DOI: 10.11817/j.ysxb.1004.0609.2020-37665

热处理纤维增强碳基复合材料的力学性能和抗氧化性能

邹 雪1,代吉祥1, 2,沙建军1, 2,吕钊钊1

(1. 大连理工大学 工业装备结构分析国家重点实验室,大连 116024;

2. 大连理工大学 航空航天学院,辽宁省空天飞行器前沿技术重点实验室,大连 116024)

摘 要:以不同温度热处理纤维为增强体,以酚醛树脂为碳基体先驱体,利用先驱体浸渍裂解(PIP)工艺制备碳纤维增强碳基(C/C)复合材料。微观形貌观察发现纤维热处理能够改变C/C多孔体(经过一次裂解后)的孔隙尺寸和分布模式。力学性能测试发现,随着热处理温度提高,C/C复合材料的力学性能不断提高,对纤维进行1200 ℃热处理后,C/C弯曲强度和层间剪切强度分别提高了1.58倍和1.21倍,同时失效模式由脆性断裂转变为假塑性断裂。抗氧化性能研究发现,600 ℃热处理纤维增强材料的抗氧化性能提升,而更高温度的纤维热处理导致材料抗氧化性能下降。C/C复合材料性能变化的主要原因是热处理降低纤维表面的反应活性,使得C/C获得结合适宜的纤 维/基体界面。

关键词:C/C复合材料;热处理;力学性能;抗氧化性能

文章编号:1004-0609(2020)-09-2084-10 中图分类号:TB332 文献标志码:A

碳/碳(C/C)复合材料是以碳纤维织物为增强相的碳基复合材料,其比强度高、热膨胀系数小、热导率高以及高温力学性能优异,是极少数可用于2000 ℃以上的热结构材料之一,因此被广泛地应用在火箭喷管、再入飞行器头部及翼前缘等高温结构领域[1-4]。当前,C/C复合材料的编织、成型和复合技术取得了长足的进展,已开发出气相和液相工艺路线,这两种工艺均有优缺点[5-7]。气相法的优点是致密化过程可以精细控制,制备的C/C复合材料性能突出,英国在20世纪70年代已将这种工艺路线制备的C/C复合材料用在“协和号”飞机上[8]。但该工艺制备周期长、效率低且成本高。液相法主要是利用树脂或沥青等碳源材料在高温下的流动性对预制体进行浸渍,再通过裂解获得碳基体,但是在裂解过程中基体结构将出现大量孔隙,因此需要多次循环浸渍裂解才能获得致密基体。

无论采取何种工艺,界面是影响复合材料关键性能的核心要素。一方面,在高温有氧环境下,C/C复合材料的氧化优先在纤维/基体界面处发起并沿着界面不断深入[9-11],因此,高温氧化一直是限制这类材料更广泛应用的关键问题。通过在基体中添加氧化抑制剂和在材料表面制备高温抗氧化涂层,使得该类材料理论上能达到1773 K甚至更高温度的长时间抗氧化能力,从而在高温结构领域实现新的突破[12-16]。另一方面界面结合特性直接影响着纤维-基体间的载荷传递能力[17],FITZER等[18]提出碳纤维/基体先驱体弱界面观点,过强的界面结合在碳化后会产生大的收缩应力,促进裂纹向纤维扩展,使得材料破坏呈脆性断裂模式,脆性断裂的材料易引发灾难性后果,不宜作为工程材料使用。

纤维增强复合材料的界面结合分为物理结合和化学结合,物理结合主要与纤维表面结构有关,纤维表面越粗糙,纤维/基体界面的比表面积越大,且机械啮合作用越强。化学结合主要与纤维表面活性有关,纤维表面活性越高,其与基体的界面结合能力越强[19]。未经任何处理的原始碳纤维表面通常会有聚酰胺酯、环氧树脂等上浆剂,这些有机物含有较多的含氧官能团,其中—OH、—COOH会与酚醛树脂的—OH发生缩聚反应,在碳化后形成C—C键,使纤维/基体形成强界面结合[20]。

对碳纤维进行表面处理能够调整其表面状态,从而实现对纤维与基体之间界面结合特性的调控[9, 21-24]。易增博等[22]利用硝酸对纤维进行表面处理,酸处理会使得纤维表面活性提高,从而提高了其与基体的界面结合强度,因此明显改善了复合材料的拉伸强度和弯曲强度,但是复合材料断裂模式倾向于脆性断裂。LABRUQUERE等[9]使用预氧化碳纤维制备了C/C复合材料,发现与未处理纤维相比,预氧化改变了纤维表面的粗糙度,表面沟槽呈现阶梯状,纤维/基体界面物理结合加强;LI等[23]同样对纤维进行了大气预氧化处理,发现氧化处理会使得纤维与基体的物理结合强度升高,从而提高了复合材料的弯曲强度,但是这种预氧化处理方法会暴露纤维表面的结构缺陷,降低纤维的自身拉伸强度;李伟等[24]则对纤维在2500 ℃氩气环境下进行热处理,发现经过热处理后纤维表面的活性基团显著减少,纤维/基体界面结合以物理结合为主,其断裂模式虽然转变为假塑性,但是C/C复合材料的强度却明显下降。

在前期的研究中发现[25-26],对碳纤维经过不同温度的热处理后,与C原子结合的含氧官能团相对含量随热处理温度增高呈现出明显下降趋势。这表明高温热处理会降低纤维表面的活性,因此其与树脂基体的结合作用就减弱。采用单纤维顶出实验表征了纤维增强树脂基复合材料中热处理碳纤维与树脂的界面结合强度[27],发现随着纤维热处理温度的升高,纤维与树脂基体界面结合强度明显下降,下降原因主要是热处理导致纤维表面活性降低。在聚合物浸渍裂解工艺(PIP)制备C/C复合材料中,先驱体中纤维/树脂界面结合的强弱会直接影响到C/C复合材料的微观结构[18],微结构不同就直接影响最终材料的关键性能,因此C/C复合材料的相关性能可以通过纤维热处理进行调控。

为此,在本研究中对碳纤维进行不同温度的热处理,改变其与碳基体的界面结合特性,通过聚合物浸渍裂解工艺(PIP)制备了C/C复合材料,采用三点弯曲法和动、静态氧化实验来研究热处理纤维增强碳基复合材料的力学性能和抗氧化性能,并通过微观形貌观察来探究纤维热处理对C/C复合材料性能的影响机制。

1 实验

1.1 试样制备

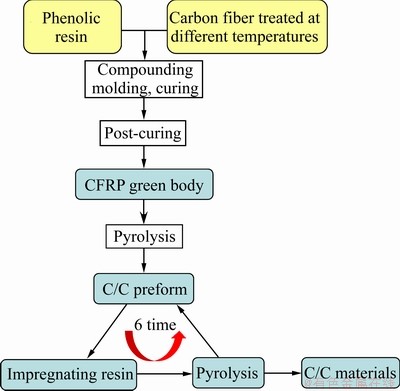

采用平纹编织的T300碳纤维(0/90°编织,日本东丽公司生产),将原始纤维布裁剪为模具大小尺寸后置于高温石墨炉中,然后高温炉加热至设定温度后在氮气氛围保持60 min进行热处理,热处理温度分别为600、1200和1500 ℃,保温结束后随炉冷却取出纤维布,将这些纤维布在酚醛树脂溶液中进行浸渍晾干后,在模具中将纤维布依次进行叠加铺层,按照设定好的试样厚度进行铺层,铺层结束后连同整个模具进行温压固化,固化结束进行脱模处理。为消除固化过程中的热应力和增加碳残留率[28],将脱模后获得的碳纤维增强树脂先驱体(Carbon fiber reinforced polymer, CFRP)进行后固化,之后将CFRP先驱体在高温(>1000 ℃)真空环境中裂解获得碳/碳多孔体,将此多孔体再经过树脂浸渗和高温裂解,如此往复循环6次后得到致密的C/C复合材料,具体制备流程如图1所示。最终复合材料中纤维的体积分数基本一致,约为50%。

图1 先驱体浸渍裂解法制备C/C复合材料的工艺流程

Fig. 1 Flow chart for fabrication of C/C composites by precursor impregnation pyrolysis

1.2 孔隙率与致密度

采用阿基米德排水法(Archimedes’s)测量样品的孔隙率和密度,计算公式如下:

(1)

(1)

(2)

(2)

式中:m1为试样的干燥质量;m2为饱和试样在空气中的质量;m3为饱和试样在蒸馏水中质量;q、 、

、 分别为试样的开孔率、密度和蒸馏水的密度。

分别为试样的开孔率、密度和蒸馏水的密度。

1.3 力学性能

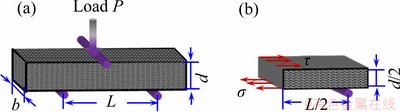

利用万能力学试验机,采用三点弯曲法分别对复合材料的弯曲强度和层间剪切强度进行测试。图2所示为三点弯曲测试的样品示意图和受力分析。

图2 三点弯测试复合材料力学性能示意图

Fig. 2 Schematic illustrations of three-point bending test for mechanical properties(a) and analysis of shear stress during loading(b)

图2(a)中P为试样所受载荷,L为跨距,b为试样宽度,d为试样厚度。取1/4样品进行受力分析(见图2(b)),其中 为最大弯曲应力,

为最大弯曲应力, 为最大层间剪切应力。其计算公式如下:

为最大层间剪切应力。其计算公式如下:

(3)

(3)

(4)

(4)

弯曲应力最大值和切应力最大值的关系为:

(5)

(5)

从式(5)可知,当跨厚比( )较小时,

)较小时, 较小,更倾向于层间剪切破坏模式;当跨厚比(

较小,更倾向于层间剪切破坏模式;当跨厚比( )较大时,

)较大时, 较大,更倾向于弯曲破坏模式。因此,当样品厚度一定时,通过调整三点弯的跨距可以改变材料的破坏模式。根据ASTM D790-17,弯曲强度按照式(3)进行计算,测试尺寸为50 mm×10 mm×4 mm,跨距为40 mm;层间剪切测试根据ASTM D2344,剪切强度按照式(4)进行计算,测试尺寸为25 mm×10 mm×4 mm,跨距为16 mm,加载速度均为0.5 mm/min;每个条件取不少于5个样品用于测试。测试结束后用扫描电镜(SEM,QUANTA 450)观察试样的断口形貌。

较大,更倾向于弯曲破坏模式。因此,当样品厚度一定时,通过调整三点弯的跨距可以改变材料的破坏模式。根据ASTM D790-17,弯曲强度按照式(3)进行计算,测试尺寸为50 mm×10 mm×4 mm,跨距为40 mm;层间剪切测试根据ASTM D2344,剪切强度按照式(4)进行计算,测试尺寸为25 mm×10 mm×4 mm,跨距为16 mm,加载速度均为0.5 mm/min;每个条件取不少于5个样品用于测试。测试结束后用扫描电镜(SEM,QUANTA 450)观察试样的断口形貌。

1.4 抗氧化性能

采取热重分析(TGA,SDT Q600)和等温氧化实验来测试材料的抗氧化性能。热重分析的升温速率为10 ℃/min,测试最高温度为800 ℃,测试中记录样品质量随温度升高的变化曲线。等温氧化实验温度为650 ℃,氧化总时长为100 min,质量测试时长间隔为20 min,测试结束后采用扫描电镜观察氧化后的微观形貌。

2 结果与讨论

2.1 致密度

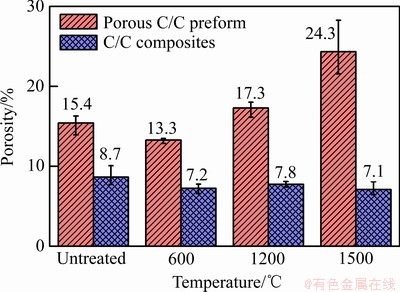

图3所示为致密化前后材料的孔隙率变化。

图3 经1次和6次致密化后C/C复合材料的孔隙率变化

Fig. 3 Porosity of C/C composites after 1 and 6 PIP cycles

可以看到经过第一次PIP工艺后,未处理纤维增强复合材料的孔隙率为15.4%。而经600 ℃热处理后,孔隙率略有下降(13.3%),更高温度的热处理明显导致材料的孔隙率增大,1500 ℃热处理纤维增强材料的孔隙率为24.3%,是未处理纤维增强材料的1.58倍。这表明纤维热处理改变了C/C多孔体中的孔隙率,这些孔隙将在PIP循环中被碳基体所填充,在经过6个循环后,C/C复合材料的孔隙率均降至10%以下。

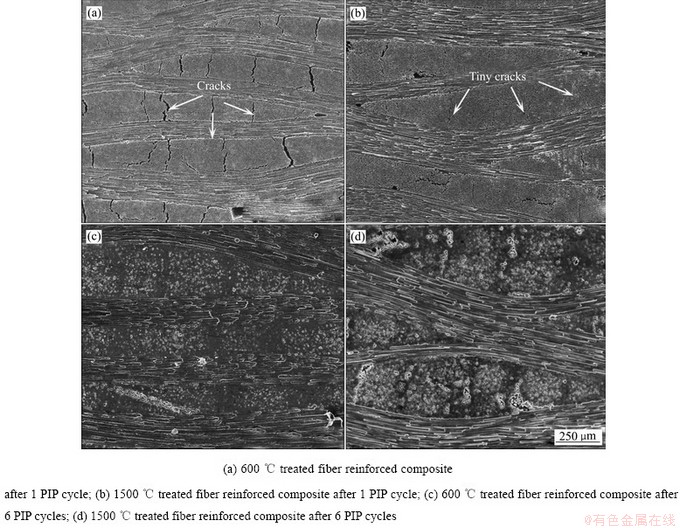

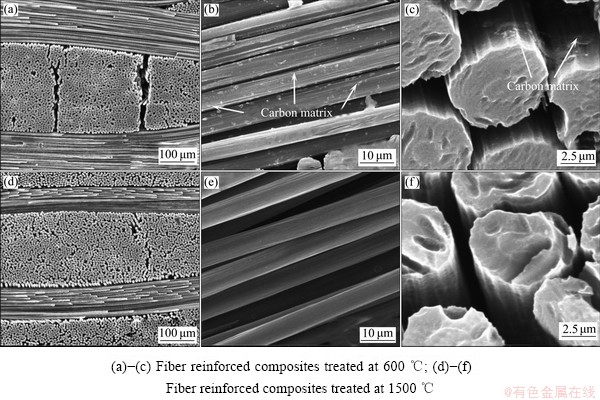

2.2 微观形貌

图4所示为不同温度热处理纤维增强复合材料经1次和6次PIP致密化后的微观形貌,观察发现热处理温度对材料微观形貌产生了显著影响。由图4(a)可以看出,600 ℃热处理纤维增强材料经过1次PIP后,在经向纤维束内分布着很多规则的贯穿裂纹,同时纬向纤维束和经向纤维束的界面处分布着脱层裂纹。贯穿裂纹使得经向纤维束呈段状分布,在每一段内C/C材料较为致密。随着热处理温度升高,大的贯穿裂纹减少但是细小微裂纹增多,材料孔隙率增大(见图3),1500 ℃热处理纤维增强材料经过1次PIP后,贯穿裂纹消失,主要为纤维/基体之间的脱粘微裂纹,如图 4(b)所示。由于大量脱粘微裂纹的存在,虽然孔隙尺寸小,但孔隙率却高于其他低温处理纤维增强的材料。

图4 不同温度热处理纤维增强复合材料经1次和6次PIP致密化后的微观形貌

Fig. 4 Morphologies of different C/C composites after 1 PIP cycle and 6 PIP cycles

C/C多孔体裂纹模式和孔隙率的变化主要与CFRP先驱体中纤维与树脂先驱体之间的界面结合相关[27, 29]。纤维经过600 ℃热处理后,纤维表面的有机物挥发暴露了其沟槽结构,从而使得纤维与树脂先驱体的物理结合更紧,而更高温度的热处理将主要影响纤维表面的活性官能团。从XPS 的精细元素谱分析可知,C 原子结合的含氧官能团的相对含量分别为35.56%(未处理纤维),18.15%(900 ℃热处理),10.3% (1500 ℃热处理),呈现明显下降趋势[25],纤维表面含氧官能团的降低导致其化学活性降低,继而先驱体中纤维与树脂之间的界面结合也变弱[26]。在先驱体的高温裂解过程中,树脂基体发生显著收缩并与纤维相互作用产生内应力。当材料内部应力超过基体所能承受的应力时,裂纹首先在基体中萌生,而基体收缩产生的拉应力将使得萌生的微小裂纹沿着与拉应力垂直的方向扩展,从而造成裂纹呈竖状规则分布,形成图4(a)中的裂纹分布模式。纤维高温热处理后,其与基体的界面结合减弱,微裂纹倾向于在纤维/基体的弱界面处萌生扩展,从而导致纤维与基体的大面积脱粘,出现图4(b)中的裂纹分布模式,这种分布模式造成材料的孔隙率明显提高。这些孔隙在经过6次PIP循环之后,绝大多数孔隙均被碳基体所填充,孔隙率明显降低,如图4(c)~(d)所示。

2.3 力学性能

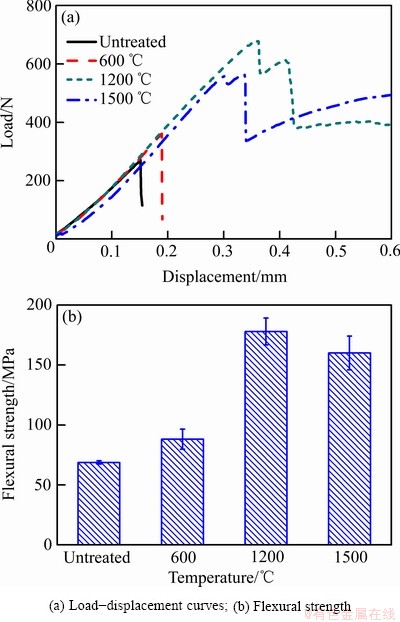

图5所示为不同温度热处理纤维增强碳基复合材料的弯曲强度测试结果。图5(a)显示了测试过程中的位移-载荷曲线,可以看出这些曲线明显不同。

图5 热处理温度对复合材料弯曲强度的影响

Fig.5 Influence of fibers’ heat treatment temperature on flexural strength of composites

未处理和600 ℃热处理纤维增强的材料呈现出典型的脆性断裂特征,且其断裂载荷值也较低。随着纤维热处理温度的上升,材料的断裂特征发生了明显变化,断裂载荷值显著增大,且载荷在达到最高值后阶梯状下降,每个台阶均有上升趋势,但上升趋势逐渐减缓,呈典型的假塑性断裂特征。对比1200 ℃热处理纤维增强材料,1500 ℃热处理纤维增强材料的断裂载荷值出现下降。根据图5(a)中的最高载荷值可以计算出其弯曲强度,结果如图5(b)所示,可以发现随着热处理温度的提高,C/C复合材料的弯曲强度逐渐提高,1200 ℃热处理纤维增强材料的弯曲强度最高,达到(178±11) MPa,相比未处理纤维增强的材料提高了1.58倍。当温度继续提高时,弯曲强度却反而下降。

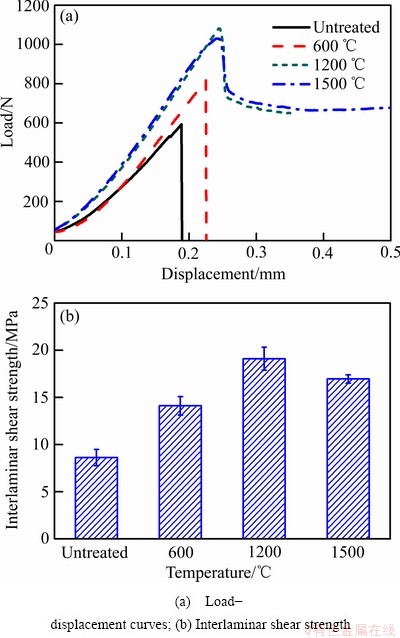

图6所示为不同温度热处理纤维增强C/C复合材料的层间剪切测试结果,图6(a)为层间剪切测试中的载荷-位移曲线,可以看出断裂模式与弯曲强度测试基本一致(见图5(a)),只是在1200 ℃和1500 ℃热处理纤维增强的材料中,载荷并没有阶梯式下降,而是缓慢下降为平台。

图6(b)所示为计算得到的层间剪切强度,可以看出变化趋势和弯曲强度类似,1200 ℃热处理纤维增强材料的剪切强度最高,为(19±1) MPa,相比未处理纤维增强材料提高了1.21倍。

图6 热处理温度对复合材料层间剪切强度的影响

Fig.6 The influence of fibers’ heat treatment temperature on interlaminar shear strength of composites

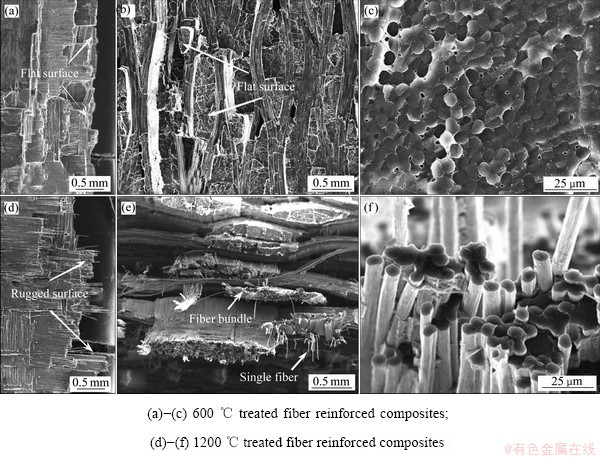

2.4 断口形貌

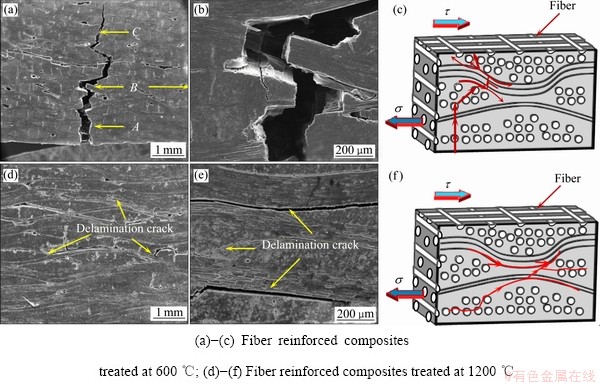

为探究纤维热处理影响C/C复合材料力学性能的原因,对测试后的断口形貌进行观察分析。图7所示为不同复合材料弯曲强度测试后的断口侧面和断口正面。从图7(a)中可以看出断口比较整齐,而在图7(b)可进一步看出纤维拔出长度短,且纤维束的断面比较平整,这表明此类材料中纤维与基体的界面结合较强(见图7(c)),因此表现为脆性破坏模式。

1200 ℃热处理纤维增强材料的断口参差不齐,如图7(d)所示,其纤维的拔出量不仅多而且长度长。此外,也观察到有很多单根纤维的拔出(见图7(e)),这些拔出行为更能够耗散能量,从而提高C/C复合材料的弯曲强度。同时其断裂曲线出现阶梯状的原因可能是在力最大时,材料失去进一步抵抗变形的能力,部分基体开裂,同时伴随着少量纤维的断裂和脱粘,消耗掉一部分能量,此时材料完整部分仍具有承载能力,但承载能力降低(载荷直线下降),这时纤维仍然具有较强的承载能力,因此曲线以新的趋势上升。随着基体开裂和纤维断裂/脱粘的不断增多,材料抵抗外力能力逐渐变弱,因此在台阶式断裂中,每一个新的台阶斜率逐步趋于平缓(见图5(a))。在1200 ℃热处理纤维增强的复合材料中,纤维与基体之间的结合强度适中(见图7(f)),材料的力学性能最优。

图7 C/C复合材料弯曲强度测试后的断口形貌

Fig. 7 Fracture morphologies of different C/C composites after flexural test

图8所示为不同材料在层间剪切测试中的裂纹传递路线,图8(a)所示为600 ℃热处理纤维增强材料中的裂纹扩展路线。根据材料测试中的受力状态,可以自下而上将裂纹扩展分为A、B、C三个区域。在区域A,材料主要经受的是张应力作用;区域B为张应力向压应力的过渡区;区域C中材料主要受压应力作用。区域A主要是竖向传递裂纹,区域B中剪切应力作用突出,因此剪切破坏特征比较明显,如图8(b)所示,裂纹既有竖向扩展又有横向扩展。由于600 ℃热处理纤维增强材料中的纤维/基体界面结合较强,裂纹不易沿层间传播,因此裂纹主要为竖向传播(见图8(c)),这种裂纹传递释放能量较快,因此造成了脆性断裂。当裂纹穿过区域B后进入区域C,由于区域C压应力较大,因此裂纹尖端的应力强度较弱,压应力抑制了裂纹的扩展,所以裂纹逐渐终止。图8(d)所示为1200 ℃热处理纤维增强材料的裂纹传递路线,在材料中没有明显的破坏裂纹,但是高倍显微分析发现了很多层间传递的裂纹。这些层间传递的裂纹主要分布在经向和纬向纤维束间和经向纤维束内(见图8(e))。由于1200 ℃热处理纤维增强材料中纤维与基体的结合较弱,在剪应力作用下,裂纹主要在弱界面处传递(见图8(f))。这种传递形式释放能量较慢,材料为逐步破坏,导致材料假塑性断裂(见图6(a)),但是由于厚度方向上没有增强纤维,而平面内纤维的拔出对层间传递裂纹的影响有限,因此层间剪切曲线并没有出现阶梯状。

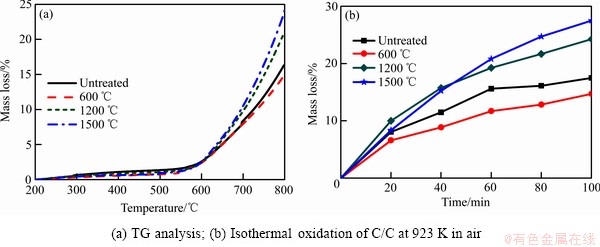

2.5 抗氧化性能

图9所示为不同温度热处理纤维增强材料的氧化实验结果。图9(a)所示为热重分析结果,可以看到相比未处理纤维增强材料,600 ℃热处理纤维增强材料的抗氧化性得到提高,而1200 ℃和1500 ℃热处理纤维增强材料的抗氧化性能下降。等温氧化实验结果与热重分析结果一致,如图9(b)所示。另外还可以看到,氧化初始阶段(前20 min),C/C复合材料的氧化速率较快(0.175~0.270 mg/min),随着氧化时间增加,氧化速率开始降低(0.054~0.129 mg/min)。

图8 C/C复合材料层间剪切测试后的裂纹传递路线

Fig.8 Crack propagation routes of different C/C composites after interlaminar shear test

图9 C/C复合材料氧化质量损失率与氧化时间的关系

Fig. 9 Mass loss as a function of exposure time for C/C composites under oxidative environments

图10所示为600 ℃和1500 ℃热处理纤维增强材料热重分析后的微观形貌,低倍镜下可以看到复合材料中出现大量孔隙及裂纹(见图10(a)与(d))。这些孔隙和裂纹的分布模式和未致密化的C/C多孔体类似(如图4(a)~(b)),表明氧化使得致密化过程中填充的碳基体被部分消耗。进一步放大可以看到,两种材料中的碳纤维几乎都没有明显的损伤。600 ℃热处理纤维表面可以观察到部分残留的碳基体,而1500 ℃热处理纤维表面相对比较干净,碳基体几乎被氧化消耗殆尽。C/C复合材料的氧化性能与其纤维/基体界面结合特性有着紧密的联系[9],600 ℃热处理纤维与基体有着强结合的界面,在氧化过程中,氧不容易通过这种强结合的纤维/基体界面扩散至材料内部,从而氧化质量损失小。而1200 ℃和1500 ℃热处理纤维的表面活性显著下降[25-26],C/C多孔体的孔隙率明显上升,纤维与基体的界面结合适中,所以其力学性能明显提升且为假塑性断裂模式。但是变弱的纤维/基体界面容易导致部分界面脱粘,界面的脱粘成为氧渗入的通道,促进材料的不断氧化,从而此类材料的质量损失较高。

图10 C/C复合材料TG抗氧化测试后的微观形貌

Fig. 10 Microstructures of different C/C composites after TG tests

3 结论

1) 纤维热处理温度提高,C/C复合材料的力学性能逐渐提高,1200 ℃热处理纤维增强材料的弯曲强度和层间剪切强度相比未处理纤维增强的材料,分别提高了1.58倍和1.21倍,同时其失效模式逐步由脆性断裂转变为假塑性断裂。

2) 抗氧化性能研究发现,600 ℃热处理纤维增强材料的抗氧化性能提升,而1200 ℃和1500 ℃热处理纤维增强材料的抗氧化性能下降。

3) 力学性能的显著改善主要是由于纤维热处理降低了纤维表面的反应活性,使得其增强的C/C复合材料获得了结合适中的纤维/基体界面,但是这种界面却不利于材料的抗氧化性能改善。

REFERENCES

[1] WINDHORST T, BLOUNT G. Carbon-carbon composites: A summary of recent developments and applications[J]. Materials & Design, 1997, 18(1): 11-15.

[2] FU Q G, SHAN Y C, WEN S Q, LI H J, CHU Y H, LIU X S. Oxidation pre-treatment to improve the mechanical property and oxidation resistance of Si-Mo-Cr coated C/C composites[J]. Corrosion Science, 2014(83): 103-110.

[3] FANG H C, XIAO P, XIONG X, YU G J. Microstructures, mechanical and oxidation behaviors of C/C composites modified by NiAl alloy[J]. Transactions of Nonferrous Metals Society of China, 2016, 26(1): 196-202.

[4] GE C Y, LIU Y Q, WU S, WU H, MAO P L,YI M Z. Characterization of SiC nanowires prepared on C/C composite without catalyst by CVD[J]. Transactions of Nonferrous Metals Society of China, 2015, 25(10): 3258-3264.

[5] DELHAES P. Chemical vapor deposition and infiltration processes of carbon materials[J]. Carbon, 2002, 40(5): 641-657.

[6] 夏莉红, 黄伯云, 张福勤, 黄启忠, 王 蕾. C/C复合材料致密化工艺的研究进展[J]. 材料导报, 2008(5): 107-110.

XIA Li-hong, HUANG Bai-yun, ZHANG Fu-qin, HUANG Qi-zhong, WANG Lei. Research progress in densification techniques for carbon/carbon composites[J]. Materials Reports, 2008(5): 107-110.

[7] 熊 翔, 黄伯云. 沥青炭基体C/C复合材料单向层间剪切性能及破坏机理[J]. 中国有色金属学报, 2003, 13(2): 377-382.

XIONG Xiang, HUANG Bai-yun. Interlaminar shear strength and destroy mechanism of 1D C/ C composites with pitch-C matrix[J]. The Chinese Journal of Nonferrous Metals, 2003, 13(2): 377-382.

[8] WINDHORS T, BLOUNT G. Carbon-carbon composites: A summary of recent developments and applications[J]. Materials & Design, 1997, 18(1): 11-15.

[9] LABRUQUERE S, BOURRAT X, PAILLER R, NASLAIN R. Structure and oxidation of C/C composites: role of the interface[J]. Carbon, 2001, 39(7): 971-984.

[10] NASLAIN R, PAILLER R, BOURRAT X, LABRUQUERE S, DUVIVIER E. The role of interfaces in the oxidation of 3D-carbon/carbon composites[J]. Ceramic Engineering and Science Proceedings, 2002, 23(3): 287-294.

[11] ZHANG C Y, YAN K F, QIAO S R, LI M, HAN D, GUO Y. Effect of oxidation on fracture toughness of a carbon/carbon composite[J]. Journal of Wuhan University of Technology-Materials Science Edition, 2012, 27 (5): 944-947.

[12] PARK S J, SOE M K. The effects of MoSi2 on the oxidation behavior of carbon/carbon composites[J]. Carbon, 2001, 39(8): 1229-1235.

[13] YANG J H, JIAO J, WANG L, LI B W. Spark plasma sintering of silicon carbide powders with carbon and boron as additives[M]. Ceramic Transactions. New Jersey: John Wiley & Sons Inc, 2017.

[14] WANG C C, LI K Z, HE Q C, SU Y Y, HUO C X, SHI X H. Oxidation resistance and mechanical properties of LaB6-MoSi2-SiC ceramic coating toughened by SiC nanowires[J]. Ceramics Intentional, 2018, 44(14): 16365-16378.

[15] ZHUANG L, FU Q G, YU X. Improved thermal shock resistance of SiCnw/PyC core-shell structure toughened CVD-SiC coating[J]. Journal of the European Ceramic Society, 2018, 38(7): 2808-2814.

[16] 王宇杰, 张明瑜, 苏哲安, 李一鸣, 黄启忠. C/C复合材料预氧化处理对其SiC-ZrC-ZrB2涂层抗氧化性能的影响[J]. 中国有色金属学报, 2019, 29(3): 559-568.

WANG Yu-jie, ZHANG Ming-yu, SU Zhe-an, LI Yi-ming, HUANG Qi-zhong. Effect of pre-oxidation treatment of C/C composites on its oxidation resistance of SiC-ZrC-ZrB2 coating[J]. The Chinese Journal of Nonferrous Metals, 2019, 29(3): 559-568.

[17] LU X F, XIAO P, XU X F, CHENG J. Flexural destructive process of unidirectional carbon/carbon composites reinforced with in situ grown carbon nanofibers[J]. Transactions of Nonferrous Metals Society of China, 2014, 24(10): 3134-3141.

[18] FITZER E, GRIGL K H, HUTTNER W. The influence of C-fiber surface treatment on the mechanical properties of C/C composites[J]. Carbon, 1980, 18(1): 62-62.

[19] SUN W C, LI H J, FU Q G, ZHANG S Y . Influence of carbon fiber pre-treatments on interlaminar shear strength and fracture behavior of C/C composites[J]. Materials Science Forum, 2011, 1299(1372): 482-487.

[20] 李崇俊, 金志浩, 郑金煌, 马伯信. 碳纤维表面状态对C/C复合材料性能影响的研究[J].宇航材料工艺, 2000(3): 25-29.

LI Chong-jun, JIN Zhi-hao, ZHENG Jin-huang, MA Bo-xin. Effects of carbon fiber surface states on properties of C/C composites[J]. Aerospace Materials & Technology, 2000(3): 25-29.

[21] 乔伟静, 田艳红, 张学军. 国产聚丙烯腈基高强高模碳纤维电化学氧化表面处理工艺[J]. 复合材料学报, 2018, 35(9): 2449-2457.

QIAO Wei-jing, TIAN Yan-hong, ZHANG Xue-jun. Electrochemical oxidation surface treatment of domestic polyacrylonitrile-based high strength and high modulus carbon fiber[J]. Acta Materiae Compositae Sinica, 2018, 35(9): 2449-2457.

[22] 易增博, 冯利邦, 郝相忠, 薛向军, 郭玉雄. 表面处理对碳纤维及其复合材料性能的影响[J]. 材料研究学报, 2015, 29(1): 67-74.

YI Zeng-bo, FENG Li-bang, HAO Xiang-zhong, XUE Xiang-jun, GUO Yu-xiong. Effect of surface treatment on properties of carbon fiber and reinforced composites[J]. Chinese Journal of Materials Research, 2015, 29(1): 67-74.

[23] LI B, ZHANG C R, CAO F, WANG S Q, CHEN B, LI J S. Effects of fiber surface treatments on mechanical properties of T700 carbon fiber reinforced BN-Si3N4 composites[J]. Materials Science and Engineering A, 2007, 471(1/2): 169-173.

[24] 李 伟, 李贺军, 魏建峰, 张守阳, 王 沛, 傅杨茜. 炭纤维热处理对C/C复合材料力学性能的影响[J]. 中国材料进展, 2013, 32(5): 314-317.

LI Wei, LI He-jun, WEI Jian-feng, ZHANG Shou-yu, WANG Pei, FU Yang-qian. Effect of heat treatment of carbon fibers on the mechanical properties of C/C composites[J]. Materials China, 2013, 32(5): 314-317.

[25] SHA J J, DAI J X, LI J, WEI Z Q, HAUSHERR J M, KRENKEL W. Influence of thermal treatment on thermo-mechanical stability and surface composition of carbon fiber[J]. Applied Surface Science, 2013(274): 89-94.

[26] SHA J J, DAI J X, LI J, WEI Z Q, HAUSHERR J M, KRENKEL W. Influence of carbon fiber’s surface state on interlaminar shear properties of CFRP laminate[J]. Composite Interfaces, 2013, 20(8): 543-552.

[27] 代吉祥. 碳纤维热处理对C-SiC基复合材料微观组织结构及性能影响的研究[D]. 大连: 大连理工大学, 2015.

DAI Ji-xiang. Effect of thermal treatment of carbon fiber on microstructure and properties of C-SiC-based composites[D]. Dalian: Dalian University of Technology, 2015.

[28] 李崇俊, 马伯信, 金志浩. 酚醛树脂前驱体C/C复合材料研究—硼酚醛树脂理化性能分析及固化、热解过程研究[J]. 新型炭材料, 2001(1): 19-24.

LI Chong-jun, MA Bo-xin, JIN Zhi-hao. Physical-chemical properties and curing pyrolysis processes of boron-phenolics precursor in carbon-carbon composites[J]. New Carbon Materials, 2001(1): 19-24.

[29] 张亚妮, 徐永东, 高列义, 张立同, 成来飞. 基于酚醛树脂的碳/碳复合材料在高温分解过程的微结构演变[J]. 复合材料学报, 2006, 23(1): 37-43.

ZHANG Ya-ni, XU Yong-dong, GAO Lie-yi, ZHANG Li-tong, CHENG Lai-fei. Microstructural evolution of phenolic resin-based carbon/carbon composites during pyrolysis[J]. Acta Materiae Compositae Sinica, 2006, 23(1): 37-43.

Mechanical properties and oxidation resistance of heat-treated fiber reinforced carbon matrix composites

ZOU Xue1, DAI Ji-xiang1, 2, SHA Jian-jun1, 2, Lü Zhao-zhao1

(1. State Key Laboratory of Structural Analyses for Industrial Equipment, Dalian University of Technology, Dalian 116024, China;

2. School of Aeronautics and Astronautics, Dalian University of technology, Liaoning Provincial Key Laboratory of Advanced Technology for Aerospace Vehicle, Dalian 116024, China)

Abstract: Carbon fiber reinforced carbon matrix composites (C/C) were prepared by precursor impregnation pyrolysis (PIP) method, carbon fibers heat-treated at different temperatures were used as reinforcement, phenolic resin was used as carbon precursor. The results show that the size and distribution pattern of pores in porous preform (after primary cracking) are changed, according to micromorphology observation. Mechanical properties of C/C composites are improved with the increase of heat treatment temperature. Flexural strength and interlaminar shear strength of C/C increase by 1.58-fold and 1.21-fold after fibers heat-treated at 1200 ℃. With the heat treatment temperature rising, the fracture mode of C/C is changed from brittle to pseudoplastic. Oxidation resistance of 600 ℃ heat-treated fiber reinforced composite is improved, while those of 1200 ℃ and 1500 ℃ heat-treated fiber reinforced composites decrease. The property of C/C is changed because heat treatment reduces the surface activity of fibers, so C/C composite has a suitable interface.

Key words: C/C composites; heat treatment; mechanical property; oxidation resistance

Foundation item: Project(11802049) supported by the National Natural Science Foundation of China; Project (DUT18RC(3)08) supported by the Fundamental Research Funds for the Central Universities, China; Project(1552642982138) supported by the Natural Fund project of Liaoning Province, China

Received date: 2019-11-20; Accepted date: 2020-06-23

Corresponding author: SHA Jian-jun; Tel: +86-411-84709004; E-mail: jjsha@dlut.edu.cn

(编辑 王 超)

基金项目:国家自然科学基金资助项目(11802049);中央高校基本科研业务费资助项目(DUT18RC(3)08);辽宁省自然基金资助项目(1552642982138)

收稿日期:2019-11-20;修订日期:2020-06-23

通信作者:沙建军,教授,博士;电话:0411-84709004;E-mail:jjsha@dlut.edu.cn