DOI:10.19476/j.ysxb.1004.0609.2018.07.07

C、W摩尔比对真空烧结反应合成WC-Fe耐磨材料组织和性能的影响

肖逸锋1, 2,杨 燕1,吴 靓1,许艳飞1,钱锦文1,李浪浪1,贺跃辉3

(1. 湘潭大学 机械工程学院 焊接机器人及应用技术湖南省重点实验室,湘潭 411105;

2. 湘潭大学 复杂轨迹加工工艺及装备教育部工程研究中心,湘潭 411105;

3. 中南大学 粉末冶金国家重点实验室,长沙 410083)

摘 要:以钨铁和炭黑为反应源,采用真空烧结法反应制备不同n(C)/n(W)的WC-Fe耐磨材料。采用XRD、SEM、EDS、宏观硬度与磨粒磨损等测试技术,对比研究n(C)/n(W)对WC-Fe耐磨材料组织与性能的影响。结果表明:正常WC+γ两相组织对应的n(C)/n(W)范围为1.1~1.3,n(C)/n(W)低于1.1时,出现η相;而n(C)/n(W)高于1.3时,出现C相。随着n(C)/n(W)在0.9~1.7之间增加,硬质WC的含量与平均晶粒尺寸先显著增加后缓慢变化,材料的密度、线收缩率与硬度逐渐下降,磨损质量损失不断增加。

关键词:钨铁;真空烧结;原位合成;WC-Fe耐磨材料

文章编号:1004-0609(2018)-07-1328-07 中图分类号:TG135 文献标志码:A

在制备WC颗粒增强金属基复合材料的过程中,微量C含量的波动都会引起材料组织与性能的变化。在缺碳环境下,易产生脆性η相(M6C或M12C型碳化物),使材料强度下降;在高碳环境下,易产生游离石墨相,破坏组织连续性[1]。为避免缺碳相与富碳相的不利影响,大量研究致力于探索理想WC+γ (Fe/Co/Ni-W-C固溶体)两相组织所对应的C含量区间。在各项条件相同的情况下,采用Fe做粘接相时获取理想的WC+γ两项组织、对应的碳含量区间最窄;采用Co做粘接相时,理想碳含量区间较宽;采用Ni做粘接相时,理想碳含量区间最宽。而出现正常组织时合金含碳量在Ni粘结时较低,Co粘结时稍高,Fe粘结时最高[2]。而对不同制备方法下的不同合金体系而言,则情况更加复杂。就加压烧结WC-10Co-0.6Cr3C2而言,理想碳含量为5.41%~5.55% (质量分数)[3]。而Ni做粘接相的低压烧结WC-6%Ni合金对应的两相区碳含量为6.03%~6.06%(质量分数)[4]。氩弧熔覆反应制备WC颗粒增强Fe基复合材料时,由于电弧对石墨的烧损使其最佳n(C)/n(W)为1.5[5]。此外,C含量还极大地影响WC颗粒的数量、形貌与分布、基体组织的成分与含量以及反应制备各个阶段的致密化过程,这都将对材料的组织与性能产生极大的影响[6-10]。采用钨铁和炭黑为反应源制备WC-Fe耐磨材料具有成本低、工艺简单等特点,但由于钨与铁的润湿性不如钨与钴,有关真空烧结一步原位合成制备WC-Fe耐磨材料的研究相对较少。

基于此,本文作者在以钨铁和炭黑为反应源,采用真空烧结复合原位合成技术,成功地制备了WC-Fe耐磨材料的基础上,研究了n(C)/n(W)对其组织与性能的影响,为制备低成本WC-Fe 耐磨材料奠定基础。

1 实验

1.1 材料及试样制备

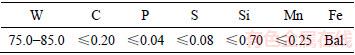

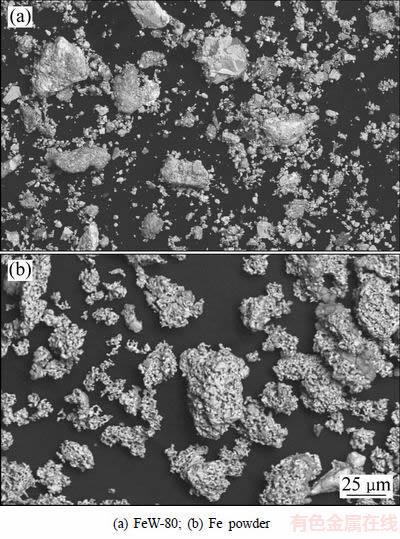

实验选用FeW-80(78.1%W,<40 μm,FeW-80的化学成分见表1)、炭黑(<5 μm)和铁粉(<40 μm)为原材料,FeW-80和铁粉的原始形貌见图1。由图1可知, FeW-80原始粉末中大小颗粒混合分布,小颗粒约5 μm,大颗粒高达40 μm,铁粉的粒度较FeW-80偏大,整体在20~40 μm区间内的分布居多。通过固定FeW-80的含量,即W的含量,改变碳含量来调节烧结材料的n(C)/n(W),制备n(C)/n(W)为0.9、1.1、1.3、1.5与1.7的试样,并分别标记为试样1~5。

表1 FeW-80的化学成分

Table 1 Composition of FeW-80 powder (mass fraction, %)

图1 原始粉末的SEM像

Fig. 1 SEM images of original powder

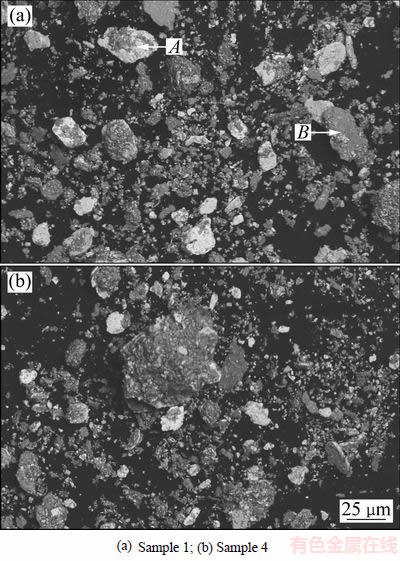

将钨铁、炭黑与铁粉的混合粉末置于球料质量比为4:1的硬质合金球磨罐中加无水乙醇湿磨24 h,再置于真空干燥箱中经75 ℃保温4 h,经球磨过筛后获取的混合粉末的形貌如图2所示,对图中A点所示的亮白色物质与B点所示的深灰色物质进行EDS分析知:A的成分为W 53.88、Fe 8.64、O 13.09、C余量(摩尔分数,%),B的成分为Fe 34.74、O 17.65、C余量(摩尔分数,%),可见亮白色物质为富W相,深灰色物质为富Fe相。部分富W相以大颗粒形式存在,其粒径相较于原始大颗粒FeW-80粉末略有减小,但也达30 μm左右,而富Fe相较原始铁粉显著细化,且以包裹大颗粒富W相或者小颗粒的形式存在。而不同物质中的O来源于混合粉末制备过程中的氧化。最后将预制粉末置于尺寸为70 mm×31mm的模具中进行压块,并将压坯放入真空烧结炉中,按工艺升温至1400 ℃保温1 h后随炉冷却。

1.2 实验方法

采用D/MAX2500型X射线衍射仪对试样进行物相测定;采用 JSM-6360LV型扫描电子显微镜(带Oxford7854电子能谱仪)进行材料的显微组织分析与微区成分探测;利用Image-Pro Plus分析材料的晶粒尺寸;采用阿基米德排水法测量样品的密度;采用HR-150A的洛氏硬度计测量样品的宏观硬度值(加载载荷为147 N);采用MLS-23型湿沙橡胶轮式磨损试验机测试样的耐磨性能,试样尺寸为57 mm× 25 mm×5 mm,磨料质量为1.5 kg,圆盘转速为220 r/min,磨损程度为1000 r,施加载荷为24.5 N。

图2 球磨后混合粉末的SEM像

Fig. 2 SEM images of mixed powder after ball milling

2 结果与分析

2.1 C、W摩尔比对材料物相与显微组织的影响

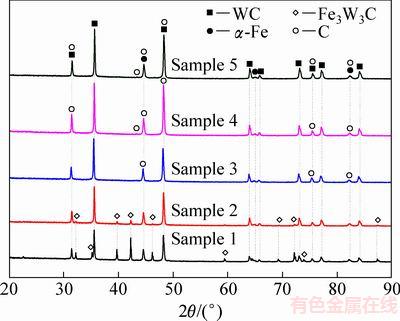

图3所示为烧结试样1~5的XRD谱。从图3中可以看出,各试样主要由WC和α-Fe组成,且WC的衍射峰随n(C)/n(W)的增大而增强。当n(C)/n(W)低于1.1时,试样中还存在Fe3W3C相,且其衍射峰随n(C)/n(W)的增大而减弱;当n(C)/n(W)由1.1增大到1.3时,经历了Fe3W3C逐渐消失而微量石墨相开始出现的过程,因此有望通过在该区间内调整n(C)/n(W)来获取WC与α-Fe的两相组织;进一步增加n(C)/n(W),石墨相的含量增多。这表明在较低的n(C)/n(W)条件下,没有足量的C来补充其耗损,故构成缺碳环境而生成η相,但本实验条件下的缺碳程度并不严重,故形成的是Fe3W3C而不是缺碳程度更严重的Fe6W6C;随着n(C)/n(W)增加,C量充足而促进WC的形核与长大,但C量过剩便会以石墨相的形式存在,故在n(C)/n(W)从1.1增大到1.3时,Fe3W3C逐渐消失,且微弱石墨峰开始出现。进一步增加n(C)/n(W),碳量严重富余而使石墨相剧增[11]。

图3 不同C、W摩尔比烧结试样的XRD谱

Fig. 3 XRD patterns of sintering samples with different molar ratios of C and W

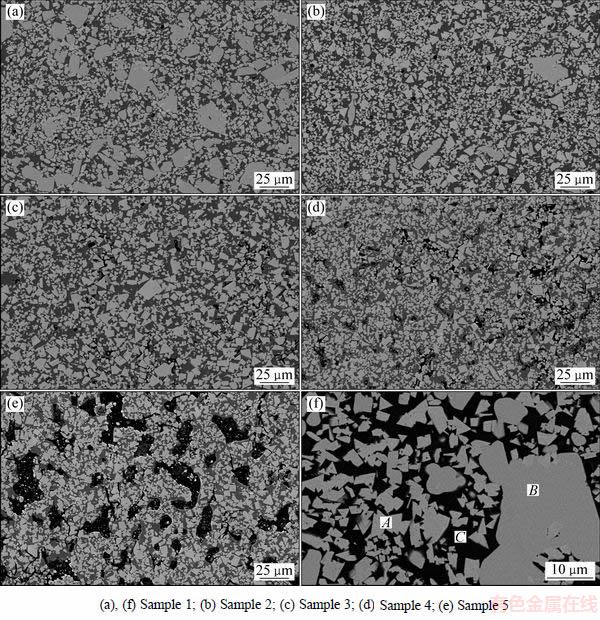

图4所示为烧结试样1~5的SEM像。图4(a)所示为样品1的低倍组织,其显微组织由数量较多的亮白色颗粒物质、孔径较小且呈圆形的黑色孔隙以及连续的深灰色物质组成。其中亮白色颗粒物质包含两种类型,一类粒径较大且边界圆滑,另一类粒径较小且边界棱角分明。对图4(f)中的A、B、C 3点进行能谱分析,其结果如表2所示。从表2分析可知,A点所示的粒径较小且边界棱角分明的物质中,W的摩尔分数为31.3%,结合图3的XRD结果知,其为反应生成的WC;B点所示的物质中Fe、W的摩尔分数接近1,结合XRD谱的结果知,此类粒径较大且边界圆滑的物质为反应生成的Fe3W3C;深灰色的C物质以Fe元素为主,包含少量W、C元素,其为固溶强化的基体组织。表明当C含量较低,即n(C)/n(W)较小时,小颗粒WC数量较多,且弥散分布于基体,而伴随生成的η相Fe3W3C也占据了一定比例,并与WC混杂分布构成材料的增强体。图4(b)所示为样品2的显微组织,对比图4(a)可知,当n(C)/n(W)增加到1.1时,WC颗粒数量增多,分布更加均匀,而Fe3W3C相数量减少,分布均匀程度下降。这是由于在烧结时,Fe基中固溶了一定量的W,同时还有少量的C,原子半径较小的C向W进行扩散形成WC,同时消耗大量的C,在烧结体内形成易于η相Fe3W3C形成的缺C环境。但在WC+γ+η的成分范围内,随着C含量的增加,Fe3W3C的总量减少[12]。

图4(c)、(d)与(e)所示分别为n(C)/n(W)为1.3、1.5与1.7的样品的显微组织。从图4(c)、(d)和(e)中可以看出,WC是主要的颗粒增强相,没有观测到Fe3W3C相。当n(C)/n(W)为1.3时,呈典型三角形、四边形形态的WC颗粒弥散分布于基体,但部分颗粒间开始出现极少数黑色物质,经分析这是富余的石墨相,但含量极少。这是由于C含量略高于W的碳化需要消耗的C,剩余的C在组织内原位残余,形成黑色的石墨相[13]。随着n(C)/n(W)增加,残余的石墨相也越来越多,尤其当n(C)/n(W)达1.7时(见图4(e)),石墨相的面积较大,已严重割裂基体而影响到组织的连续性。

图4 不同C、W摩尔比烧结试样的SEM像

Fig. 4 SEM images of sintering samples with different molar ratios of C and W

表2 图4(f)中各点的EDS成分测试结果

Table 2 EDS composition test results of points in Fig. 4(f)

2.2 C、W摩尔比对原位合成的WC颗粒增强相的影响

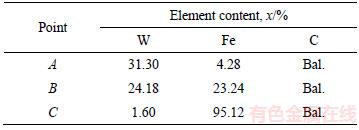

就本反应体系而言,WC是最主要的颗粒增强相。图5所示为不同n(C)/n(W)条件下不同晶粒尺寸WC的体积分数与WC的平均晶粒尺寸。由图5可知,原位合成的WC主要分布在1.3~2.5 μm与2.5~6.0 μm两个尺寸区间内。随着n(C)/n(W)增加,1.3 ~2.5 μm尺寸区间内的WC颗粒数量增多,虽然在n(C)/n(W)达1.7时,其体积分数有所降低,但2.5~6.0 μm尺寸区间内的WC颗粒数量增多。综合考虑两种粒径较大的WC,其总体积分数由75%上升至90%左右,这说明高的n(C)/n(W)促进WC长大。WC平均晶粒尺寸随n(C)/n(W)增加而增加,然后再趋于稳定的变化过程也从另一方面说明了这一点。

图5 不同晶粒尺寸WC的体积分数与WC的平均晶粒尺寸

Fig. 5 Volume fraction of different grain sizes and average particle size of WC

C极大地影响烧结体中液相出现的时间及其数量,从而影响烧结的各个过程。从理论上讲,高碳使合金的共晶点降低,也就是说碳含量高时在相同的烧结温度下相应地增加了液相量并延长了液相保持时间。在本反应体系中,随着n(C)/n(W)的增大,液相数量增多且存在时间变长。一方面,高温下W、C原子扩散速度加快,W、C不断沿WC边界析出,使WC颗粒长大;另一方面,WC颗粒在液相中不断地调整位向,使WC沿着最有利于长大的位向进行生长。但当n(C)/n(W)达1.3后再继续增大其比例,WC颗粒尺寸变化不大反而还略有减小,是由于残余的石墨相阻碍WC晶粒在基体中的移动,相应地阻碍了其生长[1]。

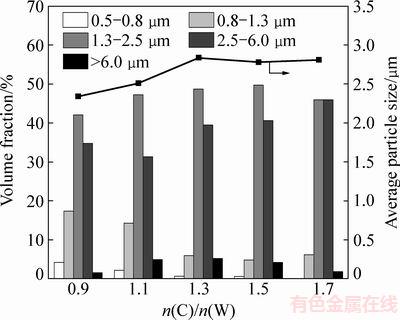

2.3 C、W摩尔比对材料烧结性能的影响

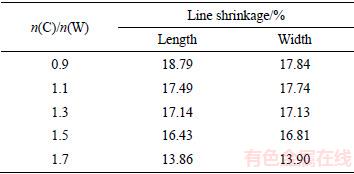

图6所示为不同n(C)/n(W)条件下烧结试样的密度与相对密度变化曲线。由图6可以看出,随着n(C)/n(W)增大,材料密度下降。当n(C)/n(W)较小时,材料密度最大,高达11.73 g/cm3;增大n(C)/n(W)到1.3,材料密度虽有所降低,但整体居于11.00 g/cm3以上;继续增大n(C)/n(W),材料密度显著下降,尤其是n(C)/n(W)达1.7时,材料的密度降至8.88 g/cm3。当n(C)/n(W)小于1.5时,材料的相对密度均大于100%,且其值随着n(C)/n(W)的增加而先增大后降低,当n(C)/n(W)增大到1.7时,相对密度降至95%左右。表3为相对应的各烧结试样沿长度方向与宽度方向的线收缩率,不难发现,其与材料密度呈现相似的变化规律。当n(C)/n(W)较低时,材料沿两个维度的收缩都比较大,收缩率多集中在17%~18%;当n(C)/n(W)较高时,材料沿两个维度的收缩仍比较均匀,但收缩率迅速下降,最终降至14%左右。

图6 C、W摩尔比对烧结试样密度与相对密度的影响

Fig. 6 Effect of molar ratio of C and W on density and relative density of sintering samples

表3 烧结试样沿长度方向与宽度方向的线收缩率

Table 3 Line shrinkage along length direction and width direction of sintering samples

由图4的分析可知,本体系材料在n(C)/n(W)较小时,其组织中基本未见孔隙,而随着n(C)/n(W)增大,逐渐出现石墨相,且其相对体积分数逐渐增大。一方面,密度极低的石墨含量增加,致使材料的密度降低;另一方面,石墨含量增加,石墨相对富余,石墨相会残留而使得材料的烧结收缩显著下降,其密度自然也显著下降。而就相对密度而言,无论是W、C在Fe基中固溶形成γ相和η相,还是C在W中固溶形成WC,在不考虑质量损失的情况下合金的体积是明显减小的,从而导致其实际密度明显高于理论密度而使相对密度大于100%。当n(C)/n(W)从0.9增大到1.3时,原位合成WC不断增多,由此引起的体积缩小作用增强,故相对密度越来越大;当n(C)/n(W)达1.5时,一定数量的石墨相抵消了部分由原子固溶引起的体积缩小作用,相对密度有所下降,但仍高于100%;而当n(C)/n(W)达1.7时,大片石墨相严重削弱体积缩小作用,材料的实际密度低于其理论密度,故相对密度降至95%左右。

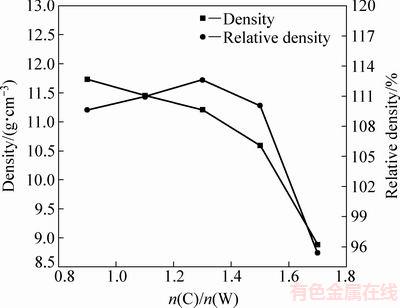

2.4 C、W摩尔比对材料硬度与耐磨性能的影响

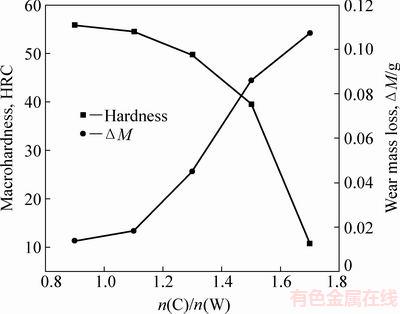

图7所示为不同n(C)/n(W)烧结试样的硬度与磨损质量损失曲线。由图7可以看出,随着n(C)/n(W)增加,材料的硬度呈现下降的变化规律。当n(C)/n(W)低于1.3时,硬度下降缓慢,整体保持在50HRC左右;当n(C)/n(W)增大到1.5时,硬度下降趋势变大;继续增大n(C)/n(W),材料硬度急剧下降。这是由于当n(C)/n(W)较低时,反应生成的WC+γ+η的三相组织中,硬质WC颗粒本身就具有很高的硬度,而伴随产生的η相也是一种致密相,WC颗粒与η相混杂着弥散分布于基体,使材料的硬度保持在较高的水平[14-15]。而当n(C)/n(W)较高时,反应生成的WC+γ+C的三相组织中,虽然WC的硬度很高,但残余的石墨相割裂基体,降低组织的连续性,从而严重影响材料的硬度。材料的磨损质量损失与硬度呈现相反的变化规律,即随着n(C)/n(W)的增加,材料的磨损质量损失呈现上升的变化规律。当n(C)/n(W)为0.9与1.1时,材料的磨损失重较小,磨损量不超过0.02 g,耐磨性能较好;而随n(C)/n(W)的增加,材料的磨损质量损失增加,尤其是n(C)/n(W)达1.7时,磨损量高达0.11 g,耐磨性能急剧恶化。

图7 C、W摩尔比对烧结试样硬度与磨损质量损失的影响

Fig. 7 Effect of molar ratio of C and W on macrohardness and wear mass loss of sintering samples

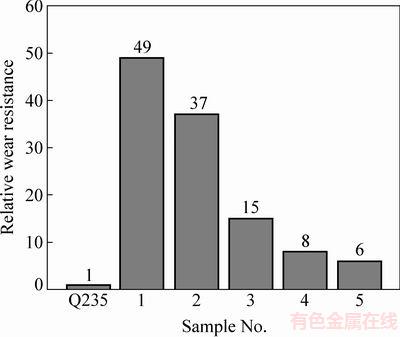

图8所示为相同实验条件下Q235钢与不同n(C)/n(W)烧结试样相对耐磨性的对比。由图8可以看出,各烧结试样的耐磨性相较于Q235而言都有不同程度的提高,这主要得益于硬质颗粒与合金元素的强化作用。就软质的Q235而言,当硬质磨粒在橡胶轮的带动下不断对其表面进行切削的时候,必然会损失掉相当一部分材料,耐磨性较差。而对本烧结试样而言,一方面,基体固溶了大量W、C原子,其抵抗切削的能力大大增强;另一方面,硬质WC颗粒弥散分布于基体,极大地削弱了硬质磨粒的切削作用,故而耐磨性较好。但n(C)/n(W)较低时,致密η相与WC颗粒协同增强,使材料的相对耐磨性较高,最高可达Q235的49倍。而n(C)/n(W)较高时,残余C相影响组织连续性,进而降低材料的相对耐磨性,当n(C)/n(W)由1.1上升到1.3时,其相对耐磨性下降了22倍,且这样的影响随n(C)/n(W)的增加而加剧。

图8 Q235钢和不同C、W摩尔比烧结试样的相对耐磨性

Fig. 8 Relative wear resistance of Q235 steel and sintering samples with different molar ratios of C and W

3 结论

1) 以钨铁和炭黑为反应源,以铁为粘接相,采用真空烧结复合原位合成技术,可以成功地制备WC-Fe耐磨材料。当碳钨原子比较低,即n(C)/n(W)为0.9~1.1时,材料的组织为WC+γ+η三相组织,η相随n(C)/n(W)的增大而减少;当碳钨摩尔比较高,即n(C)/n(W)在1.3~1.7之间变化时,对应的材料的组织为WC+γ+C三相组织,C相随n(C)/n(W)的增大而增多。因此有望通过在1.1~1.3之间调整n(C)/n(W)来获取理想的WC+γ两相组织。

2) 在反应体系中,随着n(C)/n(W)增大,粒径较大的WC的体积分数不断增加,而WC的平均晶粒尺寸则先显著增加后缓慢变化。

3) 低n(C)/n(W)时,致密的η相与WC颗粒混杂增强基体,使材料具有较高的硬度与良好的耐磨性;高n(C)/n(W)时,残余的石墨相割裂基体,降低组织的连续性,恶化材料的硬度与耐磨性能。

REFERENCES

[1] 吴悦梅, 熊 计, 赖人铭. 碳含量对WC-Co硬质合金显微组织的影响及其控制[J]. 硬质合金, 2008, 25(3): 179-185.

WU Yue-mei, XIONG Ji, LAI Ren-ming. Influence of carbon content on the microstructure of WC-Co cemented carbides and carbon control[J]. Cemented Carbides, 2008, 25 (3): 179-185.

[2] 柏振海, 孙宝琦, 黎文献. 铁、钴、镍粘结的 (W、Ti) C 硬质合金的碳含量研究[J]. 硬质合金, 2002, 19(2): 70-73.

BAI Zhen-hai, SUN Bao-qi, LI Wen-xian. The carbon content of (W, Ti)C cemented carbide bonded with Fe, Co, Ni[J]. Cemented Carbides, 2002, 19(2): 70-73.

[3] 张守全. 碳含量对 WC-10Co-0.6Cr3C2 硬质合金组织结构与性能的影响[J]. 粉末冶金材料科学与工程, 2014, 19(3): 446-450.

ZHANG Shou-quan. Effect of carbon content on Microstructure and properties of WC-10Co-0.6Cr3C2 cemented carbide[J]. Materials Science and Engineering of Powder Metallurgy, 2014, 19(3): 446-450.

[4] 董凯林, 时凯华, 江 庆, 周科朝. 碳含量对 WC-6%Ni 细晶硬质合金组织结构及性能的影响[J]. 硬质合金, 2013 , 30(4): 190-196.

DONG Kai-lin, SHI Kai-Hua, JIANG Qing, ZHOU Ke-chao. Influence of carbon content on microstructure and properties of WC-6%Ni cemented carbide[J]. Cemented Carbides, 2013, 30(4): 190-196.

[5] 李雪丰. 氩弧熔覆原位合成 WCp 增强铁基涂层组织与耐磨性[D]. 湘潭: 湘潭大学, 2015: 1-54.

LI Xue-feng. Microstructure and wear resistance of in-situ synthesized WCp reinforced coating fabricated by argon arc cladding[D]. Xiangtan: Xiangtan University, 2015: 1-54.

[6] POETSCHKE J, RICHTER V, GESTRICH T, MICHAELIS A. Grain growth during sintering of tungsten carbide ceramics[J]. International Journal of Refractory Metals and Hard Materials, 2014, 43: 309-316.

[7]  A, LAY S. Evolution of the WC grain shape in WC-Co alloys during sintering: Effect of C content[J]. International Journal of Refractory Metals and Hard Materials, 2009, 27(1): 140-148.

A, LAY S. Evolution of the WC grain shape in WC-Co alloys during sintering: Effect of C content[J]. International Journal of Refractory Metals and Hard Materials, 2009, 27(1): 140-148.

[8]  A, LAY S. Evolution of the WC grain shape in WC-Co alloys during sintering: Cumulated effect of the Cr addition and of the C content[J]. International Journal of Refractory Metals and Hard Materials, 2009, 27(2): 189-197.

A, LAY S. Evolution of the WC grain shape in WC-Co alloys during sintering: Cumulated effect of the Cr addition and of the C content[J]. International Journal of Refractory Metals and Hard Materials, 2009, 27(2): 189-197.

[9] BOUNHOURE V, LAY S, CHARLOT F, ANTONI-ZDZIOBEK A , PAUTY E, MISSIAEN J M. Effect of C content on the microstructure evolution during early solid state sintering of WC-Co alloys[J]. International Journal of Refractory Metals and Hard Materials, 2014, 44: 27-34.

[10] 赵立英, 刘平安. 氧燃比对爆炸喷涂碳化钨涂层结构和性能的影响[J]. 材料工程, 2016, 44(6): 50-55.

ZHAO Li-ying, LIU Ping-an. Effects of oxygen-fuel ratio on structure and property of detonation gun sprayed WC coating[J]. Journal of Materials Engineering, 2016, 44(6): 50-55.

[11] 肖逸锋, 贺跃辉, 丰 平, 谢 宏, 张丽娟, 黄自谦, 黄伯云. 碳含量对缺碳硬质合金组织和性能的影响[J].中国有色金属学报, 2007, 17(1): 39-44.

XIAO Yi-feng, HE Yue-hui, FENG Ping, XIE Hong, ZHANG Li-juan, HUANG Zi-qian, HUANG Bo-yun. Effects of carbon content on microstructure and properties of carbon-deficient cemented carbides [J].The Chinese Journal Nonferrous Metals, 2007, 17(1): 39-44.

[12] 刘寿荣. WC-Co 硬质合金中的η相[J]. 硬质合金, 1997, 14(4): 198-203.

LIU Shou-rong. η-phase in WC-Co cemented carbides[J]. Cemented Carbides, 1997, 14 (4): 198-203.

[13] LA P, OU Y, HAN S, WEI Y, ZHU D, FENG J. Effect of carbon content on morphology, size and phase of submicron tungsten carbide powders by salt-assisted combustion synthesis[J]. Rare Metal Materials and Engineering, 2016, 45(4): 853-857.

[14] 鲍 瑞, 易健宏, 杨亚杰, 彭元东, 张浩泽, 娄 静. 微波烧结粗晶低钴YG 硬质合金存在的脱碳问题及其改进[J]. 粉末冶金材料科学与工程, 2012, 17(2): 172-176.

BAO Rui, YI Jian-hong, YANG Ya-jie, PENG Yuan-dong, ZHANG Hao-ze, LOU Jing. Decarbonization and its improvement of coarse-grained low cobalt cemented carbide sintered by microwave irradiation[J]. Materials Science and Engineering of Powder Metallurgy, 2012, 17(2): 172-176.

[15] 王淑峰, 李惠琪, 迟 静, 李 敏, 柴 禄, 许 慧. 等离子原位冶金复合碳化钨合金组织特性与结晶机理研究[J]. 材料工程, 2011 (8): 72-76.

WANG Shu-feng, LI Hui-qi, CHI Jing, LI Min, CHAI Lu, XU Hui. Microstructure and crystallization mechanism of composite WC alloy produced by plasma in-situ metallurgy[J]. Journal of Materials Engineering, 2011(8): 72-76.

Effect of molar ratio of C and W on microstructure and properties of in-situ synthesized WC-Fe wear resistant materials by vacuum sintering

XIAO Yi-feng1, 2, YANG Yan1, WU Liang1, XU Yan-fei1, QIAN Jin-wen1, LI Lang-lang1, HE Yue-hui3

(1. Key Laboratory of Welding Robot and Application Technology of Hunan Province, School of Mechanical Engineering, Xiangtan University, Xiangtan 411105, China;

2. Engineering Research Center of Complex Tracks Processing Technology and Equipment, Ministry of Education, Xiangtan University, Xiangtan 411105, China;

3. State Key Laboratory of Powder Metallurgy, Central South University, Changsha 410083, China)

Abstract: The in-situ synthesized WC-Fe wear resistant materials with different molar ratios of C to W were prepared by vacuum sintering using ferrotungsten and carbon black as reaction source. The effects of molar ratios of C and W on microstructure and properties were studied by XRD, SEM, EDS, macro-hardness tester and abrasive wear testing technology. The results show that when the molar ratios of C to W of the materials varies from 1.1 to 1.3, the materials have a normal two-phase structure. The molar ratios of C to W of the materials is lower than 1.1, the η phase appears, as when molar ratios of C to W is higher than 1.3, the C phase appears. The content and the average grain size of hard WC observably increase and then change slowly with molar ratios of C and W increase. The density, linear shrinkage and hardness of the material gradually decrease with molar ratios of C and W increase. And the wear mass loss constantly increases with increasing molar ratios of C to W.

Key words: ferrotungsten; vacuum sintering; in-situ synthesis; WC-Fe wear resistant material

Foundation item: Project(51271158) supported by the National Natural Science Foundation of China; Project(17A204) supported by the Research Foundation of Education Bureau of Hunan Province, China; Project supported by Innovative Experimental Program for College Students of Hunan Province, China

Received date: 2017-06-05; Accepted date: 2018-01-20

Corresponding author: WU Liang; Tel: +86-731-58292214; E-mail: csuwuliang0830@aliyun.com

(编辑 李艳红)

基金项目:国家自然科学基金资助项目(51271158);湖南省教育厅重点项目(17A204);湖南省大学生创新性实验计划项目

收稿日期:2017-06-05;修订日期:2018-01-20

通信作者:吴 靓,副教授,博士;电话:0731-58292214;E-mail:csuwuliang0830@aliyun.com