J L, WANG L D, et al. Microstructure and mechanical properties of Mg-4.5Zn-xNd (x=0, 1 and 2, %) alloys[J]. Materials Science and Engineering A, 2008, 479(1): 339-344.

[23] WANG Z J, JIA W P, CUI J Z. Study on the deformation behavior of Mg-3.6%Er magnesium alloy[J]. Journal of Rare Earths, 2007, 25(6): 744-748.

[24] GAO L, CHEN R S, HAN E H. Solid solution strengthening behaviors in binary Mg-Y single phase alloys[J]. Journal of Alloys and Compounds, 2009, 472(1): 234-240.

[25] WANG C, XU Y B, HAN E H. Portevin-Le Chatelier effect of LA41 magnesium alloys[J]. Frontiers of Materials Science in China, 2007, 1(1): 105-108.

[26] LI T Q, LIU Y B, CAO Z Y, et al. The twin mechanism of Portevin Le Chatelier in Mg-5Li-3Al-1.5Zn-2RE alloy[J]. Journal of Alloys and Compounds, 2011, 509(28): 7607-7610.

[27] 钱匡武, 彭开萍, 陈文哲. 金属动态应变时效现象中的“锯齿屈服”[J]. 福建工程学院学报, 2003, 1(1): 4-8.

QIAN Kuangwu, PENG Kaiping, CHEN Wenzhe. Features of serrated yielding of dynamic strain aging phenomenon in metals and alloys[J]. Journal of Fujian University of Technology, 2003, 1(1): 4-8.

[28] JIANG H F, ZHANG Q C, CHEN X D, et al. Three types of Portevin-Le Chatelier effects: experiment and modeling[J]. Acta Materialia, 2007, 55(7): 2219-2228.

[29] RANC N, WAGNER D. Experimental study by pyrometry of Portevin-Le  plastic instabilities-Type a to type b transition[J]. Materials Science and Engineering A, 2008, 474(1): 188-196.

plastic instabilities-Type a to type b transition[J]. Materials Science and Engineering A, 2008, 474(1): 188-196.

[30] 钱匡武, 李效琦, 萧林钢, 等. 金属和合金中的动态应变时效现象[J]. 福州大学学报(自然科学版), 2001, 29(6): 8-23.

QIAN Kuangwu, LI Xiaoqi, XIAO Lingang, et al. Dynamic strain aging phenomenon in metals and alloys[J]. Journal of Fuzhou University (Natural Science), 2001, 29(6): 8-23.

[31] 普瓦里耶 J P. 晶体的高温塑性变形[M]. 关德林, 译. 大连: 大连理工大学出版社, 1989: 35-44.

POIRIER J P. High temperature plastic deformation of crystal[M]. GUAN Delin, trans. Dalian: Dalian University of Technology Press, 1989: 35-44.

[32] 张雪敏, 曹福洋, 岳红彦, 等. TC11 钛合金热变形本构方程的建立[J]. 稀有金属材料与工程, 2013, 42(5): 937-941.

ZHANG Xuemin, CAO Fuyang, YUE Hongyan, et al. Establishment of constitutive equations of TC11 alloy during hot deformation[J]. Rare Metal Materials and Engineering, 2013, 42(5): 937-941.

[33] 胡丽娟. AZ31镁合金板材温热变形行为的数值分析与试验研究[D]. 上海: 上海交通大学材料科学与工程学院, 2010: 39.

HU Lijuan. Numerical and experimental studies on warm deforming of AZ31 magnesium alloy sheet[D]. Shanghai: Shanghai Jiao Tong University. School of Materials Science and Engineering, 2010: 39.

[34] 周海涛, 彭谦之, 杨红星, 等. GH690-RE合金高温塑性本构方程研究[J]. 特种铸造及有色合金, 2012, 32(7): 597-600.

ZHOU Haitao, PENG Qianzhi, YANG Hongxing, et al. Constitutive equations of GH690-RE alloy at hot deformation[J]. Special Casting & Nonferrous Alloys, 2012, 32(7): 597-600.

[35] ZENER C, HOLLOMON J H. Effect of strain rate upon plastic flow of steel[J]. Journal of Applied Physics, 1944, 15(1): 22-32.

[36] 廖乾初, 孙福玉, 蓝芬兰. 准解理断裂的本质[J]. 金属学报, 1979, 15(2): 259-313.

LIAO Qianchu, SUN Fuyu, LAN Fenlan. An investigation of quasi-cleavage fracture in steel[J]. Acta Metallurgica Sinica, 1979, 15(2): 259-313.

[37] 崔约贤, 王长力. 金属断口分析[M]. 哈尔滨: 哈尔滨工业大学出版社, 1998: 43.

CUI Yuexian, WANG Changli. Analysis of metal fracture surface[M]. Harbin: Harbin Institute of Technology Press, 1998: 43.

(编辑 杨幼平)

收稿日期:2017-03-21;修回日期:2017-06-09

基金项目(Foundation item):国家自然科学基金资助项目(51461018);江西省自然科学基金重点资助项目(20133BAB20008) (Project(51461018) supported by the National Natural Science Foundation of China; Project(20133BAB20008) supported by the Key Program of Natural Science Foundation of Jiangxi Province)

通信作者:周海涛,教授,博士生导师,从事有色金属塑性加工等研究;E-mail: htzhou@csu.edu.cn