DOI:10.11817/j.ysxb.1004.0609.2021-42006

铸态亚稳β钛合金高应变速率动态再结晶机理

赵秦阳1,陈永楠1,徐义库1,Rob Torrens2,Leandro Bolzoni2,Fei Yang2

(1. 长安大学 材料科学与工程学院,陕西 西安 710064;

2. 怀卡托大学 先进材料与加工中心,新西兰 汉密尔顿 3240)

摘 要:针对铸态亚稳β型Ti-5553钛合金,基于热模拟试验,研究了合金在高温高应变速率条件下的热变形行为,并发现了一种全新的动态再结晶机制。结合多种材料表征技术,揭示了新动态再结晶机制的微观组织演变机理,并分析了变形参数对再结晶行为的影响。研究发现,合金在高温高速率条件下的显著动态软化是动态再结晶和流变失稳共同作用的结果,动态再结晶产生新晶粒的形核位置、尺寸和组织占比都对热变形参数有较高的敏感性。发现和揭示的新动态再结晶机制是连续和不连续这两种常见机制混合而成的耦合机制,既包含了引发不连续动态再结晶的晶界应变集中效应,又包括了连续动态再结晶的亚晶旋转形核过程。

关键词:亚稳β钛合金;热变形;微观组织演变;变形机制;动态再结晶

文章编号:1004-0609(2019)-11-2627-10 中图分类号:TG146.2 文献标志码:A

亚稳β型钛合金作为钛合金的一类重要分支,因其具有高比强度、优良淬透性和出色的疲劳性能,被视为是在航空航天、远洋航海、武器装备等重要战略领域有广阔应用前景的先进结构材料[1-6]。其中,本研究中选择的Ti-5553(Ti-5Al-5Mo-5V-3Cr)是一种成熟商业化的亚稳β型钛合金,正逐渐代替早年飞机大型轻量化结构件使用的Ti-1023(Ti-10V-2Fe-3Cr)合金,被成功应用于波音787、空客A380等新型大型客机的起落架和骨架的部分结构件[7-10]。

在实际生产与应用中,亚稳β型钛合金优良的物理性能和力学性能在很大程度上依赖于精密的加工技术,尤其是复杂的多道次热加工[11-14]。热加工不仅能大范围改变钛合金工件的成型形状,更是对合金进行微观组织调控和性能优化的关键工艺步骤。在金属材料的热加工过程中,加工硬化和流变软化通常同时发挥作用,加工硬化和流变软化的竞争会决定热加工过程中工件的力学反馈与加工性,而流变软化机制将决定合金加工后的微观组织。钛合金热变形过程中常见的流变软化机制有动态回复、动态再结晶(DRX)、流变失稳、第二相动态析出等,其中DRX发生时通常会使新的等轴状再结晶晶粒在变形组织中析出,同时消耗大量变形储存能和变形增殖位错,是热变形时合金组织细化和达到稳定平衡态的必经过程。因此,研究亚稳β钛合金的热变形行为并探究其流变软化机制,尤其是动态再结晶机制有重要意义。

金属材料发生DRX的条件一般是在足够高的变形温度下有足够长的变形时间并达到足够量的变形量[15-17],因此在大多数先前针对钛合金的研究中发现和探究的都是较低应变速率下的动态再结晶行为,且这些研究多以加工态细晶合金为研究对象[18-20]。目前针对铸态钛合金进行热变形行为与DRX机制的研究仍十分有限,但铸态正是实际生产中钛合金热加工的起始状态。同时,针对钛合金高应变速率下DRX行为的捕捉与研究也一直被忽略。

本文针对铸态亚稳β型Ti-5553钛合金,基于热模拟试验,研究了合金在高温高应变速率条件下的热变形行为,并发现了一种全新的动态再结晶机制。结合多种材料表征技术,揭示了新发现DRX机制的微观组织演变机理,并分析了变形参数(变形温度、变形速率、变形量)对再结晶行为的影响。本研究旨在为铸态亚稳β型钛合金的热加工提供理论指导和数据支持,并补充完善金属结构材料在高应变速率条件下的DRX机制与理论。

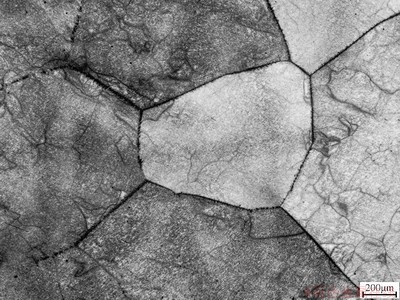

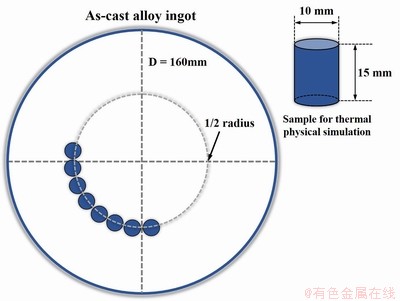

1 实验

本研究采用的材料是经过两次真空自耗熔炼所得的质量为35 kg、直径为160 mm的 Ti-5553合金铸锭。经化学成分分析,合金的实际成分为: Ti-5.14Al-5.02Mo-5.03V-3.10Cr-0.08O,合金相变点经过金相法测定为875 ℃±5 ℃。图1为铸态合金的金相显微组织,可以看出铸态合金的组织粗大,包含等轴状的β晶粒(晶粒尺寸为1000-2000 μm)和弥散分布的α相析出。按照图2所示的取样方法,通过线切割从铸锭中心位置取圆柱形试样(直径10 mm、高度15 mm),在经过表面精密机械加工后,在Gleeble-3800D热模拟试验机上进行高温压缩试验。热压缩温度为1000 ℃和1100 ℃,应变速率为1 s-1和10 s-1,变形量为50%和70%。在加热前,将一对Pt-Rh热电偶点焊在试样中部的外表面上用来监测和控制加热及变形过程中的样品温度,在试样两端和夹头之间放置钽片和石墨片用来减小样品与压头之间的摩擦并增强压缩测试系统的导电性。以10 ℃/s的加热速率将样品加热到目标温度后,保温4分钟后开始压缩。在压缩过程中,经试验系统记录,样品的绝热温升都小于25 ℃,压缩结束后立即对样品进行水淬以保持高温变形组织。

图1 铸态Ti-5553合金的金相组织

Fig. 1 OM microstructure of as-cast Ti-5553 alloy

将热压缩变形后的样品沿轴线剖开,经过打磨、机械抛光和化学腐蚀后,利用光学显微镜(OM)、扫描电子显微镜(SEM)、原子力显微镜(AFM)对样品微观组织进行观察。利用装有电子背散射衍射(EBSD)探头的扫描电子显微镜,对经过机械打磨和电解抛光的样品进行测试与分析(HKL Channel 5)。取薄片状合金试样,打磨至60 μm后冲出直径为3 mm的样品,经过离子减薄后,利用透射电镜(TEM)观察更微观的组织形貌特征。

图2 热模拟试样的取样位置示意图

Fig. 2 Schematic diagram demonstrating the sampling positions of as-cast Ti-5553 alloy for thermal physical simulation

2 结果与讨论

2.1 应力-应变曲线

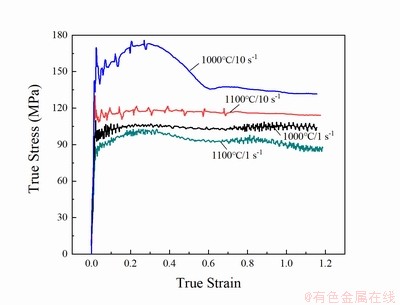

图3为合金在不同变形温度与应变速率下的真应力应变曲线图(变形量为70%)。从图中可以看出,与大多数金属材料一样,所有变形条件下合金都经历了快速加工硬化和逐渐硬化与软化平衡两个过程,峰值应力也随变形温度的升高和应变速率的降低而降低。值得注意的是,不同于到达峰值应力后直接趋于平衡,在1000 ℃/10 s-1 和1100 ℃/1 s-1这两个条件下,样品在真应变为0.3-0.6之间的阶段出现了明显的流变应力降低,说明在此阶段合金的流变软化效果更显著,这可能是由失稳变形、动态再结晶等机制引起的,需要通过微观组织观察确定。

图3 合金在不同变形温度与应变速率下应力应变曲线图

Fig. 3 Typical true stress-true strain curves of as-cast Ti-5553 alloy deformed at various temperatures and strain rates

2.2 微观组织表征

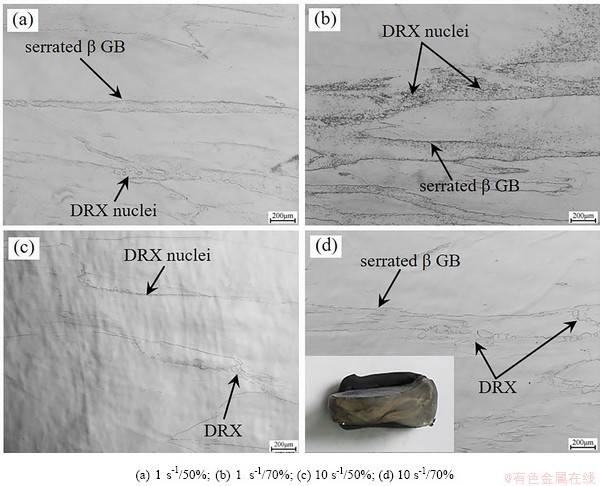

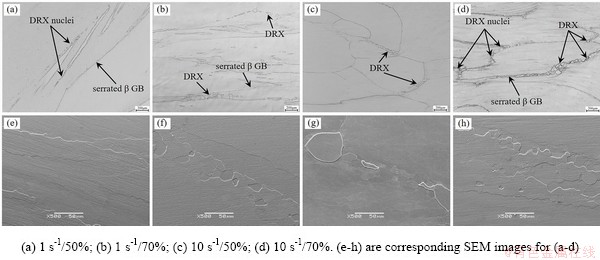

图4为合金在变形温度为1000 ℃条件下,经不同应变速率和不同应变量变形后的微观组织。从图4a中可以看出合金在经过1 s-1/50% 热变形后,呈全β相组织,β晶界被拉长且呈锯齿状,三叉晶界处出现少量尺寸小于10 μm的细小等轴状DRX晶粒;当变形量增加到70%时(1 s-1,图4b),可见这种细小DRX晶粒的数量显著升高,但尺寸没有明显变化。当应变速率为10 s-1时,经较低变形量压缩(50%,图4c),组织中DRX晶粒的尺寸和组织占比相对于1 s-1时都有明显上升。升高变形量至70%(70%,图4d),三叉晶界处再结晶晶粒的尺寸明显增大(20-50 μm);而此时变形样品已明显出现了流变失稳特征,宏观变形不均匀,样品发生局部扭折,这说明合金在高温高速率条件下的显著动态软化是由DRX和流变失稳共同造成的。

图5为合金在变形温度为1100 ℃条件下,经不同应变速率和不同应变量变形后的OM和SEM微观组织,总体可见1100 ℃变形后合金的组织相比于1000 ℃的变形组织更粗大,相邻β晶界之间的间距扩大,这是更高变形温度下合金晶粒粗化程度更显著导致的。经过1 s-1/50% 热变形(图5a),锯齿状晶界上有部分小晶粒产生,而这些小DRX晶粒在高应变量变形后尺寸明显增大(1 s-1/70%,图5b);经过10 s-1/50% 热变形(图5c),组织中沿部分平直β晶界出现了连续均匀分布的DRX晶粒,这些晶粒在经过10 s-1/70%热变形后(图5d),尺寸和组织占比都大幅升高。

图4 合金在1000 ℃条件下经不同应变速率和不同应变量下变形后的微观组织(变形沿垂直方向进行)

Fig. 4 Microstructures of the alloy deformed at 1000 ℃ with various strain rates and deformation degrees

图5 合金在1100 ℃条件下经不同应变速率和不同应变量变形后微观组织(变形沿垂直方向进行)

Fig. 5 Microstructures of the alloy deformed at 1100 ℃ with various strain rates and deformation degrees

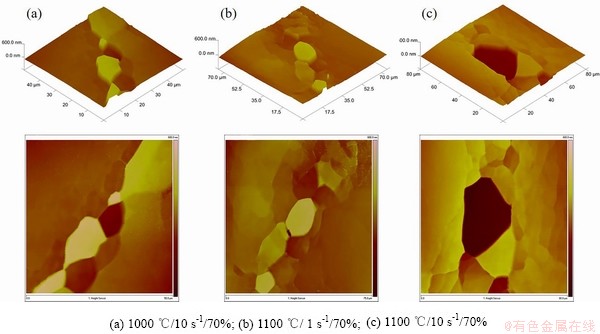

图6是合金在不同条件变形后的二维和三维AFM组织照片,AFM形貌反映了合金金相样品经腐蚀后不同晶粒或结构对腐蚀剂敏感性不同带来的表面起伏,从而将不同的组织结构在二维和三维图像上区分开来。从图6a中可以看出,经过1000 ℃/10 s-1/70%变形后,在三叉晶界处形成了聚集分布的DRX晶粒,无其他明显结构;同样应变量下(70%),当温度升高至1100 ℃(图6b-c),除了在原始β晶界上连续分布的DRX晶粒,在这些晶粒周围出现了一些边界较为模糊的亚结构,他们所构成的亚晶界也近似呈等轴状,同时可以观察到这些亚结构在更高应变速率变形后(10 s-1, 图6c)更为显著,且组织占比也更高。

图6 合金在不同条件变形后二维和三维AFM组织照片

Fig. 6 2D and 3D AFM microstructures of the alloy deformed at various conditions

结合OM、SEM和AFM的微观组织表征结果,合金在高温高应变速率条件下的DRX现象随变形参数的变化规律可以总结如下:(1)当变形温度为1000 ℃时,新产生的DRX晶粒主要分布在三叉β晶界处,而在1100 ℃时,新产生的DRX晶粒则沿着部分平直原始晶界连续均匀分布;(2)应变速率越高(从1 s-1升至10 s-1)、总应变量越大(从50%升至70%),则DRX晶粒的数量和尺寸也随之增多和变大。

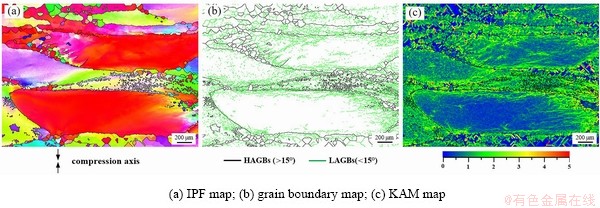

2.3 再结晶机制分析

为了深入分析和揭示合金在高温高速率条件下DRX现象的组织演变机理,对1100 ℃/10 s-1/70%变形后合金组织进行了EBSD和TEM表征。图7展示了EBSD测试结果,包括取向反极图(图7a)、晶界分布图(图7b)和相对位错密度分布图(图7c)。可以看出,在粗大原始β晶粒的部分晶界上有由大角度晶界(HAGB)围成的等轴状DRX晶粒,并且在这些DRX晶粒周围的部分区域虽然未形成DRX晶粒,但是其晶体学取向与原始β晶粒内的其余区域已有明显差异,而且这些区域位错密度相对高,并富含小角度晶界(LAGB)。与此相反,原始粗大β晶粒内部位错密度相对很低,存在的亚结构很少。

图7 合金在1100 ℃/10 s-1/70%条件下变形后微观组织的EBSD表征结果

Fig. 7 EBSD results of the alloy deformed at 1100 ℃/10 s-1/70%

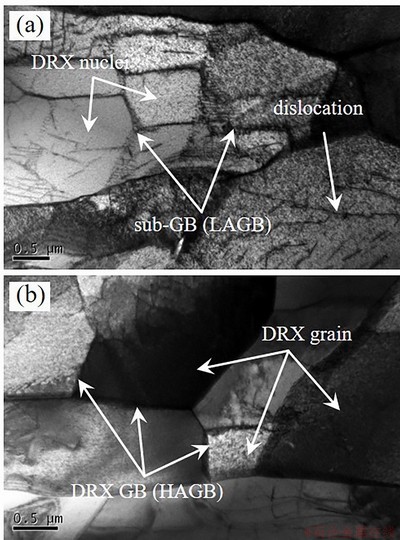

图8 合金在1100 ℃/10 s-1/70%条件下变形后的TEM组织

Fig. 8 TEM microstructure of the alloy deformed at 1100 ℃/10 s-1/70%

图8所示为1100 ℃/10 s-1/70%变形条件下对应的TEM组织照片,图8a中可以看出大的原始β晶粒呈经过高速率变形后呈“破碎化”状态,被大量由位错聚集而成的亚结构分割成不同的区域,这些亚结构中已有一部分形成了小角度亚晶界,并正在构成近似等轴状的亚晶;进一步结合图8b中同一变形条件下的TEM微观组织特征可知,这种小角度亚晶界会随着变形的进行转变为大角度晶界,而他们围绕而成的亚晶也会逐渐转变为新形核的DRX晶粒。

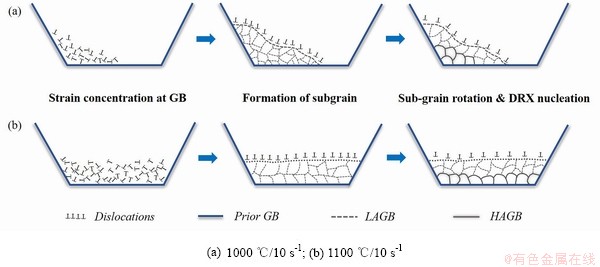

通过综合研究分析以上各类微观组织表征结果,可揭示并阐明合金在高温高速率条件下DRX过程机制及其组织演变特征随变形参数变化规律的微观机理,图9为合金在高温高速率条件下DRX过程的微观机制示意图。在前期高温加热和保温过程中,晶粒的快速长大过程导致变形前合金的组织十分粗大;在高速率的短时变形条件下,合金中应变及储存能陡然增高,引发了流变失稳,但应变在粗大晶粒内部的分布不均匀,应变主要集中在原始β晶界处;1000 ℃时(图9a)应变主要集中在三叉β晶界处,而在1100 ℃时(图9b)应变则沿整个平直晶界呈较均匀分布态势,原因是更高温度下组织更粗大,变形时晶界间距更宽,形态更平直;由于变形在高应变速率条件下进行,应变集中区域的位错密度将激增,这些位错不断增殖和运动并逐渐聚集、缠节成小角度亚晶界,从而形成亚晶,使得应变集中区域的组织呈“破碎化”状态;产生的这些亚晶在变形中不断吸收变形能和内能,容纳、兼并位错并发生旋转,导致相邻亚晶之间的取向差不断增大,小角度亚晶界逐渐转变为大角度晶界,亚晶也随之转变为新的DRX晶粒。

图9 合金在高温高应变速率条件下的动态再结晶过程示意图

Fig. 9 Schematic diagrams showing the DRX mechanisms of the alloy at high-temperature and high-strain-rate deformation

关于变形参数变化对DRX过程的影响,其微观机理可被阐述如下:当应变速率和总应变量升高时,组织中因快速变形所产生的位错及其交互作用也随之增多和增强,使原始β晶粒在晶界附近产生的亚结构密度更高(即组织“破碎”程度更剧烈);与此同时,更高速率的大变形所提供的形变储存能也更高,从而促进亚晶的形成与旋转,进而加速DRX的形核与长大;这些微观作用机理将使DRX行为更加显著,导致形成新晶粒的数量和尺寸也随之越多和越大,同时也伴随着更加显著的流变软化效果。

值得注意的是,本研究中发现和揭示的动态再结晶机制与传统金属材料热变形过程中常见的不连续动态再结晶机制(DDRX)和连续动态再结晶机制(CDRX)都是不同的[21-23],是一种新的DRX机制。DDRX虽然主要出现在原始晶界处,并且也是由变形不均匀引发的,但在这一机制中,新的大角度晶界是直接从原始晶界弓出形成并发生长程迁移从而形成新DRX晶粒[24,25];CDRX虽然是由小角度晶界两侧的亚晶通过持续晶体旋转逐步增大两侧取向差形成,但此机制通常是在较均匀变形时发生在原始晶粒内部,并不依赖于原始晶界处的应变集中[26,27]。结合这两种常见的DRX机制,本研究中发现和探究的新动态再结晶机制可认为是DDRX 和CDRX这两种机制混合而成的耦合机制,既在再结晶起始阶段依靠引发DDRX的晶界应变集中效应,产生了大量的亚结构,又在形核阶段借助了CDRX的亚晶旋转形核机制,最终形成了新的再结晶组织。这一新机制的产生是由高速率大塑性变形和合金粗大的起始组织(铸态合金本身的组织粗大,高温变形中加热和保温过程使得晶粒进一步长大)所共同引发的,这一不寻常的DRX行为也使得动态流变失稳和DRX共同主导了合金在高温高速率变形条件下流变软化行为。

3 结论

1) 铸态粗晶Ti-5553 合金在变形温度为1000 ℃和1100 ℃,应变速率为1 s-1和10 s-1的高温高速率条件下发生了反常的动态再结晶行为。

2) 动态再结晶行为产生新晶粒的形核位置、尺寸大小和组织占比都对包括温度、应变速率和变形量的热变形参数有较高的敏感性。

3) 合金在高温高速率条件下的显著动态软化是动态再结晶和流变失稳共同作用的结果。

4) 发现和揭示的新动态再结晶机制是由连续和不连续这两种常见机制混合而成的耦合机制,既在再结晶起始阶段依靠引发DDRX的晶界应变集中效应,产生了大量的亚结构,又在形核阶段通过CDRX的亚晶旋转形核机制,最终形成了新的再结晶组织。

REFERENCES

[1] 赖敏杰, 李金山. 亚稳β钛合金的变形孪晶和应力诱发相变[J]. 中国有色金属学报, 2019, 29(9): 2185-2191.

LAI Min-jie, LI Jin-shan. Deformation twinning and stress-induced phase transformation in metastable β titanium alloys[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(9): 2185-2191.

[2] 金和喜, 魏克湘, 李建明, 等. 航空用钛合金研究进展[J]. 中国有色金属学报, 2015, 25(2): 280-292.

JIN He- xi, WEI Ke- xiang, LI Jian -ming, et al. Research development oftitanium alloy inaerospaceindustry[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(2): 280-292.

[3] 陈强, 王庆娟, 王鼎春, 等. 锻件组织不均匀性对新型近β钛合金组织与力学性能的影响[J]. 中国有色金属学报, 2018, 28(1): 87-96.

CHEN Qiang, WANG Qing- juan, WANG Ding-chun, et al. Effect of microstructure inhomogeneity of forgings on microstructure and mechanical properties of new near β titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(1): 87-96.

[4] 张崇乐, 包翔云, 张金钰, 等. 亚稳态β钛合金的成分设计、变形机制与力学性能[J]. 稀有金属材料科学与工程, 2021, 50(2): 717-724.

ZHANG Chong-le, BAO Xiang-yun, ZHANG Jin-yu, et al. Composition design, deformation mechanism and mechanical properties of metastable β titanium alloy[J]. Rare Metal Materials and Engineering, 2021, 50(2): 717-724

[5] 李超, 张晓泳, 李志友, 等. 热处理对超细晶Ti-55511近β钛合金显微组织和力学性能的影响[J]. 中国有色金属学报, 2014, 24(5): 1251-1258.

LI Chao, ZHANG Xiao-yong, LI Zhi-you, et al. Effect of heat treatment on microstructure and mechanical properties of ultra-fine grained Ti-55511 near β titanium alloy[J]. The Chinese Journal of Nonferrous Metals, 2014, 24(5): 1251-1258.

[6] BANERJEE Dipankar WILLIAMS J C. Perspectives on titanium science and technology[J]. Acta Materialia, 2013, 61: 844-879.

[7] HUA Ke, XUE Xiang-yi, KOU Hong-chao, et al. Characterization of hot deformation microstructure of a near beta titanium alloy Ti-5553[J]. Journal of Alloys and Compounds, 2014, 615: 531-537.

[8] 周伟, 葛鹏, 赵永庆, 等. Ti-5553合金高温变形时动态再结晶行为[J]. 稀有金属材料科学与工程, 2012, 41(8): 1381-1384.

ZHOU WEI, GE Peng, ZHAO Yong-qing, et al. he Dynamic Recrystallization behavior of Ti-5553 titanium alloy during hot deformation[J]. Rare Metal Materials and Engineering, 2012, 41(8): 1381-1384.

[9] 张乐, 刘莹莹, 孙宇幸, 等. 缺口和平均应力对 TC18 棒材疲劳强度的影响[J]. 中国有色金属学报, 2018, 28(12): 2450-2456.

ZHANG Le, LIU Ying- ying, SUN Yu -xing, et al. Effect of notch and mean stress on fatigue strength of TC18 alloy bars[J]. The Chinese Journal of Nonferrous Metals, 2018, 28(12): 2450-2456.

[10] 贾宝华, 刘思勇, 李革, 等. TC18 合金高温动态力学行为表征[J]. 中国有色金属学报, 2019, 29(10): 2292-2298.

JIA Bao-hua, LIU Si- yong, LI Ge, et al. Characterization of high temperature dynamic mechanical behavior for TC18 alloy[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(10): 2292-2298.

[11] YANG F, GABBITA S. Feasibility of producing Ti-6Al-4V alloy for engineering application by powder compact extrusion of blended elemental powder mixtures[J]. Journal of Alloys and Compounds, 2017, 695: 1455-1461.

[12] ZHAO Qin-yang, YANG Fei, TORRENS Rob, et al. Evaluation of the hot workability and deformation mechanisms for a metastable beta titanium alloy prepared from powder[J]. Materials Characterization, 2019, 149:226-238.

[13] WEISS I, SEMIATIN S L. Thermomechanical processing of beta titanium alloys—an overview[J]. Materials Science and Engineering A, 1998, 243: 46-65.

[14] 黄伯云, 韦伟峰, 李松林, 等. 现代粉末冶金材料与技术进展[J]. 中国有色金属学报, 2019, 29(9): 1917-1933. HUANG Bai-yun, WEI Wei-feng, LI Song-lin, et al. Development of modern powder metallurgy materials and technology[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(9): 1917-1933.

[15] SAKAI Taku, BELYAKOV Andrey, KAIBYSHEY Rustam, et al. Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions[J]. Progress in Materials Science, 2014, 60:130-207.

[16] ZHANG H K, XIAO H, FANG X W, et al. A critical assessment of experimental investigation of dynamic recrystallization of metallic materials[J]. Materials and Design, 2020, 193: 108873.

[17] MIZADEH H, NAJAFIZADEH A, Prediction of the critical conditions for initiation of dynamic recrystallization[J]. Materials and Design, 2010, 31: 1174-1179.

[18] LIN Y C, HUANG Juan, HE Dao-guang, et al. Phase transformation and dynamic recrystallization behaviors in a Ti55511 titanium alloy during hot compression[J]. Journal of Alloys and Compounds, 2019, 759: 471-482.

[19] NING Y Q, LIANG H Q, GUO H Z, et al. Competition between dynamic recovery and recrystallization during hot deformation for TC18 titanium alloy[J]. Materials Science and Engineering A, 2015, 635: 77-85.

[20] ZHOU Da-di, ZENG Wei-dong, Xu Jian-wei, et al. Evolution of equiaxed and lamellar α during hot compression in a near alpha titanium alloy with bimodal microstructure[J]. Materials Characterization, 2019, 151:103-111.

[21] HUANG K, LOGE R E. A review of dynamic recrystallization phenomena in metallic materials[J]. Materials and Design, 2016, 111: 548-574.

[22] JIANG M G, Xu C, YAN H, et al. Unveiling the formation of basal texture variations based on twinning and dynamic recrystallization in AZ31 magnesium alloy during extrusion[J]. Acta Materialia, 2018, 157: 53-71.

[23] HAO Mei-juan, CHENG Wei-li, WANG Li-fei, et al. Texture evolution induced by twinning and dynamic recrystallization in dilute Mg-1Sn-1Zn-1Al alloy during hot compression[J]. Journal of Magnesium and Alloys, 2020, 8: 899-909.

[24] YAN C K, FENG A H, QU S J, et al. Dynamic recrystallization of titanium: Effect of pre-activated twinning at cryogenic temperature[J]. Acta Materialia, 2018, 154: 311-324.

[25] WANG Ke-hua, LIU Gang, HUANG K, et al. Effect of recrystallization on hot deformation mechanism of TA15 titanium alloy under uniaxial tension and biaxial gas bulging conditions[J]. Materials Science and Engineering A, 2017, 708: 149-158.

[26] WU Yang, KOU Hong-chao, WU Zhi-hong, et al. Dynamic recrystallization and texture evolution of Ti-22Al-25Nb alloy during plane-strain compression[J]. Journal of Alloys and Compounds, 2018, 749: 844-852.

[27] WANG Xuan, WANG Liang, LUO Liang-shun, et al. Hot deformation behavior and dynamic recrystallization of melt hydrogenated Ti-6Al-4V alloy[J]. Journal of Alloys and Compounds, 2017, 728: 709-718.

Dynamic recrystallization mechanism of as-cast metastable β titanium alloy during high-strain-rate deformation

ZHAO Qin-yang1, CHEN Yong-nan1, XU Yi-ku1, TORRENS Rob2, BOLZONI Leandro2, YANG Fei2

(1. School of Materials Science and Engineering, Chang’an University, Xi’an 710064, China;

2. Waikato Centre for Advanced Materials and Manufacturing, University of Waikato, Hamilton 3216, New Zealand)

Abstract: Based on thermal-mechanical simulation, the hot deformation behaviour of as-cast metastable β Ti-5553 titanium alloy at the conditions of high-temperature and high-strain-rate was investigated thoroughly. With the combination of various characterization approaches, the detailed microstructure evolution process of the novel dynamic recrystallization (DRX) mechanism and the effects of deformation parameters on it are revealed and analyzed. It is found that the flow softening of the alloy at high-temperature and high-strain-rate conditions are dominated by the synergy of dynamic recrystallization and deformation instability. The nucleation site, grain size and fraction of the recrystallized grain show great sensitivity to the deformation parameters. The disclosed DRX process is revealed to be controlled by the coupling mechanism of widely-accepted discontinuous (DDRX) and continuous (CDRX) mechanisms, containing strain localization induced nucleation and sub-grain rotation induced transformation.

Key words: metastable β titanium alloy; hot deformation; microstructural evolution; deformation mechanism; dynamic recrystallization

Foundation item: Young Talents Promotion Project of CAST; Science and Technology Major Project of Shaanxi Province (2020-zdzx04-01-02); Key Research Plan of Shaanxi Province (2021KW-18; 2020ZDLGY12-03)

Received date: 2021-07-08; Accepted date: 2021-08-05

Corresponding author: ZHAO Qin-yang; Tel: +86-15029095873; E-mail: zqy@chd.edu.cn

(编辑 某某某)

基金项目:中国科协青年人才托举工程;陕西省科技重大专项(2020zdzx04-01-02);陕西省重点研发计划(2021KW-18, 2020ZDLGY12-03)

收稿日期:2021-07-08;修订日期:2021-08-05

通信作者:赵秦阳,博士;电话:15029095873;E-mail:zqy@chd.edu.cn