真空烧结制备三维通孔不锈钢泡沫材料

王辉,周向阳,李昌林,李劼,宋泓宇

(中南大学 冶金科学与工程学院,湖南 长沙,410083)

摘要:采用真空烧结制备具有三维通孔网状结构的316L不锈钢泡沫材料,研究烧结温度和保温时间对不锈钢泡沫材料的表观密度、开孔孔隙率、抗弯强度、抗氧化性等方面的影响。研究结果表明:随着烧结温度的升高,泡沫材料的表观密度和线收缩率增大,抗氧化性能提高,开孔孔隙率减小;随着烧结温度的升高,泡沫材料抗弯强度明显增大,但当烧结温度超过1 260 ℃,由于液相的产生,使其抗弯强度降低;随着保温时间的延长,不锈钢泡沫的表观密度、线收缩率和抗弯强度增大,开孔孔隙率降低;前驱体在1 260 ℃温度下烧结 60 min,可制得孔径为 1 mm 左右、具有良好三维通孔结构的不锈钢泡沫,该泡沫的开孔孔隙率为 81.4 %,抗弯强度达 56.8 MPa。

关键词:真空烧结;不锈钢泡沫;抗弯强度;抗高温氧化性

中图分类号:TG142.71 文献标志码:A 文章编号:1672-7207(2011)08-2178-06

Vacuum sintering of stainless steel foam with

3-D open-cell network structure

WANG Hui, ZHOU Xiang-yang, LI Chang-lin, LI Jie, SONG Hong-yu

(School of Metallurgical Science and Engineering, Central South University, Changsha 410083, China)

Abstract: The stainless steel foam with 3-D open-cell network structure were prepared by vacuum sintering. The effects of sintering temperature and soaked time on the apparent density, open porosity, bending strength and oxidation resistance performance of the stainless steel foam were investigated. The experimental results show that with the increase of the sintering temperature, the apparent density, linear shrinkage rate and oxidation resistance performance of the sintered product increase, but the open porosity reduces; the bending strength firstly rises and then declines after the temperature exceeds 1 260 ℃ because of the emergence of liquid; with the prolongation of the soaked time, the apparent density, linear shrinkage rate and oxidation resistance performance augment, the open porosity reduces. When the precursor is sintered at 1 260 ℃ for 60 min, the stainless steel foam with favorable 3-D open-cell network structure can be obtained, of which the aperture size is about 1 mm, the open porosity is 81.4% and the bending strength is 56.8 MPa.

Key words: vacuum sintering; stainless steel foam; bending strength; oxidation resistance performance

不锈钢泡沫材料的独特结构特征,使得其兼顾了结构材料和功能材料的特点[1-2]。作为结构材料,它具有轻质和高比强度的特点;作为功能材料,它具备吸声、隔声、隔热、散热、阻燃、减震、吸收冲击能电磁屏蔽等多种物理性能[3-6],因此,它在航天、航空、运输、电子、军工、化工、环保、能源、机械、生物等各个高科技领域都有广阔的应用前景[7-11]。然而,目前国内外对不锈钢泡沫的研究还不是很多,还处于制备工艺研究阶段。国内外大都采用常规的粉末冶金方法,采用这种方法所制备的不锈钢等高温泡沫多为闭孔;尽管有些方法也能制备出通孔高温泡沫,但这些泡沫的孔隙率通常较低(<70%),而且三维通孔性较差[12-16]。这表明目前的制备工艺大大限制了高温泡沫的应用范围与实用化进程,因此,研究新颖的高温泡沫制备技术意义重大。在前期工作中,本课题组研究出一种新颖的高温金属泡沫制备方法,该方法已经申报了国家发明专利[17]。在此,本文作者在前期工作的基础上,采用真空烧结制备三维通孔不锈钢泡沫材料,重点研究烧结温度和保温时间对不锈钢泡沫的孔洞形貌、开孔率、抗弯强度以及抗高温氧化性等方面的 影响。

1 实验

1.1 多孔不锈钢样品的制备

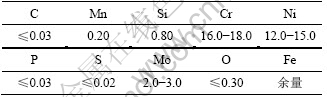

本实验采用316L不锈钢粉末为原料,其平均粒径为44 μm,主要成分见表1。样品的制备分为前驱体制备、脱脂和烧结。前驱体的制备工艺可简要描述为:(1) 将不锈钢粉末与适量黏结剂A 配成具有一定固含的料浆;(2) 将料浆灌入预处理过的聚氨酯海绵中,制成具有一定负载量的浸浆海绵;(3) 将浸浆海绵先在室温下自然干燥24 h,后在120 ℃下烘干12 h,即制得本研究的前驱体,具体制备过程见文献[18]。然后采用真空热脱脂工艺除去前驱体中的有机物和残留水分,最后在ZT-40-20型真空电阻炉中进行真空烧结(真空度为1×10-2~1×10-3 Pa,升温速率为8 ℃/min)。

表1 316L不锈钢粉末化学成分(质量分数)

Table 1 Chemical composition of 316L stainless steel %

1.2 性能检测与表征

1.2.1 试样形貌的表征

利用高像素数码相机(SONY,DSC-P10)来观察所测试样的宏观形貌,利用SEM(日本电子公司(JEOL)JSM5600型扫描仪)观察所测试样的表面和截面形貌,利用金相显微镜(XJP-6A)观察孔壁的形貌组织及微孔特征。

1.2.2 表观密度与开孔孔隙率的计算

先在空气中称试样的质量m,再将试样浸到熔融的石蜡中,冷却后除去表面石蜡,再次称其在空气中的质量m1;然后用铜丝吊住试样称其在水中的质量,该质量除去铜丝的质量后即得到试样在水中的质量m2。表观密度和开孔孔隙率计算公式如下:

(1)

(1)

(2)

(2)

式中:ρ1 为称量时所用浸渍液体的密度,g/cm3,本实验采用熔融石蜡。

1.2.3 力学性能测试

本研究采用CSS-44100型电子万能试验机测定试样的抗弯强度。试验跨距为25 mm,位移加荷速度为0.5 mm/min,所用试样的长×宽×高为30 mm×12 mm×6 mm。

1.2.4 抗氧化性能测试

采用恒温氧化实验对样品的高温抗氧化性能进行测试,实验氧化温度为800 ℃,气氛为空气,在预定时间点采集质量数据。

2 结果与讨论

2.1 烧结温度对不锈钢泡沫性能的影响

2.1.1 烧结温度对致密度的影响

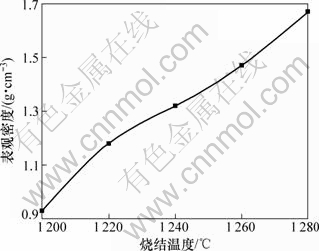

图1和图2所示分别为不同烧结温度下保温60 min得到样品的表观密度和线收缩率。由图1和图2可见:表观密度和线收缩率具有相似的变化趋势,随着烧结温度的升高,试样的表观密度和线收缩率都增大。这是高温烧结过程主要是扩散引起的,烧结温度升高,扩散速度加快,原子的迁移距离增大,粉末颗粒之间的接触面积增大,单位体积内形成烧结颈的尺寸区域增多,体积扩散和传质得以充分进行,颗粒之间以范德华力为主的弱连接转变为较强的晶体接触,孔隙由不规则多面体收所为接近球形,孔隙尺寸和数量减少,从而使试样的表观密度和线收缩率增大[19]。由晶体中空位平衡浓度C=Ae-μ/(KT)(其中μ为形成1个空位所需的内能,K为波尔兹曼常数)可知:温度升高,空位的浓度增大,加速了烧结过程中的物质传递和致密化速率。

图1 烧结温度与表观密度的关系

Fig.1 Relationship between sintering temperature and apparent density

图2 烧结温度与线收缩率的关系

Fig.2 Relationship between sintering temperature and linear shrinkage rate

从图2还可以看出:试样的线收缩率在1 260~ 1 280 ℃之间产生了较大的变化。这可能是当烧结温度达到1 280 ℃时,烧结体中开始出现了液相,加剧了样品的收缩变形,并且使用该法制备泡沫金属时聚氨酯海绵本身具有较大的孔洞,未经过传统的粉末冶金中的压制过程,粉末不致密,从而导致在烧结出现液相时样品急剧收缩。

2.1.2 烧结温度对力学性能的影响

图3所示为不同烧结温度下保温60 min得到样品的开孔率和抗弯强度。从图3可以看出:在1 200~1 260 ℃之间,随着烧结温度升高,试样的抗弯强度明显提高。这是由于温度越高,烧结致密化程度越高,颗粒间的结合强度越大,使得其抗弯强度越高。根据Griffith强度理论σf= 可知:弹性模量E、单位面积表面能γ和裂纹半长度C决定材料的强度,弹性模量E与断裂应力σf成正比。而弹性模量E与开孔率有如下关系[20]:E=E0exp(-Bp)。式中:B为常数;E0为气孔率为零时材料的弹性模量;p为开孔率。开孔率随烧结温度的升高而减小,因此,随着烧结温度的升高,开孔率减小,从而使弹性模量增大,抗弯强度提高。另外根据前面的分析,当温度超过1 260 ℃后,试样中开始形成液相,从而使部分孔筋被熔断,使得材料整体抗弯强度减小,并且样品产生严重变形。

可知:弹性模量E、单位面积表面能γ和裂纹半长度C决定材料的强度,弹性模量E与断裂应力σf成正比。而弹性模量E与开孔率有如下关系[20]:E=E0exp(-Bp)。式中:B为常数;E0为气孔率为零时材料的弹性模量;p为开孔率。开孔率随烧结温度的升高而减小,因此,随着烧结温度的升高,开孔率减小,从而使弹性模量增大,抗弯强度提高。另外根据前面的分析,当温度超过1 260 ℃后,试样中开始形成液相,从而使部分孔筋被熔断,使得材料整体抗弯强度减小,并且样品产生严重变形。

图3 烧结温度与开孔率和抗弯强度的关系

Fig.3 Relationship among sintering temperature, open porosity and bending strength

2.1.3 烧结温度对微观组织的影响

图4所示为在相同保温时间60 min下,于1 240 ℃和1 260 ℃得到的烧结体孔壁金相图。从图4(a)可见:温度为1 240 ℃时,烧结颗粒之间产生局部结合,颗粒与颗粒之间形成烧结颈,在烧结颈项周围仍然存在大量的孔洞,烧结体孔壁孔隙率较高,孔隙球化程度低,而且分布不均匀;而当温度达到1 260 ℃时,烧结颗粒之间的结合基本完成,颗粒与颗粒之间由烧结颈项连接变为界面结合,原来的小颗粒合并为大颗粒,颗粒与颗粒间孔隙数量明显减少,孔径明显变小,孔隙球化程度增大。这也说明:提高烧结温度,烧结体的致密度增加,有利于力学性能的提高。这与前面的分析结果相一致。

图4 不同温度下烧结样品孔壁的金相照片

Fig.4 Metallographic structures of sintered samples at different sintering temperatures

2.1.4 烧结温度对抗高温氧化性的影响

表2所示为不同温度烧结得到的烧结样品在800 ℃下的氧化质量增加率。从表2可以看出:随着烧结温度的升高,单位质量烧结样品的氧化质量增加率呈降低趋势,说明烧结温度的提高有利于提高烧结样品的抗高温氧化性。由前面的分析可知:样品的烧结密度随着烧结温度的升高而增大,表明孔隙是影响该材料抗氧化性和耐蚀性能的主要因素,较多数量和较大尺寸的孔隙会增加氧气与样品的接触面积,从而使抗氧化性降低。

表2 不同烧结温度下烧结样品的氧化质量增加率

Table 2 Oxidation increment ratio of sintered samples at different temperatures mg?g-1

2.2 保温时间对不锈钢泡沫性能的影响

保温时间可由烧结温度和所要求的孔隙度、孔隙形貌及材料的抗弯强度等决定。在烧结过程中,过长的保温时间会使烧结制品的力学性能降低,这是因为增加保温时间会导致晶粒长大,同时,高温下长时间保温会使孔壁的孔隙聚集,而这样的大孔难以再收缩或消除,是材料的薄弱部位,容易导致材料破坏。根据以上烧结工艺的要求,本实验研究了在1 260 ℃下分别保温20,40,60和90 min对不锈钢泡沫性能的影响。

表3所示为不同保温时间下的表观密度、线收缩率和开孔率。从表3可以看出:随着保温时间的延长,制品的线收缩率增大,但保温时间对制品线收缩率的影响远小于烧结温度对其的影响;当保温时间从20~90 min时,线收缩率仅变化4.3%,而当温度从 1 200 ℃到1 280 ℃时,制品线收缩率变化9.8%。表观密度跟线收缩具有相同的变化趋势,也是随着保温时间的延长而增大,而开孔率与之相反。

表3 不同保温时间的表观密度、线收缩率和开孔率

Table 3 Apparent density, linear shrinkage rate and open porosity of sintered samples at different soaked time

图5所示为在1 260 ℃温度下不同保温时间对制品抗弯强度的影响。由图5可以看出:随着保温时间的延长,制品的抗弯强度增大,当保温时间从20 min变化到60 min时,抗弯强度从46.1 MPa增加到56.8 MPa,抗弯强度增加比较大;当保温时间在60 min和90 min之间时,对抗弯强度的影响比较小。

图5 保温时间与抗弯强度的关系

Fig.5 Relationship between soaked time and bending strength

2.3 优化条件下不锈钢泡沫的宏观形貌与内部结构

图6(a)和6(b)所示分别为前驱体和优化工艺条件下(1 260 ℃×60 min)制得的不锈钢泡沫材料的宏观形貌图。由图6可见:通过本工艺可以制备出具有良好三维通孔结构的泡沫材料,在整个制备过程中,样品始终保持原有形貌,无开裂,无变形等缺陷;不锈钢泡沫材料表面孔洞分布均匀且具有良好的网状结构。

图7所示为用该法制备的不锈钢泡沫材料表面和内部截面的SEM图。由图7可以看出:不锈钢泡沫内部与表面相似,孔洞分布也比较均匀,孔径为1 mm左右,而且通孔性能良好,使多孔金属具有较高的开孔率和良好的透气性能。另外,在以上条件下制备的不锈钢泡沫材料也具有较高的的力学性能,抗弯强度达到55 MPa以上。

图6 前驱体及烧结体的宏观形貌

Fig.6 Macro-structures of sample before and after sintering

图7 烧结体表面和内部截面的SEM图

Fig.7 SEM images of surface and Internal cross-section of sample

3 结论

(1) 不锈钢泡沫材料的表观密度、线收缩率以及抗氧化性随温度的升高而增大,开孔孔隙率随温度的升高而减小。抗弯强度在1 200~1 260 ℃之间随温度升高而增大,当温度超过1 260 ℃时,其抗弯强度反而降低。

(2) 随着保温时间的延长,不锈钢泡沫的表观密度、线收缩率和抗弯强度增大,开孔孔隙率降低。但是,烧结温度对不锈钢泡沫的线收缩率、抗弯强度等性能方面的影响比保温时间的影响大。

(3) 在1 260 ℃下保温60 min 得到的不锈钢泡沫材料具有良好的三维通孔结构、较高的开孔率和良好的透气性能,其孔径为1 mm左右,开孔率为81.4%,抗弯强度达56.8 MPa。

参考文献:

[1] Lefebvre L P, Banhart J, David C D. Porous metals and metallic foams:current status and recent developments[J]. Advanced Engineering Materials, 2008, 10(9): 775-787.

[2] Banhart J. Manufacture, characterisation and application of cellular metals and metal foams[J]. Progress in Material Science, 2001, 46: 559-632.

[3] ZHANG Bo, CHEN Tian-ning. Calculation of sound absorption characteristics of porous sintered fiber metal[J]. Applied Acoustics, 2009, 70: 337-346.

[4] LIU Yu, GONG Xiao-lu. Compressive behavior and energy absorption of metal porous polymer composite with interpenetrating network structure[J]. Transactions of Nonferrous Metals Society of China, 2006, 16(Z1): 439-443.

[5] Thomas K M. Hydrogen adsorption and storage on porous materials[J]. Catalysis Today, 2007, 120: 389-398.

[6] 沈以赴, 吴鹏, 顾冬冬, 等. 激光烧结制备藕状316不锈钢多孔材料的微孔结构特征[J]. 航空学报, 2007, 28(5): 1236-1241.

SHEN Yi-fu, WU Peng, GU Dong-dong, et al. Micropore structures of lotus-type porous 316 stainless steel prepared by laser sintering[J]. Acta Aeronautica et Astronautica Sinica, 2007, 28(5): 1236-1241.

[7] Montasser M D, Khalil A K, Lim J M. Processing and mechanical properties of porous 316L stainless steel for biomedical applications[J]. Transactions of Nonferrous Metals Society of China, 2007, 17(3): 468-473.

[8] Halil I B. A novel water leaching and sintering process for manufacturing highly porous stainless steel[J]. Scripta Materialia, 2006, 55: 203-206.

[9] Ambrozio F, Lima D, Luis C P. Preparation and characterization of stainless steel filters[J]. Advances in Powder Metallurgy, 1992, 5: 439-444.

[10] Banhart J,Baumeister J. Deformation characteristics of metal foams[J]. Journal of Materials Science, 1998, 33: 1431-1440.

[11] WANG Zhi-hua, MA Hong-wei, ZHAO Long-mao, et al. Studies on the dynamic compressive properties of open-cell aluminum alloy foams[J]. Scripta Materialia, 2006, 54(1): 83-87.

[12] Park C, Nutt S R. Effects of process parameters on steel foam synthesis[J]. Materials Science and Engineering, 2001, 297: 62-68.

[13] 乔吉超, 奚正平, 汤慧萍, 等. 粉末冶金技术制备金属多孔材料研究进展[J]. 稀有金属材料与工程, 2008, 37(11): 2054-2058.

QIAO Ji-chao, XI Zheng-ping, TANG Hui-ping, et al. Current status of metal porous materials by powder metallurgy technology[J]. Rare Metal Materials and Engineering, 2008, 37(11): 2054-2058.

[14] Gulsoya H O, German R M. Production of micro-porous austenitic stainless steel by powder injection molding[J]. Scripta Materialia, 2008, 58: 295-298.

[15] 张冬平, 蒋业华, 卢德宏, 等. 熔体发泡法制备多孔泡沫钢发泡剂的研究[J]. 铸造技术, 2008, 29(5): 622-625.

ZHANG Dong-ping, JIANG Ye-hua, LU De-hong, et al. Research on the foaming agent of porous steel prepared by smelting foaming[J]. Foundry Technology, 2008, 29(5): 622-625.

[16] Kanetake N, Kobashi M. Innovative processing of porous and cellular materials by chemical reaction[J]. Scripta Materialia, 2006, 54(4): 521-525.

[17] 周向阳, 李劼, 龙波, 等. 三维通孔或部分孔洞彼此相连多孔金属泡沫及其制备方法: 中国, 200510032174.7[P]. 2007-03-28.

ZHOU Xiang-yan, LI Jie, LONG Bo, et al. The preparation means of the porous metal foam with 3-D open cells or portion cells connected with each other: China, 200510032174.7[P]. 2007-03-28.

[18] 周向阳, 龙波, 李劼, 等. 前驱体制备对三维通孔不锈钢泡沫性能的影响[J]. 中国有色金属学报, 2006, 16(9): 1615-1620.

ZHOU Xiang-yan, LONG Bo, LI Jie, et al. Effects of precursor preparation on performances of stainless steel foam with 3-D open cells network structure[J]. The Chinese Journal of Nonferrous Metals, 2006, 16(9): 1615-1620.

[19] 赵密, 郭英奎, 俞泽民, 等. 烧结温度对不锈钢(316L)致密性及强度的影响[J]. 哈尔滨理工大学学报, 2000, 5(3): 105-107.

ZHAO Mi, GUO Ying-kui, YU Ze-min, et al. Influence of sintering temperature on densification and flexural strength of stainless steel(316L)[J]. Journal of Harbin University of Science and Technology, 2000, 5(3): 105-107.

[20] 宝鸡有色金属研究所.粉末冶金多孔材料: 下册[M]. 北京: 冶金工业出版社, 1978: 58-66.

BAOJI Institute for Non-ferrous Metal Research. Porous materials by powder metallurgy: Last volume[M]. Beijing: Metallurgical Industry Press, 1978: 58-66.

(编辑 杨幼平)

收稿日期:2010-08-18;修回日期:2010-11-21

基金项目:国家自然科学基金资助项目(50974136);中南大学米塔尔创新项目(08MX14)

通信作者:周向阳(1969-),男,湖南益阳人,博士,教授,从事多孔金属材料研究;电话:0731-88836329;E-mail:zxy13908482918@163.com