Ta有机溶剂热处理转变生成TaC的过程

闫志巧, 熊 翔, 肖 鹏, 李江鸿, 黄伯云

(中南大学 粉末冶金国家重点实验室, 长沙 410083)

摘 要: Ta有机溶剂浸渍C/C复合材料经热处理后可制备TaC均匀分布的C/C-TaC复合材料, 采用X射线衍射和扫描电镜技术研究了Ta有机溶剂热处理转变生成TaC的过程。 研究表明: 在热处理过程中, Ta有机溶剂先转变为氧氟化钽(TaO2F)和Ta2O5等中间相; 在1500℃热处理后, Ta全部转变为TaC。 热力学计算表明, C还原Ta2O5生成TaC的温度为1109℃, 与1200℃热处理后TaC的X射线衍射结果一致。

关键词: Ta有机溶剂; C/C复合材料; 热处理 中图分类号: TB332

文献标识码: A

Conversion process of Ta organic solvent into TaC by heat treatment

YAN Zhi-qiao, XIONG Xiang, XIAO Peng, LI Jiang-hong, HUANG Bai-yun

(State Key Laboratory of Powder Metallurgy,Central South University, Changsha 410083, China)

Abstract: C/C-TaC composites with well-distributed TaC particles were made by C/C composites infiltrated with Ta organic solvent and heat treated. The forming process of TaC is characterized by XRD and SEM. The results show that Ta organic solvent forms intermediates, namely tantalum oxide fluoride (TaO2F) and Ta2O5, and Ta finally turns into TaC after 1500℃ heat treated. The calculated thermodynamic temperature of C reducing Ta2O5 is 1109℃ and corresponds well with the XRD results after 1200℃ heat treated. After heat treated, lots of air holes appear on the surface of solidified Ta organic solvent and the pits appear on the surface of C/C composites heat treated at the same time.

Key words: Ta organic solvent; C/C composites; heat treatment

C/C复合材料具有极好的高温力学性能[1], 是惟一能在1700℃以上使用的结构材料, 主要用作固体火箭发动机(SRM)喷管的喉衬材料。 喉衬是固体发动机的关键件, 因此高性能固体火箭发动机对喉衬材料的烧蚀率提出了更高的要求。 尽管对耐烧蚀C/C喉衬材料进行从编织增强体到复合工艺等诸方面进行研究, 期望降低其烧蚀率, 但很难降至0.10mm/s以下。 文献[2]表明, 把难熔碳化物加到复合基体中, 能有效提高材料的耐烧蚀性能。 Choury[3]指出, 研制能承受3700℃以上温度的喉衬材料, 必须将难熔金属碳化物添加到C/C复合材料中。 TaC具有高熔点(3880℃)、 高硬度(莫氏硬度为9~10)、 热力学稳定性好、 耐蚀和耐热冲击以及抗氧化性高等优点[4, 5], 无疑是较好的难熔碳化物和具有广阔应用前景的耐烧蚀涂层材料。 C/C复合材料通过TaC改性基体或涂覆TaC涂层可以降低其烧蚀率。 文献[6-9]报道的TaC制备工艺主要为化学气相沉积、 液相浸渍、 溶胶-凝胶、 离子束辅助沉积等, 其中液相浸渍具有工艺简单、 周期短、 可靠性高等优点。 但由于一般Ta有机溶剂价格昂贵和氧含量较高, 不适于用作C/C-TaC复合材料中的TaC源, 因此, 液相浸渍工艺的使用范围不大。 本文作者自行配制了一种价格相对便宜、 氧含量相对较低的Ta有机溶剂, 并以此作为TaC源, 浸渍C/C材料制备C/C-TaC复合材料。 且该有机溶剂具有粘度低、 流动性好等特点, 在室温、 1.4~2.0MPa压力、 2h, 即可对C/C材料实现充分、 均匀浸渍, 然后自然固化。 浸渍试样经1500℃热处理成功制备出C/C-TaC复合材料。 材料中TaC尺寸细小、 结晶度高、 分布均匀[10]。 本文作者借助X射线衍射和SEM等检测手段, 研究固化后的Ta有机溶剂在热处理过程中的组成和形貌变化, 有助于进一步认识反应过程。

1 实验

1.1 Ta有机溶剂的制备和热处理

自行配制Ta溶液, 选用某种有机溶剂为C源, 将两者按一定质量比混合配制Ta有机溶剂。 混合初期, 该种Ta有机溶剂粘度较低, 而随时间的延长, 粘度逐渐变大, 2h内可完全固化。 将固化的Ta有机溶剂置于石墨化炉中进行系列不同温度热处理。 热处理温度分别为700、 850、 1500和2000℃。 2000℃热处理时, 将C/C试样与固化的Ta有机溶剂进行同炉热处理。 同时, 补充Ta有机溶剂于1200℃的热处理实验中。

1.2 检测分析

Ta有机溶剂经系列不同温度热处理后, 对其进行物相分析和微观形貌观察。 物相分析在Gdianjiigaku-3014型X射线衍射仪上进行。 采用粉末试样, Si为内标, 实验参数为CuKα1单色光辐射、 管电压35kV、 电流20mA, 扫描范围为10°~90°、 间隔0.02°、 速度0.01(°)/s。 微观形貌观察在KYKY-2800型和JSM-5600LV型扫描电镜上进行。

2 结果和讨论

2.1 固化Ta有机溶剂热处理后的物相分析

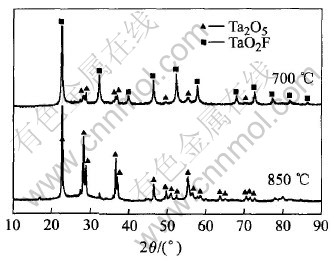

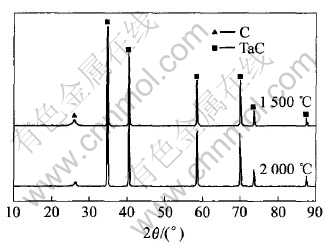

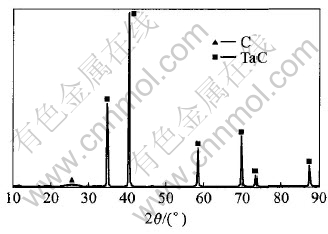

图1所示为固化的Ta有机溶剂经700和850℃热处理后的X射线衍射结果。 由图1可看出, 经700℃热处理后, Ta有机溶剂转变为氧氟化钽(TaO2F)和Ta2O5; 经850℃热处理后, 则只有Ta2O5相。 而经1500和2000℃等较高温度热处理后, 转变产物除极少量残留的C外, 绝大部分转变为结晶度高的TaC晶体(面心结构), 其结果如图2所示。

图1 固化的Ta有机溶剂经不同温度热处理后的X射线衍射谱

Fig.1 XRD patterns of solidified Ta organic solvent after heat treated at different temperatures

图2 固化的Ta有机溶剂经不同温度热处理后的X射线衍射谱

Fig.2 XRD patterns of solidified Ta organic solvent after heat treated at different temperatures

从图1和2所示的X射线衍射结果可以得出, 在Ta有机溶剂热处理转变生成TaC的过程中, 随着热处理温度的升高, Ta有机溶剂先转变为中间相的氧氟化钽和Ta2O5, 最终与C发生还原—化合反应生成TaC。

当进行较低温度热处理时, Ta有机溶剂先转变为氧氟化钽和Ta2O5。 该转变过程为发生一步反应和两步反应的过程[11]。 其中, 一步反应认为Ta有机溶剂直接热分解为Ta2O5, 即

2Ta5++yF-+CxHyOz→ Ta2O5+(x+5-z)C+yHF+(z-5)CO(1)

式中 CxHyOz为有机溶剂。

二步反应认为有机溶剂中的—OH与F-、 Ta5+反应先生成羟桥化合物(羟联)。 生成羟桥化合物的过程往往伴随着氧桥合作用(即羟基转化成桥接氧基)或者阴离子置换或者同时伴随两种过程[12], 即

n(—OH)+Ta5++5F-→ (—O—)nTaF5-n+nHF(2)

n(-O)+ Ta5++5F-→ (—O—)nTaF5-n+nF-(3)

随热处理温度进一步升高, 氧氟化钽中的F完全被O取代, Ta全部转变为Ta2O5。 经1500℃热处理后, Ta2O5全部被C还原-化合为TaC:

Ta2O5(s)+7C(s) → 2TaC(s)+5CO(g)(4)

图1中的X射线衍射结果未探测到C存在, 是由于Ta有机溶剂转变生成的树脂炭为非晶态玻璃炭, 在进行较低温度热处理时, 未能发生石墨化转变, 因此探测不到C的衍射峰。 而经较高温度热处理时, 树脂炭非晶程度降低, 开始发生一定的石墨化转变, 因此显示C的衍射峰(见图2)。

2.2 C还原Ta2O5生成TaC的热力学计算

C还原Ta2O5生成TaC(即反应(4))的标准吉布斯自由能可计算为

ΔGT=∑nΔGf, res-∑mΔGf, reac

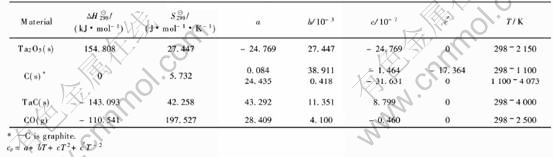

根据文献[13]所提供的热力学数据(见表1), 则

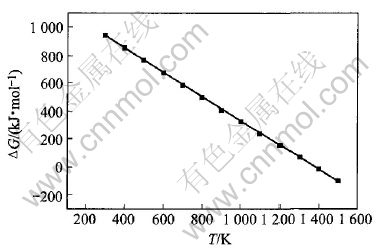

根据式(5)绘制反应(4)的标准生成自由能曲线如图3所示。 当ΔGT=0时, T=1382K(1109℃), 即C还原Ta2O5的起始温度为1382K。 Villalobos等[14]热力学计算Ta2O5与CO或C反应生成TaC的温度为1379K。

为验证这一反应温度, 对固化的Ta有机溶剂进行1200℃热处理, 用X射线衍射探测其物相组成, 结果如图4所示。 由图4可看出, Ta有机溶剂全部转变为C和TaC, 表明C在1109℃时还原Ta2O5生成TaC的计算结果是正确的。 此外, 与图1中的X射线衍射相比, 图4中出现了非晶态树脂炭的衍射胞。

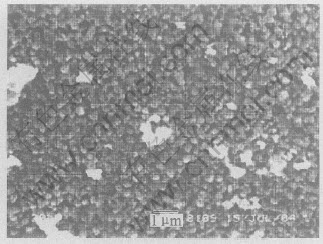

传统的利用碳热还原Ta2O5制备TaC工艺, 还原温度通常在1500℃以上, 更高温度反应时TaC颗粒容易长大, 从而降低力学性能[15]。 与此相比, 利用Ta有机溶剂为浸渍液制备TaC时, 在1200℃即可生成TaC, 且生成的TaC颗粒细小(约为300nm, 见图5), 结晶度高, 有助于提高材料的综合性能, 为低温下制备TaC提供了理论依据。

2.2 固化Ta有机溶剂热处理后的微观形貌

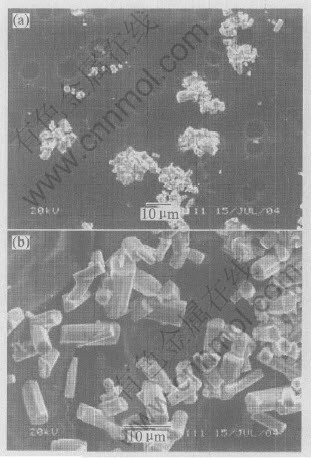

固化Ta有机溶剂经700℃ 热处理后, 宏观上固化块表面有一层白色霜状物质, 其微观形貌如图6所示。 从图6(a)可以看出, 固化块表面出现许多气孔, 气孔周围附有白色团聚物。 气孔是由于在热处理时, Ta有机溶剂产生气相小物质挥发所致, 而较难挥发的含Ta物质滞留在凹坑周围。 由放大后的图6(b)可以看出, 白色物质呈短棒状, 有明显的

表1 Ta2O5等物质的热力学参数

Table 1 Thermodynamic parameters of some materials[13]

图3 根据反应(4)计算的标准生成自由能曲线

Fig.3 Formation free energy curve calculated by chemical reaction(4)

图4 固化的Ta有机溶剂经1200℃热处理后的X射线衍射谱

Fig.4 XRD pattern of solidified Ta organic solvent after heat-treated at 1200℃

图5 固化的Ta有机溶剂经1200℃热处理后所生成TaC的SEM像

Fig.5 SEM image of TaC by heat-treated solidified Ta organic solvent at 1200℃

晶棱, 表明已经完全发生晶化。 对这些白色短棒状物质进行能谱分析, 结果表明只含有Ta和O两种元素, 结合700℃热处理后的X射线衍射结果, 可以认为这种少量的物相是Ta2O5相。 文献[16]指出采用CVD工艺制备Ta2O5涂层时, 在一定条件下, 制备的Ta2O5呈柱状或晶须状。 Raj[17]的研究表明, 采用OSI工艺煅烧制备的Ta2O5粉呈六角杆/管状, 长度小于1μm或大于50μm。 在图6(b)中, Ta2O5呈柱状, 长度约为10μm。

图6 固化的Ta有机溶剂经700℃热处理后的 SEM像

Fig.6 SEM images of solidified Ta organic solvent after heat-treated at 700℃

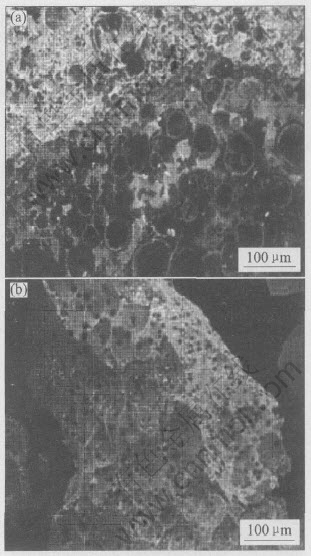

Ta有机溶剂经1500和2000℃热处理后, 宏观上固化块均呈现金黄色, 表明生成了TaC, 其微观形貌如图7所示。 由图7可以看出, 固化块表面也出现大量气孔。 与700℃热处理后的形貌相比, 气孔数量进一步增多。 在1500℃热处理时, 采用快速升温工艺, 且整个热处理过程中炉内均有保护性氩气保持微正压, 不利于气相小物质的排出, 它们在固化块内部迅速聚集、 膨胀, 达到一定压强时, 冲破表面的束缚, 因此固化块表面出现较大尺寸的气孔。 而在2000℃热处理时, 采用了慢速升温工艺, 炉内无保护气氛, 有利于气相小物质的排出, 因此固化块表面出现的气孔尺寸较小。

与固化的Ta有机溶剂同炉2000℃热处理后的C/C试样, 其表面也呈金黄色, 表明表面有TaC生成, 其扫描电镜像如图8所示。 由图8可以看出,微观平整的C/C试样表面被刻蚀成凹坑, 凹坑周

图7 固化的Ta有机溶剂经1500℃(a)和2000℃(b)热处理后的SEM像

Fig.7 SEM images of solidified Ta organic solvent after heat treated at 1500℃(a) and 2000℃(b)

图8 与固化的Ta有机溶剂同炉经2000℃热处理C/C试样的SEM像

Fig.8 SEM image of C/C composite after heat treated with solidified Ta organic solvent at 2000℃

围附有颗粒状物质, 这些颗粒状物质为TaC。

由图6和7所示的扫描电镜像可知, 固化的Ta有机溶剂在热处理时, 发生裂解, 产生挥发性小分子, 如H2O、 CO和HF等, 热处理初期在固化块表面形成气泡, 最终摆脱固化块表面的束缚而破裂形成大量气孔。 随热处理温度的升高, 小分子挥发加剧, 气孔数目增多。 同时, 部分Ta有机溶剂发生气化, 在气相中形成Ta2O5, 当Ta2O5达到饱和浓度后开始沉积, 一定条件下, 与C/C试样表面的热解碳发生还原-化合反应生成TaC(见反应(4)), 使得C/C试样表面出现刻蚀凹坑(见图8)。

由于H2O(g)的存在, 发生水煤气反应, 也会引起C的刻蚀, 即

C+H2O(g)→CO(g)+H2(g)(6)

因此, Ta有机溶剂转变生成TaC的过程十分复杂, 固化块表面的气孔和C/C试样表面的刻蚀凹坑是多方面因素共同作用的结果。

3 结论

1) 在热处理过程中, Ta有机溶剂先转变为氧氟化钽(TaO2F)和Ta2O5等中间相, 经1500℃热处理后, Ta全部转变生成TaC。

2) 热力学计算C还原Ta2O5生成TaC的温度为1109℃, 实验结果表明, 经1200℃热处理后, Ta全部转变为TaC, 为低温下制备TaC提供了理论依据。

3) 热处理后, 固化的Ta有机溶剂表面由于气态物质挥发而出现大量气孔, 而同炉处理的C/C试样表面则出现刻蚀凹坑。

REFERENCES

[1]于澍, 刘根山, 李溪滨, 等. 炭/炭复合材料导热系数影响因素的研究[J]. 稀有金属材料与工程, 2003, 32(3): 213-215.

YU Shu, LIU Gen-shan, LI Xi-bin, et al. The main factors on heat conductivity for carbon-carbon composites[J]. Rare Metal Materials and Engineering, 2003, 32(3): 213-215.

[2]卢嘉德. 固体火箭发动机复合材料技术的进展及其应用前景[J]. 固体火箭技术, 2001, 4 (1): 46-52.

LU Jia-de. The progress and application prospect of composite techniques for SRM[J]. Journal of Solid Rocket Technology, 2001, 4(1): 46-52.

[3]Choury J J. Carbon-carbon materials for nozzles of solid propellant rocket motors[R]. 76-609, Los Angeles, USA: AIAA, 1976.

[4]Kim C, Gottstein G, Grummon D S. Plastic flow and dislocation structures in tantalum carbide: deformation at low and intermediate homologous temperatures[J]. Acta Metal Mater, 1994, 42(7): 2291-2301.

[5]Chen Y J, Li J B, Wei Q M, et al. Preparation and growth mechanism of TaCx whickers[J]. Journal of Crystal Growth, 2002, 224(3): 244-250.

[6]Rubinshtein A, Shneck R, Danon A, et al. Surface treatment of tantalum to improve its corrosion resistance[J]. Mater Sci Eng A, 2001, A302(1): 128-134.

[7]崔红, 苏君明, 李瑞珍, 等. 添加难熔金属碳化物提高C/C复合材料抗烧蚀性能的研究[J]. 西北工业大学学报, 2000, 18(4): 669-673.

CUI Hong, SU Jun-ming, LI Rui-zhen, et al. On improving anti-ablation property of multi-matrix C/C to withstand 3700K[J]. Journal of Northwest Polytechnical University, 2000, 18(4): 669-673.

[8]Preiss H, Schultze D, Klobes P. Formation of NbC and TaC from gel-derived precursors[J]. Journal of the European Ceramic Society, 1997, 17(12): 1423-1435.

[9]Zhang Q Y, Mei X X , Yang D Z, et al. Preparation, structure and properties of TaN and TaC films obtained by ion beam assisted deposition[J]. Nuclear Instruments and Methods in Physics Research, 1997, B127/128: 664-668.

[10]闫志巧, 熊翔, 肖鹏, 等. 液相浸渍C/C复合材料反应生成TaC的形貌及其形成机制[J]. 无机材料学报, 2005, 20(5): 1195-1200.

YAN Zhi-qiao, XIONG Xiang, XIAO Peng, et al. Study on morphology and formation mechanism of TaC made by liquid phaseinfiltration method in C/C composites[J]. Journal of Inorganic Materials, 2005, 20(5): 1195-1200.

[11]Kaupo K, Jaan A, Aleks A, et al. In situ study of atomic layer epitaxy growth of tantalum oxide thin films from Ta(OC2H5) and H2O[J]. Applied Surface Science, 1997, 112: 236-242.

[12]Eлютин A B, Кopщyнов B Г. 铌与钽[M]. 马福康, 邱向东, 贾厚生, 等译. 长沙: 中南工业大学出版社, 1997. 95-97.

Eлютин A B, Кopщyнов B Г. Nb and Ta[M]. MA Fu-kang, QIU Xiang-dong, JIA Hou-sheng, et al transl. Changsha: Central South University of Technology Press, 1997. 95-97.

[13]叶大伦, 胡建华. 实用无机热力学数据手册[M]. 北京: 冶金工业出版社, 2002. 973-979.

YE Da-lun, HU Jian-hua. Handbook of Practicality Inorganic Thermodynamics[M]. Beijing: Metallurgical Industry Press, 2002. 973-979.

[14]Villalobos G R, Speyer R F. Effect of CO and C on the formation of TaC in a lithium aluminosilicate glass/ceramic with Ta2O5 additions[A]. Proceedings of the 20th Annual Conference on Composites, Advanced Ceramics, Materials, and Structures—A[C]. Westerville, OH: American Ceramic Soc, 1996. 195-205.

[15]Kwon D H, Hong S H, Kim B Y. Fabrication of ultrafine TaC powders by mechano-chemical process[J]. Materials Letters, 2004, 58(30): 3863-3867.

[16]David W G, David P S. Development of tantalum pentoxide coatings by chemical vapor deposition[J]. J Am Ceram Soc, 1994, 77(9): 2298-2304.

[17]Raj P S. Processing of Ta2O5 powders for electronic applications[J]. Journal of Electronic Materials, 2001, 30(12): 1584-1594.

(编辑李艳红)

基金项目: 国家高技术研究发展计划资助项目(2002AA305207)

收稿日期: 2005-04-13; 修订日期: 2005-06-21

作者简介: 闫志巧(1980-), 女, 博士研究生

通讯作者: 肖 鹏, 教授; 电话: 0731-8830131; E-mail: xiaopeng@mail.csu.edu.cn