DOI:10.19476/j.ysxb.1004.0609.2017.08.16

C/C复合材料ZrB2-SiC基陶瓷涂层的微观结构及氧化机理

王馨爽,陈招科,熊 翔,张天助,孙 威,王雅雷

(中南大学 粉末冶金研究院 粉末冶金国家重点实验室,长沙 410083)

摘 要:为提高C/C复合材料在高温富氧环境中的抗氧化性能,采用两步刷涂+化学气相沉积法在C/C复合材料表面制备含Si3N4、MoSi2、TaC等添加剂的ZrB2-SiC基多层复合陶瓷涂层。利用XRD和SEM等分析测试手段研究涂层的物相组成和微观结构,并分析讨论涂层在900和1500 ℃的等温抗氧化机理。结果表明:利用两步刷涂+化学气相沉积法制备的ZrB2-SiC基复合陶瓷涂层整体厚度约为200 μm。Si3N4、MoSi2可很好地促进ZrB2-SiC基氧阻挡层的高温烧结,使涂层致密化,并提高涂层在900 ℃的抗氧化性能;与之相比,TaC则不能很好地发挥致密化作用,对涂层在900 ℃时抗氧化性能的提高有限。在900 ℃时,ZrB2-SiC基陶瓷涂层的氧化过程主要受氧在涂层孔隙等缺陷中的扩散所控制,添加剂主要通过改变涂层的致密化程度来影响涂层的抗氧化性能。在1500 ℃氧化过程中,涂层抗氧化性能恶化,但致密的化学气相沉积SiC封填层的引入可显著改善涂层在1500 ℃时的抗氧化性能,涂层表面生成了完整的含有ZrO2和ZrSiO4等高熔点颗粒的SiO2玻璃态氧化膜,为基体提供有效的氧化防护。

关键词:C/C复合材料;ZrB2-SiC基涂层;添加剂;抗氧化机理

文章编号:1004-0609(2017)-08-1670-09 中图分类号:TB332 文献标志码:A

C/C复合材料具有低密度、高比强度、高比模量、高热导、低热膨胀系数、耐磨损等优异性能,是航空、航天工业及国防领域理想的高温材料[1-3]。然而,C/C复合材料在高温富氧环境下极易氧化。研究表明[4],C/C复合材料在氧化气氛下370 ℃即开始氧化,氧化速率随着温度的升高而迅速增加,并导致力学性能急剧下降,极大地限制C/C复合材料在高温有氧环境中的使用。因此,提高C/C复合材料在高温有氧环境中的抗氧化性能是至关重要的[5]。

目前,提高C/C复合材料抗氧化性能的方法主要有基体改性和涂层两种[6-7]。与基体改性相比,涂层将基体与外部氧化性气体隔离,防止氧扩散至基体内部,对C/C复合材料的氧化防护更为直接。然而,单一涂层的氧化防护效果并不理想,必须设计多层涂层体系,并使各涂层间相互协调、互为补充。完整的高温抗氧化涂层体系应包含以下3种功能涂层[8-9]:1) 过渡层。主要作用是缓解涂层与基体间的热膨胀系数失配; 2) 氧阻挡层:主要作用是阻挡氧化性气体侵入基体内部,是决定涂层抗氧化性能的关键;3) 封填层。主要作用是提高涂层体系外部的致密度,降低涂层孔隙率,减少氧化活性中心。

近几年来,有关ZrB2基陶瓷涂层的制备及氧化烧蚀性能研究成为了国内外材料学者的研究重点和热点。超高温陶瓷ZrB2[10-11]具有高熔点、高硬度、高稳定性、耐腐蚀性、良好的导电、导热性等特点,可作为氧阻挡层材料,然而,纯ZrB2陶瓷的熔点高、烧结困难。目前,大部分的材料研究者主要是通过添加一定量的SiC来改善ZrB2的烧结性能、抗氧化性能和力学性能[12],而很少有进一步引入其他添加剂的文献报道。例如,ZOU等[13]在C/C复合材料表面通过包埋法制备了ZrB2-SiC涂层,对涂层进行1727 ℃、40 s的氧炔焰烧蚀实验,其线烧蚀率为4.4×10-3 mm/s,质量烧蚀率为6.2×10-5 g/s。ZHANG等[14]利用包埋法在C/C复合材料表面制备SiC过渡层,再使用刷涂法制备ZrB2-SiC涂层,该涂层体系在1000 ℃氧化30 h后质量损失5.3%,在1500 ℃氧化10 h后质量损失3.0%。

目前,在C/C复合材料表面制备ZrB2-SiC基涂层的方法主要有包埋法、刷涂法、化学气相沉积、等离子喷涂法等。其中,刷涂法制备方法简单,成本低,不受基体形状及尺寸限制,且具有工业应用潜力。

因此,本文作者采用两步刷涂+化学气相沉积法在C/C复合材料表面制备了分别含有Si3N4、MoSi2及TaC等添加剂的ZrB2-SiC基复合陶瓷涂层,研究ZrB2-SiC涂层的微观结构、物相组成及涂层在900和1500 ℃等温抗氧化机理,并初步探讨了上述添加剂对涂层微观结构及抗氧化机理的影响。

1 实验

1.1 涂层制备

将密度为1.60 g/cm3 的C/C复合材料机加工成尺寸为30 mm×20 mm×5 mm的块状试样,用800号SiC砂纸打磨试样表面,再进行超声波清洗,烘干后备用。

Zr-Si-B4C反应烧结过渡层的制备。首先配制2.2Zr-0.8Si-B4C(摩尔比)的混合粉末,将该混合粉末在真空球磨罐中湿磨10 h,干燥后,加入适量的酒精和PVB胶,搅拌均匀配制成刷涂浆料;将配制好的浆料刷涂在C/C复合材料试样表面;然后,在400 ℃、真空环境下进行脱胶处理,并在Ar气氛1900 ℃下进行常压烧结,在基体表面获得ZrB2-SiC-ZrC过渡层。

ZrB2-SiC基阻氧层的制备。首先配制ZrB2- 15%SiC-5%Si3N4、ZrB2-15%SiC-10%MoSi2、ZrB2-15%- 20%TaC(体积分数)3种混合粉末,经湿磨、干燥、搅拌后制备成刷涂浆料,刷涂在已制备了过渡层的试样表面;然后,进行脱胶和常压烧结,制备工艺与ZrB2-SiC-ZrC过渡层的相同,在基体表面获得ZrB2-SiC基复合陶瓷涂层。根据刷涂浆料的成分配比,将阻氧层成分为ZrB2-15%SiC-5%Si3N4的样品命名为ZSS、成分为ZrB2-15%SiC-10%MoSi2的样品命名为ZSM、成分为ZrB2-15%-20%TaC的样品命名为ZST。

CVD SiC封填层的制备。采用CH3SiCl3-H2-Ar气相反应体系制备SiC封填层,最终,获得三层ZrB2-SiC基复合陶瓷涂层。

1.2 氧化实验

采用静态空气恒温氧化实验测试涂层的抗氧化性能。实验过程如下:1) 将实验试样放入烘箱中烘干后称量;2) 将开放式刚玉管管式氧化炉升温至测试温度(900和1500 ℃)并保温30 min,使炉温均匀;3) 将烘干后的试样放置于氧化铝瓷舟中,迅速推入恒温区;4) 每隔一段时间将试样从炉中取出并在空气中冷却称量。根据得到的数据,按式(1)进行氧化质量损失率(ΔW)计算,最终得到涂层试样的氧化质量损失曲线。

ΔW=100%×(m1-m0)/m0 (1)

式中:m0和m1分别为试样氧化前后质量。

1.3 检测分析

采用D/max 2550VB+18KW型转靶X射线衍射仪(Rigaku Corporation,Japan,Cu Kα,λ=0.154056 mm)对涂层试样的物相组成进行检测。采用Nava-Nano SEM230及Quanta FEG 250型场发射扫描电镜观察试样表面微观形貌及断面组织结构。利用扫描电镜附带的能谱仪(Energy dispersive spectroscopy,EDS)对试样微区所含元素进行分析。

2 结果与分析

2.1 涂层的组织结构

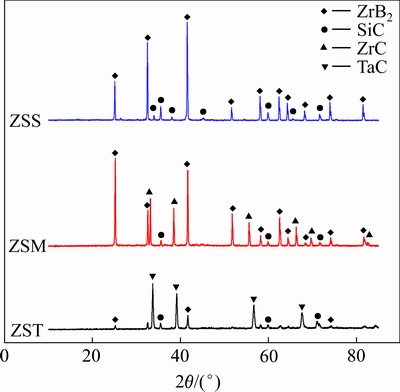

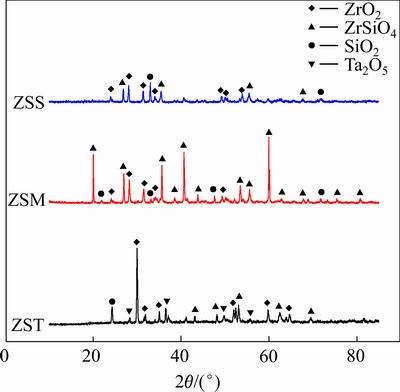

图1所示为制备氧阻挡层后C/C复合材料涂层表面的XRD谱。由图1可知,ZSS涂层主要包含ZrB2与SiC两相。ZSM涂层则包含ZrB2、SiC及ZrC三相,ZrC出现的主要原因是在烧结过程中MoSi2引入液相,使ZrB2晶界能降低,C还原ZrB2晶粒表面的ZrO2生成了ZrC,ZST涂层则主要包含ZrB2、SiC、TaC相。

图1 制备了氧阻挡层后C/C复合材料的表面XRD谱

Fig. 1 XRD patterns of as-sintered anti-oxidation coating on C/C composites

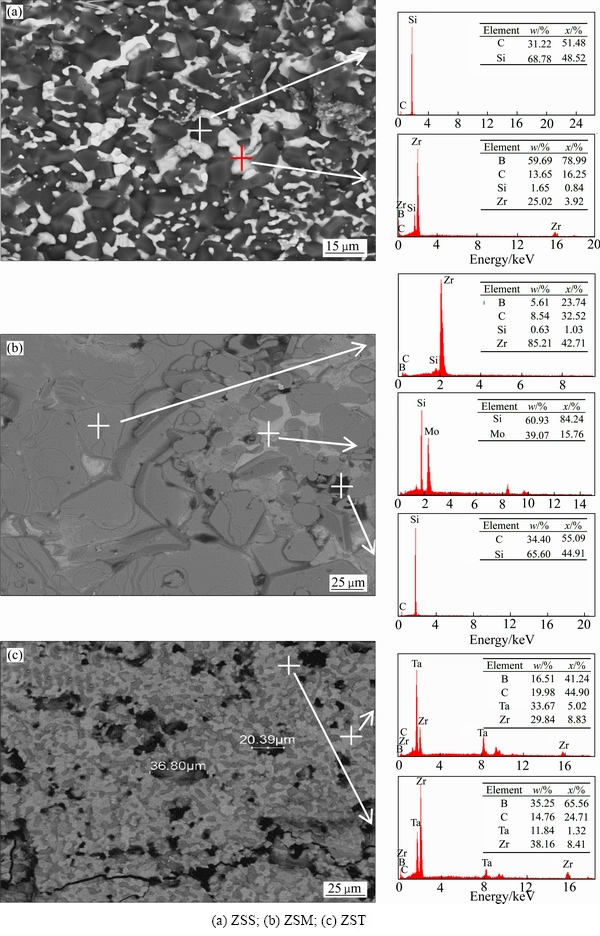

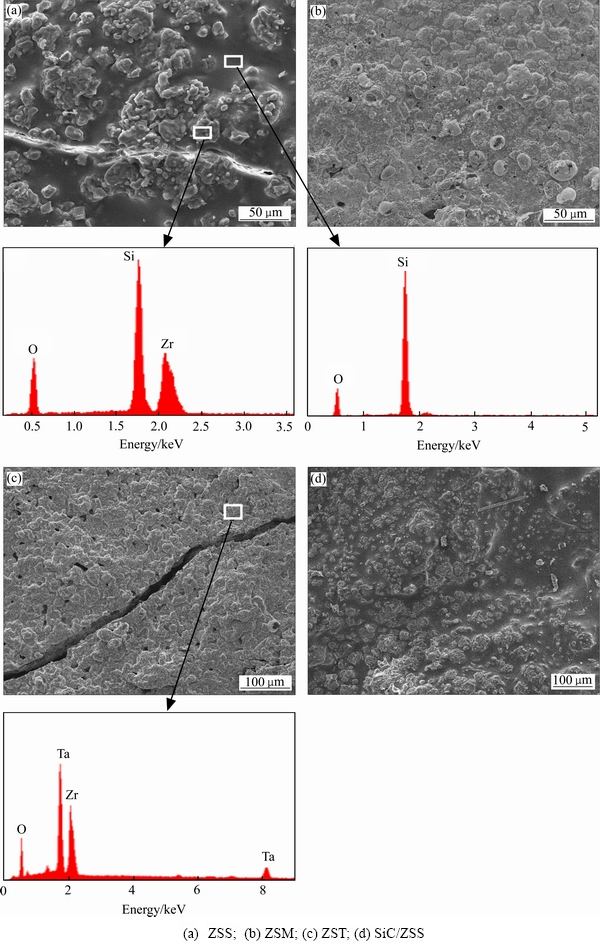

图2所示为3种氧阻挡层的表面形貌照片及EDS分析结果。由图2(a)看出,ZSS涂层主要包含白色的ZrB2及黑色的SiC相,ZrB2和SiC两相均匀分布,晶粒大小约为2~10 μm,晶粒间存在较多微孔孔隙。由图2(b)看出,ZSM涂层主要由灰色的ZrB2相、白色的MoSi2相、黑色的SiC相组成[15];另外,结合XRD结果可知,部分ZrB2晶粒表面还附着了ZrC;与ZSS涂层相比,ZSM涂层整体较为致密,未发现大孔洞及裂纹,但晶粒较大且分布不均匀。由图2(c)看出,ZST涂层主要由深灰色的ZrB2相和浅灰色的TaC相组成[16],涂层中ZrB2晶粒和TaC晶粒相互夹杂生长且结合紧密,两种晶粒均非常细小且分布均匀;然而,该涂层中存在较多的大尺寸孔洞及裂纹。综上所述可知,ZSS涂层致密性较好,但涂层中存在微孔孔隙;ZSM涂层致密性最好,主要是MoSi2对晶界有润湿作用,液相的引入使体系烧结驱动力增大,改善了烧结机制;而ZST涂层大孔洞及裂纹较多,未达到理想效果。

图2 氧阻挡层的表面形貌及EDS分析结果

Fig. 2 Surface morphologies and EDS analysis results of oxygen barrier coating on C/C composite

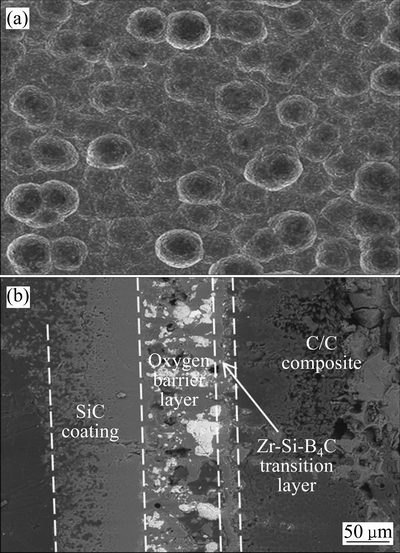

图3所示为化学气相沉积SiC封填层表面微观形貌及ZrB2-SiC基复合陶瓷涂层截面形貌。由图3(a)可知,化学气相沉积SiC涂层表面由直径40~60 μm的圆球状晶粒堆积而成,呈较为典型的菜花形貌;晶粒间结合良好,但也存在明显的晶间微裂纹。由图3(b)可知,SiC封填层厚度约60~80 μm(涂层整体厚约200 μm),SiC涂层内部较致密,但与氧阻挡层间有明显分界线。化学气相沉积SiC涂层不仅能对内涂层表面的孔隙进行封填,还能在氧化过程中反应生成大量氧渗透率极低且流动性好的SiO2,可填充缺陷,从而提高涂层抗氧化性能。

图3 化学气相沉积SiC封填层表面微观形貌及ZrB2-SiC基复合陶瓷涂层截面形貌

Fig. 3 Surface micrograph of CVD SiC coating(a) and cross-section morphology of ZrB2-SiC ceramic coating(b)

2.2 抗氧化性能

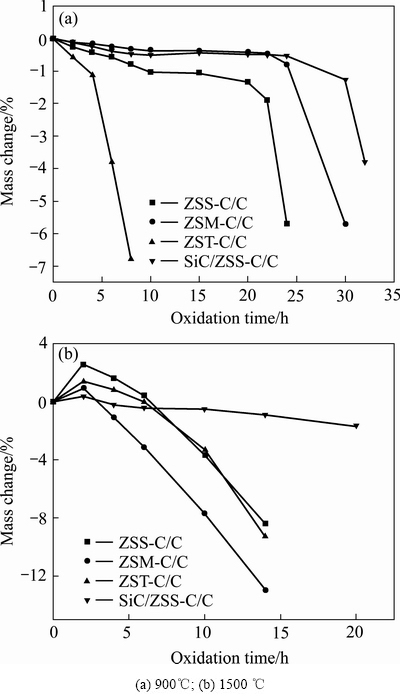

图4所示为不同涂层C/C复合材料试样在900和1500 ℃的等温氧化曲线。

图4 C/C复合材料涂层试样的等温氧化曲线

Fig. 4 Isothermal oxidation curves of different coated C/C samples

由图4(a)可知,900 ℃时涂层的抗氧化性能上大到小的顺序为ZSS/SiC、ZSM、ZSS、ZST。ZSS涂层在0~20 h内样品质量相对稳定,20h后氧化质量损失逐渐加剧,并在24 h时质量损失率为5.69%;ZSM涂层在0~25 h内样品质量相对稳定,25 h后涂层急剧质量损失,并在30 h时质量损失率达5.65%;ZST涂层氧化质量损失速率较快,8 h后即达到6.78%;SiC/ZSS涂层在0~25 h内质量相对稳定,25 h后氧化质量损失逐渐加剧,最终在32 h时质量损失率达3.56%。综上所述,不同添加剂的加入使涂层具有不同的致密度,从而对涂层抗氧化性能产生显著影响。同时,致密的CVD SiC封填层的引入可显著改善涂层的抗氧化性能。

由图4(b)可知,在1500 ℃氧化时,ZSS、ZSM、ZST这3种涂层试样在氧化初期均有一定程度的氧化增量;2 h后,随氧化时间增加,质量损失呈直线下降。其中,ZSM涂层试样氧化质量损失相对较高,这主要是由该涂层的氧化产物MoO3在高温下挥发所致。对于SiC/ZSS涂层,氧化初期质量增加较少;2 h后,随氧化时间增加,质量损失也较为缓慢,明显低于ZSS、ZSM、ZST这3种涂层的质量损失,说明涂层试样的抗氧化性能明显提高。

2.3 氧化后涂层物相及微观结构

图5所示为是不同涂层C/C复合材料试样在1500 ℃等温氧化后表面XRD谱。ZSS涂层氧化后,表面主要存在ZrSiO4、ZrO2、SiO2相;ZrSiO4相由ZrO2与SiO2反应生成,具有良好的高温稳定性;而由ZrB2氧化生成的副产物B2O3在高温下挥发,故产物中无B2O3存在。ZSM涂层氧化后表面也主要包含ZrSiO4、ZrO2、SiO2相;同样地,由于MoSi2氧化生成MoO3在高温下挥发,导致产物中无MoO3存在;ZST涂层氧化后表面主要包含ZrO2、ZrSiO4、SiO2、Ta2O5相,其中Ta2O5是TaC的氧化产物。

图5 涂层C/C复合材料1500 ℃氧化后XRD谱

Fig. 5 XRD patterns of coated C/C composites after oxidation at 1500 ℃

图6所示为不同涂层C/C复合材料1500 ℃氧化后的微观形貌及EDS分析。由图6(a)可知,ZSS涂层表面形成了一层均匀地包裹着大量固体颗粒的玻璃态熔体。结合EDS和XRD谱分析可知,玻璃态熔体为SiO2,固体颗粒是ZrSiO4与ZrO2的混合物。

由图6(b)可知,1500 ℃氧化后ZSM涂层表面也均匀覆盖一层玻璃态的熔体,但与ZSS不同,在涂层表面存在较多的孔洞、裂纹及气泡破裂的痕迹。这主要是涂层内部ZrB2、SiC、MoSi2及C等相氧化,生成CO、CO2、B2O3、MoO3等气态物质,向外挥发时受到SiO2玻璃相的阻挡,导致气泡的产生,当蒸汽压大于大气压时气泡破裂,生成新的缺陷。

由图6(c)可知,ZST涂层表面主要由ZrO2和Ta2O5组成,晶粒较小且分布均匀。同时涂层氧化后表面存在大尺寸裂纹,这种裂纹是多次热震所产生的内应力不断作用的结果。

由图6(d)可知,与ZSS、ZSM涂层相比,1500 ℃氧化后SiC/ZSS涂层表面生成的ZrO2、ZrSiO4等高熔点颗粒在SiO2玻璃态熔体中的分布更加弥散均匀,且涂层没有孔隙、裂纹等缺陷存在。

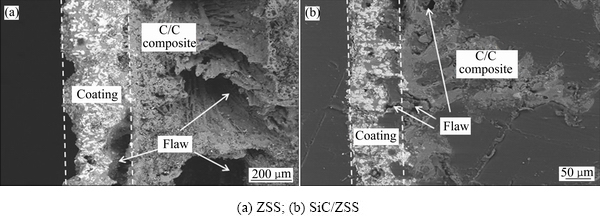

图7所示为ZSS、SiC/ZSS涂层C/C复合材料1500 ℃氧化后截面微观形貌。ZSS涂层在1500 ℃的长时氧化后,涂层表面存在贯穿性裂纹(见图6(a)),为氧气进入提供通道,使C/C试样内部严重氧化形成大孔洞(见图7(a))。与ZSS相比,1500 ℃氧化后SiC/ZSS涂层表面生成了含ZrO2和ZrSiO4等高熔点颗粒的SiO2玻璃态氧化膜,有效地抑制了氧的入侵,C/C试样内部发生轻微氧化,产生少量较小的孔洞,如图7(b)所示。

2.4 氧化机理研究

在900 ℃时,ZrB2-SiC基涂层体系主要发生以下氧化反应:

2ZrB2(s)+5O2(g)→2ZrO2(s)+2B2O3(s)

ΔG=-1992.8+0.40278T (kJ/mol) (2)

2SiC(s)+3O2(g)→2SiO2(s)+2CO(g)

ΔG=-948.8+0.127T (kJ/mol) (3)

反应(2)的吉布斯自由能负值绝对值更大,因此,在900 ℃时优先发生。研究表明[17-18],在此温度段,SiC的氧化速率低于ZrB2的,所以涂层由ZrO2、B2O3、ZrB2、SiC及少量的SiO2组成。由图4(a)可知,在900 ℃时,可将涂层的氧化质量损失曲线分为3个阶段。以ZSS-C/C试样为例,涂层在0~10 h内氧化质量损失缓慢;在10~20 h时,质量损失相对稳定,氧化过程中生成的B2O3玻璃相可填充涂层表面缺陷,为C/C复合材料提供一定的氧化防护;20 h后,随着氧化过程的进行,由于形成的SiO2、B2O3玻璃相相对较少,无法完全封填涂层中的孔洞、裂纹等缺陷,氧化性气体通过涂层孔洞、裂纹等缺陷进入试样内部,引起C/C基体氧化,造成试样质量损失率迅速上升。综合比较图2和图4(a)分析可知,900 ℃时,涂层试样的氧化过程主要受涂层表面的孔隙、裂纹等缺陷的控制,涂层的致密度越高,其在900 ℃时的抗氧化性能就越好;Si3N4、MoSi2、TaC等添加剂主要通过改变涂层的致密度来影响涂层的抗氧化性能。

图6 涂层C/C复合材料1500 ℃氧化后表面形貌及EDS分析结果

Fig. 6 Surface morphologies and EDS analysis results of coated C/C composites after oxidation at 1500 ℃

图7 ZSS、SiC/ZSS涂层C/C复合材料经1500 ℃氧化后的截面微观形貌

Fig. 7 Cross-section microphologies of ZSS, SiC/ZSS coated C/C composites after oxidation at 1500 ℃

根据图4(b)可知,ZSS、ZSM、ZST这3种涂层在1500 ℃时的氧化质量损失曲线相似,本实验中以ZSS-C/C试样为例,分析3种涂层在1500 ℃时的抗氧化机理。在1500 ℃时,ZSS涂层试样在氧化过程中发生的主要反应如下:

SiC(s)+2O2(g)→SiO2(s)+CO2(g) (4)

Si(s)+O2(g)→SiO2(s) (5)

ZrO2(s)+SiO2(s)→ZrSiO4(s) (6)

C(s)+O2(g)→CO2(g) (7)

2C(s)+O2(g)→2CO(g) (8)

在氧化起始阶段,ZSS涂层与氧气发生式(2)~(5)所示的反应。此时,涂层表面生成ZrO2、SiO2等氧化产物,涂层质量增加。在氧化后期,由于涂层受到频繁的热震,虽然SiO2有一定自愈合能力,但无法完全弥补贯穿性裂纹,为氧气的扩散提供了通道,使基体发生快速氧化,如式(7)和(8)所示,导致ZSS涂层试样质量迅速减小。经分析可知,在1500 ℃时,上述3种涂层的氧化过程依然主要受氧在涂层孔隙等缺陷中的扩散所控制;但与900 ℃相比,Si3N4、MoSi2、TaC等添加剂对涂层试样抗氧化性能的影响弱化。

SiC/ZSS-C/C涂层试样在氧化初始阶段,与ZSS涂层发生相同反应,生成ZrO2、SiO2等氧化物,导致涂层质量增加。但随着氧化反应的继续进行,SiC氧化生成大量SiO2非晶相。部分熔融态的SiO2直接填充材料内部孔隙,而部分SiO2则与ZrO2发生反应(6),生成高温稳定性好的ZrSiO4。ZrSiO4相弥散分布于SiO2玻璃态中,并对其起钉扎作用[19-20],二者共同抑制氧组元向试样内部的渗入,为基体提供有效地氧化防护。此时,氧化曲线趋于平缓,说明涂层试样的抗氧化性能明显提高。该氧化过程是由氧通过涂层表面SiO2、ZrSiO4等阻挡介质向内部扩散所控制。

3 结论

1) 采用两步刷涂+化学气相沉积法在C/C复合材料表面制备了由Zr-Si-B4C反应烧结过渡层ZrB2-SiC氧阻挡层、SiC封填层组成的ZrB2-SiC基多层复合陶瓷涂层,整体厚度约200 μm。

2) Si3N4、MoSi2可很好地促进ZrB2-SiC基氧阻挡层的高温烧结,使涂层致密化,并提高涂层在900 ℃的抗氧化性能;与之相比,TaC则不能很好地发挥致密化作用,对涂层在900 ℃时抗氧化性能的提高有限。

3) 在900 ℃时,ZrB2-SiC基陶瓷涂层的氧化过程主要受氧在涂层孔隙等缺陷中的扩散所控制,添加剂主要通过改变涂层的致密化程度来影响涂层的抗氧化性能。

4) 在1500 ℃氧化过程中,涂层抗氧化性能恶化,但致密的化学气相沉积SiC封填层的引入可显著改善涂层在1500 ℃时的抗氧化性能,涂层表面生成了完整的含有ZrO2和ZrSiO4等高熔点颗粒的SiO2玻璃态氧化膜,为基体提供了有效的氧化防护。

REFERENCES

[1] 黄伯云, 熊 翔. 高性能炭/炭航空制动材料的制备技术[M]. 长沙: 湖南科学技术出版社, 2006: 1-2.

HUANG Bai-yun, XIONG Xiang. Manufacturing of carbon/carbon composites for aircraft brakes[M]. Changsha:Hunan Science and Technology Publishing House, 2006: 1-2.

[2] 李 斌. TaC陶瓷改性C/C复合材料的设计、制备及其性能[D]. 长沙: 中南大学, 2013: 1-80.

LI Bin. Design, preparation and properties of TaC ceramic modified C/C Composites[D]. Changsha: Central South University, 2013: 1-80.

[3] 李 军, 杨 鑫, 刘红卫, 黄启忠, 苏哲安. 耐烧蚀超高温陶瓷改性C/C复合材料的研究进展[J]. 中国有色金属学报, 2015, 25(7): 1731-1743.

LI Jun, YANG Xin, LIU Hong-wei, HUANG Qi-zhong, SU Zhe-an. Research process of ultra high temperature ceramics modified carbon/carbon composites for ablation resistance[J]. The Chinese Journal of Nonferrous Metals, 2015, 25(7): 1731-1743.

[4] 李 斌, 陈招科, 熊 翔. 热处理对含 C-SiC-TaC-C 界面 C/C 复合材料力学性能的影响[J]. 复合材料学报, 2012, 29(1): 98-103.

LI Bin, CHEN Zhao-ke, XIONG Xiang. Effect of heat treatment on mechanical properties of C/C composites with C-SiC-TaC-C multi-innterlayers[J]. Acta Materiae Compositae Sinca, 2012, 29(1): 98-103.

[5] ZHANG Yu-lei, LI He-jun, LI Ke-zhi, FEI Jie, ZENG Xie-rong. C/SiC/Si-Mo-Cr multilayer coating for carbon /carbon composites for oxidation protection[J]. New Carbon Materials, 2012, 27(2): 105-110.

[6] 胡兴华, 吴明铂, 查庆芳. 炭/炭复合材料抗氧化研究进展[J]. 炭素, 2006 (3): 38-45.

HU Xing-hua, WU Ming-bo, ZHA Qing-fang. Development of oxidation resistance of carbon/carbon composites at high temperature[J]. Carbon, 2006(3): 38-45.

[7] 任富建, 刘红娟, 沈 毅. C/C复合材料高温抗氧化性的研究进展[J]. 中国陶瓷工业, 2008, 14(5): 28-31.

REN Fu-qiang, LIU Hong-juan, SHEN Yi. Progress in the study on oxidation resistance of carbon/carbon composites at high temperature[J]. China Ceramic Industry, 2008, 14(5): 28-31.

[8] 韩立军, 李铁虎, 郭恩明, 刘方军, 武洪臣, 邱海鹏. 碳/碳复合材料抗氧化方法及发展趋势[J]. 航空制造技术, 2003, 5(12): 26-30.

HAN Li-jun, LI Tie-hu, GUO En-ming, LIU Fng-jun,WU Hong-chen, QIU Hai-peng. Oxidation protection development trend for carbon-carbon composites[J]. Aeronautucal Manufacturing Technology, 2003, 5(12): 26-30.

[9] ZHU Y C, OHTANI S, SATO Y, IWAMOTO N. Formation of a functionally gradient (Si3N4+SiC)/C layer for the oxidation protection of carbon–carbon composites[J]. Carbon, 1999, 37(9): 1417-1423.

[10] PI H, FAN S, WANG Y. C/SiC-ZrB2-ZrC composites fabricated by reactive melt infiltration with ZrSi2 alloy[J]. Ceramics International, 2012, 38(8): 6541-6548.

[11] 刘国玺, 郭在在, 燕东明, 牟晓明, 常永威, 傅宇东. 二硼化锆超高温陶瓷的研究进展[J]. 兵器材料科学与工程, 2012, 35(1): 102-106.

LIU Guo-xi, GUO Zai-zai, YAN Dong-ming, MU Xiao-ming, CHANG Yong-wei, FU Yu-dong. Research and development of ZrB2 ultra-high temperature ceramics[J]. Ordnance Material Science and Engineering, 2012, 35(1): 102-106.

[12] YAN Y, ZHANG H, HUANG Z, LIU J, JIANG D, HUANG Z. In situ synthesis of ultrafine ZrB2-SiC composite powders and the pressureless sintering behaviors[J]. Journal of the American Ceramic Society, 2008, 91(4): 1372-1376.

[13] ZOU X, FU Q, LIU L, LI H, WANG Y, YAO X, HE Z. ZrB2-SiC coating to protect carbon/carbon composites against ablation[J]. Surface and Coatings Technology, 2013, 226: 17-21.

[14] ZHANG W Z, ZENG Y, GBOLOGAH L, XIONG X, HUANG B Y. Preparation and oxidation property of ZrB2-MoSi2/SiC coating on carbon/carbon composites[J]. Transactions of Nonferrous Metals Society of China, 2011, 21(7): 1538-1544.

[15] ZHANG Yu-lei, LI He-jun, HU Zhi-xiong, LI Ke-zhi, ZHANG Lei-lei. C/SiC/MoSi2-SiC-Si multilayer coating for oxidation protection of carbon/carbon composites[J]. Transactions of Nonferrous Metals Society of China, 2013, 23(7): 2118-2122.

[16] WANG Y, MA B, LI L, AN L. Oxidation behavior of ZrB2-SiC-TaC ceramics[J]. Journal of the American Ceramic Society, 2012, 95(1): 374-378.

[17] REZAIE A, FAHRENHOLTZ W G, HILMAS G E. Evolution of structure during the oxidation of zirconium diboride-silicon carbide in air up to 1500 ℃[J]. Journal of the European Ceramic Society, 2007, 27(6): 2495-2501.

[18] 王 超. ZrB2-SiC 基超高温陶瓷复合材料失效机制的表征与评价[D]. 哈尔滨:哈尔滨工业大学, 2009.

WANG Chao. Characterization and evaluation of failure mechanism of ZrB2-SiC ultra high temperature ceramic composites[D]. Harbin: Harbin Institute of Technology, 2009.

[19] 曾 毅, 张武装, 熊 翔. C/C复合材料SiC/ZrB2-MoSi2复合涂层的抗氧化机制[J]. 复合材料学报, 2010(3): 50-55.

ZENG Yi, ZHANG Wu-zhuang, XIONG Xiang. Anti-oxidation mechanisms of the SiC/ZrB2-MoSi2 coating on the carbon/carbon composites[J]. Acta Materiae Compositae Sinca, 2010(3): 50-55.

[20] 周 庭, 谢征芳. ZrB2陶瓷制备研究进展[J]. 化工进展, 2013, 32(10): 2434-2439.

ZHOU Ting,XIE Zheng-fang. Research progress of preparation of zirconium boride ceramics[J]. Chemical Industry and Engineering Progress, 2013, 32(10): 2434-2439.

Microstructure and oxidation mechanism of ZrB2-SiC ceramic coating on C/C composite material

WANG Xin-shaung, CHEN Zhao-ke, XIONG Xiang, ZHANG Tian-zhu, SUN Wei, WANG Ya-lei

(State Key Laboratory of Powder Metallurgy, Powder Metallurgy Research Institute, Central South University, Changsha 410083, China)

Abstract: To improve the anti-oxidation performance of C/C composites under high temperature and oxygen enriched environment, ZrB2-SiC based ceramic coatings with Si3N4, MoSi2 and TaC addition were prepared by two-step slurry painting+chemical vapor deposition (CVD). Phase composition and microstructure of the as-prepared coating were investigated by using X-ray diffractometry and scan electron microscopy, and the isothermal anti-oxidation mechanism at 900 ℃ and 1500 ℃ were also analyzed and discussed. The conclusions are as follows, the thickness of the as-prepared ZrB2-SiC based composite ceramic coating is about 200 μm. The densification and the anti-oxidation properties of the coating can be improved by the addition of Si3N4 and MoSi2, effectively. While the anti-oxidation properties of the coating can not be improved by the addition of TaC effectively at 900 ℃. At 900 ℃, the oxidation process of ZrB2-SiC ceramic coating was mainly controlled by the diffusion of oxygen in pore and other defects in the coating. The anti-oxidation property of coating can be improved by the addition by affecting the density of coating. In the oxidation process of 1500 ℃, the oxidation resistance of the coating decreases. The introduction of the compact structure of CVD SiC sealing layer can improve the oxidation resistance significantly. At 1500 ℃, in oxidation process, SiO2 glassy oxide film with ZrO2 and ZrSiO4 on the coating is generated, this can provide effective oxidation protection for the substrate.

Key words: C/C composite; ZrB2-SiC based coating; additive; anti-oxidation mechanism

Foundation item: Project(2011CB605805) supported by National Basic Research Development Program of China; Project(2015WK3013) supported by the Science-Technology Foundation of Hunan Province, China; Project supported by the State Key Laboratory of Powder Metallurgy, Central South University, China; Project supported by Space Joint Innovation Fund Project in Universities, China; Project (201622ts271) supported by Central South University Master’s Independent Exploration and Innovation Project in 2016, China

Received date: 2016-07-19; Accepted date: 2016-12-21

Corresponding author: CHEN Zhao-ke; Tel: +86-13187015470; E-mail: chenzhaoke2008@csu.edu.cn

(编辑 龙怀中)

基金项目:国家重点基础研究发展计划资助项目(2011CB605805);湖南省科技计划资助项目(2015WK3013);中南大学粉末冶金国家重点实验室资助项目;航天一院高校联合创新基金项目;2016年中南大学硕士生自主探索创新项目(201622ts271)

收稿日期:2016-07-19;修订日期:2016-12-21

通信作者:陈招科,副教授,博士;电话:13187015470;E-mail: chenzhaoke2008@csu.edu.cn